Automated Plasmid Purification - Hamilton Robotics

Automated Plasmid Purification - Hamilton Robotics

Automated Plasmid Purification - Hamilton Robotics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

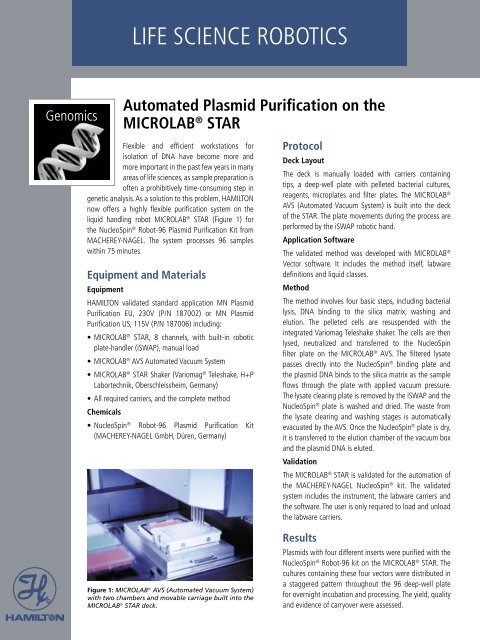

LIFE SCIENCE ROBOTICSGenomics<strong>Automated</strong> <strong>Plasmid</strong> <strong>Purification</strong> on theMICROLAB ® STARFlexible and efficient workstations forisolation of DNA have become more andmore important in the past few years in manyareas of life sciences, as sample preparation isoften a prohibitively time-consuming step ingenetic analysis. As a solution to this problem, HAMILTONnow offers a highly flexible purification system on theliquid handling robot MICROLAB ® STAR (Figure 1) forthe NucleoSpin ® Robot-96 <strong>Plasmid</strong> <strong>Purification</strong> Kit fromMACHEREY-NAGEL. The system processes 96 sampleswithin 75 minutes.Equipment and MaterialsEquipmentHAMILTON validated standard application MN <strong>Plasmid</strong><strong>Purification</strong> EU, 230V (P/N 187002) or MN <strong>Plasmid</strong><strong>Purification</strong> US, 115V (P/N 187006) including:• MICROLAB ® STAR, 8 channels, with built-in roboticplate-handler (iSWAP), manual load• MICROLAB ® AVS <strong>Automated</strong> Vacuum System• MICROLAB ® STAR Shaker (Variomag ® Teleshake, H+PLabortechnik, Oberschleissheim, Germany)• All required carriers, and the complete methodChemicals• NucleoSpin ® Robot-96 <strong>Plasmid</strong> <strong>Purification</strong> Kit(MACHEREY-NAGEL GmbH, Düren, Germany)ProtocolDeck LayoutThe deck is manually loaded with carriers containingtips, a deep-well plate with pelleted bacterial cultures,reagents, microplates and filter plates. The MICROLAB ®AVS (<strong>Automated</strong> Vacuum System) is built into the deckof the STAR. The plate movements during the process areperformed by the iSWAP robotic hand.Application SoftwareThe validated method was developed with MICROLAB ®Vector software. It includes the method itself, labwaredefinitions and liquid classes.MethodThe method involves four basic steps, including bacteriallysis, DNA binding to the silica matrix, washing andelution. The pelleted cells are resuspended with theintegrated Variomag Teleshake shaker. The cells are thenlysed, neutralized and transferred to the NucleoSpinfilter plate on the MICROLAB ® AVS. The filtered lysatepasses directly into the NucleoSpin ® binding plate andthe plasmid DNA binds to the silica matrix as the sampleflows through the plate with applied vacuum pressure.The lysate clearing plate is removed by the iSWAP and theNucleoSpin ® plate is washed and dried. The waste fromthe lysate clearing and washing stages is automaticallyevacuated by the AVS. Once the NucleoSpin ® plate is dry,it is transferred to the elution chamber of the vacuum boxand the plasmid DNA is eluted.ValidationThe MICROLAB ® STAR is validated for the automation ofthe MACHEREY-NAGEL NucleoSpin ® kit. The validatedsystem includes the instrument, the labware carriers andthe software. The user is only required to load and unloadthe labware carriers.Figure 1: MICROLAB ® AVS (<strong>Automated</strong> Vacuum System)with two chambers and movable carriage built into theMICROLAB ® STAR deck.Results<strong>Plasmid</strong>s with four different inserts were purified with theNucleoSpin ® Robot-96 kit on the MICROLAB ® STAR. Thecultures containing these four vectors were distributed ina staggered pattern throughout the 96 deep-well platefor overnight incubation and processing. The yield, qualityand evidence of carryover were assessed.

