equipment profile - Finning Canada

equipment profile - Finning Canada

equipment profile - Finning Canada

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

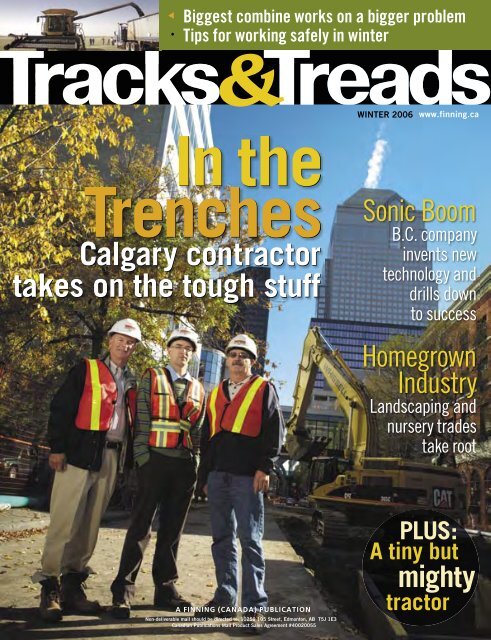

1418Departments4 The <strong>Finning</strong> FocusThese are the good old days6 GroundbreakerCat goes green; Magic bus;Meeting emissions standards;Tractors small but mighty;New Cat website; Send usyour stories; Meet a collector12 Yesterday/TodayIn the 1920s there weretractors and there were dieselengines. Caterpillar put thetwo together13 Yellow IronNew products and servicesfrom <strong>Finning</strong>22 Safety FirstWorking in winter has itsown issues34 Meeting the ChallengeAn Alberta Cat owner puts hisclass-9 combine to work to feedthe poor36 Field TestCat’s back in the forwarderbusiness with the new 57441 Bill’s BusinessCheck out the new Bill andlook in on his use of operatorenhancement trainingNEW!42 Count on UsAnother Cat FlashbackCONTENTS WINTER 2006Features14 Pier PressureFlatiron Constructors takes onan eye-popping project on oneof <strong>Canada</strong>’s most dramatic andtoughest stretches of highway18 Do You Hear What I Hear?The guys behind Sonic DrillCorporation invent a technologyand build a business to support it30 Whissell While You WorkThis Calgary contractor takes onthe toughest jobs. And that meansit’s business as usual38 Nothing Shifty HereCat’s TH35 automatictransmission delivers the goods ontime, every time41Industry Report23 The Landscaping andNursery Trades24 Nursing the LandscapeDesigning and managing our outdoorspaces is a blooming industry. A lotgoes into growing a trade27 Tooling AroundThe right tools make challenginglandscaping jobs easier. Meet the proswho use the tools30ON THE COVERWhissell Constructors (from left to right)Brian Whissell, Jarrad Whissel and Bill HeatheringtonPHOTOGRAPH BY ROTH AND RAMBERGwww.finning.ca Winter 2006 • TRACKS & TREADS 3

The <strong>Finning</strong> FocusThe Good Old DaysB Y J E F F H O W A R DJEFF HOWARD,PUBLICATIONS MANAGER,FINNING (CANADA)An insightful manager here at <strong>Finning</strong> (<strong>Canada</strong>)borrows a line from a Carly Simon tune when describingthe present business climate. “These arethe good old days,” he says.Indeed, for most Tracks & Treads readers, 2006will be recalled as a time when opportunity was toorich, a time when <strong>equipment</strong> owners and operatorswere called to burn the candle at three ends.Next year will likely be filed under the “goodold” category as well, unless you’re in the forest sectorwhere a tiny bug, as in a pine beetle, and a giantslug, as in the nose-diving U.S. housing market,will gnaw away at your profits.Of course, the big concern these good old daysis finding new, young employees. For kids gettingstarted, career possibilities are limitless. Heck, eventhe 7-Eleven across the street from my house offersa $700 signing bonus, which makes me a wee bitjealous. Back in the early 1980s, when I was on thehunt for new opportunities, you needed a PhD justto get an interview at 7-Eleven.The tables have turned. The other day I saw a U.S.police force recruitment ad that encouraged applicantswho “had failed psychological tests between1996 and 2001” to reapply.Despite these crazy people shortages, Tracks &Treads readers found ways to get projects done. Justas importantly, they found ways to improve productivity.Here’s a look back at some of the memorablequotes you offered – in these, the very buoyant, thevery busy “good old days.”On wise fatherly advice:“My dad always said to buy the best <strong>equipment</strong>you can to get the job done right, and for him thatwas Caterpillar machines. He still comes aroundand gives me hell now and then.” – Dean Price, NahanniConstruction Ltd., Prince George, B.C.On the advantages of new technology:“In the past, we used laser systems and old fashionedsurveying methods, which meant we hadto constantly monitor what we were doing to ensurewe stayed on grade. Now we have taken theguesswork out of it (with use of the AccuGradesystem) and my previously overworked surveyorsand operators are much more efficient and relativelystress-free. At the end of the day, everyone ismuch happier.” – Paul Garvie, president, Cutting Edge GolfInternational, Victoria, B.C.On youthful visions:“Since I am only 24 and have not fully settleddown, a woodworking shop was somewhat adream for the future, since they tend to be stationary.To build a shop that I could take withme wherever I go, I constructed my woodworkingshop in a seaborne shipping container. Thatway, if I move, I can easily take my shop with meworldwide by truck, rail or container ship.”– Mark Roen, woodworker, Calgary, Alta.(Mark builds Cat scale models – a recent creation is aD6R XL made of 1,021 custom-made wood pieces.)On sensible <strong>equipment</strong>:“We used to use two of the competitor’s combinesand we needed two operators for them.We’re doing the same amount of work now (with aLexion 590 combine), but with only half the labourand less capital investment.” – Peter Biemans, farmer,Seven Persons, Alta.On determination:“Nobody knows how long the good times willlast, so we’re just taking things as they come. Wehope it’ll last beyond the Olympics, of course. Butif it doesn’t, we’ll still find work. We’re pretty confidentabout the future, no matter what happens.”– Rick Schnurr, co-owner, L&A Equipment Ltd., Squamish, B.C.4 TRACKS & TREADS • Winter 2006 www.finning.ca

WINTER 2006 Volume 46, No. 4PUBLISHERRuth Kellyrkelly@venturepublishing.caASSOCIATE PUBLISHERTeresa Secrettsecret@venturepublishing.caEXECUTIVE EDITORJeff Howardjhoward@finning.caEDITORMifi Purvismpurvis@venturepublishing.caART DIRECTORCharles Burkecburke@venturepublishing.caCONSULTING ART DIRECTORJennifer WindsorASSOCIATE ART DIRECTORVanlee RobbleePRODUCTIONGunnar BlodgettCIRCULATION COORDINATORAndrea CruikshankADVERTISING REPRESENTATIVEAnita McGillisamcgillis@venturepublishing.caCONTRIBUTING WRITERSRobin Brunet, David DiCenzo, Keith Haddock,Jim Stirling, Bill Tice, Katherine FawcettCONTRIBUTING PHOTOGRAPHERSAND ILLUSTRATORSBluefish, Sylvie Bourbonnière, Keith Haddock,Ian Jackson, Ricardo Leiva,Roth and Ramberg, Chip ZdarskyTracks & Treads is published to provide its readerswith relevant business, technology, product and serviceinformation in a lively and engaging manner.Tracks & Treads is published for<strong>Finning</strong> (<strong>Canada</strong>) byVenture Publishing Inc.10259-105 StreetEdmonton, Alberta T5J 1E3Phone: 780-990-0839 / Fax: 780-425-4921Contents © 2006 by <strong>Finning</strong> (<strong>Canada</strong>)No part of this publication should bereproduced without written permission.Letters & FeedbackI ENJOY SEEING Tracks & Treads in the mailbox. I’m retired now anddon’t own any Cat-powered <strong>equipment</strong> any more. I can just thinkback to what was good. Looking at the old Cat <strong>equipment</strong> picturesin the magazine, I decided to pull out some of my own family photosof some early iron. One is of my father on a small Cat pulling sledsof cordwood near Whitecourt about 1930. The other is of a newD8 caught in a holewhile trying to redirect aflooding Mark Creek inKimberley in April 1948.The small Cat came withmy father when he cameback to <strong>Canada</strong>, havingworked for Caterpillar inPeoria. The D8, I think,belonged to Bennett andWhite Construction orCominco.Doug FrankChristina Lake, B.C.A NEIGHBOUR of mine, nowretired from <strong>Finning</strong>, passedalong a copy of the summer2006 Tracks & Treads. I read itfrom cover to cover and enjoyedit so much. I spent 32 yearsin the machinery business– 28 of those with RollinsMachinery. I’ve been retiredfor 14 years, but still takegreat interest in machinery.I found Tracks & Treadsvery informative as well asentertaining. I cannot drive by a construction site without looking to seewhat machinery is working on it. The story of Mark Roen (Meeting theChallenge, Summer 2006) designing and building a working model ofthe D6R XL out of wood was totally fascinating; what a clever craftsmanhe is.Harry ThomsonSurrey, B.C.Tell us what you thinkTracks & Treads would love to hear from you. Tell us what you think of themagazine, its stories, its columns, its look. Tell us how we can improve themagazine and make it a more interesting read.Send your comments to executive editor Jeff Howard by e-mail at jhoward@fi nning.caor the old-fashioned way to: Jeff Howard, Tracks & Treads, <strong>Finning</strong> (<strong>Canada</strong>),16830 - 107 Avenue, Edmonton, Alberta, T5P 4C3www.finning.cawww.finning.caWinter 2006 • TRACKS & TREADS 5

