You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

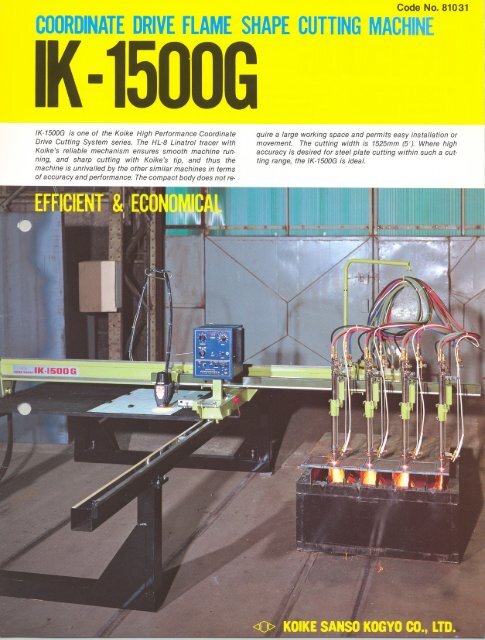

Code No. 81031<strong>COORDINATEDRIVEFLAMESHAPECUTTING</strong>.<strong>MACHINE</strong>.IK-1500G is one of the Koike High Performance CoordinateDrive Cutting System series. The HL-B Linatrol tracer withKoike's reliable mechanism ensures smooth machine running,and sharp cutting with Koike's tip, and thus themachine is unrivalled by the other similar machines in termsof accuracy and performance. The compact body does not requirea large working space and permits easy installation ormovement. The cutting width is 1525mm (5'). Where highaccuracy is desired for steel plate cutting within such a cuttingrange, the IK-1500G is ideal.

<strong>COORDINATEDRIVEFLAMESHAPECUTTING</strong><strong>MACHINE</strong>IK.1500G0 HIGHLY RELIABLECOORDINATE DRIVETRACING SYSTEM.Koike is the largest supplier of this sizeof cutting machines with HL-8 tracingsystems. As its proof of machine superiority, the followings are provided.Drawing line detection and motor drivealong the X and Y axis are done simultaneouslyso that cutting is made in asmooth manner according to the drawing.Even if the tracing spot moves offthe line/edge for some reason, machineoperation will automatically stop instantlyto ensure against a defectiveproduct. There is no need to use aradius corner for any shape since thistracer will follow the corner exactly.The tracer has no gears or any slipringsand is entirely free from the needfor adjustment of the optical system orcontact failure from wear, so that it requireslittle maintenance. The tracer isseparately slidable along the bar, onwhich torches are mounted, so that itcan be positioned with ease.8THE MAIN CONTROL PANELDESIGNED FOR SIMPLEAND EASY OPERATIONAll of the operating functions necessaryfor cutting are centralized on thispanel and allow the desired work to becarried out by simple switch operation,and the position of the main controlpanel is located for easy/smoothoperation.A: Power switchB: Drive switchC: Speed adjustment dialD: Mode dialE: Direction dialF: Cutting oxygen switchG: Start switchf)n

Optional control switchH: Auto-ignition switchI: Preheat switchJ: Torch height control switch(Motorized torch riser - S)8SMOOTH <strong>MACHINE</strong>RUNNINGThe drive of the X and Y traveling carriagesis powered by a combination ofDC servo motor and friction roller bymeans of specially designed reductiongears. Controlled by detection commandsfrom the tracer, the drive motorruns both X and Y carriages simultaneouslyto create the path of thetorch. For positioning, etc., release Xand the Y clutches by lever operation,and The machine will move freely.0 EASY TO HANDLE GASDISTRIBUTION UNITRegulate gas pressure according tothe plate thickness to be cut, and gassupply will be smothly carried outunder the control of the solenoidvalve.0OCUTTINGTORCHESThe standard number of torches is 2but another 2 torches can be fitted.Cutting thickness capacity:200mm (8") with 1 torch150mm (6") with 2 torches100mm (4") with 3 torches50mm (2") with 4 torches0L1GHT AND COMPACTBODY WITHRIGID PEDESTALThe workability is improved by a longerbody than that of the conventional typeand a rail pedestal of more rigid construction,of whose square bars of weldconstruction are particularly resistantto distortion, vibration, heavy load andwear. The precision finish of the travelingrail surface promises high accuracyand sharp cutting.NESTING CUTRECOMMENDEDThe tracer can trace exactly an edge ofO.6mm line width. Thus, it permits continuouscut by nesting which allowseconomical use of steel plate and improvesthe work efficiency greatly.

