Cooper B-Line Strut Systems - Dixie Construction Products

Cooper B-Line Strut Systems - Dixie Construction Products

Cooper B-Line Strut Systems - Dixie Construction Products

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

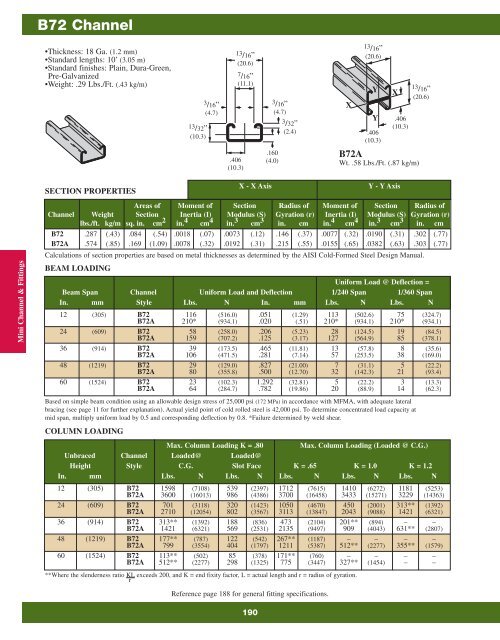

B72 Channel•Thickness: 18 Ga. (1.2 mm)•Standard lengths: 10’ (3.05 m)•Standard finishes: Plain, Dura-Green,Pre-Galvanized•Weight: .29 Lbs./Ft. (.43 kg/m)13 /32”(10.3)3 /16”(4.7).406(10.3)13 /16”(20.6)7 /16”(11.1)3 /16”(4.7).160(4.0)3 /32”(2.4)X13 /16”(20.6)YY.406(10.3)X.406(10.3)B72AWt. .58 Lbs./Ft. (.87 kg/m)13 /16”(20.6)SECTION PROPERTIESX - X AxisY - Y AxisMini Channel & FittingsAreas of Moment of Section Radius of Moment of Section Radius ofChannel Weight Section Inertia (I) Modulus (S) Gyration (r) Inertia (I) Modulus (S) Gyration (r)lbs./ft. kg/m sq. in. cm 2 in. 4 cm 4 in. 3 cm 3 in. cm in. 4 cm 4 in. 3 cm 3 in. cmB72 .287 (.43) .084 (.54) .0018 (.07) .0073 (.12) .146 (.37) .0077 (.32) .0190 (.31) .302 (.77)B72A .574 (.85) .169 (1.09) .0078 (.32) .0192 (.31) .215 (.55) .0155 (.65) .0382 (.63) .303 (.77)Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual.BEAM LOADINGUniform Load @ Deflection =Beam Span Channel Uniform Load and Deflection 1/240 Span 1/360 SpanIn. mm Style Lbs. N In. mm Lbs. N Lbs. N12 (305) B72 116 (516.0) .051 (1.29) 113 (502.6) 75 (324.7)B72A 210* (934.1) .020 (.51) 210* (934.1) 210* (934.1)24 (609) B72 58 (258.0) .206 (5.23) 28 (124.5) 19 (84.5)B72A 159 (707.2) .125 (3.17) 127 (564.9) 85 (378.1)36 (914) B72 39 (173.5) .465 (11.81) 13 (57.8) 8 (35.6)B72A 106 (471.5) .281 (7.14) 57 (253.5) 38 (169.0)48 (1219) B72 29 (129.0) .827 (21.00) 7 (31.1) 5 (22.2)B72A 80 (355.8) .500 (12.70) 32 (142.3) 21 (93.4)60 (1524) B72 23 (102.3) 1.292 (32.81) 5 (22.2) 3 (13.3)B72A 64 (284.7) .782 (19.86) 20 (88.9) 14 (62.3)Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateralbracing (see page 11 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity atmid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear.COLUMN LOADINGMax. Column Loading K = .80 Max. Column Loading (Loaded @ C.G.)Unbraced Channel Loaded@ Loaded@Height Style C.G. Slot Face K = .65 K = 1.0 K = 1.2In. mm Lbs. N Lbs. N Lbs. N Lbs. N Lbs. N12 (305) B72 1598 (7108) 539 (2397) 1712 (7615) 1410 (6272) 1181 (5253)B72A 3600 (16013) 986 (4386) 3700 (16458) 3433 (15271) 3229 (14363)24 (609) B72 701 (3118) 320 (1423) 1050 (4670) 450 (2001) 313** (1392)B72A 2710 (12054) 802 (3567) 3113 (13847) 2043 (9088) 1421 (6321)36 (914) B72 313** (1392) 188 (836) 473 (2104) 201** (894) – –B72A 1421 (6321) 569 (2531) 2135 (9497) 909 (4043) 631** (2807)48 (1219) B72 177** (787) 122 (542) 267** (1187) – – – –B72A 799 (3554) 404 (1797) 1211 (5387) 512** (2277) 355** (1579)60 (1524) B72 113** (502) 85 (378) 171** (760) – – – –B72A 512** (2277) 298 (1325) 775 (3447) 327** (1454) – –**Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration.rReference page 188 for general fitting specifications.190