GROUNDBREAKERNEWS &REVIEWSGROUNDBREAKERBY DAVID DICENZOCat Goes GreenThe bright yellow of a Cat machine is asymbol of the brand. Though you’ll never actuallysee it painted on any iron, Caterpillar ismaking a serious effort to add a touch of greento its palette. For 80 years, Caterpillar has hadits fingerprints on development worldwide,and with such vast influence comes substantialresponsibility – especially in a time when criticalenvironmental concerns have taken centre stage.On the heels of a new mandate to improvesustainable development,Caterpillar released its first everSustainability Report last April.“Because Caterpillar has licly set aggressive metricspub-and goals for the way wedesign our products, runour operations and workwith our customers aroundthe world,” said Ali Bahaj,“our enterprise-wide commitmentwill help drive behaviorsacross the company.” Bahaj is theCaterpillar vice-president with responsibilityfor sustainable development.The company has made great strides towardsmaking a positive impact on the environment.For example, Cat gives new life to old products.In 2005, Caterpillar remanufactured more than2.2 million end-of-life units, saving space inlandfills and reducing energy spent in manufacturing.Caterpillar Bus EngineAs one of the hubs of the technologicalworld, Seattle has developed a reputation forbeing one of those cities ahead of the game.That innovative environment was on full displayin the summer of 2005 when the transitsystem received a big-time makeover – with alittle help from Caterpillar – en route to earningthe Clean Air Excellence Award for 2005from the American Environmental ProtectionAgency (EPA).The King County Metro Transit systemhad to do something about its aging fleet ofvehicles so it rounded up a talented crew ofcompanies to develop a clean-air hybrid bus.Emission reduction is another area in whichCaterpillar has become a worldwide leader.Since 1988, the company has reduced theparticulate matter emissions in its clean-dieselengines by more than 80%, and dating back to2004, more than 340,000 engines have beenshipped with ACERT Technology, aCaterpillar-specific emissions reductionsadvancement.In addition to the landmark sustainabilityreport, Caterpillar has solidified its reputationas a philanthropic leader with its recentdonation of $7.5 millionto support the WorldResources Institute’sCentre for Transportand the Environment,known as EMBARQ.EMBARQ workswith local governmentsand leaders to developintelligent, sustainablesolutions to urban transportationproblems. By replacingold, outdated <strong>equipment</strong> andimplementing modern diesel technology intoexisting buses, for instance, the goal is toaddress troubling issues such as air pollution,greenhouse gas emissions, traffic congestionand safety.The colour will always be yellow. But makeno mistake – Cat’s going green.Renowned bus manufacturer New Flyer Industries,headquartered in Winnipeg, drew up theplans for the vehicles, Allison Transmissioncontributed the hybrid electric drive and Caterpillarsupplied the C-9 engines with ACERTTechnology.That successful combo translated into amassive reduction of emissions for the entirefleet of 235 new buses by the end of 2005,along with the prestigious award, announcedthis past June from the EPA.“Our goal has been to reduce emissionswhile improving fuel economy and reducingmaintenance costs,” said Greg Gauger, direc-6 TRACKS & TREADS • Winter 2006 www.finning.ca

GROUNDBREAKERPHOTOGRAPH BY NED AHRENS, KING COUNTYtor, Caterpillar On-Highway Power Systems. “This awardfor King County Metro shows that we are definitely onthe right track.”The buses did exactly that. The first 24 hit the Seattlestreets in June of 2004, and by the end of 2005, with all235 in operation, they racked up eight million miles onthe road over the course of that year. Compared to theold diesel fleet, the new buses produced 32% less green-“Our goal has been to reduceemissions while improvingfuel economy and reducingmaintenance costs.This award for King CountyMetro shows that we aredefinitely on the right track.”house gas emissions and 50% fewer oxides ofnitrogen and particulate matter. The ACERTengine, which reduces emissions at the pointof combustion, was a big factor in those staggeringnumbers.With ultra-low sulfur diesel in the tanks and electricitygeneratingbatteries attached to the roof, the King CountyMetro buses also saw a 31% improvement in fuel economy,in addition to a drastic decrease in maintenance costs.It all meant for cleaner, quieter rides for Seattle’s busridingpopulation. No wonder the EPA came calling.Kudos From OperatorsA little bit of praise goes a long way.The gang at Caterpillar are understandablyfeeling pretty pleased about theirrecent achievements. Cat customershave spoken and – for the sixth time– awarded the prize for customersatisfaction (in the Heavy Duty TruckEngine and Transmission CustomerSatisfaction Survey) to a heavy-dutytruck engine from Caterpillar Inc.J.D. Power and Associates, aninternational marketing outfit,awarded Caterpillar’s C-12 clean powerengine its highest levels of customer satisfaction.The presenters said that Cat has done an excellent job inmeeting new emission standards. To do that, Cat created itsown innovative emission technology. Meeting the standardswith their engines is a prize in itself, and a nod from satisfiedcustomers is the icing on the cake.Caterpillar’s C-12 engine won the award in the “vocational”category, which includes trucks that pros use in toughsituations such as construction, refuse hauling and utilityservices. The survey was based on interviews with 2,529customers who own two-year-old Class 8 trucks. It measurescustomer satisfaction in four areas of engine performance:engine quality, engine performance, engine cost of ownershipand engine warranty.“The credibility of the J.D. Power and Associates Award isthat it is customer-driven, reflecting the feedback and voicesof the end-users who rely on Caterpillar’s engines,” saysJim Parker, Caterpillar vice president with responsibilityfor the company’s Power Systems Marketing Division.According to operators, Team Caterpillar is on the righttrack.The C-12 relies on Cat’s ACERT Technology to reduceemissions at the point of combustion without sacrificingengine performance and reliability. ACERT relies onadvanced technologies in four key areas: improved airmanagement, precision combustion technology, advancedengine electronics and a simple after-treatment process.“This is an exciting time for Caterpillar as we continueto see strong customer acceptance for our engines poweredby ACERT Technology,” says Parker. “ACERT Technologyremains the solution for future engines.” Cat customers aretesting 100 engines that meet even tougher 2007 emissionregulations. Industry testing racked up more than 12 millionmiles on evaluation as of mid-October.The C-15 follows the C-12 in the rankings with strongcustomer satisfaction scores. The study examined 2004truck engines, the second model year impacted by EPAemissions standards. And Cat has submitted the necessarydocuments in preparation to roll out 2007-compliantengines. Because Cat is the leading manufacturer andsupplier of truck and bus engines in the medium- andheavy-duty categories in North America, it’s especiallyimportant to set the bar high. Besides, Cat customersexpect nothing less.To learn more about Caterpillar On-Highway Engines,visit: www.cattruckengines.comwww.finning.ca Winter 2006 • TRACKS & TREADS 7

GROUNDBREAKERCat.com LandscapingWe live in a wired world. And eventhough Canadian landscapers shape theaesthetics on the outside of it, they toorely on technology to assist with gettingthe tools to do their job. Caterpillar understood– and did something about it.With the summer launch of a newlandscape industry component on thecompany’s website, green professionalsnow have a destination to get the skinnyon the Cat products that help beautifyour cities.“As Caterpillar becomes an increasinglypreferred brand among landscapeprofessionals, our customers are tellingus that they want to go to a place onthe website that applies directly to theunique work they do,” said Kent Pellegrini, green industriesmanager for Caterpillar’s North American CommercialDivision.The destination www.cat.com/landscaping offers aplethora of information on products, detailed machinespecs and application-specific machine and work toolpairings. There are more links to other services, such asdealer locators, operator training and the Build & Quoteonline price feature. As this new component of the siteevolves, surfers can expect some news and event listingsSmall But MightyYou don’t need to be big to be effective.Just look at a hockey rink these days. There areplenty of pint-sized pros that can do the job, likeD-man Andrew Ference of the Calgary Flames,or feisty Edmonton Oilers blueliner Marc-AndreBergeron. In the heavy <strong>equipment</strong> world, theequivalent is Cat’s MT200B series of compacttractors.Launched at the tail end of 2004, the smallestof the increasingly popular series isthe tiny MT225B, which measures 102inches (259 cm) in length, 48 inches(122 cm) in width, 77 inches (195 cm)in height, including the roll bar, andtips in at just 1,604 pounds (727 kg).But even with such a small frame, thenew Cats pack a punch. Because of that, theyhave emerged as a favourite choice for acreageowners throughout Alberta. Continues next pageand a host of industry links that will help them in theirown business. And once in, you can bet they’ll take a peekelsewhere in Cat’s web world.“If customers enter the overall site through the LandscapingIndustry area, they still will have easy access tothe rest of the cat.com site for information about Caterpillar,merchandise, and the products and services availablethroughout the company,” Pellegrini added.See our Industry Report on page 23 for more about thelandscaping and nursery trades.8 TRACKS & TREADS • Winter 2006 www.finning.ca

