Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

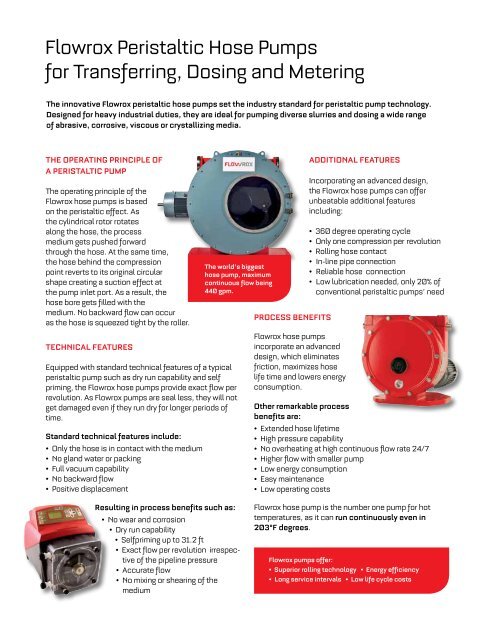

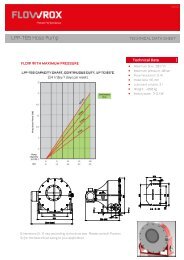

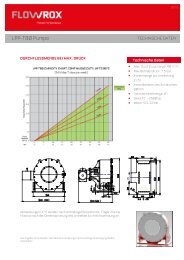

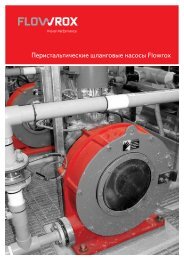

<strong>Flowrox</strong> <strong>Peristaltic</strong> <strong>Hose</strong> <strong>Pumps</strong>for Transferring, Dosing and MeteringThe innovative <strong>Flowrox</strong> peristaltic hose pumps set the industry standard for peristaltic pump technology.Designed for heavy industrial duties, they are ideal for pumping diverse slurries and dosing a wide rangeof abrasive, corrosive, viscous or crystallizing media.THE OPERATING PRINCIPLE OFA PERISTALTIC PUMPThe operating principle of the<strong>Flowrox</strong> hose pumps is basedon the peristaltic effect. Asthe cylindrical rotor rotatesalong the hose, the processmedium gets pushed forwardthrough the hose. At the same time,the hose behind the compressionpoint reverts to its original circularshape creating a suction effect atthe pump inlet port. As a result, thehose bore gets filled with themedium. No backward flow can occuras the hose is squeezed tight by the roller.TECHNICAL FEATURESEquipped with standard technical features of a typicalperistaltic pump such as dry run capability and selfpriming, the <strong>Flowrox</strong> hose pumps provide exact flow perrevolution. As <strong>Flowrox</strong> pumps are seal less, they will notget damaged even if they run dry for longer periods oftime.Standard technical features include:• Only the hose is in contact with the medium• No gland water or packing• Full vacuum capability• No backward flow• Positive displacementThe world’s biggesthose pump, maximumcontinuous flow being440 gpm.PROCESS BENEFITS<strong>Flowrox</strong> hose pumpsincorporate an advanceddesign, which eliminatesfriction, maximizes hoselife time and lowers energyconsumption.ADDITIONAL FEATURESIncorporating an advanced design,the <strong>Flowrox</strong> hose pumps can offerunbeatable additional featuresincluding:• 360 degree operating cycle• Only one compression per revolution• Rolling hose contact• In-line pipe connection• Reliable hose connection• Low lubrication needed, only 20% ofconventional peristaltic pumps’ needOther remarkable processbenefits are:• Extended hose lifetime• High pressure capability• No overheating at high continuous flow rate 24/7• Higher flow with smaller pump• Low energy consumption• Easy maintenance• Low operating costsResulting in process benefits such as:• No wear and corrosion• Dry run capability• Selfpriming up to 31.2 ft• Exact flow per revolution irrespectiveof the pipeline pressure• Accurate flow• No mixing or shearing of themedium<strong>Flowrox</strong> hose pump is the number one pump for hottemperatures, as it can run continuously even in203°F degrees.<strong>Flowrox</strong> pumps offer:• Superior rolling technology • Energy efficiency• Long service intervals • Low life cycle costs