8EcoR Iundigested71 2 1 2 1 2 1 2 3 4 3 4 3 4 3 4 1 2 1 2 1 2 1 26DNA Yields (μg)Yield and QualityThe yield obtained by automated processing using the MICROLAB ®STAR was compared with the yield from manual processing.The yields ranged from approximately 3µg to 6.5µg, dependingon the purified plasmid. The yields from the automated systemwere consistent with, if not greater than the yields from manualprocessing (Figure 2). The A260/280 ratios of the processed DNAfor both the manual and automated systems were all within optimalranges (Figure 3). The samples processed with the MICROLAB ® STARwere consistent, clean and ready to use in downstream applications,such as digestion with restriction enzymes (Figure 4).OD 260/2805432102.221.61.41.21Carryover1 2 3 4ManuallySample NumberML STARManuallyML STARFigure 2: pGEM plasmid yields from manual and automatedpreparation. Average values and standard deviation values weredetermined from 24 parallel isolations per plasmid (96 in total).Figure 3: The A260/280 ratio for thepurified plasmidsfrom 96 isolationsin total. The A260/280 ratio for boththe manually andautomaticallyprepared sampleswas within theoptimal range.Figure 4 shows results from the isolation. No cross-contamination ofplasmids from adjacent wells is visible on the gel. In order to furthertest for carryover, each purified sample was PCR-amplified withvector-specific primers. No carryover was seen (data not shown).Figure 4: Purified plasmid DNA (pGEM with insert sizes of 359bp(1), 645bp (2), 982bp (3), and 1484bp (4)). Different plasmidswere located in adjacent wells of the plates. Randomly-selectedplasmids of all insert sizes were digested with EcoR I. Digestedand undigested plasmids (10μl) were run on a 1% agarose gel.Throughput and CapacityThe NucleoSpin ® kit process was completed in 75 minutes for one96-well plate. This system can process up to two 96-well plates in 2hours and 30 minutes without user intervention. The iSWAP is usedfor removing the NucleoSpin binding plate and the MN wash platefrom the AVS prior to the elution step. Additional plate stackers mayeasily be integrated to increase deck capacity and walk-away time.DiscussionHAMILTON and MACHEREY-NAGEL have developed a validatedmethod for fully automated plasmid purification with maximumreliability, yield and throughput. MICROLAB ® STAR with theflexible AVS vacuum manifold can also be used to automate otherMACHEREY-NAGEL vacuum separation kits. HAMILTON’s uniqueCO-RE (Compression-induced O-Ring Expansion) technology for tipcoupling on the pipetting channels of MICROLAB ® STAR allows the useof both disposable tips and washable needles within this application.Features and Benefits• Fully automated hands-free processing with built-in roboticplate-handler (iSWAP)• High yield and DNA quality• Validated method available• Process control and security with MICROLAB ® AVS (<strong>Automated</strong>Vacuum System)• <strong>Automated</strong> additional applications, such as DNA normalization,PCR set up, or restriction analysis• A wide range of MACHEREY-NAGEL kit types can be automatedon the same platformwww.hamiltoncompany.com/roboticsLit. No. BR-0302-03/00 ©<strong>Hamilton</strong> Bonaduz AG 03/02 Printed in Switzerland<strong>Hamilton</strong> Bonaduz AGVia Crusch 8CH-7402 BonaduzSwitzerlandTelephone: +41-(0)81-660-60-60Fax: +41-(0)81-660-60-70infoservice@hamilton.ch<strong>Hamilton</strong> Company4970 Energy WayReno, Nevada 89520 USAToll-Free: 800-648-5950Telephone: +1-775-858-3000Fax: +1-775-856-7259sales@hamiltoncompany.com<strong>Hamilton</strong> Great Britain LtdUnit 2, Enterprise WayAston Science ParkBirmingham, B7 4BH, UKTelephone: +44-(0)121-260-0301Fax: +44-(0)121-260-0302info.gb@hamiltonrobotics.com<strong>Hamilton</strong> Deutschland GmbHFraunhoferstr. 17D-82152 MartinsriedGermanyTelephone: +49-(0)89-5526-49-0Fax: +49-(0)89-5526-49-10info.de@hamiltonrobotics.com<strong>Hamilton</strong> France S.A.R.L.Parc du Moulin de Massy37 rue du Saule TrapuF-91300 Massy/FranceTelephone +33-(0)1-69-75-16-16Fax +33-(0)1-60-11-57-16info.fr@hamiltonrobotics.com