GROUNDBREAKER“They’re kindof like a Swissarmy knife –you can do alot of thingswith them.”“They’re just getting on the radar,” says<strong>Finning</strong>’s Grant Dykstra, a small tractorspecialist who notes that compact tractorsmake up the fastest growing segment inNorth America’s heavy <strong>equipment</strong> market.“They’re kind of like a Swiss army knife –you can do a lot of things with them.”The sturdy line features engines that rangefrom 22.5 to 52 horsepower, ensuring thatowners are getting the most out of themin their numerous applications.The tractors can mow, rototill, dofinishing work in spots with tightclearances and even move bales tofeed cattle. Renowned equestriancentre Spruce Meadows actually hasfive of the mini tractors on site tohelp maintain their grounds.“The thing the owners like themost is that they’re compact andrugged,” says Dykstra. “They’re metal, witha rugged front axle and there’s no worry ofoverworking them. They’re good, quality tractors.”<strong>Finning</strong> heavy <strong>equipment</strong> mechanic BradHepworth, who works out of Fort MacMurray,liked the line so much that he bought anMT225 for his hobby farm in Colinton, Alta.Hepworth and his wife take care of two biggardens on the property, in addition to hispigs and chickens, so he got a loader and arototiller for his tractor.“It’s real handy to get in tight spots,” hesays. “And it’s got a lot of power. I had differentoptions and I tried out all of the tractorsout there. But I like this one.”What the Hepworths especially like is theno clutch transmission that makes it easy todrive. “It’s quick and it’s user-friendly,” hesays. “For out here, it’s perfect.”Cat Stories WantedTo the layperson, seeingsomeone operate a bigCat excavator, a toughlittle loader or a handygrapple is no big deal.But for those peoplewho have invested theirtrust and hard-earnedbucks in the yellow,Caterpillar is more a culture than simply abrand. And they have many interesting talesto tell.Remember Tim Loewen? In October of2005, the Chilliwack native and owner ofPine Meadows Tree Farms Ltd. said good byeto the single life and tied the knot with hislovely fiancée Tracy Wollard. The dedicatedCat customer received a special box from his<strong>Finning</strong> <strong>Canada</strong> rep Ray Gerein but insteadof the typical gift-opening frenzy on the dayafter the wedding, Loewen and Wollard wereencouraged to open up the present beforethey walked the aisle. Inside were two pairsof sparkling new Cat boots that the couplewere instructed to wear during the ceremonyand beyond. Just why a beautiful brideagreed to wear black boots with hergown might be a mystery to most, butit is a statement on what thebride and groom thinkof their trusty 287 Catloader.Dan Bustin isanother memberof the Cat family.Bustin, the ownerof a logging business,Medara ContractingLtd., and anemployee at Garnet Contractingin Campbell River, B.C., participatesin the local Cops For Cancer fundraiser on anannual basis. He got involved in 2001 after hisgood buddy from Garnet, Don Jinda passed away fromcolon cancer. Every year, Bustin does a little home-salonwork to his ‘do before shaving it to the wood in time forthe charity Cops event. The most recent style included abright yellow dye job with the Cat logo carefully craftedinto the back of his head.Up in Fort McPherson in the Northwest Territories, ahulking piece of Cat iron had a huge impact on all the peopleof the tiny hamlet last winter.Continues next pagewww.finning.ca Winter 2006 • TRACKS & TREADS 9

GROUNDBREAKERContinued from previous pageRecord snowfalls produced mammoth-sizeddrifts that paralyzed the residents in townin the early stages of one of the most brutalseasons ever experienced there. With his oldloader on its death bed, Fort McPherson’sDirector of Public Works Ernie Firth put in adesperate plea to <strong>Finning</strong> to prep a powerful,new 930G Cat as fast as humanly possible.An incredible team effort got the loaderdelivered within a few weeks, allowing Firthand his crew to dig out the hamlet before thesituation became too critical.That Cat was much more than aclean-up tool – it helped a strugglingcommunity get back on itsfeet again.There are many Cat stories like thisthroughout Western <strong>Canada</strong>.Tell us yours -(jhoward@fi nning.ca)and it might just hit the pages of a futureissue of Tracks & Treads.Cat Model CollectorRick Gauvreau’s son comes by his appreciationfor heavy <strong>equipment</strong> honestly. Brent’sfather Rick noticed that, even at the age oftwo, his little lad had a mesmerized look onhis face whenever he saw a big piece of irondoing its thing. It got to the point where Rickwould take young Brent down to a site just sohe could watch the heavy <strong>equipment</strong> work.“It was easy entertainment,” says Dad.“And it seemed to progress from there.”A couple of years later, the ambitious kidfrom Sherwood Park, Alta. was already collectingmodels of the impressive machines headmires so much.“My Dad got me some old ones at a garagesale,” says Brent, who celebrated his 12thbirthday back in August.There have been some significant upgradesto the collection in the approximatelyeight years since he began the hobby. Brent’scollection is vast and pristine, with the prizecomponent being 43 Cats, most of which aredie cast, which he keeps stored in the originalboxes.His 797 truck and D-11 tractor are thestandouts of the collection. “I like the sizeof them,” he says, referring to the real-lifebeasts. “They’re wicked.”Brent’s grasp of the machines and whatthey can do simply amazes Rick. The elderGauvreau is fascinated by his son’s obviousdedication to this unique interest, notingthat he thinks it’s a real positive way for a kidto spend his time.“He’s so knowledgeable, more so thanme,” says Rick, who knows more aboutheavy <strong>equipment</strong> than most people as anemployee of Bird Construction. “It’s quitethe collection. And he’s always looking formore pieces.”Next up on Brent’s wish list are a bigwheel loader and a wheel dozer. But acquiringnew pieces has required a little morepatience than usual after the local store heused to purchase them from closed up shop.Now, he keeps an eye on pieces online, alwayslooking for something cool.While Dad has had thepleasure of sitting ina monstrous 797 Cattruck, Brent has gottena small taste of workingheavy <strong>equipment</strong>thanks to a friendlystranger.“I remember oneday, we were watchingthis fleet of buggies goby,” he says. “One ofthe guys stopped andasked if we wantedto go up there for aride. It was great.”“I like thesize of them…they’rewicked.”PHOTOGRAPHY: CHRISTY DEAN10 TRACKS & TREADS • Winter 2006 www.finning.ca

GROUNDBREAKERBy the NumbersGross mining revenuesin B.C. in 2005:$6,290,000,000Price Donald Trump wantsfor his Palm Beachmansion:Percentage of B.C. land baseused to generate these revenues:$125,000,000Price he paid for this80,000-square-foot homein 2004:$41,000,0000.03Number of years since there’sbeen such a sharp year-overyeardrop in the U.S. medianhome price:35Residential vacancyrate inGrande Prairie, AB:0.2Number of RV camping spotsavailable at theBear Creek Golf Course,on land originally peggedas a driving range:20Percentage memory testscore improvementafter a one-hour nap:15Approximate percentageof video gamerswho are addicted:20Ranking of the followingvideo games on a list ofWorst Game Names Ever:Irritating Stick, 1st;If It Moves, Shoot It, 2nd;and Pesterminator:The WesternExterminator,4 thwww.finning.ca Winter 2006 • TRACKS & TREADS 11

