1 How to write a risk assessment The University has a Duty of Care ...

1 How to write a risk assessment The University has a Duty of Care ...

1 How to write a risk assessment The University has a Duty of Care ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> Kyle Rhea Tidal Stream ArrayVolume INon-Technical Summary

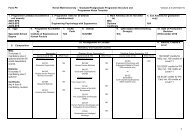

isk is by skin absorption). An additional concern involves inhalation <strong>of</strong> thepowdered dye and the possible development <strong>of</strong> respira<strong>to</strong>ry distress.Solvents. One-litre quantities <strong>of</strong> absolute ethanol, 95% methanol and ace<strong>to</strong>ne are keptin screw capped glass bottles within a metal solvent cupboard. One hundred millilitrequantities <strong>of</strong> these solvents are contained in glass bottles, and used for decolorizingbiological stains and for chemical extractions. <strong>The</strong> most likely hazard stems from fireand explosion.Disinfectants. Sodium hypochlorite, in 5 litre containers, is s<strong>to</strong>red in the labora<strong>to</strong>ry,and used as a disinfectant. Small (200 ml) volumes <strong>of</strong> diluted (0.1% v/v) Chloros iscontained in open polypropylene containers, as disinfectant. Direct contact with theskin or eyes could result in (chemical) burns.5. Trips and falls – from items left inadvertently on floors.6. Electrical hazards (Electrical at Work Regulations, 1989) – electric shocks fromsockets; problems (electric shocks) from unsafe equipment7. Cuts/injections – from broken glass, sharps, needles8. Explosion hazards – from the inadvertent mixing <strong>of</strong> chemicals; solvents.9. Centrifuge. <strong>The</strong>re is the possibility that an improperly balanced centrifuge couldfail, causing the centrifuge head <strong>to</strong> become detached and released explosivelyfrom the machine leading <strong>to</strong> severe injury.10. Display screen equipment. Two computers are available for use by the staff andstudents. Separate <strong>risk</strong> <strong>assessment</strong>s have been made, and for the staff eyeexaminations are arranged on a rolling three-year programme. <strong>The</strong> hazardsconcern eyestrain, headaches and repetitive strain injury.11. Fire – from solvents, chemicals and paper (ignited by Bunsen flames andspontaneous self-ignition).PERSONS AT RISKa. Staff and students who use the labora<strong>to</strong>ry.b. Visi<strong>to</strong>rs.LEVEL OF RISK1. Low (this assumes that the au<strong>to</strong>clave is used strictly according <strong>to</strong> themanufacturers instructions; fortunately, the electric au<strong>to</strong>clave <strong>has</strong> sufficientau<strong>to</strong>matic fail safes <strong>to</strong> reduce further any concerns).2. Moderate (due <strong>to</strong> the regularity that staff and students use hot water, au<strong>to</strong>claves,and Bunsen burners, it is considered that there is a moderate <strong>risk</strong> <strong>of</strong> minor burnsand scalds despite the presence <strong>of</strong> warning notices).3. Low (the cultures used in the labora<strong>to</strong>ry are not harmful pathogens, and the <strong>risk</strong> <strong>of</strong>harm resulting from their use is considered <strong>to</strong> be “low”)4. Low (<strong>The</strong> quantities in the labora<strong>to</strong>ry are low, and with current practices observedduring the <strong>assessment</strong> and the irregular use <strong>of</strong> these chemicals, a realistic <strong>risk</strong> <strong>of</strong>harm is “low”).5. Low6. Low (high voltage items are not present; all electrical items, i.e. computers,printers, refrigera<strong>to</strong>rs, deep freezers, centrifuges, mixers and spectropho<strong>to</strong>meters)5