OPTIONAL FEA TU RESAND EQUIPMENTMOTORIZEDTORCH RISER.S 0Popular economical version of the Motorized Torch Riser.This unit raises and lowers each torch block, and is actuatedby the optional control panel switch.AUTOMATIC IGNITION SYSTEM 8This unit lights the cutting torches by a pilot torch with anignition device, it is actuated by the optional control panelswitch.WATER SPRAYThis unit is turned on and off by a solenoid valve with supplyof cutting oxygen to the torches.LONG SIZE RAIL AND PEDESTALSRail length: 7,OOOmm(275")CIRCLE CUTTING ATTACHMENTEffective circle cutting dia.: 200-1,200mm(8-47inch

SPECI FICATIONSTracing range Width 1525mm (60")Length 1200mm (47-1/4")Cutti ng range Width 1525mm (60")Length 3000mm (118")Minimum torch pacing 55mm (80mm when the auto-(Minimum cutting width)ignition and/or water spraydevice is/are fitted)Number of torches 2 (maximum 4)Cutting thickness capacityCutting surface shapeStraight line cutting200mm (8") with 1 torch150mm (6") with 2 torches100mm (4") with 3 torches50mm (2") with 4 torchesSquare cutting (I-shape)Possible when four directionswitch is used Withoutenergizing tracerhead, machine will strip, (parallelcut) in any of the four pre.selected directions.Automatic lead-in Possible in 4 directionsCutting speed 100-1000mm/min. (4-40in/min.)TracerHL-8 LinatrolDriveTracingLine widthKerf compensationTracing accuracyPosition of control assemblyCoordinate drive by X and Y drivemotorsCircle scanning edge tracing0.6mm (0.024") and wider.Silhouette drawing is permissibleoI=1.5mm(0.06")oI=O.25mm(0.01") deviation fromedge of line on straight line.Left side of the machine whenfacing it.Travel of the machine Roller friction travel controlled byDC servo motor with reductionCutting oxygenCutting oxygen emergencyshut-off solenoid valvePower sourceOxygen/fuel gas pressureMachine weightgear.ON/OFF operations are preformedby solenoid valves.Works on any emergency, linkingwith the tracer.Single phase, AC 100V/115V,50Hz/60HzPressure to be decided inaccordance with our cuttingdata.150kg (340 Ibs.)ACCESSORIESTip. koike 100 series tips,#1, #2, #3Standard tools3 tips/1 torchOne setTip cleaner,lighter, spannersSource lampsFull setFusesFull setPower cable Bm (315") OneGas hoses (cutting oxygen, One each Bm (315")preheat oxygen, fuel gas)

DIMENSIONS)J :lJ:OVERALL WIDTH 4,000 mm0~]EE0It)00.~EE00m01 04,000 mmORDERING INFORMATIONStandard unitComposed of: Machine base unit with 2 torches.Basic rail and pedestals.HL-81 line/edge coordinate drive system.Tracing table.Gas distribution unit.Instruction50Hz/60Hz, 100/115VOptional equipmentLong size rail and pedestalsAdditional torch unit:Torch adaptor unitTorch and torch holder unitmanuals and accessories.Water spray basic unit (1 per machine)Water spray nozzle unit (1 per torch)Auto ignitor basic unit (1 per machine)Auto ignitor torch unit (1 per torch)Motorized torch riser-SCircle cutting attachmentTransformer (for 200/220/400/440/460V supply)Recommended spare partsI)"KOIKESANSOKOGYOCO.,LTD.Soldby:3-1,Shinden 2-chome, Ichikawa, Chiba 272-0035Telex: 2993-105 KSKSEI JFacsimile: 047-378-8393Telephone: 047-376-3211JapanOur marketing and service function is totally customeroriented and depends on you and your needs. How wellwe are able to anticipate and meet your future requirementswill determine the final success of our "responsible marketing"concept, and that's exactly why we hope you will contact ustoday or any time with any questions, problems, or suggestions.Specifications shown herein are subject to change without notice. Printed in Japan