Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>ARCA</strong>PRO ®<strong>positioner</strong>

<strong>ARCA</strong>PRO ®<strong>positioner</strong>Positionercustomized for specific tasks231A linear function between the input signal and stroke is thebest way to ensure maximum control precision. Controlvalves with pneumatic actuators, however, are subject tofriction, media pressure, and high flow forces, whichmeans that this linearity is not intrinsic in the system. Onlya <strong>positioner</strong> can eliminate positioning errors. To do so, itcompares the input signal (reference variable w) with theactual stroke (control variable x). Depending on the controldeviation (x W), the <strong>positioner</strong> uses the intake air pressure(p Z) to yield the actuating pressure (p S) for the actuator(actuating variable y). Either 0.2…1 bar, 4…20 mA ordigital signals can be used as input signals.1 Positioner mounting to IEC 534 (NAMUR)The standard mounting method to IEC 534 is based onmanufacturer-neutral mechanical interfaces with the actuatoryoke and stem. A bracket is normally used to securethe <strong>positioner</strong>, while the feedback lever comprises a leverwith a spring element. The inlet air is connected to the<strong>positioner</strong>, while the pneumatic connection with the actuatoris realized by means of a pipe or hose.2 Direct integrated mountingThe <strong>positioner</strong> can be easily mounted on the actuator yokeby means of two screws to ensure that it is robust andprotected against vibrations. The feedback lever is locatedwithin the yoke, which offers better protection than theNAMUR mounting method. The actuating pressure is channeledfrom the <strong>positioner</strong> through the actuator yoke to theactuator without the need for additional piping, therebypreventing any leakage. The inlet air is connected directlyto the <strong>positioner</strong>.3 Integrated mounting to VDI/VDE 3847As with the NAMUR mounting method, this method usesstandardized mechanical interfaces with the actuator yokeand stem. The actuator interface, however, is also a pneumaticinterface, which means that, as with the directmounting method, the actuating pressure is channeled tothe actuator through the actuator yoke. In addition, the rearof the yoke is equipped with an interface for a solenoidvalve, which is pneumatically connected between the <strong>positioner</strong>and actuator, thereby enabling a safety shutdown ofthe unit. The inlet air is connected directly to the yoke,which means that no work needs to be carried out on thepiping if the <strong>positioner</strong> is replaced.244 <strong>ARCA</strong>PLUG ® stroke pick-upThe patented <strong>ARCA</strong>PLUG ® stroke pick-up connects thevalve stem and the stroke scanning lever. The taperedroller, which is made of wear-resistant plastic, gripsbetween two pins on the stem. The spring mechanism forthe tapered roller is self-adjusting, which means that thestroke is always detected without any zero backlash andwithout hysteresis. Even strong vibrations or heavyimpacts do not cause any wear and tear, and the spacingtolerances of the pins are optimal equalized.

