Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

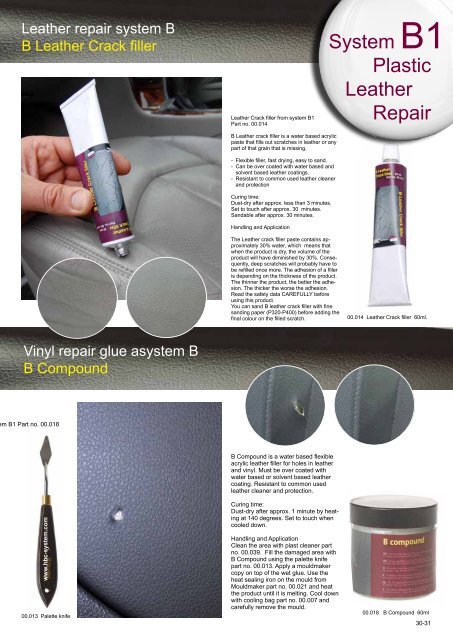

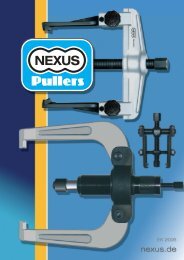

Leather repair system BB Leather Crack fillerLeather Crack filler from system B1Part no. 00.014System B1PlasticLeather<strong>Repair</strong>B Leather crack filler is a water based acrylicpaste that fills out scratches in leather or anypart of that grain that is missing.- Flexible filler, fast drying, easy to sand.- Can be over coated with water based andsolvent based leather coatings.- Resistant to common used leather cleanerand protectionCuring time:Dust-dry after approx. less than 3 minutes.Set to touch after approx. 30 minutes.Sandable after approx. 30 minutes.Handling and ApplicationThe Leather crack filler paste contains approximately30% water, which means thatwhen the product is dry, the volume of theproduct will have diminished by 30%. Consequently,deep scratches will probably have tobe refilled once more. The adhesion of a filleris depending on the thickness of the product.The thinner the product, the better the adhesion.The thicker the worse the adhesion.Read the safety data CAREFULLY beforeusing this product.You can sand B leather crack filler with finesanding paper (P320-P400) before adding thefinal colour on the filled scratch.00.014 Leather Crack filler 60ml.Vinyl repair glue asystem BB Compoundm B1 Part no. 00.018www.hbc-system.com00.013 Palette knifeB Compound is a water based flexibleacrylic leather filler for holes in leatherand vinyl. Must be over coated withwater based or solvent based leathercoating. Resistant to common usedleather cleaner and protection.Curing time:Dust-dry after approx. 1 minute by heatingat 140 degrees. Set to touch whencooled down.Handling and ApplicationClean the area with plast cleaner partno. 00.039. Fill the damaged area withB Compound using the palette knifepart no. 00.013. Apply a mouldmakercopy on top of the wet glue. Use theheat sealing iron on the mould fromMouldmaker part no. 00.021 and heatthe product until it is melting. Cool downwith cooling bag part no. 00.007 andcarefully remove the mould.00.018 B Compound 60ml30-31