equipment profile - Finning Canada

equipment profile - Finning Canada

equipment profile - Finning Canada

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

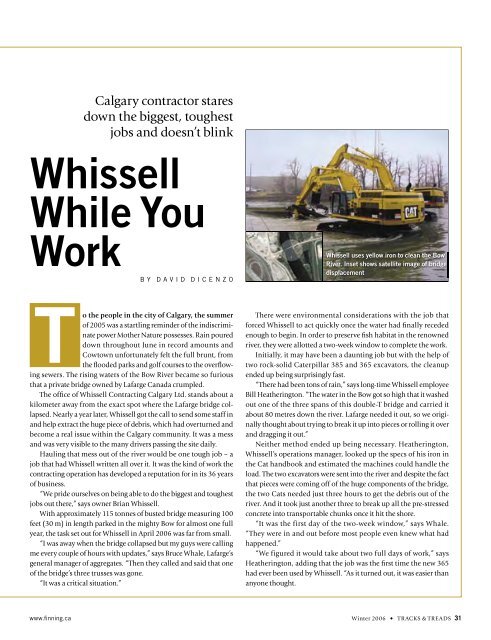

Calgary contractor staresdown the biggest, toughestjobs and doesn’t blinkWhissellWhile YouWorkB Y D A V I D D I C E N Z OWhissell uses yellow iron to clean the BowRiver. Inset shows satellite image of bridgedisplacementTo the people in the city of Calgary, the summerof 2005 was a startling reminder of the indiscriminatepower Mother Nature possesses. Rain poureddown throughout June in record amounts andCowtown unfortunately felt the full brunt, fromthe flooded parks and golf courses to the overflowingsewers. The rising waters of the Bow River became so furiousthat a private bridge owned by Lafarge <strong>Canada</strong> crumpled.The office of Whissell Contracting Calgary Ltd. stands about akilometer away from the exact spot where the Lafarge bridge collapsed.Nearly a year later, Whissell got the call to send some staff inand help extract the huge piece of debris, which had overturned andbecome a real issue within the Calgary community. It was a messand was very visible to the many drivers passing the site daily.Hauling that mess out of the river would be one tough job – ajob that had Whissell written all over it. It was the kind of work thecontracting operation has developed a reputation for in its 36 yearsof business.“We pride ourselves on being able to do the biggest and toughestjobs out there,” says owner Brian Whissell.With approximately 115 tonnes of busted bridge measuring 100feet (30 m) in length parked in the mighty Bow for almost one fullyear, the task set out for Whissell in April 2006 was far from small.“I was away when the bridge collapsed but my guys were callingme every couple of hours with updates,” says Bruce Whale, Lafarge’sgeneral manager of aggregates. “Then they called and said that oneof the bridge’s three trusses was gone.“It was a critical situation.”There were environmental considerations with the job thatforced Whissell to act quickly once the water had finally recededenough to begin. In order to preserve fish habitat in the renownedriver, they were allotted a two-week window to complete the work.Initially, it may have been a daunting job but with the help oftwo rock-solid Caterpillar 385 and 365 excavators, the cleanupended up being surprisingly fast.“There had been tons of rain,” says long-time Whissell employeeBill Heatherington. “The water in the Bow got so high that it washedout one of the three spans of this double-T bridge and carried itabout 80 metres down the river. Lafarge needed it out, so we originallythought about trying to break it up into pieces or rolling it overand dragging it out.”Neither method ended up being necessary. Heatherington,Whissell’s operations manager, looked up the specs of his iron inthe Cat handbook and estimated the machines could handle theload. The two excavators were sent into the river and despite the factthat pieces were coming off of the huge components of the bridge,the two Cats needed just three hours to get the debris out of theriver. And it took just another three to break up all the pre-stressedconcrete into transportable chunks once it hit the shore.“It was the first day of the two-week window,” says Whale.“They were in and out before most people even knew what hadhappened.”“We figured it would take about two full days of work,” saysHeatherington, adding that the job was the first time the new 365had ever been used by Whissell. “As it turned out, it was easier thananyone thought.www.finning.ca Winter 2006 • TRACKS & TREADS 31