Carbon Brushes and Brush Systems State-of-the-art Technology for ...

Carbon Brushes and Brush Systems State-of-the-art Technology for ...

Carbon Brushes and Brush Systems State-of-the-art Technology for ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

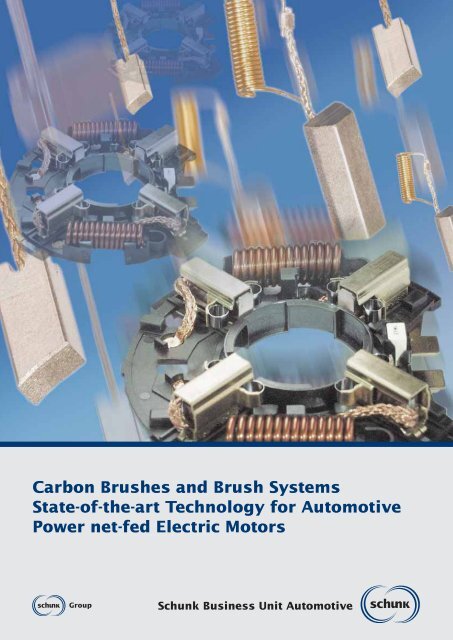

<strong>Carbon</strong> <strong><strong>Brush</strong>es</strong> <strong>and</strong> <strong>Brush</strong> <strong>Systems</strong><strong>State</strong>-<strong>of</strong>-<strong>the</strong>-<strong>art</strong> <strong>Technology</strong> <strong>for</strong> AutomotivePower net-fed Electric MotorsSchunk Business Unit Automotive

The Business Unit AutomotiveThe Automotive Field –<strong>the</strong> “Motor <strong>of</strong> Development”Core Competency:Automotive EngineeringThe worldwide dem<strong>and</strong> <strong>for</strong> <strong>and</strong> <strong>the</strong>quality requirements placed on carbonbrushes <strong>and</strong> complete brush systems<strong>for</strong> <strong>the</strong> automotive industry has steadilyincreased in recent years. For <strong>the</strong>future, we anticipate more <strong>and</strong> more<strong>and</strong> higher <strong>and</strong> higher expectationsin this field.Technical challenges, such as continualimprovement <strong>of</strong> com<strong>for</strong>t <strong>and</strong> safety, <strong>the</strong>introduction <strong>of</strong> <strong>the</strong> 42 volt power net,as well as higher <strong>and</strong> higher dem<strong>and</strong>splaced on <strong>the</strong> level <strong>of</strong> interference suppressionin electrical motors used inautomobiles, are also becoming a“motor <strong>of</strong> development” <strong>for</strong> <strong>the</strong> automotiveindustry in <strong>the</strong> area <strong>of</strong> carbonbrushes <strong>and</strong> completebrush systems.This applies to innovative materials <strong>and</strong>optimal design shapes <strong>for</strong> carbonbrushes, carbon brushes with fittingsor complete units with holders, as wellas <strong>for</strong> complex systems <strong>for</strong> electricalst<strong>and</strong>ard features <strong>and</strong> safety equipment<strong>and</strong> com<strong>for</strong>t features in nearlyall models <strong>of</strong> <strong>the</strong> leading automobilemanufacturers worldwide.Through years <strong>of</strong> cooperation with ourp<strong>art</strong>ners in <strong>the</strong> automotive industry, weknow <strong>the</strong> special needs <strong>of</strong> this market.To us, core competency in automotiveengineering does not only meanworking toge<strong>the</strong>r with our customers in<strong>the</strong> area <strong>of</strong> design, ra<strong>the</strong>r it also meansconsistently producing top quality overlong periods <strong>of</strong> time.We accompany our customers through<strong>the</strong> entire development <strong>and</strong> productionprocess. This includes:material recommendationssupport <strong>for</strong> <strong>the</strong> optimal design <strong>of</strong>componentsdetermination <strong>of</strong> <strong>the</strong> most efficientmethods <strong>of</strong> production<strong>of</strong>fers <strong>for</strong> individual logisticsolutions.

