Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

Flowrox Peristaltic Hose Pumps US

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Flowrox</strong> <strong>Peristaltic</strong> <strong>Hose</strong> <strong>Pumps</strong>

<strong>Flowrox</strong> <strong>Peristaltic</strong> <strong>Hose</strong> <strong>Pumps</strong>for Transferring, Dosing and MeteringThe innovative <strong>Flowrox</strong> peristaltic hose pumps set the industry standard for peristaltic pump technology.Designed for heavy industrial duties, they are ideal for pumping diverse slurries and dosing a wide rangeof abrasive, corrosive, viscous or crystallizing media.THE OPERATING PRINCIPLE OFA PERISTALTIC PUMPThe operating principle of the<strong>Flowrox</strong> hose pumps is basedon the peristaltic effect. Asthe cylindrical rotor rotatesalong the hose, the processmedium gets pushed forwardthrough the hose. At the same time,the hose behind the compressionpoint reverts to its original circularshape creating a suction effect atthe pump inlet port. As a result, thehose bore gets filled with themedium. No backward flow can occuras the hose is squeezed tight by the roller.TECHNICAL FEATURESEquipped with standard technical features of a typicalperistaltic pump such as dry run capability and selfpriming, the <strong>Flowrox</strong> hose pumps provide exact flow perrevolution. As <strong>Flowrox</strong> pumps are seal less, they will notget damaged even if they run dry for longer periods oftime.Standard technical features include:• Only the hose is in contact with the medium• No gland water or packing• Full vacuum capability• No backward flow• Positive displacementThe world’s biggesthose pump, maximumcontinuous flow being440 gpm.PROCESS BENEFITS<strong>Flowrox</strong> hose pumpsincorporate an advanceddesign, which eliminatesfriction, maximizes hoselife time and lowers energyconsumption.ADDITIONAL FEATURESIncorporating an advanced design,the <strong>Flowrox</strong> hose pumps can offerunbeatable additional featuresincluding:• 360 degree operating cycle• Only one compression per revolution• Rolling hose contact• In-line pipe connection• Reliable hose connection• Low lubrication needed, only 20% ofconventional peristaltic pumps’ needOther remarkable processbenefits are:• Extended hose lifetime• High pressure capability• No overheating at high continuous flow rate 24/7• Higher flow with smaller pump• Low energy consumption• Easy maintenance• Low operating costsResulting in process benefits such as:• No wear and corrosion• Dry run capability• Selfpriming up to 31.2 ft• Exact flow per revolution irrespectiveof the pipeline pressure• Accurate flow• No mixing or shearing of themedium<strong>Flowrox</strong> hose pump is the number one pump for hottemperatures, as it can run continuously even in203°F degrees.<strong>Flowrox</strong> pumps offer:• Superior rolling technology • Energy efficiency• Long service intervals • Low life cycle costs

