download - Bharat Petroleum

download - Bharat Petroleum

download - Bharat Petroleum

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

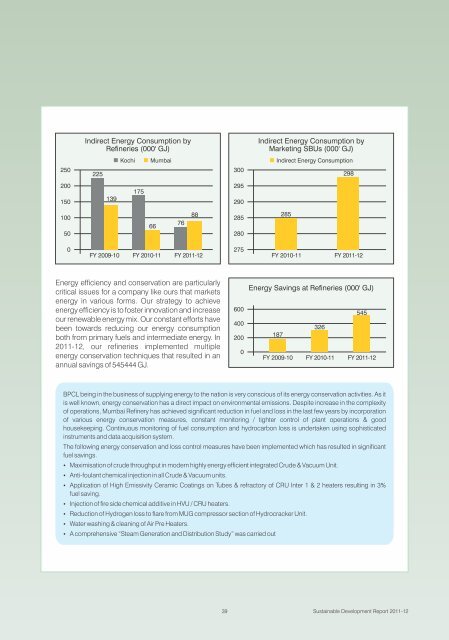

Indirect Energy Consumption byRefineries (000' GJ)Indirect Energy Consumption byMarketing SBUs (000' GJ)250225KochiMumbai300Indirect Energy Consumption298200150139175295290100506676882852802850FY 2009-10 FY 2010-11 FY 2011-12275FY 2010-11 FY 2011-12Energy efficiency and conservation are particularlycritical issues for a company like ours that marketsenergy in various forms. Our strategy to achieveenergy efficiency is to foster innovation and increaseour renewable energy mix. Our constant efforts havebeen towards reducing our energy consumptionboth from primary fuels and intermediate energy. In2011-12, our refineries implemented multipleenergy conservation techniques that resulted in anannual savings of 545444 GJ.6004002000Energy Savings at Refineries (000' GJ)545326187FY 2009-10 FY 2010-11 FY 2011-12BPCL being in the business of supplying energy to the nation is very conscious of its energy conservation activities. As itis well known, energy conservation has a direct impact on environmental emissions. Despite increase in the complexityof operations, Mumbai Refinery has achieved significant reduction in fuel and loss in the last few years by incorporationof various energy conservation measures, constant monitoring / tighter control of plant operations & goodhousekeeping. Continuous monitoring of fuel consumption and hydrocarbon loss is undertaken using sophisticatedinstruments and data acquisition system.The following energy conservation and loss control measures have been implemented which has resulted in significantfuel savings. Maximisation of crude throughput in modern highly energy efficient integrated Crude & Vacuum Unit. Anti-foulant chemical injection in all Crude & Vacuum units. Application of High Emissivity Ceramic Coatings on Tubes & refractory of CRU Inter 1 & 2 heaters resulting in 3%fuel saving. Injection of fire side chemical additive in HVU / CRU heaters. Reduction of Hydrogen loss to flare from MUG compressor section of Hydrocracker Unit. Water washing & cleaning of Air Pre Heaters. A comprehensive “Steam Generation and Distribution Study” was carried out39Sustainable Development Report 2011-12