CHAPTER 6 SMALL ELEMENT PAVEMENTS - TU Delft

CHAPTER 6 SMALL ELEMENT PAVEMENTS - TU Delft

CHAPTER 6 SMALL ELEMENT PAVEMENTS - TU Delft

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

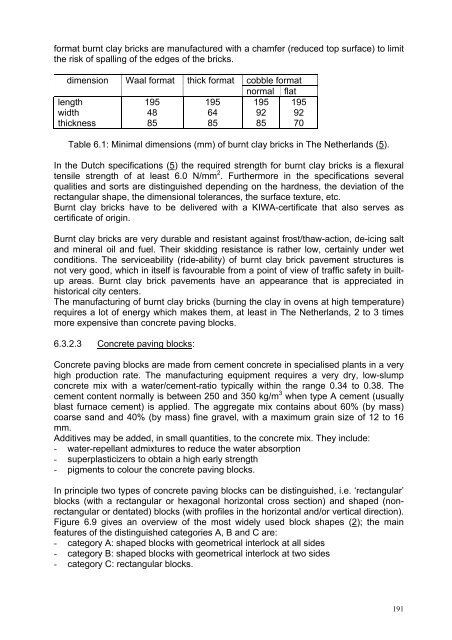

format burnt clay bricks are manufactured with a chamfer (reduced top surface) to limitthe risk of spalling of the edges of the bricks.dimension Waal format thick formatlengthwidththickness19548851956485cobble formatnormal flat195 19592 9285 70Table 6.1: Minimal dimensions (mm) of burnt clay bricks in The Netherlands (5).In the Dutch specifications (5) the required strength for burnt clay bricks is a flexuraltensile strength of at least 6.0 N/mm 2 . Furthermore in the specifications severalqualities and sorts are distinguished depending on the hardness, the deviation of therectangular shape, the dimensional tolerances, the surface texture, etc.Burnt clay bricks have to be delivered with a KIWA-certificate that also serves ascertificate of origin.Burnt clay bricks are very durable and resistant against frost/thaw-action, de-icing saltand mineral oil and fuel. Their skidding resistance is rather low, certainly under wetconditions. The serviceability (ride-ability) of burnt clay brick pavement structures isnot very good, which in itself is favourable from a point of view of traffic safety in builtupareas. Burnt clay brick pavements have an appearance that is appreciated inhistorical city centers.The manufacturing of burnt clay bricks (burning the clay in ovens at high temperature)requires a lot of energy which makes them, at least in The Netherlands, 2 to 3 timesmore expensive than concrete paving blocks.6.3.2.3 Concrete paving blocks:Concrete paving blocks are made from cement concrete in specialised plants in a veryhigh production rate. The manufacturing equipment requires a very dry, low-slumpconcrete mix with a water/cement-ratio typically within the range 0.34 to 0.38. Thecement content normally is between 250 and 350 kg/m 3 when type A cement (usuallyblast furnace cement) is applied. The aggregate mix contains about 60% (by mass)coarse sand and 40% (by mass) fine gravel, with a maximum grain size of 12 to 16mm.Additives may be added, in small quantities, to the concrete mix. They include:- water-repellant admixtures to reduce the water absorption- superplasticizers to obtain a high early strength- pigments to colour the concrete paving blocks.In principle two types of concrete paving blocks can be distinguished, i.e. ‘rectangular’blocks (with a rectangular or hexagonal horizontal cross section) and shaped (nonrectangularor dentated) blocks (with profiles in the horizontal and/or vertical direction).Figure 6.9 gives an overview of the most widely used block shapes (2); the mainfeatures of the distinguished categories A, B and C are:- category A: shaped blocks with geometrical interlock at all sides- category B: shaped blocks with geometrical interlock at two sides- category C: rectangular blocks.191