- Page 1 and 2:

SS-09Strut SystemsChannels, Hardwar

- Page 3 and 4:

New ProductsDURA-BLOKROOFTOP SUPPOR

- Page 5 and 6:

BTS22THTELESCOPING CHANNELPg. 38 &

- Page 7 and 8:

Table of ContentsIntroduction . . .

- Page 9 and 10:

IntroductionB-Line’s Metal Framin

- Page 11 and 12:

Technical DataFINISHESZinc Coatings

- Page 13 and 14:

Technical DataWELDINGThe welding pr

- Page 15 and 16:

Technical DataType 304 Type 316 Zin

- Page 17 and 18:

Technical DataSafety FactorThe desi

- Page 19 and 20:

RECOMMENDED BOLTED METALFRAMING SPE

- Page 21 and 22:

ChannelSELECTION CHARTfor Channels,

- Page 23 and 24:

B11 Beam & Column Loading DataYX3 1

- Page 26 and 27:

B22 ChannelB22•Thickness: 12 Gaug

- Page 28 and 29:

B22 Beam Loading DataChannel & Comb

- Page 30 and 31:

B24 Channel & CombinationsB24•Thi

- Page 32 and 33:

B26 Channel & CombinationsB26•Thi

- Page 34 and 35:

B32 Channel & CombinationsB32•Thi

- Page 36 and 37:

B42 Channel & CombinationsB42•Thi

- Page 38 and 39:

B52 Channel & CombinationsB52•Thi

- Page 40 and 41:

B54 Channel & CombinationsB54•Thi

- Page 42 and 43:

B56 Channel & CombinationsB56•Thi

- Page 44 and 45:

Telescoping ChannelBTS22TH•Can be

- Page 46 and 47:

Channel Hole PatternsB11SH THRU B56

- Page 48:

Channel Hole PatternsBK22H112 THRU

- Page 53 and 54:

Channel NutsNote: See page 50 for r

- Page 55 and 56:

Channel NutsNote: See page 50 for r

- Page 57 and 58:

Channel NutsPULL-OUT STRENGTH•Wit

- Page 59 and 60:

HardwareHHCSHEX HEAD CAP SCREWS•S

- Page 61 and 62:

SLN SLIP-ON LOCK NUT•Material: AS

- Page 63 and 64:

KWIKWIRE HANGING SYSTEMKwikWire Har

- Page 65 and 66:

B200-B202-2•Standard finishes: ZN

- Page 67 and 68:

B137FOUR HOLE CORNERGUSSET PLATE•

- Page 69 and 70:

B361TWO HOLE CORNER ANGLE•Standar

- Page 71 and 72:

B844UNIVERSAL SHELF BRACKET•Stand

- Page 73 and 74:

B496TWO HOLE ADJUSTABLECORNER ANGLE

- Page 75 and 76:

Angular FittingsB156 - B161TWO HOLE

- Page 77 and 78:

BracesB261TWO HOLE 45° KNEE BRACE

- Page 79 and 80:

B527THREE HOLE OFFSET PLATECONNECTI

- Page 81 and 82:

B333SLOTTED THREE HOLEU-SUPPORT FOR

- Page 83 and 84:

B526TWO HOLEOFFSET Z-SUPPORT•Stan

- Page 85 and 86:

B410-52CHANNEL HANGERBRACKET FOR B5

- Page 87 and 88:

B120SIX HOLE DOUBLECORNER CONNECTIO

- Page 89 and 90:

B279POST BASE FOR B22•Standard fi

- Page 91 and 92:

BracketsB187 BRACKET•Uniform Load

- Page 93 and 94:

B292 20 1 /2” (520.7) BRACKET•U

- Page 95 and 96:

BracketsB370 BRACKET FOR B22A & B11

- Page 97 and 98:

BracketsB811-W•Can be attached di

- Page 99 and 100:

Miscellaneous FittingsB664DOUBLE PI

- Page 101 and 102:

Miscellaneous FittingsB376FOUR BEAR

- Page 103 and 104:

Miscellaneous FittingsB823PROFILE E

- Page 105 and 106:

Beam ClampsB351LSTEEL C-CLAMP WITH

- Page 107 and 108:

Beam ClampsB210BEAM CLAMP•Design

- Page 109 and 110:

Beam ClampsB7553 /8 BEAM CLAMP•Sa

- Page 111 and 112:

Beam ClampsB441-22BEAM CLAMP•Desi

- Page 113 and 114:

Beam ClampsB427BEAM CLAMP•Design

- Page 115 and 116:

B614COLUMN SUPPORT FOR B22•Quick

- Page 117 and 118:

Pipe ClampsB2207 THRU B2213MULTI-GR

- Page 119 and 120:

Pipe ClampsB2000 SERIESPVC CLAMPS

- Page 121 and 122:

Pipe ClampsB2000 SERIESO.D. PIPE AN

- Page 123 and 124:

B-LineB2609-3/43/4" STDPipe ClampsB

- Page 125 and 126:

VibraClamp ® Pipe ClampsBVP SERIES

- Page 127 and 128:

