Evaluation of âSpot and Sweepâ Blasting as a Cost Effective ... - NSRP

Evaluation of âSpot and Sweepâ Blasting as a Cost Effective ... - NSRP

Evaluation of âSpot and Sweepâ Blasting as a Cost Effective ... - NSRP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

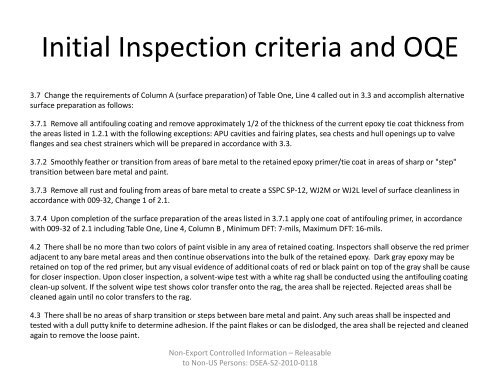

Initial Inspection criteria <strong>and</strong> OQE3.7 Change the requirements <strong>of</strong> Column A (surface preparation) <strong>of</strong> Table One, Line 4 called out in 3.3 <strong>and</strong> accomplish alternativesurface preparation <strong>as</strong> follows:3.7.1 Remove all antifouling coating <strong>and</strong> remove approximately 1/2 <strong>of</strong> the thickness <strong>of</strong> the current epoxy tie coat thickness fromthe are<strong>as</strong> listed in 1.2.1 with the following exceptions: APU cavities <strong>and</strong> fairing plates, sea chests <strong>and</strong> hull openings up to valveflanges <strong>and</strong> sea chest strainers which will be prepared in accordance with 3.3.3.7.2 Smoothly feather or transition from are<strong>as</strong> <strong>of</strong> bare metal to the retained epoxy primer/tie coat in are<strong>as</strong> <strong>of</strong> sharp or "step"transition between bare metal <strong>and</strong> paint.3.7.3 Remove all rust <strong>and</strong> fouling from are<strong>as</strong> <strong>of</strong> bare metal to create a SSPC SP-12, WJ2M or WJ2L level <strong>of</strong> surface cleanliness inaccordance with 009-32, Change 1 <strong>of</strong> 2.1.3.7.4 Upon completion <strong>of</strong> the surface preparation <strong>of</strong> the are<strong>as</strong> listed in 3.7.1 apply one coat <strong>of</strong> antifouling primer, in accordancewith 009-32 <strong>of</strong> 2.1 including Table One, Line 4, Column B , Minimum DFT: 7-mils, Maximum DFT: 16-mils.4.2 There shall be no more than two colors <strong>of</strong> paint visible in any area <strong>of</strong> retained coating. Inspectors shall observe the red primeradjacent to any bare metal are<strong>as</strong> <strong>and</strong> then continue observations into the bulk <strong>of</strong> the retained epoxy. Dark gray epoxy may beretained on top <strong>of</strong> the red primer, but any visual evidence <strong>of</strong> additional coats <strong>of</strong> red or black paint on top <strong>of</strong> the gray shall be causefor closer inspection. Upon closer inspection, a solvent-wipe test with a white rag shall be conducted using the antifouling coatingclean-up solvent. If the solvent wipe test shows color transfer onto the rag, the area shall be rejected. Rejected are<strong>as</strong> shall becleaned again until no color transfers to the rag.4.3 There shall be no are<strong>as</strong> <strong>of</strong> sharp transition or steps between bare metal <strong>and</strong> paint. Any such are<strong>as</strong> shall be inspected <strong>and</strong>tested with a dull putty knife to determine adhesion. If the paint flakes or can be dislodged, the area shall be rejected <strong>and</strong> cleanedagain to remove the loose paint.Non-Export Controlled Information – Rele<strong>as</strong>ableto Non-US Persons: DSEA-S2-2010-0118