hdx/hsx 2 series headers - Centre Agricole.ca

hdx/hsx 2 series headers - Centre Agricole.ca

hdx/hsx 2 series headers - Centre Agricole.ca

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

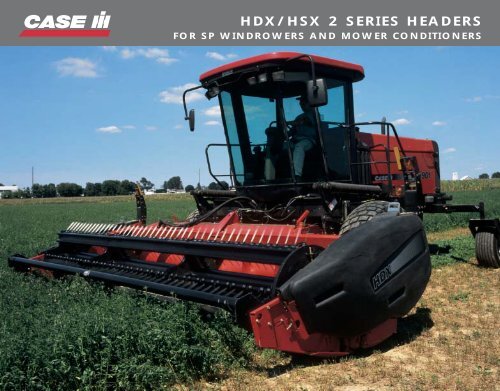

HDX/HSX 2 SERIES HEADERSFOR SP WINDROWERS AND MOWER CONDITIONERS

HARVEST CROPS QUICKLY, YET GENTLYHay HeadersGrass Seed HeaderHEADER COMPATIBILITY HDX122 HDX142 HDX162 HDX182 HSX142SCX100 Mower Conditioner • •WDX901 Windrower • • • •WDX1101 Windrower • • • • •WDX1701 Windrower • • • •A new heavy-duty,dual-sickle drive providessmooth, high-speed cuttingperformance with minimalmaintenance. Sickledrives are shaft-drivenfor synchronized,vibration-free performance.Pair the HDX 2 Series header with the SCX100center-pivot pull frame to gain the <strong>ca</strong>pacity andcontrol of a windrower in a pull-type package.A three-point link suspension and full lateralflotation allow Case IH HDX and HSX 2 Series<strong>headers</strong> to closely follow ground contours for thefullest, most complete harvest.Convenient, in-<strong>ca</strong>b hydrauli<strong>ca</strong>djustment is available on windrowermodels. The windrow-forming shieldsand swath board are easily adjustedwith no tools. Simply pull the hairpincotter and reposition the shield to thedesired windrow width. A fluffing baffleat the rear of the forming shields forcesthe windrow to “stand up” for faster,more thorough drying.See your Case IH dealer to equip yourWDX Series self-propelled windrower orSCX Series center-pivot mower conditionerwith an HDX or HSX 2 header. Case IH<strong>headers</strong> harvest crops quickly — in mostany conditions.3

HDX 2 SERIES SICKLE BAR HEADERThe durable HDX 2 Series Sickle BarHeader is built to handle a full range of cropswhile providing even conditioning. Theconditioning rolls crimp plant stems thoroughlyfor fast dry-down. Roll gap and pressure changesare made easily to allow you maximum flexibilityto adjust to your crop conditions.Conditioning rolls are available inintermeshing rubber-on-rubber or long-life steel-onsteelversions. Both types of rolls deliver superiorcrimping and crushing action for fast andthorough crop drying. Steel-on-steel rolls providelong-life performance in high-volume crops. TheCase IH conditioning system automati<strong>ca</strong>lly clearsslugs, and allows for easy changes inconditioning intensity.For crops that do not requireconditioning rolls, removing thelower roll is easy. Simplydisengage the roll driveshaft, remove the mountingat each end to drop thebottom roll and return towork. That versatility isthe kind of Case IHhallmark youwon’t find on manycompetitor models.The roll-pressure indi<strong>ca</strong>tor helps theoperator easily fine tune rollpressure. Roll gap is adjusted atboth ends of the conditioning rollusing a handy on-board wrench.Make even minute adjustments toprovide the exact amount ofconditioning without increasingleaf loss.Preparing to harvest crops thatdon’t need conditioning is madeeasy by removing the bottomconditioning roll.4Steel-on-steel and rubber-on-rubber conditioning rolls areavailable on both 14-foot (4.34 m) and 16-foot (4.95 m)models. The Case IH conditioning system saves time byclearing slugs automati<strong>ca</strong>lly.Standard on the HDX122, rubberon-rubberconditioning rolls gentlyand evenly process crops for quickdry-down. Changing conditioningintensity is easy with the Case IHsystem.With rugged construction, steelon-steelrolls excel with highercrop volumes. Steel rolls offersuperior crimping and crushingaction for faster dry-down.