Yesterday/TodayBY KEITH HADDOCKIN THE 1920s, THERE WERE TRACTORS AND THERE WERE DIESEL ENGINES.CATERPILLAR PLAYED A MAJOR PART IN FIGURING OUT HOW TO PUT THETWO TOGETHER, DEVELOPING A DIESEL ENGINE FOR MOBILE USECat’s FirstDiesel TractorThe diesel engine wasn’t new whenCaterpillar launched its first diesel tractor.In fact, the technology had been around for25 years. It was a German inventor,Rudolph Diesel, who first published aresearch paper about the engine in 1893.He was awarded a German patent for hisdesign theory for a high-compression,sparkless engine. The prototype enginewas operational two years later. Diesel soldseveral manufacturing licenses to entrepreneursincluding one to Adolphus Busch, awealthy brewer from St. Louis, Missouri,who began producing the first diesel enginefor sale in the United States in 1898.Before the Holt and Best companiesmerged in 1925 to form Caterpillar TractorCompany, they had already considered installingdiesel engines in their tractors. Butdiesel engines of the day were heavy andbulky, more suited to marine and stationaryapplications. For the most part, dieselengines were used to power <strong>equipment</strong>inside buildings, where engine sprawlingsize was not an issue and maintenancecould be carried out in relatively cleanconditions. And size wasn’t the only thingholding tractor manufacturers back. Stationaryengines operate at constant speedunder a uniform load, unlike a tractorengine, which varies its speed and load continuallyand operates outdoors in all kindsof grades and conditions.Soon after the Holt and Best merger andthe inception of the Caterpillar TractorCompany, the diesel engine concept startedto gain momentum. Gasoline tractor saleswere plummeting despite Caterpillar’sefforts to bolster sales with new designsand features. With the onslaught of theGreat Depression in 1929, Caterpillar realizedthat a new, more efficient tractor wasneeded if the company were to survive. TheTHE DIESEL SEVENTY-FIVE of 1933 was the forerunner of thefirst series D8 crawler tractor, introduced in 1935CATERPILLAR’S FIRST DIESEL TRACTOR, the 1931 Diesel Sixty at 63 horsepower pulling a Caterpillar elevating graderbrass decided to take a good look at diesel.To adapt an unwieldy diesel engine foruse in mobile <strong>equipment</strong>, the new companyneeded a radical new design. Caterpillarallocated nearly all its engineering researchbudget to the diesel over a number of years.The company spent more than $1 millioneven before the first prototype was tested.The first Caterpillar diesel tractor, the DieselSixty series 1C, was ready for the marketin September, 1931.Compared to the gas-powered Sixty, theDiesel Sixty had a heavier reinforcedframe, modified radiator, and a speciallower-geared transmission. Steel castingsin several areas replaced former fabricatedor riveted components, and overall weightincreased by nearly 4,000 pounds (morethan 1,800 kg) to 24,390 (11,065 kg) overthe weight of the gas tractor. But unlikemodern crawler tractors, the Diesel Sixtybore almost no sheet metal, exposing thediesel engine and all its components to theelements.The 4-cylinder engine in Caterpillar’sfirst diesel tractor was the D9900 listed at63 drawbar-horsepower and 75 belt-horsepower,but by the time the 1C-series tractorproduction run ceased at the end of 1932,power ratings were listed as 70 drawbarhorsepowerand 84 belt-horsepower at alow 700 rpm.Caterpillar’s increased sales of dieseltractors soon offset declining sales of gaspoweredunits as the advantages of dieselbecame apparent to tractor users. A dieselpoweredtractor possesses much greaterlugging capability with maximum poweravailable over a much wider working rangethan a gas tractor of similar horsepower.Another advantage is diesel’s superiorfuel economy. The big gasoline tractors ofthe early 1930s consumed an enormousamount of fuel, making gas tractors greaterthan 70 horsepower almost uneconomicalto operate, even though fuel was relativelycheap at that time. Caterpillar’s successfuldiesel tractor line soon extended to allpopular sizes and caused the almost totalextinction of its gasoline models by the endof the 1930s, with only two small modelssurviving into the early 1940s.2PHOTOGRAPH COURTESY OF KEITH HADDOCK12 TRACKS & TREADS • Winter 2006 www.finning.ca

YELLOWIRONNew Products and Ser vices from <strong>Finning</strong>A Cat part for every needMachine near the end of its lifecycle? Get more life outof it with Cat Classic Parts, a reduced-cost line of partscovering key components. Cat Classic Parts are availableto repair axles, differentials, transmissions, hydraulicpumps, steering, swing and tandem drives, torque convertersand winches. Recently released Classic partsinclude piston/liner kits, valve kits, head assemblies,crankshafts, exhaust manifolds, mufflers and more.Numbers you can count on: 1-888-FINNING & 24/7Working in the wee hours? Need to order parts at 3 a.m.?No problem. At the <strong>Finning</strong> Customer Support Centre,we're here for you with the advice you need 24 hoursa day, seven days a week. Call 1-888-FINNING fromanywhere, day or night, to reach skilled, knowlegeable<strong>Finning</strong> <strong>equipment</strong> professionals.For all your insurance needsFor contractors and <strong>equipment</strong> operators, <strong>Finning</strong> offersa multiple-line insurance program for fleet auto liability;commercial general liability; <strong>equipment</strong>, buildings andcontents; bonding and many other miscellaneous formsof insurance. Flexibility, insurance expertise and an understandingof the heavy <strong>equipment</strong> industry enables us tocustomize insurance packages for any size of business.Call <strong>Finning</strong> Insurance Services today at 1-888-FINNING.The WAVS of the futureThe new, versatile Caterpillar Work Area Vision System(WAVS) provides machine operators with views from asmany as three cameras. While not intended to be used inplace of direct views or installed mirrors, WAVS is a greatasset for operators at any level. Developed specifically forrugged applications and environments, WAVS is simple toinstall on any machine and is easy to use, offering powerfulcapabilities and features to improve productivity.www.finning.ca Winter 2006 • TRACKS & TREADS 13

COMPANY PROFILE: Flatiron ConstructorsThe scale of the Kicking Horse project is huge, but so far,it’s business as usual for FlatironPHOTOGRAPH COURTESY FLATIRON CONSTRUCTORS14 TRACKS & TREADS • Winter 2006 www.finning.ca

Flatiron Constructors takeson an eye-popping project,upgrading a 1950s-era sectionof road on one of <strong>Canada</strong>’s mostdramatic, and toughest,stretches of highwayPierPressureB Y R O B I N B R U N E TPHOTO COURTESY: B.C. MINISTRY OF TRANSPORTATIONAcompany as well established as FlatironConstructors Ltd. could take a job likethe Kicking Horse Canyon HighwayImprovement Project in stride. But the sheermagnitude of the work involved – fromexcavating 2.5 million cubic metres of rockto building a 400-metre-long bridge and 5.8 kilometers ofnew road – would cause seasoned contractors to have sleeplessnights.Careful planning, plenty of Caterpillar <strong>equipment</strong>, a closeworking relationship with <strong>Finning</strong>, and a long history of civilengineering projects under the company’s belt translates intoFlatiron crews surmounting problems as they come. “We’vegot good people and mild weather on our side, and despite thephysical challenges it’s also a very safe site we’re working in,”says Flatiron operations manager Blair Brandon.The 26-kilometre Kicking Horse Canyon thoroughfare islocated on the Trans-<strong>Canada</strong> Highway in eastern B.C. and isthe major east-west connection between that province andAlberta. (Nine-thousand vehicles drive through the canyonduring the summer months). The $730 million design-buildimprovement project is centred between Golden, B.C. andthe western boundary of Yoho National Park. The narrow,winding two-lane road has steep rock faces on one side andsharp drop-offs into the Kicking Horse River on the other.The canyon-side road has an unfortunate accident rate that’snearly two and a half times higher than the average for thistype of roadway and it is one of the highest rock fall hazardareas in the provinces. The Alberta side of the road has notreceived any significant upgrades since its construction in themid-1950s.Flatiron was widely regarded as an ideal contractor to rectifythese shortcomings and bring the road into the 21 st century.With headquarters in Colorado, the company is renowned fordelivering some of the most complex and sophisticated bridgeand transportation projects in North America, most recentlythe $1-billion San Francisco-Oakland Bay Bridge upgrade, the$803-million Eastern Transportation Corridor in California’sOrange County, and the $541-million cable-stayed CooperRiver Bridge in Charleston, North Carolina.The objective of the three-phase Kicking Horse CanyonHighway Improvement project sounds simple on paper: maketraffic safer and more efficient by reducing sharp curves andsteep grades, increase capacity (to four lanes) and improvetraffic operations. Flatiron, which won the contract for thesecond phase of the project (rock work and highway realignmentthat comprised Phase One has been completed byother contractors), conducted extensive pre-planning in late2005 to determine how best to deploy its resources, then satdown with <strong>Finning</strong> to order <strong>equipment</strong>.“Flatiron <strong>equipment</strong> manager Matt Harrison explainedthe logistics to us and wound up purchasing 12 Cat 740-articulated rock trucks and renting six others,” says JimEtherington, <strong>Finning</strong>’s branch operations manager inCranbrook. “Flatiron also ordered a new 385 mass loader, two345s, a 330, one 365 excavator, two D8Rs, one D6R, oneD10R, two compactors, a rental 365,and a grader. Almostall the <strong>equipment</strong> being used up there is Caterpillar.” Thewww.finning.ca Winter 2006 • TRACKS & TREADS 15