Vibra Cushion ® AccessoriesB1999VI

- Page 129 and 130: Pipe ClampsB437 SERIES TWO PIECE PI

- Page 131 and 132: Pipe ClampsB2301 SERIESONE HOLE EMT

- Page 133 and 134: Pipe HangersB3690 SERIESADJUSTABLE

- Page 135 and 136: B591 SERIESPIPE BRACKET SADDLE AND

- Page 137 and 138: B218PIPE ROLLERS- 1 /2” (15) TO 8

- Page 139 and 140: Pipe RollersB219 SIZING CHARTInsula

- Page 141 and 142: Pipe RollersB479PIPE ROLLERS-16”

- Page 143 and 144: SUPPORT BASES ONLYNEW• Base only

- Page 145 and 146: NEWDBE SERIESSUPPORT BASE WITH ROD

- Page 147 and 148: Dura-Blok Rooftop SupportsDB__DS SE

- Page 149 and 150: Dura-Blok Rooftop SupportsROOFTOP A

- Page 151 and 152: DURA CLEAN CHANNELNEW• Thickness:

- Page 153 and 154: U-BOLTSNEW• Material: Stream clea

- Page 155 and 156: Dura Clean AccessoriesOther Stainle

- Page 157 and 158: Electrical Accessories(8)(9)(11)(7)

- Page 159 and 160: Fluorescent Fixture HangersB616S-22

- Page 161 and 162: Electrical AccessoriesB217-20SNAP C

- Page 163 and 164: Junction BoxesB718UNIVERSAL JUNCTIO

- Page 165 and 166: Strut JoinersB166FOUR HOLESPLICE CL

- Page 167 and 168: Insulclamp ® ClampsB4060 THRU B409

- Page 169 and 170: Maple ClampsB4000 THRU B4007MAPLE C

- Page 171 and 172: Aluminum Channel & Closure StripsB1

- Page 173 and 174: AluminumALUMINUM FITTINGSMost fitti

- Page 175 and 176: Stainless SteelSTAINLESS STEEL FITT

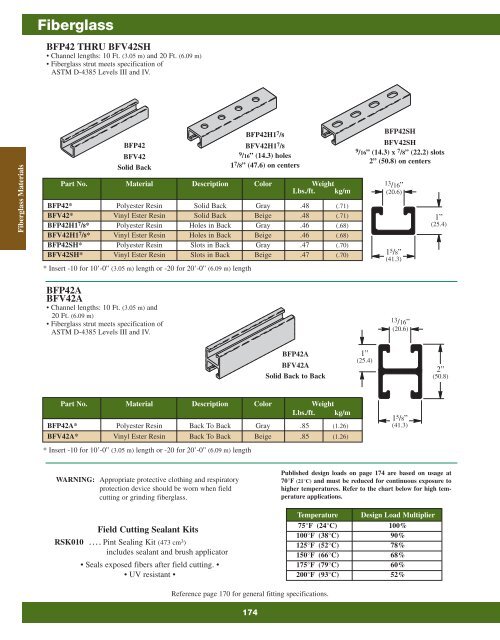

- Page 177 and 178: FiberglassCHANNEL RESIN INFORMATION

- Page 179: FiberglassBEAM LOADING DATA FOR GLA

- Page 183 and 184: CHANNEL NUTS• Design Load Safety

- Page 185 and 186: FiberglassBFV100 thru BFV300ADJUSTA

- Page 187 and 188: FiberglassBFV755BEAM CLAMP• Desig

- Page 189 and 190: FiberglassBFV201SQUARE WASHER FOR 3

- Page 191 and 192: FiberglassBFV135THREE HOLE FLAT GUS

- Page 193 and 194: FiberglassBFV280SQPOST BASE FOR BF*

- Page 195 and 196: •Thickness: 18 Ga. (1.2 mm)•Sta

- Page 197 and 198: Mini Channel Nuts & FittingsNUTS FO

- Page 199 and 200: Mini FittingsB6133FOUR HOLE TEE PLA

- Page 201 and 202: B6134R&LFOUR HOLE CORNER GUSSET•S

- Page 203 and 204: B6168THREE HOLE SPLICECLEVIS FOR B7

- Page 205 and 206: B6205END CAP FOR B62•Material: AS

- Page 207 and 208: Typical Econo-Strut ApplicationsEco

- Page 209 and 210: Concrete InsertsContinuous concrete

- Page 211 and 212: Continuous Concrete InsertsB32ICONT

- Page 213 and 214: Spot InsertsB2500SPOT INSERT•Desi

- Page 215 and 216: AnchorsWEDGE ANCHOR•Safety Factor

- Page 217 and 218: Slotted Angle SizesSA158•14 Gauge

- Page 219 and 220: Slotted Angle Beam LoadingBEAM LOAD

- Page 221 and 222: AHHK- 1 /4 & AHHK- 3 /8AIR HANDLER

- Page 223 and 224: DESIGN LOAD DATA (For typical chann

- Page 225 and 226: Reference DataTABLE 2: MAXIMUM NUMB

- Page 227 and 228: Reference DataRIGID STEEL CONDUIT (

- Page 229 and 230: Reference DataSCHEDULE 40 PVC PLAST

- Page 231 and 232:

Reference DataSTANDARD WEIGHT SCHED

- Page 233 and 234:

IndexB105 . . . . . . . . . . . . .

- Page 235 and 236:

IndexB465 . . . . . . . . . . . . .

- Page 237 and 238:

IndexB4005 . . . . . . . . . . . .

- Page 239 and 240:

IndexDC-8 . . . . . . . . . . . . .

- Page 241 and 242:

235Notes

- Page 244:

Other Cooper B-Line Product LinesCa