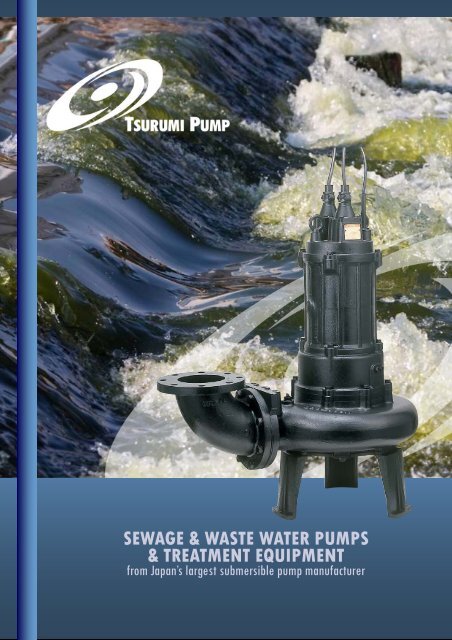

Tsurumi Industrial Pumps Introduction (Aug 2011).pub - Ferret

Tsurumi Industrial Pumps Introduction (Aug 2011).pub - Ferret

Tsurumi Industrial Pumps Introduction (Aug 2011).pub - Ferret

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Design FeaturesDABDouble Mechanical Seal insidethe oil, made of hardest siliconcarbidePatented Oil Lifter for forcedlubrication of the mechanical sealFCCThermal protection for motoragainst dry runningDAnti-wicking protection andintegrated tear relief at cableentryGEHigh tensile stainless steel shaftsupported by deep groove ballbearingsEFCopper windings with E-classinsulationBHGHSubmersible dry- type squirrelcage continuous duty ratedinduction motorMoisture sensor (30HP pumps &larger)Materials of the highest resistancefor a longer lifetimeAQuick maintenance in-housewith standard toolsLife-cycle costs significantlybelow industry averageWater Treatment equipmentLong life by designInstallation options;, Free standing, guide rail fitting, dry installationp 3Pump selection software available … Australian Pump 02 8865 3500

BZ SERIESBZ SERIES - channel impellerThe BZ SERIES <strong>Tsurumi</strong> submersible pumphas a proprietary single-channel, solidhandling impeller that allows the pump tohandle solids up to 80mm in diameterefficiently.Suitable for free-standing, guide railinstallations & dry pit designs.Discharge Model Motor Phase Head Capacity Starting Dry Max. Solid CableBore Output max. max. Method Weight Handling Length(mm) kW m l/min kg mm m80 80BZ41.5 1.5 3-phase 9.1 1480 d.o.l. 78 80 10100 100BZ42.2 2.2 3-phase 11.3 1800 d.o.l. 80 80 10100 100BZ43.7 3.7 3-phase 15.8 2220 d.o.l. 100 80 10100 100BZ45.5 5.5 3-phase 18 2630 d.o.l. 175 80 10100 100BZ47.5 7.5 3-phase 23 2960 d.o.l. 194 80 10100 100BZ411H 11 3-phase 30 2810 Star-Delta. 219 80 10100 100BZ411 11 3-phase 26 3570 Star-Delta. 219 80 10100 100BZ415 15 3-phase 11 1500 Star-Delta 295 80 10MG SERIES - grinder pumps, vortex impellerThe MG SERIES GRINDER <strong>Tsurumi</strong> submersible pump has a grinding mechanism in its suction port, and itcuts incoming solids into small pieces. This enables the pump to transfer sewage via a small diameterpipe without the fear of clogging.With the unique High Chrome grinder impeller and shredder plate design in the MG SERIES GRINDER,<strong>Tsurumi</strong> has the right model to handle every application to efficiently transfer the most aggressive solidladen liquids, in the pump market.Suitable for free-standing or guide rail installations.Discharge Model Motor Phase Head Capacity Starting Dry CableBore Output max. max. Method Weight Length(mm) kW m l/min kg m32 32MG21.0 1 3-phase 13 135 d.o.l. 36 1032 32MG21.5 1.5 3-phase 25 145 d.o.l. 34 1050 50MG22.2 2.2 3-phase 25 320 d.o.l. 54 1050 50MG23.7 3.7 3-phase 35 320 d.o.l. 55 10Australian Pump Industries (02) 8865 3500p 8

