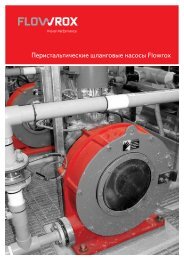

Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

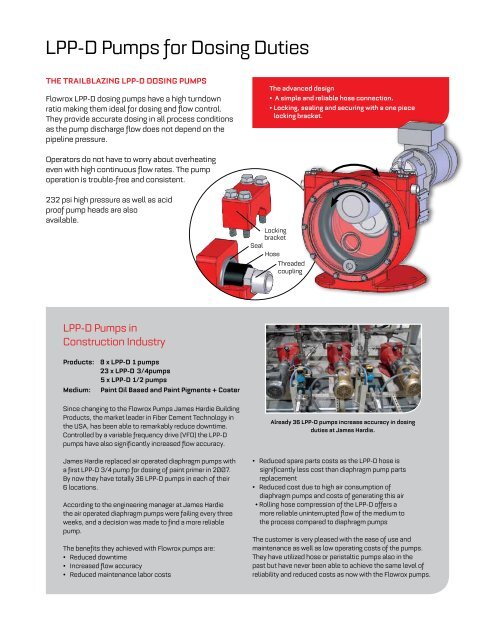

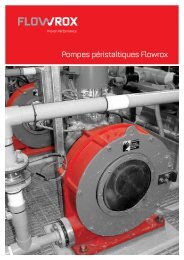

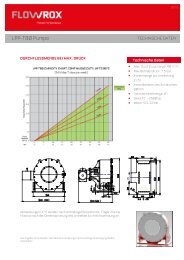

LPP-D <strong>Pumps</strong> for Dosing DutiesTHE TRAILBLAZING LPP-D DOSING PUMPS<strong>Flowrox</strong> LPP-D dosing pumps have a high turndownratio making them ideal for dosing and flow control.They provide accurate dosing in all process conditionsas the pump discharge flow does not depend on thepipeline pressure.The advanced design• A simple and reliable hose connection.• Locking, sealing and securing with a one piecelocking bracket.Operators do not have to worry about overheatingeven with high continuous flow rates. The pumpoperation is trouble-free and consistent.232 psi high pressure as well as acidproof pump heads are alsoavailable.LockingbracketSeal<strong>Hose</strong>ThreadedcouplingLPP-D <strong>Pumps</strong> inConstruction IndustryProducts: 8 x LPP-D 1 pumps23 x LPP-D 3/4pumps5 x LPP-D 1/2 pumpsMedium: Paint Oil Based and Paint Pigments + CoaterSince changing to the <strong>Flowrox</strong> <strong>Pumps</strong> James Hardie BuildingProducts, the market leader in Fiber Cement Technology inthe <strong>US</strong>A, has been able to remarkably reduce downtime.Controlled by a variable frequency drive (VFD) the LPP-Dpumps have also significantly increased flow accuracy.James Hardie replaced air operated diaphragm pumps witha first LPP-D 3/4 pump for dosing of paint primer in 2007.By now they have totally 36 LPP-D pumps in each of their6 locations.According to the engineering manager at James Hardiethe air operated diaphragm pumps were failing every threeweeks, and a decision was made to find a more reliablepump.The benefits they achieved with <strong>Flowrox</strong> pumps are:• Reduced downtime• Increased flow accuracy• Reduced maintenance labor costsAlready 36 LPP-D pumps increase accuracy in dosingduties at James Hardie.• Reduced spare parts costs as the LPP-D hose issignificantly less cost than diaphragm pump partsreplacement• Reduced cost due to high air consumption ofdiaphragm pumps and costs of generating this air• Rolling hose compression of the LPP-D offers amore reliable uninterrupted flow of the medium tothe process compared to diaphragm pumpsThe customer is very pleased with the ease of use andmaintenance as well as low operating costs of the pumps.They have utilized hose or peristaltic pumps also in thepast but have never been able to achieve the same level ofreliability and reduced costs as now with the <strong>Flowrox</strong> pumps.