COMPANY PROFILE: Snethun Klein Flatiron & Sons Constructorsfamily Ltd.Cranbrook branch, which is <strong>Finning</strong>’sclosest facility to Kicking Horse athree-hour drive away, became theofficial support shop. “By adding rentalunits – some of which <strong>Finning</strong> sourcedfrom as far away as Florida – to themachines we ordered that would notarrive until January, we were able tobegin work immediately and get a jumpon our schedule,” says Brandon. “Westill have the rentals in operation, andthat has accelerated the work rate evenfurther.”<strong>Finning</strong>’s involvement in theKicking Horse project constituteda package service: besides theCaterpillar <strong>equipment</strong>, it supplied a48-foot consignment trailer, on-sitefuel storage, two on-site swing-shiftmechanics to complement Flatiron’sin-house mechanics, and environmentalservices such as used oil disposal, filtercrushing and contamination control.The consignment trailer allowed theteam to work efficiently in concert withFining mechanics. Brandon remarks:“It’s a joint relationship between themand our mechanics, and the aim is to beas economical as possible with regardsto repairs. All the Caterpillar expertisehas been brought to the table with thisarrangement, and we are fulfilling ourwarranty requirements.”Etherington colorfully illustratesFlatiron’s task as “Taking the top off amountain and building a new bridge.”To achieve the former, Flatiron operatedits machines on two 10-hour shifts, anintense schedule that enabled crewsto haul up to 1,260 loads for everytwo shifts – this despite differentialproblems with the rock trucks.Etherington says, “When these problemscame to light we decided to service allthe trucks cyclically in Cranbrook. Wetransported each vehicle to our shopfor three days and sent it back to siteas the next truck came in, and in thisfashion we minimized downtime.”Indeed, Brandon remarks of downtimein general, “We’ve managed to achieveover 90% availability.” The earth worksportion of the Kicking Horse Project willbe finished by year-end.Flatiron has 150 hourly staff and 15permanent staff on site. The companyhas used an aggressive training programand progressive recruitment and hiringtechniques to overcome the shortage ofskilled trades people in <strong>Canada</strong>. “Wehave 12 women operating the rocktrucks and four on the compactors,” saysBrandon. Etherington, who journeysto Kicking Horse regularly, adds, “Theproject is very family-oriented in thatyou see lots of husbands and wivesworking together. It makes for anamicable atmosphere and a united crewthat pools their resources to get thingsdone.”Because the highway through KickingHorse Canyon must remain open totraffic during the upgrade, Flatiron builttwo steel bridges over the thoroughfareon mechanically-stabilized earthwalls to haul away excavated rock.Meanwhile, tower cranes perched onfive piers of the new Park Bridge (aka:PHOTOGRAPH COURTESY FLATIRON CONSTRUCTORS16 TRACKS & TREADS • Winter 2006 www.finning.ca

PHOTOGRAPH COURTESY FLATIRON CONSTRUCTORS10 Mile Bridge) are functioning to thedegree that each pier rises by the rate offour metres every two days. “The tallestpier will reach 93 metres, and early inthe New Year we’ll launch girders overthe piers,” says Brandon. The Park Bridgereplaces an older 1950s-era structurethat Flatiron will demolish in spring of2008.Working onsite, Flatiron constructionmanager Dale Gamble and projectmanager Bob Heath have endured thetough local conditions – including steepgrades and loose shale and clay baseroads that are slippery when wet – withno unreasonable <strong>equipment</strong> problems.Heath has been on the project sinceSeptember 2005, involved in projectdevelopment. “The biggest challenge,”he says, “is the tight schedule.” Theproject, evaluated on a net-present valueand cash-flow payment stream, meansearly completion is a better option,financially. So far, Heath is optimistic fora “somewhat early completion.” Heathsays that <strong>Finning</strong> rep Todd Johnson hashelped the project work towards thatgoal. “He did an excellent job finding the<strong>equipment</strong> we needed, delivering on orbefore the promised date.”While Phase Three of the KickingHorse project – which includesimprovements to the balance of thecorridor – will be determined bygovernment funding, Phase Two isalready considered by those in the knowto be a resounding success. However,Brandon is understated: “We’re satisfiedso far with our level of progress, andwe’re also hoping for another mildwinter. That’s because our people will belaunching girders for the new bridge insub-zero conditions, and the last thingwe need is lots of snow or wind to makethe job harder. With girder launching,you can only go wrong once and thenyou’re in a world of hurt.”Brandon concludes, “Our goal is to getstarted in December and get the learningcurve out of the way. If all goes well thegirders will be in place by March, andthen we can breathe easy. But not beforethen.”www.finning.ca Winter 2006 • TRACKS & TREADS 17

EQUIPMENT PROFILECat C7 engines power Sonic Drill Corp.’s machines.Likewise, Cat iron is used for the drill crawlers18 TRACKS & TREADS • Winter 2006 www.finning.ca

Sonic Drilling is more than a company.It’s also a ground-breaking techniqueDo You HearWhat I Hear?B Y B I L L T I C EPHOTOGRAPHY BY TREVOR SAVAGERay Roussy and Tom Savage, the principalowners of Surrey, B.C.-based Sonic DrillCorporation, have spent more than aquarter of a century researching, testingand perfecting a patented high-speed drillingtechnology that is exclusive to theircompany. The process is known as “sonicdrilling,” and while developing the technology,they have also managed to builda highly successful business that not onlyproduces and sells the advanced <strong>equipment</strong>required for sonic drilling worldwide, butalso handles complex projects with theirown contracting fleet through Sonic DrillingLtd.Roussy and Savage, who are both engineersby trade, started pioneering and developingsonic drilling technology in the 1970s.“Initially, the company’s focus was primarilyon producing and selling sonic drill heads,”explains Kevin Reimer, operations manager atSonic Drill Corporation. The new drill headswere for rig conversions. Drilling contractorscould replace their rotary drill head with asonic head, converting their existing gear intoa high-performance sonic drilling rig. “Rigconversions can be a very time-consumingand costly undertaking,” Reimer says. In mostcases it’s more economical to purchase a completelynew machine rather than undertake aconversion. “It’s for this reason that five yearsago we debuted our first completely new sonicdrill rig.”The company’s sales soon exploded, forcingthem to move several times to keep upwith the demand. Today, their shop is locatedin Port Kells, which is an industrial area in theVancouver suburb of Surrey. But once again,they have outgrown the facility. “We’ve beenhere for almost two years but it’s time to moveagain,” Reimer says. This time, the company isbuilding its own shop, a large, state-of-the-artfacility in Chilliwack, B.C. that’s scheduled tobe finished in early 2007.Right now, Reimer says due to space limitations,they have to subcontract some aspectsof production and work with suppliers forjust-in-time delivery of components. “Once wemake the move, we will be able to produce everythingin-house and under one roof,” he says.“In addition, the new building will provideus with more space for parts inventory. Rightwww.finning.ca Winter 2006 • TRACKS & TREADS 19

EQUIPMENT PROFILEnow, I have engines, undercarriages andother large parts stored off-site. That’s anarea where <strong>Finning</strong> has really helped us.They’re able to store our Cat engines andCat OEM undercarriages right up to thetime we need them.”The company produces crawlermountedand truck-mounted machines,both of which use the CaterpillarC-7 250 BHP Tier 3 diesel power plant.“The Cat engine is the only engine weuse,” says Reimer. “Our machines aredesigned around the C-7 engine. It wasan easy choice, as our principal, Tom Savage,has a long and successful history ofdeveloping <strong>equipment</strong> with <strong>Finning</strong> andCaterpillar.”For the undercarriages on the crawlermachines, it’s a similar story with onlyCat iron being used for the drill crawlers.Sonic Drill Corporation producestwo crawler models, the SDC550-18and the SDC550-28. The main differencesbetween the two are the size of thecarrier and the capability of the drillingmast. The SDC550-18 is mountedon a Caterpillar crawler model 312C,while the larger SDC550-28 operates onCaterpillar 315CL. Both carriers feature20-inch (500-mm) triple grouser steelshoes while rubber tracks are available asan option, as is a slew-bearing and swingdrivepackage.For the truck-mounted packages,Sonic Drill Corporation offers several differentconfigurations, including two thatrun off a deck-mounted Cat C-7 engineand two PTO (Power Take Off) models,which run off the truck’s diesel engine.“We’ve worked closely with Caterpillarand <strong>Finning</strong> over the years to come upwith the ideal engine performance packagefor our products,” Reimer says. “Caterpillarhelped us with work on a customhydraulic oil cooler and radiator coolingrequirements and they have rated our C-7 engines at a slightly lower than standardrpm, which is a safety measure toprevent the hydraulic pumps from overspeeding.”That safety measure has not“We’ve worked closelywith Caterpillar and<strong>Finning</strong> over theyears to come upwith the ideal engineperformance packagefor our products,”Kevin Reimer,Operations ManagerTOP: Sonic Drill uses Cat technology to succeed.RIGHT: Sonic drills work nearly three times fasterthan conventional models20 TRACKS & TREADS • Winter 2006 www.finning.ca