Top Quality Through SynergyOur goal is to achieve absolute topquality <strong>for</strong> our customers. There<strong>for</strong>e,we have brought toge<strong>the</strong>r a team<strong>of</strong> <strong>the</strong> most highly qualified specialists<strong>for</strong> carbon brush materials <strong>and</strong> componentknow-how at <strong>the</strong> AutomotiveBusiness Unit. Hence, in recent yearsfive companies with special knowledgewere merged into <strong>the</strong> AutomotiveBusiness Unit:Schunk Kohlenst<strong>of</strong>ftechnik GmbHH<strong>of</strong>fmann & Co. Elektrokohle AGGerhard PraezisionspresstechnikGmbHSchunk Modultechnik GmbH,SchmittenMember in an International<strong>Technology</strong> GroupThe Schunk Automotive Business Unitis p<strong>art</strong> <strong>of</strong> <strong>the</strong> multinational SchunkGroup, which employs some 7,000people worldwide <strong>and</strong> generates annualsales <strong>of</strong> 625 million Euro. The Schunkgroup is represented by 80 subsidiariesin 25 countries on 5 continents.As a customer <strong>of</strong> <strong>the</strong> AutomotiveBusiness Unit, you will automaticallypr<strong>of</strong>it from <strong>the</strong> innovations <strong>of</strong> <strong>the</strong>research <strong>and</strong> development projects <strong>of</strong>our o<strong>the</strong>r business units, such ascarbon components <strong>for</strong> fuel cells, carbonpistons <strong>for</strong> combustion engines<strong>and</strong> CFC materials <strong>for</strong> high-per<strong>for</strong>mancebrake discs, to name a few.Schunk Modultechnik GmbH,G<strong>and</strong>erkesee

Your Development P<strong>art</strong>nerContinual Development up to <strong>the</strong>Production StageAs <strong>the</strong> Automotive Business Unit,we have been working toge<strong>the</strong>r wi<strong>the</strong>ngineers, developers <strong>and</strong> productdesigners from <strong>the</strong> automotive supplyindustry <strong>for</strong> years. Toge<strong>the</strong>r with ourp<strong>art</strong>ners, we have taken p<strong>art</strong> in manyinteresting projects from <strong>the</strong> first ideathrough to <strong>the</strong> production stage.We <strong>of</strong>fer special know-how in <strong>the</strong> followingareas:Concrete Support <strong>for</strong> Your WorkYou can considerably increase <strong>the</strong> efficiency<strong>of</strong> your product developmentby working toge<strong>the</strong>r with our developmentteam <strong>and</strong> test lab. We help youto recognize <strong>and</strong> eliminate potentialsources <strong>of</strong> errors <strong>and</strong> faults as early as<strong>the</strong> structural design phase.If desired, we can also advise youat this early stage on <strong>the</strong> most costefficient production method.development <strong>of</strong> materials compliantwith EC-Directive on End-<strong>of</strong>-LifeVehicles (2000/53/EC)noise reduction in commutative systemselectromagnetic compatibilityOur Central Development Dep<strong>art</strong>ment<strong>of</strong>fers you access to our chemistry <strong>and</strong>physics labs with <strong>the</strong>ir modern analyticalmeasuring methods. We supportyou when making noise <strong>and</strong> oscillationmeasurements, as well as when measuring<strong>the</strong> degree <strong>of</strong> interference suppression.carbon brushes <strong>for</strong>42 volt power netsmodule solutions with integratedinterference elimination <strong>and</strong> speedcontrollersIn our electrical lab, we carry out per<strong>for</strong>mancemeasurements <strong>and</strong> durabilitytests in accordance with customersengineered specifications.development <strong>of</strong> commutative systems.