The classic design:analog <strong>positioner</strong> type 824<strong>ARCA</strong>PRO ® <strong>positioner</strong>Functional principlePositioner type 824 functions accordingto the tried-and-tested forcebalanceprinciple. The pneumatic setpointstandardized signal issued by apneumatic controller or I/p convertermodule generates a force on thediaphragm that is balanced with thespring force on the feedback shaft.The resulting difference in forcemoves the gate valve, which connectsthe actuator with the intake airor atmosphere, thereby controllingthe movement of the valve.Modular designPneumatic <strong>positioner</strong> type 824 ismodular in design and can be expandedwith a range of additionalmodules, thereby allowing it to beeasily customized for specific tasks.I/p converter moduleThe I/p converter module convertselectrical 0/4...20 mA input signalsto pneumatic standardized signalswith 0.2...1 bar for controlling the<strong>positioner</strong>.Limit switch moduleTwo adjustable inductive switchesenable checkback signals for limitpositions to be sent to the controlsystem (e. g. as NAMUR signal).Feedback potentiometerThe feedback potentiometer generatesa message containing the actualposition for evaluation in the controlsystem.The intelligent design:<strong>ARCA</strong>PRO ® digital <strong>positioner</strong> type 827AFunctional principle<strong>ARCA</strong>PRO ® is an intelligent, secondgeneration<strong>positioner</strong>. It not onlyoffers a wider range of functions andhigher level of reliability, but also featuresan advanced online diagnosticssystem and optional maintenance display.The position of the stem is sentto a potentiometer whose outputsignal is then compared with the setpointby the microprocessor. Using aspecial control algorithm, the controlleractivates the two piezo valves,which connect the actuator with theinlet air or atmosphere.The <strong>ARCA</strong>PRO ® <strong>positioner</strong> can beoperated locally or from the controlroom.Optimized operating modesThe <strong>ARCA</strong>PRO ® <strong>positioner</strong> supportsthe following operating modes:■ Automatic or manual mode■ Initialization■ Parameterization■ DiagnosticsModular designThe <strong>ARCA</strong>PRO ® <strong>positioner</strong> is compactand modular.Additional modules increase yourrange of options:■ Analog module: Position transmitterfor signaling the actual positionas a current signal of 4...20 mA■ Binary module: Two adjustablesoftware limit switches, fault signalingswitch, binary input■ Slot initiator module: Two variableinductive limit switches, faultsignaling switch■ Contact module: Two adjustablemechanical limit switchesAutomatic commissioningThe automatic initialization functionallows you to commission the <strong>positioner</strong>quickly and easily. The parameterscan be set on the device or bymeans of HART, PROFIBUS or FoundationFieldbus communication. Thefollowing parameters can be set:■ Setpoint direction, characteristic■ Split-range mode■ Tight closing function■ Function for position and faultsignaling outputs and the binaryinputs3

Additional modulesincrease your range of options<strong>ARCA</strong>PRO ® <strong>positioner</strong>Position transmitterThe position transmitter comprises thefeedback potentiometer and an R/Iconverter. It is used for signaling theactual position as a 0/4...20 mA signal.Gauge groupThe gauge group displays the inletair pressure, setpoint air pressureand actuating pressure. It also allowsyou to check whether or not the <strong>positioner</strong>is functioning properly.Explosion-protected designs(for type 827A too)■ Intrinsically safe (EEx ia and EEx ia/ib)■ Explosion-proof (EEx d)■ Non-sparking (EEx n)I/p module 0/4–20 mALimit switch modulePositioner type 824Position transmitter0/4–20 mAModule coverCommunicationDepending on the version, the<strong>ARCA</strong>PRO ® <strong>positioner</strong> enables communicationwith other field devices orprocess control systems via:■ HART■ PROFIBUS PA■ Foundation FieldbusAdvanced online diagnosticsto NE 91The advanced online diagnosticsfunction allows you to evaluate thestatus of the <strong>positioner</strong>. The diagnosticsvalues can be displayed locallyor queried via the communicationscable. A range of additional functionsthat enable even more accuratestatus analyses are also available:■ Partial stroke test■ Leak measurement■ Limit temperature monitoring■ Mean position value calculationMaintenance data to NE 107Three-stage limit value signaling toNE 107 can be carried out for theparameters acquired by means of theadvanced online diagnostics function.Slot initiator module(alternative)Contact module(alternative)Analog module (alternative)Filter moduleTo enable this, the relevant limit valuesthat trigger the signals must bedefined for the following statuses:■ Medium-term need for maintenance■ Urgent need for maintenance■ FailureMain electronicboardBinary module (alternative)The data is displayed on the deviceand can be sent to higher-level systemsvia the binary outputs or viaHART or bus communication. Thedata is normally evaluated in theprocess control system.4