impacted the units’ maximum availablehorsepower.Reimer says that using one type ofengine for all of their products streamlinesthe production process. Anothermajor advantage of using the Cat C-7 asthe engine of choice is the environmentalbenefits. The new C-7 power plantincludes ACERT Technology, which providesexceptional power and fuel efficiencywhile meeting the new U.S. EPATier 3 emissions requirements. The newTier 3 requirements are also required forthe Canadian and European markets.From start to finish, Reimer saysthe full cycle time required for buildingeither a crawler-mounted or truckmounteddrill rig is approximately 20weeks. “Typically we have the drill headsin stock and we keep a significant inventorylevel of key components on hand, soas soon as the order is received, we’ll getstarted. On the crawler-mounted rigs, thecrawler is the component that requiresthe longest lead time but we’re able towork with <strong>Finning</strong> so that the crawlersare in stock when we need them.”Most of Sonic Drill’s production isslated for specific orders, but Reimer saysthat they always have a stock rig in theproduction line as well. “Currently themachine we are building for stock will beon display at the National GroundwaterAssociation show that’s being held in LasVegas this December,” he says. “Stockmachines usually sell very quickly, asclients are always in a hurry to put amachine to work. So this machine willmost likely be sold before it goes to LasVegas, but with a delivery date followingthe show.”At the Las Vegas show, Sonic Drill Corporationwill also showcase their newestproduct, a fully automated radio-controlledrod handler that can automaticallyand safely draw rods from an indexingrack and load them into the drill head.To date, Sonic Drill Corporation hassupplied drilling rigs to numerous clientson four continents: North America,South America, Asia and Europe. “We arealso currently working on some potentialprojects in South Africa,” adds Reimer.Good VibrationsThe technique of sonic drillinguses rotating, pull-down andvibrating resonant sonic frequenciesthat can rapidlymove through most geologicalformations, includingmost types of rock. In theright conditions the sonicdrill is two to three timesfaster than any conventionalrotary drill.Sonic drilling has proven tobe very efficient especially in graveland boulder ground where otherrigs experience great difficulty due toloss of drill mud through gravel zones,and where other rigs must case thehole to prevent collapse of the boreholewall. Sonic drilling can also generateoutstanding continuous core samples.In recent years, the company’s sonicdrill has proven to be the fastest drillingmethod available for geothermalinstallations.The drill head is the key componentin sonic drilling technology.Sonic Drill Corporation’s Sonicor 50Kmodel works by sending high frequencymechanical oscillations downthe drill string to the bit. The frequenciescan be controlled and adjustedby the operator to match the geologicalconditions of the soil and rock.“Our people have the expertise to coordinatethe logistics of shipping heavy<strong>equipment</strong> via road, rail and ocean toany client in the world and all of ourrigs are manufactured in accordancewith strict European standards andregulations for CE conformity.”In addition to designing and buildingthe drill rigs, the company also hasa drilling contracting division called“Sonic Drilling Ltd.” that handles geothermaldrilling, environmental drillingand core sampling. Having theirown contracting group provides thecompany with the real-world scenariosneeded for successfully testing its products.“Feedback from our own drillingcrews and our customers is instrumentalin developing a machine that’s idealfor our markets,” says Reimer. “We arevery customer-service oriented andusing our own machines in the fieldhelps us come up with innovativedesigns that work for our customers.”The speed advantage of a sonic drillover a conventional rotary drill isachieved when the high frequencyvibrations fluidize the soil particles atthe bit face, allowing easy penetrationin most geological formations, includingboulders and bedrock.A compact gear box requires onlyone hydraulic motor that drives theoscillator with counter rotating rollers.This creates the high sinusoidalforces that are transmitted to the drillbit. An internal air spring isolatesvibrations from the rest of the rig. Thefrequency is adjustable between 50and 160 hertz (cycles per second),which is lower than sound vibrationsthat can be heard by humans.www.finning.ca Winter 2006 • TRACKS & TREADS 21

Safety FirstBY BILL TICEASK ANYONE WORKING OUTSIDE DURING CANADA’S LONG WINTER MONTHSABOUT THE EFFECTS OF GLOBAL WARMING AND THEY ARE LIKELY TO HAVEA GOOD LAUGHWork Safelyin WinterAnd yes, what your mother told youabout wearing a hat is true.When the temperatures drop into theminus teens and lower, and the risk of hypothermiaand frostbite rises, the only warmingeffect on an outdoor worker’s mind isthat long-awaited vacation in Mexico, orthat thermos of hot coffee on the seat oftheir nearby pick-up truck. But that steamycup of java that you think will give youa warm and fuzzy feeling inside, mayjust have a negative effect on how yourbody handles frigid conditions.Coffee, or any beverage containingcaffeine, acts as a stimulant. This cancause the heart to beat faster, whichcan speed the onset of hypothermiaand constrict blood vessels makingfingers and toes colder. And despitethe pleasant warming effect that a shotof whisky has on your cheeks, alcohol isnot a good way to stoke the internal furnace.It makes your body less able to dealwith the effects of cold, and both alcoholand caffeine dehydrate, making hypothermiamore likely. According to cold weathersurvival experts, during winter conditionsyou should stay hydrated, but do it withwater, either cold or warm, and consumehigh energy snacks and foods, such as nutsand granola bars.But there’s much more to staying healthywhile working in winter conditions than justdrinking and eating right. Wearing the rightclothes also has a major impact on yourhealth and safety. And yes, what your mothertold you about wearing a hat is true. Bodyheat does escape through your head, so keepit covered, preferably with something thatdrops down below your ears. As for the restof your clothing – think layers. That way asthe winter sun warms up the landscape, youcan stay comfortable by removing a layer ofclothing.In addition to safety issues, cold weathercan be expensive for organizations such asthe Workers’ Compensation Board (WCB).In 2005, claims related to cold environmentalconditions cost the Alberta WCB almost$82,000, which was down substantiallyfrom the almost $481,000 they paid out in2004. Add that number to the cost of claimsrelated to ice, sleet and snow – just over$166,000 in 2005 and almost $350,000 in2004, and you can have an expensive problemwhen the mercury drops.At <strong>Finning</strong>’s Ekati Branch, which is located350 kilometres northeast of Yellowknifein the Northwest Territories, winter conditionscan be more than expensive, theycan be deadly. “At this branch we have tobe extremely well focused on safety,” saysNorby Gerstel, Ekati’s branch operationsmanager. “If someone has a life-threateninginjury and we have a whiteout condition,it could be days before we can get aplane in. So working safely is always takenvery seriously.”Slips, trips and falls – a concern on anywork site – become more serious when ice,snow and water are involved. To help preventslipping, workers use Yaktrax, whichare light-weight traction devices that aregenerally made with steel wires and slipover the sole of your boots. Much like wirechains for your car’s tires. The beauty of Yaktraxis that if you go from icy conditions toworking on a steel piece of <strong>equipment</strong>, youcan easily take the tracks right off your bootsto avoid steel-on-steel slip hazards.As for clothing at the sub-Arctic worksite,Gerstel says <strong>Finning</strong> supplies employeesworking at the branch with outdoor gearthat is designed for temperatures as lowas 70 and 80 degrees below zero.Staying safe is also a prominenttopic in morning meetings, andspecial rules for working near thetreeline are discussed in greatdetail. This includes working ina “buddy system” and, if you areventuring out, making sure youhave a full tank of gas in yourvehicle. Whiteout conditions arefairly common and can last from anumber of hours to a number of days,and if you are out in a vehicle during oneof these times, you have to pull over andwait it out. Whiteout conditions at Ekatiare prioritized as levels 1, 2 or 3. During alevel-3 whiteout, Gerstel explains, all outdooractivity is suspended.Ekati is definitely more extreme thanmany of the locations where <strong>Finning</strong>’semployees and customers work and reside.But the principles are the same – make gooddecisions when it comes to food and beverages,wear appropriate clothing, and beaware of the conditions that Mother Naturemight throw your way. One last thing – thinkabout that tropical beach vacation frequently.If nothing else, it might help you forgethow cold it is.ILLUSTRATION BY SYLVIE BOURBONNIÈRE22 TRACKS & TREADS • Winter 2006 www.finning.ca

Industry ReportThe Landscaping andNursery Trades24Nursing the Landscape ToolingWestern <strong>Canada</strong>’s economyis growing. Businesses andmunicipalities are seeingthe importance of beingsurrounded by healthygreen spaces27AroundKeeping up with thedemands of industryrequires the right toolsand the support to usethem efficiently.These days, landscaping is about more thana patch of grass and a tree. The industry isblooming in the residential and commercial sectors.Find out about how the pros are tacklingcomplex jobs and how schools are educatingthe next generation.More than ever, innovative design ideas arespurring on the development of new tools. Andlandscapers are using those tools to carve outa vibrant livelihood. Meet some of the pros atwork in Western <strong>Canada</strong>.www.finning.ca Winter 2006 • TRACKS & TREADS 23