Our Design Dep<strong>art</strong>ment works withPro-Engineer, IDEAS <strong>and</strong> AutoCAD systems,among o<strong>the</strong>rs.Upon request, we can manufacturefunction samples on short notice.Teamwork from <strong>the</strong> Word “Go”The best teamwork begins as earlyas <strong>the</strong> idea phase, since this is where<strong>the</strong> paths are laid. In this early phase,we can give you a lot <strong>of</strong> tips <strong>and</strong> recommendationsto optimize your plans.Ideally, teamwork should begin with<strong>the</strong> following steps:Climatic chamber made by Weiss-Klimatechnik (Schunk Group). Regulation<strong>of</strong> humidity between 10 % – 95 % is possible,<strong>the</strong> temperature can be adjusted from– 40 °C to +180 °Ccustomer enquirynew p<strong>art</strong>s meetingfeasibility studyfeedback with <strong>the</strong> customerCAD/preliminary drawingsubmission <strong>of</strong> <strong>of</strong>fer.St<strong>art</strong>er test benchwith integratedtorque measurement,simulation<strong>of</strong> <strong>the</strong> st<strong>art</strong> process<strong>of</strong> a combustionengine using anelectronically controlledservomotor

Production, Process Security, QualityAs a Global Player, We Can Be onLocation <strong>for</strong> You Worldwide<strong>Carbon</strong> <strong><strong>Brush</strong>es</strong> <strong>and</strong> <strong>Brush</strong> <strong>Systems</strong>in Large-Series ProductionWith 13 production sites worldwide,we are one <strong>of</strong> <strong>the</strong> global players in <strong>the</strong>production <strong>of</strong> carbon brushes <strong>for</strong>power net-fed electric motors <strong>and</strong>ready to install brush systems.For <strong>the</strong> st<strong>and</strong>ard electrical features, weproduce components <strong>for</strong> <strong>the</strong> followingelectrical motors:st<strong>art</strong>ershydraulic press,power: 250kN, fullyautomatic with twindie <strong>for</strong> double layercarbon brushesWe strive to locate our production <strong>and</strong>logistics facilities to be as close as possibleto <strong>the</strong> locations <strong>of</strong> our customers.We use semi- <strong>and</strong> fully-automated systems<strong>and</strong> can manufacture manually aswell, if necessary.alternatorsengine cooling fans (ECF)heating ventilation air condition(HVAC)windshield <strong>and</strong> rear window wipersfuel pumpswater pumps.For <strong>the</strong> safety features we producecomponents <strong>for</strong>:ABS/ASR/ESPseat belt tightenersheadlight wiperselectro-hydraulic brakes (EHB).

For <strong>the</strong> area <strong>of</strong> com<strong>for</strong>t, we develop<strong>and</strong> produce brushes with <strong>and</strong> withoutholders as well as brush systems <strong>for</strong>:window lift motorsseat adjusterssun-ro<strong>of</strong> driveselectric clutch systemspower steeringsservo fly press, accuracy 0.001 mmproduction hall with modularautomatic rotary tableselectrical power locksside mirror adjusterspower antennas.For environmental protection, we develop<strong>and</strong> produce components <strong>for</strong>:catalytic converter fansthrottle controls.“Made by Schunk” MeansTop QualityIn <strong>the</strong> entire Automotive Business Unitwe have a clearly defined quality commitment<strong>and</strong> a solidly institutionalizedquality management system.Our individual companies are certifiedin accordance with ISO 9001 <strong>and</strong>some are also additionally certifiedwith QS 9000 <strong>and</strong> VDA 6.1.All st<strong>and</strong>ard quality planning, approval<strong>and</strong> release processes are carried outwithin <strong>the</strong> framework <strong>of</strong> a well establishednew p<strong>art</strong>s project-management.These include, <strong>for</strong> example, AdvancedProduct Quality Planning (APQP),Failure Mode <strong>and</strong> Effect Analysis (FMEA)<strong>and</strong> Production P<strong>art</strong>s Approval Process(PPAP) in accordance withQS 9000 or Initial Samples InspectionReport (ISIR) in accordance with VDA.automatic linear grinder LIN NT 2 <strong>and</strong> rotary table, fully automaticmachining <strong>of</strong> carbon brushes