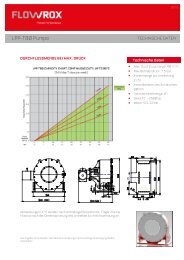

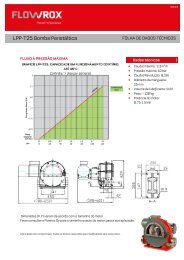

LPP-T <strong>Pumps</strong> for Transfer DutiesLPP-T pumps provide substantial savings through improved process performance and efficiency,long service intervals and low maintenance costs. They are manufactured using durableelastomers and advanced materials making them perfect for pumping a wide range of media.PATENTED ECCENTRIC HOSE ADJ<strong>US</strong>TMENT<strong>Flowrox</strong> LPP-T pumps are equipped with patented,reliable hose flange and in-line pipe connections;a hose leak detection unit and a patented adjustmentmechanism that senses hose wear when compressionis readjusted. This helps to maximize hose lifetime andminimize the risk of over-compression.There is no needfor shimming.WITH FLOWROX PUMPS THE TOTALLIFETIME COSTS ARE REDUCEDEnergy efficiency, long hose life and low maintenanceneed lead to substantial savings during the life cycle ofperistaltic pumps. <strong>Flowrox</strong> pump’s hose lifetime is morethan 4 times longer than with a conventional pump.<strong>Hose</strong> flangeO ringFasteningbushingCONVENTIONAL 2.5 HOSE PUMPdesigned flow rate 44 gpmpump will run: 44 gpm-------> 25 RPMEstimated hose life time518 400 cycles.--------> 346 hours.Seal wingsConnectionflangeFLOWROX LPP-T 2.5designed flow rate 44 gpmpump will run: 44 gpm-------> 31 RPM<strong>Flowrox</strong> estimated hose life time2 700 000 cycles.--------> 1452 hours.LPP-T <strong>Pumps</strong> inMining & Minerals IndustryProducts:Application:12 x LPP-T 2.5 pumpsWashing liquid circulation pumpTalvivaara open-pit mine has used <strong>Flowrox</strong> LPP-T 2.5 pumpssince 2008 (5 pcs) and 2009 (7 pcs). The pumps work withOutotec Larox rubber belt filters RB-SV in order to recyclewater from filter cloth and rubber belt washings to cakewashing. This saves water and all valuable minerals comingout of the cloth and rubber belt can be fed again to the cake.<strong>Flowrox</strong> hose pumps are ideal in these kinds of filterapplications, as the washing water typically has very highcontent of solids. This was one of the main reasons why thecustomer chose <strong>Flowrox</strong> hose pumps for this application.Washing liquidcirculation pumpsin Talvivaara mine.<strong>Flowrox</strong> pumps also suit extremely well for viscous,crystallizable, corrosive or abrasive media.<strong>Flowrox</strong> pumps used in Talvivaara:• 6 pumps in gypsum precipitate filters• 2 pumps in nickel-cobalt sulphide filters• 2 pumps in zinc sulphide filters• 2 pumps in copper sulphide filters

LPP-D <strong>Pumps</strong> for Dosing DutiesTHE TRAILBLAZING LPP-D DOSING PUMPS<strong>Flowrox</strong> LPP-D dosing pumps have a high turndownratio making them ideal for dosing and flow control.They provide accurate dosing in all process conditionsas the pump discharge flow does not depend on thepipeline pressure.The advanced design• A simple and reliable hose connection.• Locking, sealing and securing with a one piecelocking bracket.Operators do not have to worry about overheatingeven with high continuous flow rates. The pumpoperation is trouble-free and consistent.232 psi high pressure as well as acidproof pump heads are alsoavailable.LockingbracketSeal<strong>Hose</strong>ThreadedcouplingLPP-D <strong>Pumps</strong> inConstruction IndustryProducts: 8 x LPP-D 1 pumps23 x LPP-D 3/4pumps5 x LPP-D 1/2 pumpsMedium: Paint Oil Based and Paint Pigments + CoaterSince changing to the <strong>Flowrox</strong> <strong>Pumps</strong> James Hardie BuildingProducts, the market leader in Fiber Cement Technology inthe <strong>US</strong>A, has been able to remarkably reduce downtime.Controlled by a variable frequency drive (VFD) the LPP-Dpumps have also significantly increased flow accuracy.James Hardie replaced air operated diaphragm pumps witha first LPP-D 3/4 pump for dosing of paint primer in 2007.By now they have totally 36 LPP-D pumps in each of their6 locations.According to the engineering manager at James Hardiethe air operated diaphragm pumps were failing every threeweeks, and a decision was made to find a more reliablepump.The benefits they achieved with <strong>Flowrox</strong> pumps are:• Reduced downtime• Increased flow accuracy• Reduced maintenance labor costsAlready 36 LPP-D pumps increase accuracy in dosingduties at James Hardie.• Reduced spare parts costs as the LPP-D hose issignificantly less cost than diaphragm pump partsreplacement• Reduced cost due to high air consumption ofdiaphragm pumps and costs of generating this air• Rolling hose compression of the LPP-D offers amore reliable uninterrupted flow of the medium tothe process compared to diaphragm pumpsThe customer is very pleased with the ease of use andmaintenance as well as low operating costs of the pumps.They have utilized hose or peristaltic pumps also in thepast but have never been able to achieve the same level ofreliability and reduced costs as now with the <strong>Flowrox</strong> pumps.