HSX 2 SERIES GRASS SEED HEADERPair your windrower with the Case IHHSX 2 Series Grass Seed Header for superiorhandling of fragile crops that do not needconditioning. High stroke and sickle bar speedsprovide clean, crisp and even cutting. Available in a14-foot cutting width, the dual, counter-stroking sicklegently handles deli<strong>ca</strong>te crops such as grass seedand mint while maintaining crop quality.Standard stub-on-stub guards provide plug-freecutting of thick, tangled or downed crops.HSX <strong>headers</strong> come standard with in-<strong>ca</strong>badjustment of reel speed. The hydrauli<strong>ca</strong>lly driven,six-bat reel <strong>ca</strong>n be tuned to fit crop conditionsand dramati<strong>ca</strong>lly reduce shatter loss in valuablegrass-seed crops. The WDX Series self-propelledwindrower equipped with an HSX grassseed header will make quick work oftough field conditions — and gentlyhandle your crop.Rugged side shields molded of dual-wall polyethylenefeature a swing-up design that permits unrestrictedaccess for maintenance or servicing. The side shieldshave a crop-friendly shape to minimize run-down.Standard stub-on-stub guards on HSX <strong>headers</strong> makeharvesting easy in downed or thick crops.5

HDX/HSX 2 SERIES HEADER SPECIFICATIONSHay HeadersModel HDX122 HDX142 HDX162 HDX182 HSX142Grass Seed HeaderCutting width 12 ft. 3 in. (3.73 m) 14 ft. 3 in. (4.34 m) 16 ft. 3 in. (4.95 m) 18 ft. 3 in. (5.56 m) 14 ft. 3 in. (4.34 m)Overall width 14 ft. 3 in. (4.34 m) 16 ft. 3 in. (4.95 m) 18 ft. 3 in. (5.56 m) 20 ft. 3 in. (6.17 m) 16 ft. 3 in. (4.95 m)Weight — rubber rolls 3,630 lb. (1647 kg) 3,900 lb. (1770 kg) 4,120 lb. (1869 kg) Not available 3,260 lb. (1479 kg)— steel rolls Not available 4,000 lb. (1815 kg) 4,220 lb. (1915 kg) 4,470 lb. (2083 kg) Not availableCutter barType Timed dual counterstroking Timed dual counterstroking Timed dual counterstroking Timed dual counterstroking Timed dual counterstrokingDrives Right-hand and left-hand wobble Right-hand and left-hand wobble Right-hand and left-hand wobble Right-hand and left-hand wobble Right-hand and left-hand wobblewith shaft drive with shaft drive with shaft drive with shaft drive with timing belt driveKnives Overserrated, bolted Overserrated, bolted Overserrated, bolted Overserrated, bolted Overserrated, boltedGuards 2-tine, double hardened 2-tine, double hardened 2-tine, double hardened 2-tine, double hardened 2-tine stub, independently adjustableAngle range 6–12 degrees 6–12 degrees 6–12 degrees 6–12 degrees 6–12 degreesGuard-adjusted skid shoes 4 4 4 4 4Cutting height range 1.2–6.2 in. (30.5–157 mm) 1.2–6.2 in. (30.5–157 mm) 1.2–6.2 in. (30.5–157 mm) 1.2–6.2 in. (30.5–157 mm) 1.2–6.2 in. (30.5–157 mm)Sickle driveType Open dual wobble Open dual wobble Open dual wobble Open dual wobble Open dual wobbleSpeed 1,810 SPM 1,810 SPM 1,810 SPM 1,810 SPM 1,828 SPMStroke 3 in. (76 mm) 3 in. (76 mm) 3 in. (76 mm) 3 in. (76 mm) 3 in. (76 mm)ReelType 5-bat 5-bat 5-bat 5-bat 6-batAdjustments Fore/aft and verti<strong>ca</strong>l Fore/aft and verti<strong>ca</strong>l Fore/aft and verti<strong>ca</strong>l Fore/aft and verti<strong>ca</strong>l Fore/aft and verti<strong>ca</strong>lSpeed – Std. mech. drive 52–83 RPM 52–83 RPM 52–83 RPM 52–83 RPM Not appli<strong>ca</strong>ble– Opt. hyd. drive 0–76 RPM 0–76 RPM 0–76 RPM 0–76 RPM 0–76 RPM standardSpeed adjustment Variable sheave Variable sheave Variable sheave Variable sheave Variable, from <strong>ca</strong>bMax. diameter 42 in. (1067 mm) 42 in. (1067 mm) 42 in. (1067 mm) 42 in. (1067 mm) 42 in. (1067 mm)Drive Belt and chain Belt and chain Belt and chain Belt and chain HydraulicTine bars Segmented Segmented Segmented Segmented SegmentedCam-bearings 1.25 in. (31.75 mm) 1.25 in. (31.75 mm) 1.25 in. (31.75 mm) 1.25 in. (31.75 mm) 1.25 in. (31.75 mm)Reel bushing 1 in. (25.4 mm) 1 in. (25.4 mm) 1 in. (25.4 mm) 1 in. (25.4 mm) 1 in. (25.4 mm)ConditionerType Rubber-on-rubber Rubber-on-rubber or Rubber-on-rubber or Steel-on-steel Not availableSteel-on-steelSteel-on-steelRoll length (crush area) 102 in. (2591 mm) 102 in. (2591 mm) 102 in. (2591 mm) 102 in. (2591 mm) Not availableRoll diameter 10.375 in. (263.5 mm) 10.375 in. (263.5 mm) 10.375 in. (263.5 mm) 10.375 in. (263.5 mm) Not availableRoll drive Spur gearbox & PTOs Spur gearbox & PTOs Spur gearbox & PTOs Spur gearbox & PTOs Not availableSpeed 717 RPM 717 RPM 717 RPM 717 RPM Not availableGap/pressure adjustments Hand cranks Hand cranks Hand cranks Hand cranks Not availableAugerType Single, floating Single, floating Single, floating Single, floating Single, floatingDiameter 20 in. (508 mm) 20 in. (508 mm) 20 in. (508 mm) 20 in. (508 mm) 20 in. (508 mm)Floating range 2 in. (50.8 mm) 2 in. (50.8 mm) 2 in. (50.8 mm) 2 in. (50.8 mm) 2 in. (50.8 mm)Flighting depth 5 in. (178 mm) 5 in. (127 mm) 5 in. (127 mm) 5 in. (127 mm) 5 in. (127 mm)Speed 287 RPM (w/45T driven sprocket) 287 RPM (w/45T driven sprocket) 287 RPM (w/45T driven sprocket) 287 RPM (w/45T driven sprocket) 196 RPMWindrow width 38–96 in. (965–2438 mm) 38–96 in. (965–2438 mm) 38–96 in. (965–2438 mm) 38–96 in. (965–2438 mm) 60 in. (1524 mm)7