Analog and digital –precision through innovation<strong>ARCA</strong>PRO ®<strong>positioner</strong>Since 1917 when it released its patented nozzle-flappersystem, <strong>ARCA</strong> has been at the forefront of the industry forcontrol valves with <strong>positioner</strong>s. Our advances over theyears have helped make modern <strong>positioner</strong> technologywhat it is today – and our state-of-the-art digital <strong>positioner</strong><strong>ARCA</strong>PRO ® is just the latest in a long line of innovations.Thanks to automatic adjustment in line with the controlvalve and user-friendly parameterization (e. g. direction ofaction, split range or stroke limitation), the system is easyto commission and operate. In addition, a range of variablediagnostics parameters allow preventive maintenancemeasures to be specially planned to avoid plant downtime.Modern communication options (e. g. HART, PROFIBUS,or Foundation Fieldbus) enable function and diagnosisparameters to be sent to process control systems forevaluation.1234567Our innovationClassic or intelligent digital <strong>positioner</strong>stried-and-tested over many yearsModular, retrofittable accessoryand option modulesIntegrated, pipe-free mountingPatented <strong>ARCA</strong>PLUG feedback leverMinimal air consumptionUniversal communicationAdvanced online diagnosticsHow you benefit■✔Long service life■✔Low lifecycle costs■✔Optimal adaptionto specific applications andcontrol systems■✔Compact design■✔High mechanical resistance■✔No sensitive piping■✔Self-adjusting■✔No hysteresis■✔Minimal wear and tear■✔Low operating costs■✔Easy adjustment in line with existingplant communication systems■✔All diagnostics data can be read on thedevice or in the control room■✔Self-monitoring of the complete valve■✔Precise planning of maintenancemeasureswww.arca-valve.com5

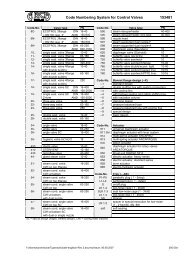

<strong>ARCA</strong>PRO ®<strong>positioner</strong>Positioner type 824General data Enclosure material Anodized aluminum / Glass-fiber-reinforced polyesterTemperature range –40…+80 °CSteady-state deviation < 0,5 %Linearity error < 2 %Hysteresis < 0,7 %Explosion protectionwithout / intrinsically safe / explosion-proofInput signal0,2…1 bar or 0/4…20 mA 2 wire connectionOption modules Position transmitter 4…20 mA, passive, 2/3 wire connection (not explosion proof)Limit switch2 NAMUR sensorsPneumatic data Inlet air pressure 1.4…6 barContinuous air consumption < 500 Ndm 3 /hMounting Linear actuators <strong>ARCA</strong>-integrated or to IEC 534; range of stroke 10…120 mmQuarter turn actuators To VDI/VDE 3845; angle of rotation 90°<strong>ARCA</strong>PRO ® <strong>positioner</strong> type 827AGeneral data Enclosure material Anodized aluminum, stainless steel, polycarbonateExplosion protectionTemperature range –30…+80 °CSteady-state deviation Typically < 0,3 %Linearity error Typically < 0,5 %Dead zone Self-adjusting (typically 0.3 %) or adjustable (0.1 % to 10 %)without / intrinsically safe / non-sparking / explosion-proofCommunication / input signal Standard / HART 4…20 mA 2 wire connection, 0/4…20 mA 3/4 wire connectionProfibus PA Profibus PA, profile B, version 3.0Foundation FieldbusH1 communicationBinary inputsSwitching or voltage inputs,parameterizable (e. g. «Move valve to CLOSED»)Option modules Analog module 4…20 mA position transmitter, passiveBinary moduleSlot initiator moduleContact modulePneumatic data Inlet air pressure 1.4…7 barContinuous air consumption < 36 Ndm 3 /h2 NAMUR limit switches, 1 NAMUR fault switch, 1 binary input2 inductive NAMUR limit switches, 1 NAMUR fault switch2 mechanical limit switchesMounting Linear actuators <strong>ARCA</strong>-integrated, integrated to VDI/VDE 3847 or to IEC 534;range of stroke 3…130 mmQuarter turn actuators Integrated to VDI/VDE 3847 or VDI/VDE 3845;angle of rotation 30…100°3049559 00 10.11.1 · Subject to change without notice<strong>ARCA</strong> Regler GmbHKempener Str.18, D-47918 TönisvorstPhone +49 (0)2156-7709-0, Fax +49 (0)2156 7709-55www.arca-valve.com, sale@arca-valve.com<strong>ARCA</strong> Flow Group worldwide: Competence in valves, pumps & cryogenicsvon <strong>Rohr</strong>Armaturen AGvon <strong>Rohr</strong><strong>ARCA</strong> <strong>BV</strong>