LPP-M <strong>Pumps</strong> for Metering DutiesSUPERIOR ACCURACY FOR YOUR PROCESSESAccuracy of metering in anyapplication is the most vitalproperty of a meteringpump. The flow rateof an LPP-M Meteringpump is not affectedby the variation of thedischarge pressurecondition. Positivedisplacement of the tubebore with zero slip providessame output volume on every cycle. The compressionpoint of the tube acts as self-cleaning check valvewithout clogging risk providing clear flow path with nopossibility for vapor lock.<strong>Flowrox</strong> LPP-M pump has a protection rating of NEMA4X/IP66 and is equipped with a unique Tube FailureDetection, which is designed to stop the pump if pumptube is ruptured and chemical enters the pump head.The non-enclosed version of the pump is designedespecially for OEM purposes.A MULTITUDE OF PROGRAMSLPP-M pumps have wider programmability and controllabilitythan any other comparable pumps. They offerexcellent connectivity to all possible customerenvironments. Inputs can include for example:• Manual adjustment• 4 to 20 mA• 0 to 10 volts DC• Frequency input (Hz)• Remote start / Stop contact closure• Flow verification system (FVS) input• Contact closure inputControl modes make a diversity of dosing functionspossible including• Pulse batch• Manual cycle adjust• Dispensing• Manual dosing• Proportional dosingAvailable display languages areEnglish, German, Spanish and French.PVDF adapter fittings allow easytube changes.LPP-M <strong>Pumps</strong> inWaste Water TreatmentProducts: 4 x LPP-M pumps + 2 LPP-D pumpsMedium: Sodium Bisulfite and Sodium HypochloriteNashua New Hampshire is one of many United States citiesand municipalities selecting <strong>Flowrox</strong> technology over inferiorpumping technologies.“<strong>Flowrox</strong> pumps offer stable flow and metering capabilitiesunder varying operating conditions, and their energyrequirement is constant”, says the customer. “They can alsohandle severe variation in suction line condition in regardto suction lift and viscosity, and they are also very userfriendly”, he continues.<strong>Flowrox</strong> engineered peristaltic pumps combine smartintelligence with superior turndown. Another remarkableadvantage is that peristaltic pumps will not experiencevacuum degassing in summer months like other designs.LPP-M pumping sodiumhypochlorite 12.5% atNashua New Hampshire.<strong>Flowrox</strong> was selected for equipment supplier based on thesuperior tube pump and control technology of the LPP-Mtube pumps. The engineering consultant, the city of NashuaNew Hampshire elected officials and contractor all formed acommon consensus to order and approve the use of <strong>Flowrox</strong>pumps. <strong>Flowrox</strong> won on the technical merits, commercialmerits and long-term operational advantages.These pumps are operating flawlessly without any downtimesince March 2008.

Optimal <strong>Hose</strong>s and Tubes for Each MediaWith decades of experience in developing innovative flow control solutions and elastomer technology,<strong>Flowrox</strong> has a wide selection of superior elastomers for diverse media and process conditions.The correct mechanical hose design and material selection are essential for optimal hose lifetime.HOSES FOR LPP-T AND LPP-D PUMPSThe high-grade hose materials include chemicalresistant ethylene propylene (EPDM), oil and fat resistantnitrile rubber (NBR), which is available also for food grademediums (NBRF) and extremely abrasive natural rubber(NR), which is ideal for heavy wearing applications. Toguarantee the best possible mechanical characteristics,the hose cover is always made of natural rubber.NR• Natural rubber• Medium: extremely abrasiveNBR• Nitrile rubber• Medium: oil and fatEPDM• Ethylene propylene• Medium: chemicalsNBRF• Nitrile rubber• Medium: fatty foodstuffs• Fulfills FDA requirementsOuter layerReinforcement layersInner layerLPP-D hose construction.The preformed LPP-Thoses ensure secure, trouble free and fast assembly.TUBES FOR LPP-M PUMPSNorprene®Norprene® tubing has excellent alkali resistance andis compatible with numerous oxidizing agents such ashydrogen peroxide, sodium hypochlorite and ozone.Norprene® tubing fully complies with FDA, 3A SanitaryStandards, and NSF Standards, which are applicable tomany food contact applications.It also offers exceptional resistance to oils, greases,fuels and many chemicals.Able to withstand rugged daily use, Tygothane® tubingresists weathering. It meets FDA criteria for food andbeverage use.Norprene® tubing exhibits excellent resistance to ozoneand UV light, with little or no signs of deterioration inlaboratory testing equivalent to 10 years of outdoorexposure. Norprene® tubing provides long service lifetime when exposed to heat, abrasion, and pressure.Tygothane®Made of a tough, ester-based polyurethane, Tygothane®tubing’s clarity, high tear strength and excellent abrasionresistance makes it ideal for many applications,including fuel and lubricant lines and abrasive producttransfer.LPP-M tube materials:Norprene® andTygothane®.

