Clear-Vu Loading Systems LOADERS - Maguire Products

Clear-Vu Loading Systems LOADERS - Maguire Products

Clear-Vu Loading Systems LOADERS - Maguire Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

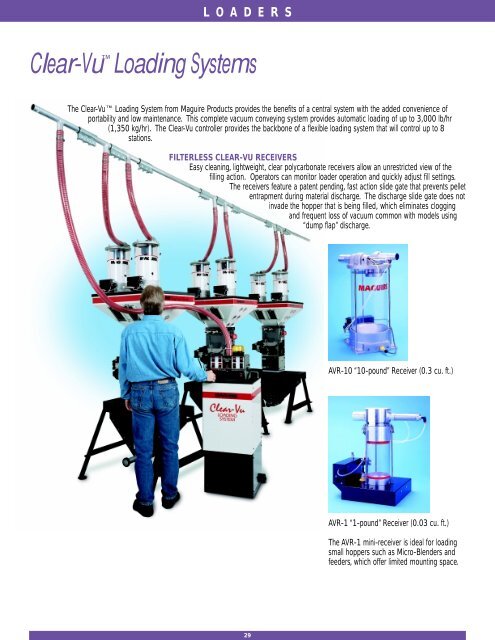

<strong>LOADERS</strong><strong>Clear</strong>-<strong>Vu</strong> <strong>Loading</strong> <strong>Systems</strong>The <strong>Clear</strong>-<strong>Vu</strong> <strong>Loading</strong> System from <strong>Maguire</strong> <strong>Products</strong> provides the benefits of a central system with the added convenience ofportability and low maintenance. This complete vacuum conveying system provides automatic loading of up to 3,000 lb/hr(1,350 kg/hr). The <strong>Clear</strong>-<strong>Vu</strong> controller provides the backbone of a flexible loading system that will control up to 8stations.FILTERLESS CLEAR-VU RECEIVERSEasy cleaning, lightweight, clear polycarbonate receivers allow an unrestricted view of thefilling action. Operators can monitor loader operation and quickly adjust fill settings.The receivers feature a patent pending, fast action slide gate that prevents pelletentrapment during material discharge. The discharge slide gate does notinvade the hopper that is being filled, which eliminates cloggingand frequent loss of vacuum common with models using“dump flap” discharge.AVR-10 “10-pound” Receiver (0.3 cu. ft.)AVR-1 “1-pound” Receiver (0.03 cu. ft.)The AVR-1 mini-receiver is ideal for loadingsmall hoppers such as Micro-Blenders andfeeders, which offer limited mounting space.29

<strong>LOADERS</strong>MLS System ControllerThe <strong>Clear</strong>-<strong>Vu</strong> microprocessor controller is a compact, remotable unitwith the capability of loading up to 8 receivers. Exclusive “Autofill” circuitryautomates the setting of fill times.Easy setting of fill time. As the receiver is filling, the operator usesa push-button to activate the “Autofill” software. When the desired levelhas been reached, the button is released and the fill time for that stationis set.Automated loading. Once load times have been set for eachreceiver, the controller sequences through the various stations loadingeach as that station’s level sensor calls for material.Individual station alarms. Load-failure alarm with reset is incorporatedin the controller and may be selectively activated for any or allstations.MLS Power UnitThe power unit is portable, and is available witha 1, 2.5, or 5 HP blower. The powerful “nomaintenance” blower eliminates bothersomemotor brush replacement. Each controller isremovable for remote operation. The dustcollector features a cartridge filter withblowback and a 5-gallon reservoir that sitsupright on a patented hinged pivot tray foreasy removal.Flexible DeploymentIn plants with many processing lines, use ofseveral <strong>Clear</strong>-<strong>Vu</strong> <strong>Loading</strong> <strong>Systems</strong>, instead ofrelying on a single larger central system,increases versatility and ensures continuedproduction by isolating problems that mayoccur.30

<strong>LOADERS</strong>Venturi <strong>Loading</strong> <strong>Systems</strong><strong>Maguire</strong> Venturi Loaders keep your hopperfilled automatically and are available with bothvisual and audible alarms to warn if the loaderfails to fill the hopper completely. The controlcan accommodate up to 4 switches to control4 venturi loaders.Choose from Four ModelsModel MLModel ML automatically loads material at ratesup to 200 lb/hr. A low-level sensor signals anair solenoid to begin loading. <strong>Loading</strong>continues until the sensor is covered. An inlineON/OFF switch is located on the powercord of the loader.Model ML-AModel ML-A adds audio and strobe lightalarms to the Model ML, which alert theoperator to exhausted material supply orstoppages. If loader “ON” time exceeds twominutes, a STROBE light will flash, and anelectronic beeper will sound continuously untilfloor personnel respond.Model MPL-ASModel MPL-AS adds an additional timer and amaterial-shutoff valve to the alarm-equippedModel ML-A. If floor personnel do not satisfythe alarm condition within five minutes, amaterial flow valve is activated. This valvediscontinues the flow of natural material to theprocess, thereby preventing the process fromcontinuing.Model ML-1R Regrind LoaderModel ML-1R is designed specifically forregrind. A larger diameter air amplifier isused to maximize airflow for efficient conveyingof regrind. With a vertical conveyingdistance up to 12 ft., the ML-1R will conveyregrind up to 200 lb/hr. This unit is veryeffective for emptying beside-the-pressgranulator drawers equipped for vacuumtakeoff or for conveying regrind from acontainer using a regrind pick-up lance. TheML-1R venturi loader is designed for regrindonly and will not convey pellets.Model ML-1R Shown31

LOADER ACCESSORIES / PARTS32AVR-1AVR-10RED PVC TUBINGTPVC16 1” tubingTPVC24 1 1/2” tubingTPVC32 2” tubingAVC-88 STATION CONTROLLERMLS DUST COLLECTOR CARTRIDGE FILTERModel HF06ML VACUUM GENERATOR371 1” vacuum generator371-15 1 1/2” vacuum generatorAVR-1 BODYAVR-10 BODYMATERIAL PICK-UP LANCES1710 1” pick-up lance assembly1714 1 1/2” pick-up lance assembly1715 2” pick-up lance assembly