Download - GSR Ventiltechnik

Download - GSR Ventiltechnik

Download - GSR Ventiltechnik

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

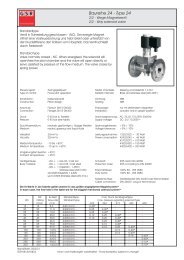

REPORTSmarket. <strong>GSR</strong> valves are used in naturalgas distribution networks as well(Figure 3 and 4). These applications requirevalves equipped with large valveseats and a robust design, which aresuitable for pressures up to 350 barand feature a long life even underrough ambient conditions. For this demandingbusiness, <strong>GSR</strong> supplies thevalve technology for the entire processchain from compressor to gas pump.Development project:hydrogen valves for fuel cellsThe <strong>GSR</strong> engineers are currently dealingwith the energy source of the future:when hydrogen is used to drive fuelcells or direct injection engines, specialvalves are needed, resisting to pressuresup to 900 bar (Figure 5). Thesevalves however cannot be assembledwith the standard components of themodular valve system, as such highFig. 4: Multiport valve for CNG stationspressures require a special casing.Some of the options however still canbe used.Also suitable for nicheapplicationsThis overview and the quoted applicationexamples prove that the flangevalve system from <strong>GSR</strong> covers a verylarge field of applications. Even forniche applications, “custom-made”valves can be configured at reasonableengineering costs. To this end, competentapplication-specific technical adviceas well as a highly flexible productionprocess is required in addition tothe modular valve system.High degree of verticalintegration, flexible productionThe manufacturer of a comprehensiveproduct range with many options musthave a flexible production process.<strong>GSR</strong> meets this requirement: even forbatch size 1, an economic productionis guaranteed and due to the high degreeof vertical integration, the deliverytimes are short. The single-part productionhowever is not often deployed, asthe individual valve is configured on thebasis of the modular system. In suchcase, the individual work often is limitedto “just” the assembly. This also offersthe advantage that spare parts arequickly at hand, even after long uptimes.<strong>GSR</strong> frequently supplies spareand wear parts from stock for valves,which have been manufactured some15 years ago and which are still operationaltoday without noteworthy failures.The prerequisites:advice and consultancyThe <strong>GSR</strong> technicians provide their customerswith detailed information andadvice, so that they can select the optimalvalve from the modular system. For,the media to be transported, the appliedprocesses and the boundary conditionsas well as the applicable safetyprescriptions and certifications play animportant part in making the rightchoice. <strong>GSR</strong> provides its customersworldwide with competent consultancy.The Chinese market for instance is animportant export market to <strong>GSR</strong> notwithstandingthe fierce competition of localcompanies. Here, the customers areadvised by engineers, who have beentrained in Germany. <strong>GSR</strong> furthermore isonly active in the upper quality segment,which is an additional advantagecompared to the competition:many international machinery and plantbuilders, who consider safety, long lifetime,long maintenance intervals andhigh availability of spare parts of paramountimportance, frequently use thevalve technology from <strong>GSR</strong>.Fig. 5:RRV ® Rapid ReactionValve resistingto pressures up to900 barJasmin Müller<strong>GSR</strong> <strong>Ventiltechnik</strong>GmbH & Co. KG,VlothoTel.: +49 5228 779 356jmueller@ventiltechnik.de20Industrial Valves 2008