C SERIES - channel impeller with cutterThe C SERIES CUTTER <strong>Tsurumi</strong> submersible pump incorporates a channel impeller with cutter mechanism.A sintered tungsten carbide alloy tip is brazed on the impeller vane and rotates on the serrated part ofthe suction cover. This mechanism cuts fibrous matter that flows into the pump.The C SERIES CUTTER has a proven track record for offering long life in both continuousand intermittent sump applications, such as; hotels, prisons, commercial, restaurants & retailapplications where down time is unacceptable.C & SF SERIESSuitable for free-standing, guide rail installations & dry pit designs.Discharge Model Motor Phase Head Capacity Starting Dry Max. Solid Cable Auto option AlternationBore Output max. max. Method Weight Handling Length (2 floats) (3 floats)(mm) kW m l/min KG mm m CA CW50 50C2.75S 0.75 single 11.5 335 capacitor 32 21 5 [50 50C2.75 0.75 3-phase 11.5 335 d.o.l. 24 21 6 [ [80 80C21.5 1.5 3-phase 13.2 810 d.o.l. 36 37 6 [ [80 80C22.2-CR 2.2 3-phase 21 750 d.o.l. 70 22x31 680 80C23.7-CR 3.7 3-phase 29 650 d.o.l. 70 22x31 680 80C25.5-CR 5.5 3-phase 32 1340 d.o.l. 125 29x23 680 80C27.5-CR 7.5 3-phase 38 1000 d.o.l. 130 26x25 680 80C211-CR 11 3-phase 47 1200 d.o.l. 156 26x27 6100 100C42.2 2.2 3-phase 13.5 1100 d.o.l. 70 44 6100 100C43.7 3.7 3-phase 16 1700 d.o.l. 86 60 6100 100C45.5 5.5 3-phase 18.1 2290 d.o.l. 140 40 6100 100C47.5 7.5 3-phase 23 2500 d.o.l. 159 40 8100 100C411 11 3-phase 26 2750 Star-Delta. 184 50 8Channel impeller with cutterAutomatic version (CA)shown with TOS guide rail fittingSF SERIES - semi open impeller, effluent pumpsThe SF SERIES is a cast iron, effluent pump with a semi-open impeller.It is designed for high-head pumping and de-foaming at wastewatertreatment plants.Discharge Model Motor Phase Head Capacity Starting Dry Max. Solid CableBore Output max. max. Method Weight Handling Length(mm) kW m l/min kg mm m50 50SF2.75 0.75 3-phase 16 250 d.o.l. 20 11 650 50SF21.5 1.5 3-phase 10.5 475 d.o.l. 33 11 650 50SF22.2 2.2 3-phase 26 640 d.o.l. 49 7.5 650 50SF23.7 3.7 3-phase 36 650 d.o.l. 56 7.5 680 80SF25.5 5.5 3-phase 32.5 1250 d.o.l. 125 15 680 80SF27.5 7.5 3-phase 38 1800 d.o.l. 128 19 880 80SF211 11 3-phase 45 1900 d.o.l. 147 22 8p 9Pump selection software available … Australian Pump 02 8865 3500

SFQ SERIES - 316 stainless steel, corrosion resistant pumps, semi open impellerBER & SQF SERIESThe SFQ-series is made of austenitic cast 316 stainless steel, ideal for draining corrosive liquid inchemical plants or other industrial plants. The pump is a highly specialist pump in term of design andmaterials.Discharge Model Motor Phase Head Capacity Starting Dry Max. Solid CableBore Output max. max. Method Weight Handling Length(mm) kW m l/min kg mm m50 50SFQ2.4 0.4 3-phase 11.2 275 d.o.l. 20 6 1050 50SFQ2.75 0.75 3-phase 14.2 430 d.o.l. 22 6 1080 80SFQ21.5 1.5 3-phase 20.9 650 d.o.l. 36 6 1080 80SFQ23.7 3.7 3-phase 24.6 1180 d.o.l. 50 15 1080 80SFQ25.5 5.5 3-phase 30 1340 d.o.l. 124 18 1080 80SFQ27.5 7.5 3-phase 34.8 2000 d.o.l. 123 23 1080 80SFQ211 11 3-phase 44 1950 d.o.l. 143 23 10SQ pump shown withTOS guide rail fittingWater TreatmentBER Submersible EjectorThe BER is designed for both very high oxygen transfer and excellent mixing. The BER is used inSequence Batch Reactors where high oxygen transfer is required during the aeration cycle andwhen the air is shut off, mixing only during the anodic cycle., Ideal for SBR treatment systems., Superior oxygen transfer rate during aeration cycle., Excellent mixing for anodic cycle when aspirating air is off., Submersible aspirating aerators range in size 1 HP to 7.5 HP., Self aspiration of oxygen eliminates need for compressed air.Australian Pump Industries (02) 8865 3500p 10