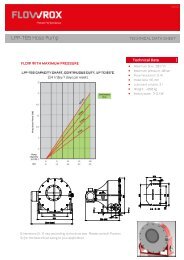

Technical Data of <strong>Flowrox</strong> LPP <strong>Pumps</strong>Technical DataLPP-T1 LPP-T1.25 LPP-T1.5 LPP-T2 LPP-T2.5 LPP-T3 LPP-T4Weight ~ 286 lb ~ 661 lb ~ 793 lb ~ 1433 lb ~ 2116 lb ~ 5401 lb ~ 11684 lbFlow/revolution 0.07 g 0.17 g 0.33 g 0.73 g 1.43 g 3.06 g 8.35 gMaximum flow 9.7 gpm 17 gpm 33 gpm 51 gpm 88 gpm 176 gpm 440 gpmMaximum pressure 150 psi 150 psi 150 psi 150 psi 150 psi 110 psi *Lubricant volume 0.21 g 0.21 g 0.26 g 0.66 g 0.79 g 2.11 g 5.28 g<strong>Hose</strong> bore andflange connection1 in. 1.25 in. 1.5 in. 2 in. 2.5 in. 3 in. 4 in.Motor power 1 - 2 hp 1 - 5 hp 1-5 - 5 hp 2 - 12 hp 4 - 14 hp 12 - 30 hp 73 - 121 hp* contact <strong>Flowrox</strong>Technical DataLPP-D3/8LPP-D1/2LPP-D3/4LPP-D1Weight104 lb104 lb104 lb132 lbFlow/revolution0.061 g0.026 g0.047 g0.079 gMaximum flow1.8 gpm2.6 gpm5.3 gpm8.8. gpmMaximum pressure232 psi232 psi232 psi232 psiLubricant volume0.10 g0.10 g0.10 g0.10 g<strong>Hose</strong> bore andflange connection0.4 in.0.6 in.0.8 in.1 in.Motor power0.75 - 1 hp0.75 - 1 hp0.75 - 1 hp1 - 1.5 hpTechnical DataLPP-MWeight/Shipping weight27.3 lb / 29.8 lbMaximum flow33.3 gphMaximum working pressure125 psiMax fluid temperature135°FEnclosureNema 4X/IP66Plug type125 V ACNema 5/15More technical information available in datasheets.All stages of the LPP-T and LPP-D pumps and their hosedesign and manufacturing are covered by ISO 9001:2000.They are also ATEX approved.

Proven Performance with <strong>Flowrox</strong>Our customers work in some of the most challenging conditions on the planet. They run extremely abrasive or corrosiveprocesses, often in remote locations. Whether they do business in mining, metallurgy, energy, cement, pulp & paper,chemical or other heavy duty industries, we are there for them.And we are glad to help.<strong>Flowrox</strong> (former Larox Flowsys) is a privately held family owned company with over 30 years of experience and morethan 100 000 global deliveries. We value long partnerships with our customers, and are inspired by their success. Ourproducts increase our customers’ productivity and offer the lowest total costs of ownership. <strong>Flowrox</strong> is the benchmarkin heavy duty valves and pumps.Experience with Insight • Participating Partner • Facilitating PerformanceContact our nearest subsidiary or one of our50+ partners we have all over the world.www.flowrox.us03/2012