inoculating loops – a small flame <strong>of</strong> ≤10 cm works just as well as a large flame;and adjusting the air hole on the Bunsen burner so that the flame may be seen (ifthe air hole is completely open, the flame is virtually invisible). It is goodpractice <strong>to</strong> ensure that there is a clear space around Bunsen burners, which MUSTbe kept well away from colleagues and overhanging shelves.3. <strong>The</strong> cultures could cause disease following infection by injection, inhalation, ororally. <strong>The</strong> procedures for Category 2 pathogens, as detailed in the SafetyBooklet MUST be followed. A synopsis <strong>of</strong> the regulations taken from the HSERegulations Governing Work with Pathogens <strong>has</strong> been included in Appendix 1.In all work with microorganisms, person protective equipment (PPE), namely aproperly fastened microbiological labora<strong>to</strong>ry coat must be worn. If contaminationis suspected, the contaminated object should be placed in an au<strong>to</strong>clave bag andsterilized at 121 o C for 15 minutes. Surface spills may be disinfected – 0.1% (v/v)Chloros is effective but a contact time <strong>of</strong> one minute is necessary. To protect theindividual, household style rubber gloves should be worn. <strong>The</strong> disinfectedsurface/object will then need <strong>to</strong> be washed carefully with tap water <strong>to</strong> remove theChloros, which is a powerful bleach. <strong>The</strong> rubber gloves may be washed inflowing tap water <strong>to</strong> remove the residual disinfectant.4. Data sheets MUST be consulted for each chemical if there is doubt about itssafety. <strong>The</strong>re are two classes <strong>of</strong> compounds that could pose problems, i.e.pharmaceutical compounds (principally antibiotics) and stains (particularly arylmethane dyes). Skin absorption may be prevented by wearing PPE, i.e.disposable gloves (this is especially recommended if it is known that theindividual <strong>has</strong> an adverse reaction <strong>to</strong> any given compound). <strong>The</strong>reafter, the usedgloves must be placed in the au<strong>to</strong>clave bags for sterilization and disposal with thestandard bacteriological waste. Also, the compounds should be weighed (andused) in laminar airflow cabinets. If a compound does come in<strong>to</strong> accidentalcontact with skin, wash thoroughly with tap water. On no account should anycompound be brought in<strong>to</strong> contact with the mouth. By use <strong>of</strong> gentle techniques,manipulations in the fume cupboards/clean air cabinet, airborne dispersal <strong>of</strong> achemical may be eliminated – do not deliberately breathe in any dust producedduring weighing or mixing procedures.Disposable gloves must not be worn outside the labora<strong>to</strong>ry. If the gloves arecontaminated then there is a <strong>risk</strong> that the contaminating material could betransferred <strong>to</strong> door handles, and therefore, other individuals could becomecontaminated.To reduce any <strong>risk</strong> associated with the use <strong>of</strong> solvents, it is essential that they ares<strong>to</strong>red in the appropriate solvent cupboard. Solvents must never be used in thepresence <strong>of</strong> naked flames (solvent vapours could all <strong>to</strong>o easily ignite). Alsosolvents must not be mixed, unless there is good chemical evidence that suchmixtures are not potentially dangerous (causing explosions or increased amounts<strong>of</strong> potentially flammable vapours). Small quantities or ethanol, methanol andace<strong>to</strong>ne may be disposed down the labora<strong>to</strong>ry sinks providing that disposal isaccompanied by copious quantities <strong>of</strong> tap water. Although there was no evidence7