High-Tech Products <strong>for</strong> Safe Current TransmissionAt <strong>the</strong> Automotive Business Unit wesupply <strong>the</strong> leading automotive suppliersworldwide with carbon brushes,holders <strong>and</strong> ready to install brushcards. A few product samples from ourportfolio are portrayed below.Assembly<strong>for</strong> Wet RunningFuel Pumpscarbon brushes<strong>and</strong> plastic holdercomplete with connector<strong>Carbon</strong> <strong>Brush</strong><strong>for</strong> AirConditioningFanscurved PTScarbonbrushes,<strong>for</strong> especiallydesigned brushholders<strong>Carbon</strong> <strong>Brush</strong><strong>for</strong> CatalyticConverter Fansaxially pressedwith pressed onhead <strong>for</strong> springcentering, groundrunning surface<strong>and</strong> welded shuntend<strong>Carbon</strong> <strong>Brush</strong><strong>for</strong> Heating Fansradially pressed,cross shaped headgroove, cable enddoubly welded,ground runningsurface2-ComponentSt<strong>art</strong>er <strong>Brush</strong><strong>for</strong> dem<strong>and</strong>ingcommutation<strong>Carbon</strong> <strong>Brush</strong><strong>for</strong> EngineCooling Fanwith an <strong>of</strong>fse<strong>the</strong>ad <strong>for</strong> bipolarmotors, specialdesign <strong>for</strong> clampfastening usinga leaf spring,welded shunt end<strong>and</strong> ground runningsurfaceassembly consisting<strong>of</strong> carbon brush <strong>and</strong>suppressor (choke) <strong>for</strong>wet running fuelpumps

EHD <strong>Brush</strong> System<strong>Brush</strong> System – Interference-Suppressed with SensorsModule <strong>for</strong> AutomaticTransmissionsAs a component <strong>of</strong> <strong>the</strong> electrical powersteering pump, <strong>the</strong> EHD brushsystem contributes directly to drivingsafety in car design. In order to optimallyuse resources, <strong>the</strong> current carrieris made <strong>of</strong> a single p<strong>art</strong> which incorporatesinnovative shaping technology.<strong>State</strong>-<strong>of</strong>-<strong>the</strong>-<strong>art</strong> injection technology,combined with electronics in <strong>the</strong>brush system. TPE sealing, injectionmolding <strong>and</strong> soldering fully automated.Temperature range between– 40 °C /+85 °C. Due to a variable-basissystem, use in several different types<strong>of</strong> vehicles is possible.<strong>Brush</strong> system with sensors, high durability<strong>of</strong> carbon brushes, temperaturerange between – 40 °C /+85 °C. Use <strong>of</strong><strong>the</strong> System contributes to <strong>the</strong> bypassing<strong>of</strong> <strong>the</strong> clutch function in vehicles<strong>and</strong> ensures output capacity when useddirectly in a motor.<strong>Brush</strong> <strong>Systems</strong> <strong>for</strong> ABS MotorsVVT <strong>Brush</strong> SystemL 100 <strong>Brush</strong> RockerPlastic composite p<strong>art</strong>, base modulemade <strong>of</strong> polyamide 50 % GF withsilicone seal molding, fully automatedmanufacture <strong>of</strong> <strong>the</strong> basis module.New manufacturing method replaces<strong>the</strong> assembly method with ordinaryO-rings previously used. Temperaturerange between – 40 °C /+120 °C.Extremely compactly built VVT brushsystem, in combination with o<strong>the</strong>r components<strong>for</strong>ms <strong>the</strong> variable valve control.The VVT brush system proves itsper<strong>for</strong>mance at acceleration <strong>of</strong>up to 40 g <strong>and</strong> temperatures <strong>of</strong> over150 °C.<strong>Brush</strong> <strong>Systems</strong> with Circuit Board<strong>for</strong> Window Lift MotorsHas proven itself a million times –<strong>the</strong> L100 brush rocker combines fullautomation with <strong>the</strong> highest degree<strong>of</strong> variability. Due to <strong>the</strong> intelligent, patenteddesign, <strong>the</strong> support plate with<strong>the</strong> integrated plastic brush boxes, including<strong>the</strong> closure valves which arelater needed, can be produced as onep<strong>art</strong>. Due to <strong>the</strong> optimal <strong>for</strong>ward re-sistance,a cost efficient control <strong>of</strong> <strong>the</strong>rotational speed can be realized.Plastic composite p<strong>art</strong>, basis modulemade <strong>of</strong> polyamide 30 % GF withThermoplastic Elastomers (TPE) sealmolding. Fully automated manufacture<strong>of</strong> <strong>the</strong> basis module. Automatic testing<strong>of</strong> <strong>the</strong> mobility <strong>of</strong> <strong>the</strong> carbon brush,spring <strong>for</strong>ce, Hall IC.