PHOTOGRAPHY COURTESY LANTANursingtheLandscapeWith Western <strong>Canada</strong>’s economy growinglike a weed, more people, businesses andmunicipalities are seeing the importanceof being surrounded by healthy greenspaces. And the landscaping, nursery andhorticulture industry is blooming. Along withthe green boom comes a changing aestheticin the industry. At one time it was more aboutcovering the dirt with lawn; today landscaping hasmore to do with creating sanctuaries.Jane Stock, executive director of the BritishColumbia Landscaping and Nursery Association(BCLNA), estimates that $1 billion per year is pumpedinto the economy through the landscaping trades.Membership in provincial trade associations isstrong as well. There are 750 members in BCLNA and360 members in the Landscape Alberta Nursery TradesAssociation (LANTA). Because many memberships arecorporately held, each member represents an estimated10 or more individuals who are connected to theindustry.Professional landscaping and design is a relativelynew field in <strong>Canada</strong>. “Today people at the regularBusinesses andmunicipalities are seeingthe importance of beingsurrounded by green spacesB Y K A T H E R I N E F A W C E T Thomeowner level don’t have time to landscape,” Stocksays, and so there has been a loss of knowledge abouthorticulture in the general population as we urbanize.The average Canadian no longer has the knowledge tocreate and maintain a vibrant green space.Know-how is necessary to maintain a healthygrowing environment, Stock says. Different plantshave different requirements for drainage, locationand soil. Without someone knowledgeable in theseelements, a landscaped space won’t thrive. “You needto understand the life cycle of insects and weeds, too,”Stock says. “An increasing number of people are saying‘I don’t have the time.’”The industry is responding by increasing itsstandards and offering more educational andapprenticeship opportunities for pros who want tospecialize. <strong>Finning</strong> (<strong>Canada</strong>) is a major sponsor ofthose initiatives.The industry has introduced the CertifiedHorticultural Program (CHT) to answer calls for highqualityspecialists in what is still an unlicensed field.After practitioners pass written and practical skillsevaluations, and prove themselves by working in the24 TRACKS & TREADS • Winter 2006 www.finning.ca

field for a minimum of 2,000 hours, CHT designationprovides landscapers with international recognition.Nigel Bowles, executive director of the LandscapeAlberta Nursery Trades Association, says that advancedtraining at the professional certified landscapers level isbettering the field.“It’s a complex field,” says Bowles.“Plant identification;the right and wrong way to plant a tree;pesticide spraying. You have to be very knowledgeable.An understanding of botany is fundamental, rightdown to the cellular level.”Students in the landscaping and nursery tradeslearn planting, plant identification, and disease andpest control and prevention. There is also a growingdemand for people skilled at designing and layingstonework and paving stones, and building retainingwalls. Ornamental water features are also becomingpopular. “These have become hot in the residentialmarket,” says Bowles.Bowles sees a new sophistication in the consumer.Fifteen or 20 years ago a patch of grass and a tree wereadequate. “Today people realize that the house doesn’tbegin at the front door, it begins at the garden gate,” hesays. “The landscape has become part of entertainingculture… where people really want to spend time, havepeople over, and relax.”As well as the big-money projects, there’s anincreasing number of people who place a high priorityon glorifying their outdoor living space. They’reinterested in doing the landscaping work aroundtheir homes themselves, but need some direction.For between $75 and $200 per hour, a professionallandscaping consultant can take a look at a yard andgive advice, sketches and suggestions on plant and treechoices and help residents avoid mistakes.“When people are looking at redesign or a newlandscape it’s a wise buying decision to bring in adesigner for a consultation,” says Stock. For thoseplanning to sell, it’s no secret that property valueis enhanced by the landscape, and a landscapeconsultant’s advice can certainly make a difference inthe final sale.Some people also choose to get regular landscapinghelp weekly, monthly, or even yearly to do thepruning, which is quite specialized and can aid insectsuppression and lawn survival.Both B.C. and Alberta’s landscaping associationsfield calls from governments on landscaping issuesoutside private jurisdiction. “I’m seeing an increase inthe number of government agencies and municipalitiesthat contact us for information or to initiate action,”says Stock. “Many municipalities want to deal withus regarding sustainable urban landscapes, pestmanagement, water cleanliness, waste reduction, airquality and plant selection.”The good news is that the landscaping industry isready to provide leadership in quality standards and setthe tone for a greener, healthier tomorrow.Clients have increasingly higher expectationsof landscapers, as is seen in this West Vancouvergarden. (See sidebar next page)www.finning.ca Winter 2006 • TRACKS & TREADS 25

3Old-world Elegance in West VanWhen her clients said they wanted a structuredgarden with “old French” influence, landscape designer MarcynWard knew she was in for a challenge.“It wasn’t unanimous. During meetings with building architects,many people thought a more natural-looking conceptwould be suitable.” After all, Vancouver is famous for its laidbackattitude, where most landscapes tend towards the unsculpted.“The client had a picture of an old-world-Europeangarden,” says Ward. “She stuck to her vision, and everyone’svery pleased.”The folks at BC Landscaping and Nursery Association(BCLNA) recently presented Ward and her partner PeterSchradi of Down to Earth Landscapes the award for best landscapedinstallation in a single family residence in the over$120,000 category.For Tomorrow’s LandscapesBy supporting and loaning <strong>equipment</strong> to educational facilities, <strong>Finning</strong>(<strong>Canada</strong>) is raising the standards for the landscaping and horticultureindustry. The company is also introducing Caterpillar products to anemerging market: the landscapers of tomorrow.“<strong>Canada</strong>’s on the cutting edge when it comes to opportunities foreducation and certification,” says Lyall Megaw, <strong>Finning</strong>’s industrymarketing manager. “With our participation we’ve tried to align ourselveswith industry.”Megaw recognizes that the more students are exposed to Caterpillarproducts, the more likely they are to become customers once they’reactive landscapers. “Landscaping is the number one growth area forCaterpillar – skid steers and the small products line,” he says. “We’recommitted to this market.”A recent drop in government funding for many of the landscapingand horticulture programs has created a void <strong>Finning</strong> is eager to fill.The company provides <strong>equipment</strong> and sponsorship to the CertifiedHorticulture Technician (CHT) program. CHT status is awarded to employeesworking in landscaping or retail horticulture with over 2,000hours of experience and who pass a written and practical test.<strong>Finning</strong> is also a main sponsor of Skills <strong>Canada</strong>, an annual competitionfor skilled workers. Bob Haraba, chair of Skills <strong>Canada</strong> ProvincialTechnical Committee for Heavy Equipment Service says that theuse of two Caterpillar skid-steer loaders and mini-excavator and thepresentation of custom-made trophies by <strong>Finning</strong> to every competitor“gave the event a truly professional edge.”At Olds College, students learn industry skills year-round in a12,000 square-foot indoor construction site. “We’re lucky enough tohave <strong>equipment</strong> on loan from <strong>Finning</strong> to teach and learn with,” saysJack Berggren, instructional assistant at the College.On hand are a skid steer, a mini-excavator, a stump-removal log machine,a Cat trencher tool and more.“The students learn better if they go out and do the work. We’re ahands-on college. We have to have the most up-to-date, best <strong>equipment</strong>– the <strong>equipment</strong> they would use in industry. That’s where <strong>Finning</strong>comes in.”Krista Manton, HortEducation B.C. workshop coordinator helpscreate opportunities for landscaping pros, students and customers tolearn about new products and techniques. It’s a joint effort betweenBC Landscaping and Nursery Association, HortBC and <strong>Finning</strong>.In the past year, four such workshops have taken place throughoutBC. “At the open houses people get a chance to play on their <strong>equipment</strong>,then take part in the educational component – the commercialvehicle safety and building your landscape business seminars.”Manton raves about <strong>Finning</strong>’s participation. “They have been justunstoppable, from the landscape perspective,” she says. “It’s had agreat impact.”26 TRACKS & TREADS • Winter 2006 www.finning.ca

ToolingAroundKeeping up with the demands of a thrivingindustry requires the right tools and machines.It also requires the support to use themefficiently. And when the job is a bit out of theordinary, the “right” tools and machines arenot enough. They have to be extraordinary.Michael Anderchek lives and works in Sechelt,a rugged but scenic town on B.C.’s SunshineCoast. Many of the waterfront homes backup against steep slopes. Others are perched oncraggy hills overlooking the ocean. It may be anartist’s dream, but some landscapers might considerit a nightmare. Certainly, the terrain makes the jobdifficult. Anderchek enjoys the challenge; for the pastdecade his company, Deluxe Landscaping, has made abusiness of tackling landscaping jobs, commercial andresidential. “We definitely get the more difficult jobs,”he says.Anderchek relies on his <strong>equipment</strong>: a 267B Cat skidsteer,a mini-excavator and four dump trucks. “We’vegot the <strong>equipment</strong> to be able to move stuff moreefficiently,” says Anderchek. “When you’re dealingwith a truckload of turf or paving stones, you wantLandscapers know thatthe right tools and supportadd value to their services,and beauty to theirclient’s groundsB Y K A T H E R I N E F A W C E T Tto be able to move it all at once. It makes a differencerather than going back and forth.”Landscaping that frames million-dollar views caninvolve some risky manoeuvers. Moving a load oftopsoil or stones up a steep incline can be daunting.“One wrong move and you’re in the sea.”To tackle those steep grades, the 18-inch tracks onhis skid steer give a much greater grip on loose, roughmaterial. “With the track width and length, there’s justthat much more contact with the ground – about eightsquare feet (nearly three-quarters of a metre) per track.It makes a big difference.”“The tracks float over the terrain, which can bebumpy and rocky,” Andercheck says. “Other rigs canbounce up and down. With this one, you can rake ita little smoother and with the low ground pressurethere’s less soil disturbance. Less of a mess.” Andminding the mess is a landscaper’s business.Other tools Anderchek relies on are the post-holeauger used for planting hedges and installing fenceposts, and his four-in-one bucket, used to remove orrelocate large rocks, or to pull out roots and stumps ofbig old West Coast trees.www.finning.ca Winter 2006 • TRACKS & TREADS 27

