Polylite 33336 Series - Reichhold

Polylite 33336 Series - Reichhold

Polylite 33336 Series - Reichhold

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

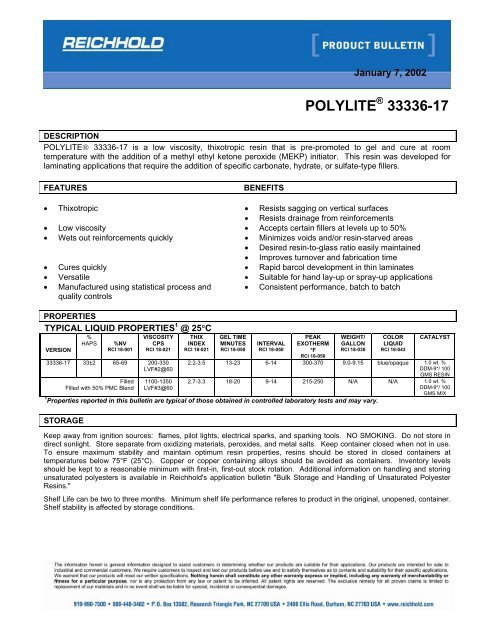

January 7, 2002POLYLITE ® <strong>33336</strong>-17DESCRIPTIONPOLYLITE® <strong>33336</strong>-17 is a low viscosity, thixotropic resin that is pre-promoted to gel and cure at roomtemperature with the addition of a methyl ethyl ketone peroxide (MEKP) initiator. This resin was developed forlaminating applications that require the addition of specific carbonate, hydrate, or sulfate-type fillers.FEATURESBENEFITS• Thixotropic • Resists sagging on vertical surfaces• Resists drainage from reinforcements• Low viscosity • Accepts certain fillers at levels up to 50%• Wets out reinforcements quickly • Minimizes voids and/or resin-starved areas• Desired resin-to-glass ratio easily maintained• Improves turnover and fabrication time• Cures quickly • Rapid barcol development in thin laminates• Versatile • Suitable for hand lay-up or spray-up applications• Manufactured using statistical process andquality controls• Consistent performance, batch to batchPROPERTIESTYPICAL LIQUID PROPERTIES 1 @ 25°CVERSION%HAPS%NVRCI 18-001VISCOSITYCPSRCI 18-021<strong>33336</strong>-17 33±2 65-69 200-330LVF#2@60FilledFilled with 50% PMC Blend1100-1350LVF#3@60THIXINDEXRCI 18-021GEL TIMEMINUTESRCI 18-050INTERVALRCI 18-050PEAKEXOTHERM°FRCI 18-050WEIGHT/GALLONRCI 18-030COLORLIQUIDRCI 18-043CATALYST2.2-3.5 13-23 6-14 300-370 9.0-9.15 blue/opaque 1.0 wt. %DDM-9*/ 100GMS RESIN2.7-3.3 18-20 9-14 215-250 N/A N/A 1.0 wt. %DDM-9*/ 100GMS MIX1Properties reported in this bulletin are typical of those obtained in controlled laboratory tests and may vary.STORAGEKeep away from ignition sources: flames, pilot lights, electrical sparks, and sparking tools. NO SMOKING. Do not store indirect sunlight. Store separate from oxidizing materials, peroxides, and metal salts. Keep container closed when not in use.To ensure maximum stability and maintain optimum resin properties, resins should be stored in closed containers attemperatures below 75°F (25°C). Copper or copper containing alloys should be avoided as containers. Inventory levelsshould be kept to a reasonable minimum with first-in, first-out stock rotation. Additional information on handling and storingunsaturated polyesters is available in <strong>Reichhold</strong>'s application bulletin "Bulk Storage and Handling of Unsaturated PolyesterResins."Shelf Life can be two to three months. Minimum shelf life performance referes to product in the original, unopened, container.Shelf stability is affected by storage conditions.

PACKAGING FORMNon-returnable 55-gallon metal drums (500 lbs. net) or 40,000-44,000 lb. tank truck.SAFETYREAD AND UNDERSTAND THE MATERIAL SAFETY DATA SHEET BEFORE WORKING WITH THIS PRODUCT. Materialsafety data sheets are available from your <strong>Reichhold</strong> Sales Representative.DIRECTLY MIXING ANY ORGANIC PEROXIDE WITH A METAL SALT, AMINE OR OTHER POLYMERIZATIONACCELERATOR OR PROMOTER WILL RESULT IN VIOLENT DECOMPOSITION. When adding peroxides to a resinsolution, promptly and thoroughly mix the resulting product. Never add organic peroxides to a hot diluent or process. Preventcontamination with foreign materials, including without limitation, accelerators or promoters (such as dimethyl aniline, otheramines, and cobalt compounds), heavy-metal oxides or salts (particularly those of cobalt, iron, and copper), strong acids, andsanding dusts. Use containers made of glass, polypropylene, Teflon®, polyethylene, or ceramic to prevent contamination ofthis material during its handling.<strong>Reichhold</strong>'s Environmental Health and Safety Hotline 1-800-275-6353.TECHNICAL SUPPORTFor technical support call 1-800-448-3482.<strong>33336</strong>-17Page 2