in the labora<strong>to</strong>ry for the presence <strong>of</strong> ethers, these compounds are extremelyvolatile and disposal is by means <strong>of</strong> collection in designated Winchester bottlesand transfer <strong>to</strong> the School s<strong>to</strong>res for later removal by a contrac<strong>to</strong>r.Although there was not any evidence for the presence <strong>of</strong> strong acids or alkalis,workers are reminded that work with such chemicals poses extra <strong>risk</strong>s that mustbe considered if use is contemplated.5. Items must NOT be left on the floor for others <strong>to</strong> trip over. Personnel need <strong>to</strong> beaware <strong>of</strong> any items, which could be left on the floor.6. Electrical items must not be used if they have not been tested or the test is out <strong>of</strong>date (there should be a sticker on the plug). If an electrical item is seen with anout-<strong>of</strong>-date sticker, the technician in charge <strong>of</strong> the labora<strong>to</strong>ry must be informed.<strong>The</strong> item will either be electrically tested or the plug removed before placement ins<strong>to</strong>rage.Hands/fingers must be kept well away from electrical sockets and well away fromthe conducting pins on the plugs7. Broken glass or glass fragments must not be picked with bare hands. Damagedglass objects should not be used. Sharps and razor blades are inherently sharp, so<strong>to</strong> minimize the <strong>risk</strong>s <strong>of</strong> cuts/stab wounds these items should NOT be left onbenches/floors or other surfaces. When changing the blade, the use <strong>of</strong> forceps isrecommended. In short, THERE IS NO NEED TO TOUCH SHARPS/BLADES.Broken glass, needles, syringes and sharps must NEVER be discarded in<strong>to</strong> theblack general refuse sacks. Instead, these items must be placed in<strong>to</strong> thedesignated container. Needles – self-injection is mostly a problem when thecover is being replaced. Minimize any <strong>risk</strong> <strong>of</strong> self-injection by keeping fingerswell away from the tip <strong>of</strong> the needles, and by placing the needle (without firstreplacing the cover) directly in<strong>to</strong> the discard bin.8. Mixtures <strong>of</strong> chemicals/solvents may become explosive or poisonous. In essence,chemicals must not be mixed unless you are certain <strong>of</strong> the result. Solvents mustalways be used/kept well away from sources <strong>of</strong> ignition, particularly nakedflames; the solvent containers must be kept well sealed and s<strong>to</strong>red in thedesignated solvent cupboards. Chemicals must not be disposed <strong>of</strong> down sinkswithout first verifying with the safety sheet that the procedure is an acceptablemeans <strong>of</strong> disposal.9. <strong>The</strong> manufacturers instructions must be followed before use <strong>of</strong> the centrifuge.Also, the user must ensure that he/she is familiar with the instrument. <strong>The</strong>technician in charge <strong>of</strong> the labora<strong>to</strong>ry will give instruction. To minimize any <strong>risk</strong>,it is essential that the centrifuge head is properly fastened, the centrifuge tubes areproperly balanced, the lid properly fastened, and speed <strong>of</strong> operation kept withinthe manufacturers guidelines, i.e. the centrifuge must not be used at speeds inexcess <strong>of</strong> 4,000 r.p.m.10. Use <strong>of</strong> the computers <strong>has</strong> been assessed separately. <strong>The</strong> height, angle andbrightness <strong>of</strong> the screen need <strong>to</strong> be adjusted <strong>to</strong> suit each user. Also, the chairs are8

<strong>of</strong> adjustable height and angle <strong>to</strong> suit the users. Footrests are available. Users areencouraged <strong>to</strong> take regular breaks, but the current usage is very low.11. Solvents must be kept well clear <strong>of</strong> any source <strong>of</strong> ignition, specifically Bunsenburners. A clear zone must be kept around Bunsen burners, which should bepositioned on heatpro<strong>of</strong> tiles. Bunsen burners must be kept clear <strong>of</strong> shelves,papers, and all chemicals.LEVEL OF RISK AFTER INSTIGATING PROCEDURES TO MINIMIZE THERISKS:1. Low2. Low3. Low4. Low5. Low6. Low7. Low8. Low9. Low10. Low11. LowTRAINING NEEDS:None identified for the current personnel.NATURE OF FURTHER ACTION NEEDED:• <strong>The</strong> draft <strong>University</strong>’s Lone Working Policy will impact on someactivities <strong>of</strong> some personnel, especially research students. Considerationwill need <strong>to</strong> given <strong>to</strong> this policy as soon as the contents are revealed.• Any further activities not covered by this <strong>risk</strong> assessed must be assessedadditionally.PREPARED BY: Pr<strong>of</strong>essor B. AustinDATE: June 25, 2004DISTRIBUTION: All labora<strong>to</strong>ry personnel; notice board; safety file.SIGNATORIES:DATE TO BE REVISED: June 25, 20059