In the foothills west of Calgary, though Lorne Bittner isalso in the landscaping business, but he has whole differentset of problems. He may not have to worry about fallinginto the sea, but he is up to his coveralls in shrubs, trees andsod. Lorne’s father started Bittner Construction in 1968.A few years ago Lorne decided to concentrate on the freshair work rather than the bricks and mortar of building. Hisdecision to move into the landscaping sector is paying off inspades. Bittner recently undertook a contract with MonterraDevelopment to do all the landscaping for a new, 700-acre(285-hectare) Cochrane Lake community.In a place where the average home runs in the milliondollarrange, with lake- or reservoir-fronts and mountainviews for every property, landscaping is crucial to development.“Everything has to be just right,” says Bittner.“It’s been a real learning experience. Figuring out what weneed to get the job done has been very involved. <strong>Finning</strong>’sbeen really good giving us demos.”One <strong>equipment</strong> demo showed him uses for his landscaperake. It’s one piece of <strong>equipment</strong> Bittner says he couldn’t livewithout. “It’s like a big rock-picker. It mounts on the skidsteer,picks rocks out of the loam, levels it, and conditions itfor the sod.” He also appreciates his new front-mount anglebroom, which makes clean-up on the new roads a breeze.Creating shade and beauty in development means about150 trees to start with – birch, aspen, spruce and othernative varieties – plus around 200 shrubs. For the trees,Bittner uses a heavy-duty auger with a 36-inch bit. “It makesfast work,” says Bittner who enjoys seeing the results of hiswork take shape quickly. “Same with the materials handlingarm, a mini-boom that we use for transporting treesaround. The pallet fork attachment is great too.”Bittner says his eight-foot bulldozer blade took somegetting used to, but was incredibly efficient. “The guys werehesitant to use it at first. It basically does grade-levellingbefore we go in there with the loam. It’s so much faster thanworking with buckets.”on the landscaping side. “We got caught in the middle,between the customer and person doing the work,” he says.“Now we’re the contractor. We eliminated the middle-man.”Demand is so high, Gyrwacheski and his approximately 50employees can’t keep up.Swan Lake plants and looks after the trees; that’s theirspecialty. Grywacheski uses a Cat 904 wheel loader with ageneral purpose bucket, a 12-foot snow blade, tree handler,and pallet forks. “I bought it this spring,” says Grywacheski.The forks are also used for unloading bags of fertilizer, sodand other commodities.Safety and efficiency are two important contributors tohis enthusiasm about the new machine. “With the reachof this machine, I can get right into the load, and haveone less person helping. Of course that makes it safer,”says Grywacheski. “There’s a cost factor too.” He also ravesabout the visibility from the cab of the new machine.“The operator of the machine can see better. You have astraightforward view. Again, it’s about safety. We’re alwayslooking for ways to make it better.”Famous for its orchards and vineyards, Vernon B.C.lies at the north end of the beautiful Okanagan Valley.Nearby are vast boreal forests, and the desert of the GreatBasin to the south. It’s no wonder Glen Grywacheski, ownerof Swan Lake Nurseryland has a difficult time answering“what kinds of trees do you plant?”“That’s a loaded question,” he jokes. “A better questionwould be ‘what don’t I plant?’”Swan Lake has been a family business since 1958. Oneof B.C.’s largest and most well-established businesses, itcurrently operates fruit farms and a nursery, and is doingmore and more residential landscaping work. While theretail and distribution end have always been strong,Grywacheski was getting frustrated acting as a go-between28 TRACKS & TREADS • Winter 2006 www.finning.ca

Glen Hubick, owner of Countryside Nursery inDeWinton, Alberta says he’s not an exclusive Catcustomer. But you’d never know it from the way hetalks. He demonstrates different makes and modelsof machines every year. He says he doesn’t choosehis <strong>equipment</strong> based on the name, but based onthe performance, efficiency, and ease of use. “Yeah,this year we went with Cat entirely,” he admits. “Butwe’ll continue to try new machines. We try all themachines every year.”Hubick currently operates his landscaping andtree farming business with a 307 Cat track hoe, 277Cat skid steer track machine, plus a 262 and a 242Cat skid steer. “It comes down to the guys in themachines. If they’re complaining about <strong>equipment</strong>,I’m the first one to know about it. I don’t run thecompany, my employees do.”Like most employers, Hubick knows that inAlberta’s hot economy, companies should try to treatemployees well, ensuring their comfort and safety. Iftheir well-being and job satisfaction are undermined,there’s probably another job opportunity waiting forthem down the street.Also, in such an economic atmosphere, a day laidup with broken <strong>equipment</strong> can mean thousands ofdollars of lost revenue.Hubick says <strong>Finning</strong>’s strength is in its commitmentto service. “If we have a machine breakdown or there’s a complication, we bend somethingor whatever, no matter where you are, it’s prettymuch a half-hour’s distance to a dealership,” saysHubick. And, if there are complications, anothermachine is delivered to him immediately. “We’verealized that our downtime has improved probably50% this year. That’s considerable, in this market.”“It doesn’t tear up theground like chains or steeltracks. And it’s a muchsmoother ride because ithas a much more flexiblesuspension.”-Glen Hubick, ownerCountryside NurseryOne machine Hubick says he’s come to depend onis his 277 skid steer track machine – especially inthe spring when the frost break-up occurs and he’sworking in muddy, sloppy conditions. “The 277means no more chains. The tracks provide flotation,plus traction going through the mud.” Hubick wassurprised at the efficiency of the rubber track. “Itdoesn’t tear up the ground like chains or steel tracks.And it’s a much smoother ride because it has a muchmore flexible suspension.”Next season he’ll demo other companies’<strong>equipment</strong> once again to make sure he’s getting thebest product for his needs, but he admits otherswould be hard-pressed to beat <strong>Finning</strong> in the aftersalecare.“<strong>Finning</strong> is always in touch with us to try toimprove our business,” says Hubick. “If there’s a newattachment, they talk to the employees about howthe comfort is, how their fatigue is at the end of theday. They look at us as a large corporation, but we’rejust a small landscape business.”Back HoeShown on a Cat 226AugerShown on a Cat 267BBucketShown on a Cat 262BladeShown on a Cat 267RakeShown on a Cat 262Fork LiftShown on a Cat 267www.finning.ca Winter 2006 • TRACKS & TREADS 29

COMPANY PROFILE: Whissell ContractingSewer and water projects are Whissel Contracting’s mainstayPHOTOGRAPHY BY ROTH & RAMBERG30 TRACKS & TREADS • Winter 2006 www.finning.ca

Calgary contractor staresdown the biggest, toughestjobs and doesn’t blinkWhissellWhile YouWorkB Y D A V I D D I C E N Z OWhissell uses yellow iron to clean the BowRiver. Inset shows satellite image of bridgedisplacementTo the people in the city of Calgary, the summerof 2005 was a startling reminder of the indiscriminatepower Mother Nature possesses. Rain poureddown throughout June in record amounts andCowtown unfortunately felt the full brunt, fromthe flooded parks and golf courses to the overflowingsewers. The rising waters of the Bow River became so furiousthat a private bridge owned by Lafarge <strong>Canada</strong> crumpled.The office of Whissell Contracting Calgary Ltd. stands about akilometer away from the exact spot where the Lafarge bridge collapsed.Nearly a year later, Whissell got the call to send some staff inand help extract the huge piece of debris, which had overturned andbecome a real issue within the Calgary community. It was a messand was very visible to the many drivers passing the site daily.Hauling that mess out of the river would be one tough job – ajob that had Whissell written all over it. It was the kind of work thecontracting operation has developed a reputation for in its 36 yearsof business.“We pride ourselves on being able to do the biggest and toughestjobs out there,” says owner Brian Whissell.With approximately 115 tonnes of busted bridge measuring 100feet (30 m) in length parked in the mighty Bow for almost one fullyear, the task set out for Whissell in April 2006 was far from small.“I was away when the bridge collapsed but my guys were callingme every couple of hours with updates,” says Bruce Whale, Lafarge’sgeneral manager of aggregates. “Then they called and said that oneof the bridge’s three trusses was gone.“It was a critical situation.”There were environmental considerations with the job thatforced Whissell to act quickly once the water had finally recededenough to begin. In order to preserve fish habitat in the renownedriver, they were allotted a two-week window to complete the work.Initially, it may have been a daunting job but with the help oftwo rock-solid Caterpillar 385 and 365 excavators, the cleanupended up being surprisingly fast.“There had been tons of rain,” says long-time Whissell employeeBill Heatherington. “The water in the Bow got so high that it washedout one of the three spans of this double-T bridge and carried itabout 80 metres down the river. Lafarge needed it out, so we originallythought about trying to break it up into pieces or rolling it overand dragging it out.”Neither method ended up being necessary. Heatherington,Whissell’s operations manager, looked up the specs of his iron inthe Cat handbook and estimated the machines could handle theload. The two excavators were sent into the river and despite the factthat pieces were coming off of the huge components of the bridge,the two Cats needed just three hours to get the debris out of theriver. And it took just another three to break up all the pre-stressedconcrete into transportable chunks once it hit the shore.“It was the first day of the two-week window,” says Whale.“They were in and out before most people even knew what hadhappened.”“We figured it would take about two full days of work,” saysHeatherington, adding that the job was the first time the new 365had ever been used by Whissell. “As it turned out, it was easier thananyone thought.www.finning.ca Winter 2006 • TRACKS & TREADS 31