Logistics <strong>and</strong> CommunicationSchunk Automotive Business Unit:We are here <strong>for</strong> you <strong>and</strong> we are gladto answer your questions.We Have Everything under Controlin <strong>the</strong> Area <strong>of</strong> Logistics AlsoIn <strong>the</strong> area <strong>of</strong> logistics <strong>and</strong> communications,we guarantee our customersa smooth <strong>and</strong> efficient flow <strong>of</strong> goods<strong>and</strong> in<strong>for</strong>mation.We <strong>of</strong>fer our customers individualpackaging solutions which best suit <strong>the</strong>respective assembly requirements: e.g.intelligent packaging alternativessuch as rolled blister-foil packaging<strong>for</strong> automated, uncontaminated<strong>and</strong> precision placing <strong>of</strong> components.A packaging alternative from <strong>the</strong>electrical <strong>and</strong> semi-conductor industry<strong>for</strong> <strong>the</strong> placement <strong>of</strong> circuit boardsusing pick <strong>and</strong> place assembly units.The designation <strong>of</strong> goods is ensured byusing barcode labeling (VDA) productstickers.If you would like to place your orderonline, Electronic Data Interchangeis available at Schunk Automotive <strong>for</strong>your convenience.Rolled blister-foil packaging <strong>for</strong>automated, uncontaminated <strong>and</strong>precise positioning <strong>of</strong> components.This method <strong>of</strong> packagingoriginated in <strong>the</strong> electrical <strong>and</strong>semi-conductor industries.

Schunk Kohlenst<strong>of</strong>ftechnik GmbHRodheimer Strasse 5935452 HeuchelheimGermanyTelephone: + 49 (641) 608 - 0Telefax: + 49 (641) 608 -1223e- Mail: infobox@schunk-group.comH<strong>of</strong>fmann & Co. Elektrokohle AGAu 624832 SteegAustriaTelephone: + 43 (6135) 400 - 0Telefax: + 43 (6135) 400 -10 or -12e- Mail: <strong>of</strong>fice@h<strong>of</strong>fmann.atwww.h<strong>of</strong>fmann.atSchunk Modultechnik GmbHSeelenbergerstrasse 1aD-61389 SchmittenTelephone: +49 (60 84) 9 45-0Telefax: +49 (60 84) 9 45-155e-Mail: smt-info@schunk-group.comSchunk Modultechnik GmbHIndustriepark 7D-27777 G<strong>and</strong>erkeseeTelephone: +49 (42 22) 43-0Telefax: +49 (42 22) 43-21e-Mail: smt-info@schunk-group.comGerhard PräzisionspresstechnikGmbHRingstrasse 2391619 ObernzennGermanyTelephone: + 49 (9844) 97 11- 0Telefax: + 49 (9844) 97 11- 50

14.02e/2002Schunk Business Unit Automotive GmbHRodheimer Straße 5935452 HeuchelheimGermanyTelephone: + 49 (641) 608 - 0Telefax: + 49 (641) 608 -1488www.schunk-group.com