APPENDIX 1 (synopsis <strong>of</strong> the regulations governing work with Category 2 pathogens).1. Microbiological pattern labora<strong>to</strong>ry coats, properly fastened, must be worn in thelabora<strong>to</strong>ry. <strong>The</strong>y must be removed before leaving the labora<strong>to</strong>ry - on no accountshould labora<strong>to</strong>ry coats be worn in tea rooms, <strong>of</strong>fices, the library or other publicareas.2. Labora<strong>to</strong>ry coats should not be worn outside labora<strong>to</strong>ries and never in a room inwhich eating, drinking or smoking is permitted.3. Labora<strong>to</strong>ry coats should not be modified in any way.4. Labora<strong>to</strong>ry coats should be au<strong>to</strong>claved at 121 o C for 15 min if contamination issuspected and routinely before sending <strong>to</strong> the laundry5. Always work on the assumption that the organisms you are dealing with arepathogens and observe appropriate precautions.6. Smoking, eating, chewing, drinking, applying cosmetics, s<strong>to</strong>ring <strong>of</strong> food anddrink must not take place in the labora<strong>to</strong>ry. Keep fingers, pens, pencils etc. awayfrom your mouth7. Mouth pipetting must not take place8. Hands must be washed with soap and water when contamination is suspected,after handling potentially infective material and before leaving the labora<strong>to</strong>ry.9. Work in a tidy manner ensuring that no unnecessary equipment or glassware isleft lying around.10. All contaminated articles not suitable for flaming should be discarded in<strong>to</strong>disinfectant <strong>of</strong> which 0.1% (v/v) sodium hypochloride, eg. "Chloros", is effectivefor Category 2 pathogens.11. Petri dishes containing cultures should be placed in Sterilin bags for au<strong>to</strong>clavingat 121 o C for 15 minutes). A spore strip (obtainable from Oxoid) should beincluded <strong>to</strong> verify inactivation <strong>of</strong> the micro-organisms.12. Do not lick labels (moisten them with water from the tap) or <strong>to</strong>uch your mouthwith finger, pen or pencil.13. Do not bring bags, clothing or other personal effects in<strong>to</strong> the labora<strong>to</strong>ry sincethey may become contaminated.14. Do not mouth pipette cultures <strong>of</strong> micro-organisms: use a safety bulb with apipette plugged with cot<strong>to</strong>n wool.15. Access will be limited <strong>to</strong> authorised personnel and other workers with alegitimate reason for access.16. <strong>The</strong> door should be kept closed when work is in progress and an appropriate sign"Containment Level 2 work in progress" displayed.17. Bench working surfaces if not <strong>of</strong> an approved type must be covered with"Benchkote" and this must be replaced when damaged.18. Outdoor clothing, handbags, briefcases, etc must not be brought in<strong>to</strong> thelabora<strong>to</strong>ry.19. During normal working care must be taken <strong>to</strong> minimise production <strong>of</strong> aerosolse.g. capped tubes should be used for mixing and centrifuging.20. Bench working areas must be disinfected with dilute sodium hypochlorite afterspillages and routinely at the end <strong>of</strong> each working day.21. Waste materials must be disposed <strong>of</strong> safely. In particular, contaminated materialsmust be <strong>to</strong>tally immersed in disinfectant or au<strong>to</strong>claved before disposal. If10

contaminated materials are <strong>to</strong> be transported <strong>to</strong> another labora<strong>to</strong>ry for au<strong>to</strong>clavingthey should be placed in an au<strong>to</strong>clave bag.22. Accidents including minor cuts and abrasions must be reported and appropriateaction taken. e.g. minor cuts should be cleaned and covered with a waterpro<strong>of</strong>dressing.23. A copy <strong>of</strong> the code <strong>of</strong> Practice <strong>has</strong> been posted in each microbiology labora<strong>to</strong>ryand must be brought <strong>to</strong> the attention <strong>of</strong> personnel involved.Further information on work involving microorganisms, may be obtained from"Guidelines for Microbiological Safety" issued by the Joint Co-ordinating Committee forthe Implementation <strong>of</strong> Safe Practices in Microbiology.11