Cat Hydraulic Systems

Cat Hydraulic Systems

Cat Hydraulic Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

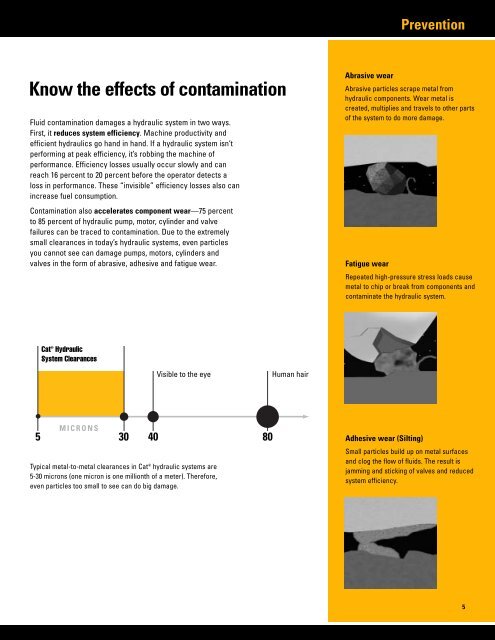

PreventionKnow the effects of contaminationFluid contamination damages a hydraulic system in two ways.First, it reduces system efficiency. Machine productivity andefficient hydraulics go hand in hand. If a hydraulic system isn’tperforming at peak efficiency, it’s robbing the machine ofperformance. Efficiency losses usually occur slowly and canreach 16 percent to 20 percent before the operator detects aloss in performance. These “invisible” efficiency losses also canincrease fuel consumption.Contamination also accelerates component wear—75 percentto 85 percent of hydraulic pump, motor, cylinder and valvefailures can be traced to contamination. Due to the extremelysmall clearances in today’s hydraulic systems, even particlesyou cannot see can damage pumps, motors, cylinders andvalves in the form of abrasive, adhesive and fatigue wear.Abrasive wearAbrasive particles scrape metal fromhydraulic components. Wear metal iscreated, multiplies and travels to other partsof the system to do more damage.Fatigue wearRepeated high-pressure stress loads causemetal to chip or break from components andcontaminate the hydraulic system.<strong>Cat</strong> ® <strong>Hydraulic</strong>System ClearancesVisible to the eyeHuman hairMICRONS5 30 40 80Typical metal-to-metal clearances in <strong>Cat</strong> ® hydraulic systems are5-30 microns (one micron is one millionth of a meter). Therefore,even particles too small to see can do big damage.Adhesive wear (Silting)Small particles build up on metal surfacesand clog the flow of fluids. The result isjamming and sticking of valves and reducedsystem efficiency.5