Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

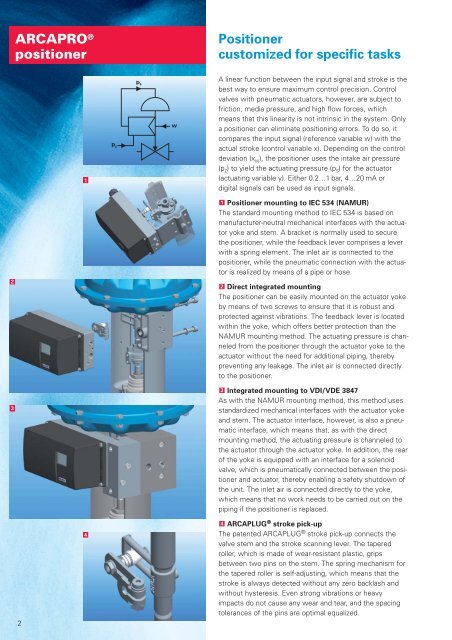

<strong>ARCA</strong>PRO ®<strong>positioner</strong>Positionercustomized for specific tasks231A linear function between the input signal and stroke is thebest way to ensure maximum control precision. Controlvalves with pneumatic actuators, however, are subject tofriction, media pressure, and high flow forces, whichmeans that this linearity is not intrinsic in the system. Onlya <strong>positioner</strong> can eliminate positioning errors. To do so, itcompares the input signal (reference variable w) with theactual stroke (control variable x). Depending on the controldeviation (x W), the <strong>positioner</strong> uses the intake air pressure(p Z) to yield the actuating pressure (p S) for the actuator(actuating variable y). Either 0.2…1 bar, 4…20 mA ordigital signals can be used as input signals.1 Positioner mounting to IEC 534 (NAMUR)The standard mounting method to IEC 534 is based onmanufacturer-neutral mechanical interfaces with the actuatoryoke and stem. A bracket is normally used to securethe <strong>positioner</strong>, while the feedback lever comprises a leverwith a spring element. The inlet air is connected to the<strong>positioner</strong>, while the pneumatic connection with the actuatoris realized by means of a pipe or hose.2 Direct integrated mountingThe <strong>positioner</strong> can be easily mounted on the actuator yokeby means of two screws to ensure that it is robust andprotected against vibrations. The feedback lever is locatedwithin the yoke, which offers better protection than theNAMUR mounting method. The actuating pressure is channeledfrom the <strong>positioner</strong> through the actuator yoke to theactuator without the need for additional piping, therebypreventing any leakage. The inlet air is connected directlyto the <strong>positioner</strong>.3 Integrated mounting to VDI/VDE 3847As with the NAMUR mounting method, this method usesstandardized mechanical interfaces with the actuator yokeand stem. The actuator interface, however, is also a pneumaticinterface, which means that, as with the directmounting method, the actuating pressure is channeled tothe actuator through the actuator yoke. In addition, the rearof the yoke is equipped with an interface for a solenoidvalve, which is pneumatically connected between the <strong>positioner</strong>and actuator, thereby enabling a safety shutdown ofthe unit. The inlet air is connected directly to the yoke,which means that no work needs to be carried out on thepiping if the <strong>positioner</strong> is replaced.244 <strong>ARCA</strong>PLUG ® stroke pick-upThe patented <strong>ARCA</strong>PLUG ® stroke pick-up connects thevalve stem and the stroke scanning lever. The taperedroller, which is made of wear-resistant plastic, gripsbetween two pins on the stem. The spring mechanism forthe tapered roller is self-adjusting, which means that thestroke is always detected without any zero backlash andwithout hysteresis. Even strong vibrations or heavyimpacts do not cause any wear and tear, and the spacingtolerances of the pins are optimal equalized.