Case IH dealers are the standard for expertsales, service and support for the mosttechnologi<strong>ca</strong>lly advanced equipment in theworld. They’re committed to understanding yourbusiness and providing unique solutions tomaximize your productivity.From tractors to hay tools that meet thespecific needs of your operation, Case IHdealers offer a full line of equipment aimed atincreasing your productivity and profitability.Coupled with timely parts and service, andflexible financing solutions through Case Credit,Case IH dealers provide a total package toensure you’re always performing at your best.But most importantly, Case IH dealers offerplanning for the long-term growth of yourbusiness. By staying at the forefront ofagronomic issues and the cutting edge oftechnology, they help prepare you for tomorrow.Whatever it takes, Case IH dealers arededi<strong>ca</strong>ted to helping your operation achievesuccess season after season. Visit your Case IHdealer today to see the advantages ofworldwide leadership.Case, LLC reserves the right to make improvements in design and changes in specifi<strong>ca</strong>tions at any time without notice and without incurring any obligation to install them on unitspreviously sold. Specifi<strong>ca</strong>tions, descriptions and illustrative material herein are as accurate as known at time of publi<strong>ca</strong>tion, but are subject to change without notice.SEE YOUR LOCAL CASE IH DEALERThis literature has been published for worldwide circulation. Availability of some models and equipment builds varies according to the country in which the equipment is used. Theillustrations and text may include optional equipment and accessories and may not include all standard equipment. Your Case IH dealer/distributor will be able to give you details of theproducts and their specifi<strong>ca</strong>tions available in your area.WORLDWIDE CASE IH CONTACT INFORMATIONUNITED STATES/CANADA: 700 STATE STREET RACINE, WI 53404 USALATIN AMERICA: AV. JUSCELINO KUBITSCHEK DE OLIVEIRA N. 11825 CAIXA POSTAL 14040 CEP 81503 CURITIBA, PARANA, BRAZILWESTERN AND CENTRAL EUROPE/CIS: CRANES FARM ROAD BASILDON ESSEX SS143AD ENGLANDEASTERN EUROPE/AFRICA/ASIA: VIALE DELLE NAZIONI 55 41100 MODENA, ITALYAUSTRALIA/NEW ZEALAND: 31-67 KURRAJONG AVENUE ST. MARYS NEW SOUTH WALES 2760 AUSTRALIASAFETY NEVER HURTS! Always readthe Operator’s Manual before operating anyequipment. Inspect equipment before using it, and besure it is operating properly. Follow the product safetysigns, and use any safety features provided.AE-529013 ©2003 Case, LLC Printed in USA Case IH and Case Credit are registered trademarks of Case, LLCAll Rights Reservedwww.<strong>ca</strong>seih.com