UROTUF L63-MPW-38 - Reichhold

UROTUF L63-MPW-38 - Reichhold

UROTUF L63-MPW-38 - Reichhold

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

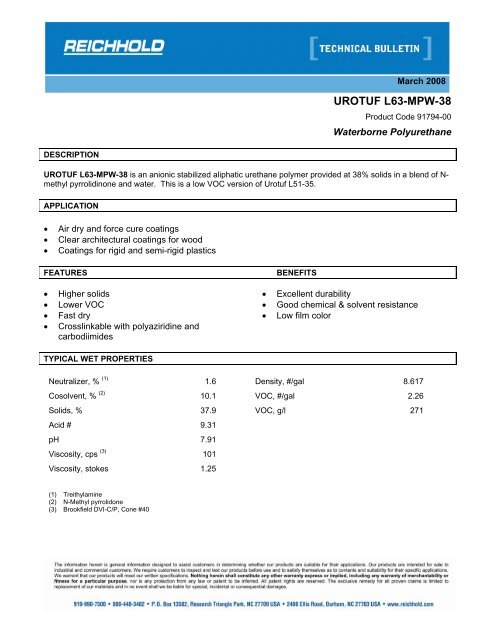

March 2008<strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong>Product Code 91794-00Waterborne PolyurethaneDESCRIPTION<strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong> is an anionic stabilized aliphatic urethane polymer provided at <strong>38</strong>% solids in a blend of N-methyl pyrrolidinone and water. This is a low VOC version of Urotuf L51-35.APPLICATION•••Air dry and force cure coatingsClear architectural coatings for woodCoatings for rigid and semi-rigid plasticsFEATURESBENEFITS••••Higher solidsLower VOCFast dryCrosslinkable with polyaziridine andcarbodiimides•••Excellent durabilityGood chemical & solvent resistanceLow film colorTYPICAL WET PROPERTIESNeutralizer, % (1) 1.6 Density, #/gal 8.617Cosolvent, % (2) 10.1 VOC, #/gal 2.26Solids, % 37.9 VOC, g/l 271Acid # 9.31pH 7.91Viscosity, cps (3) 101Viscosity, stokes 1.25(1) Treithylamine(2) N-Methyl pyrrolidone(3) Brookfield DVI-C/P, Cone #40

STORAGEStore <strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong>at less than 100 o F and avoid freezing to ensure maximum shelf life. If frozen, warmto room temperature for 24 hours and mix well before using. Read the EM-187568 Material Safety Data Sheetbefore storing, handling or using this product.Read the <strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong> Material Safety Data Sheet before handling or using this material.DILUTION CURVE1000<strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong>Dilution Curve@25 CViscosity, cps1001034 35 36 37 <strong>38</strong> 39 40Solids, % (Water)Brookfield DVI-C/P, Cone #40TYPICAL FILM MECHANICAL PROPERTIESModulus @100%, psi 4537 Split Tear, pli 235Tensile, psi 5811 Shore Hardness, A / D 95 / 65Elongation, % 200<strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong>, 91794-00Page 2

TYPICAL FILM PERFORMANCE (1,2) <strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong> <strong>UROTUF</strong> L51-<strong>MPW</strong>-35Dry Time, hr:minSet 0:10 0:15Thru 0:25 2:00Hard 0:45 3:00Tack Free (200 g), hrs:min 0:30 4:00Tack Free (500 g), hrs:min 1:05 4:15Sward Hardness 52 50Konig Hardness 135 133Pencil Hardness 3H 2HMar Resistance, days (2) > 7 > 7Impact Resistance, in-lbsDirect / Reverse 160 / 160 160 / 160Mandrel Bend, 1/8” Pass PassAbrasion Resistance, mg loss (3) 28 25Gloss (4)60 degree 91 9220 degree 77 82Varnish Film Color (4)"L" Value 91.07 91.33"a" Value -0.94 -0.96"b" Value 2.24 4.63Yellowing Index 7.63 8.27(1) Films aged 7 days @RT(2) Time to achieve mar resistance by finger nail scratch test(3) Taber, CS-17 wheels, 1000 cycles, 1 Kg load(4) 3 MWF applied to Leneta chart<strong>UROTUF</strong> <strong>L63</strong>-<strong>MPW</strong>-<strong>38</strong>, 91794-00Page 3