3700 Installation Operation and Maintenance Manual

3700 Installation Operation and Maintenance Manual

3700 Installation Operation and Maintenance Manual

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

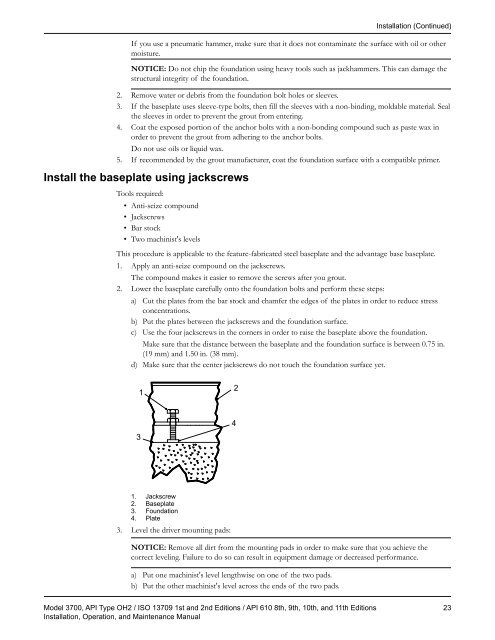

If you use a pneumatic hammer, make sure that it does not contaminate the surface with oil or othermoisture.NOTICE: Do not chip the foundation using heavy tools such as jackhammers. This can damage thestructural integrity of the foundation.2. Remove water or debris from the foundation bolt holes or sleeves.3. If the baseplate uses sleeve-type bolts, then fill the sleeves with a non-binding, moldable material. Sealthe sleeves in order to prevent the grout from entering.4. Coat the exposed portion of the anchor bolts with a non-bonding compound such as paste wax inorder to prevent the grout from adhering to the anchor bolts.Do not use oils or liquid wax.5. If recommended by the grout manufacturer, coat the foundation surface with a compatible primer.Install the baseplate using jackscrewsTools required:• Anti-seize compound• Jackscrews• Bar stock• Two machinist's levelsThis procedure is applicable to the feature-fabricated steel baseplate <strong>and</strong> the advantage base baseplate.1. Apply an anti-seize compound on the jackscrews.The compound makes it easier to remove the screws after you grout.2. Lower the baseplate carefully onto the foundation bolts <strong>and</strong> perform these steps:<strong>Installation</strong> (Continued)a) Cut the plates from the bar stock <strong>and</strong> chamfer the edges of the plates in order to reduce stressconcentrations.b) Put the plates between the jackscrews <strong>and</strong> the foundation surface.c) Use the four jackscrews in the corners in order to raise the baseplate above the foundation.Make sure that the distance between the baseplate <strong>and</strong> the foundation surface is between 0.75 in.(19 mm) <strong>and</strong> 1.50 in. (38 mm).d) Make sure that the center jackscrews do not touch the foundation surface yet.12431. Jackscrew2. Baseplate3. Foundation4. Plate3. Level the driver mounting pads:NOTICE: Remove all dirt from the mounting pads in order to make sure that you achieve thecorrect leveling. Failure to do so can result in equipment damage or decreased performance.a) Put one machinist's level lengthwise on one of the two pads.b) Put the other machinist's level across the ends of the two pads.Model <strong>3700</strong>, API Type OH2 / ISO 13709 1st <strong>and</strong> 2nd Editions / API 610 8th, 9th, 10th, <strong>and</strong> 11th Editions<strong>Installation</strong>, <strong>Operation</strong>, <strong>and</strong> <strong>Maintenance</strong> <strong>Manual</strong>23