TRN Submersible AeratorThe TRN is designed for very high oxygen transfer efficiency and to mix entrained solids., Non-clog impellers., Horsepower ranges from 1 hp to 50 hp., Can operate in water depth of 32 feet with supplemental blower., Powerful stirring and mixing capabilities for convectional circulation., Compact shape and design., Self aspiration of oxygen eliminates need for compressed air.KE & KM Bar ScreensMechanically cleaned bar screens; designed for the small plant inflows toremove solids from the wastewater, eliminating solids from aeration &Clarification tanks. Screen capacity range from 1 GPM to 690 GPM. Barspacing range from 1mm to 50mm. Screen is fabricate in 304 stainless steel forcorrosion resistance.TRN, FHP, KE & KM SERIESAPPLICATION, Primary treatment at a factory wastewater treatment plant, Screening suspended solid from kitchen effluent at hotel, factory, hospital, etc., Screening suspended solid from wastewater at small scale wastewater facilityThe KE/KS SERIES are front-type mechanical bar screens in which major parts are made of 304stainless steel. The saw teeth on each rake travel between screen bars, which prevents foreignmatters from lodging in the screen bars. The KS-series has an eccentric roller mechanism that pullsthe rake out of the screen bars at the solids releasing point and eliminates the jamming of solids.The KM/KMA SERIES are rear-type mechanical bar screens in which major parts are made of 304stainless steel. The chain and sprocket do not come in contact with the liquid that prevents stickingof solids to the rotating parts. Being a self-standing design, it can be directly installed to a U-shaped waterway.FHP Series decanting pumpThe FHP-series is a decanting pump with a device for monitoring the sludge surface. The pumpensures that only supernatant liquid is discharged, without any sediment.DischargeBore (mm)ModelMotorOutput KWFSP Series skimmer pumpPhaseStartingMethodDry Weight kgFREE STANDINGHead Max.mCapacity max./min40 FHP2-3 0.25 Capacitor 29.5 8 200 640 FHP2-3T 0.25 Capacitor 27.5 8 200 650 FHP-4 0.4 single Capacitor 29 10 280 650 FHP-4T 0.4 3-phase d.o.l. 27 10 280 650 FHP3-8T 0.75 3-phase d.o.l. 27.5 13 420 680 FHP2-15T 1.5 3-phase d.o.l. 60 11 800 6CablelengthmThe FSP-series is a scum skimmer incorporating a jet injector. It guarantees a stable sucking processeven if water, air, and suspended matter are drawn in from water surface simultaneously.DischargeBore (mm)ModelMotorOutputKWPhaseStartingMethodSpeedp 11Max. SolidHandlingmmCablelengthm50 4-FSP 0.4 3-phase d.o.l. 3000 16 650 8-FSP 0.75 3-phase d.o.l. 3000 22 6Pump selection software available … Australian Pump 02 8865 3500

Equipment Selection GuideSewage/wastewater pumpsEffluent<strong>Pumps</strong>Type Model Discharge bore mm Motor Output kW FeatureCorrosionresistantExplosion proofCorrosionresistantB 50-800 0.4-110 Basic sewage pumpBZ 80-100 1.5-15 Basic sewage pump with large solid passageC 50-100 0.75-15 Basic sewage pump with cutter mechanismU 40-80 0.25-3.7 Vortex sewage pump with 2 pole motorUZ 50-100 1.5-11 Vortex sewage pump with large solid passageUT 50 0.4 Vortex sewage pump with single phase motorPU 40-80 0.15-1.5 Vortex sewage pump - resinPN 40-50 0.25-1.5 Semi-vortex wastewater pump - resinMG 32-50 1-3.7 High head grinder pumpBQ 50-100 0.4-3.7 Cast ss version of B seriesCQ 50-100 0.75-3.7 Cast ss version of C seriesBX 80-100 1.6-3.8 Explosion proof version of B seriesCX 80-100 1.6-3.8 Explosion proof version of C seriesUX 50-80 1.6-4 Explosion proof version of U seriesPSF 40-50 0.25-1.5 High head effluent pump - resinSF 50-80 0.75-11 Semi-open impeller, for high head pumpingOM 32 0.15 Semi-vortex effluent pump - resinSQ 40-50 0.25-0.75 Lightweight ss effluent pumpSFQ 50-80 0.4-11 Chemical effluent pump - cast ssTM 40-50 0.25-0.75 Seawater pump - titanium & resinBlower RS 20-150 0.4-45 Rotary air blowerTRN 32-150 0.75-40 Submersible self aspirating aeratorAeratorWaterBER 25-50 0.75-5.5 Submersible axial-flow type aeratorTreatment Skimmer FSP 50 0.4-0.75 Floating scum skimmerEquipment Decanting pump FHP 40-80 0.25-1.5 Float type decanting pumpBar ScreenKE/KS - - Automatic mechanical bar screen (front)KM/KMA - - Automatic mechanical bar screen (rear)Dewatering pump range also available … contact Aussie <strong>Pumps</strong> for more detailsAustralian Pump Industries Pty Ltd7 Gladstone Road, Castle Hill NSW 2154Ph: (02) 8865 3500 Fax: (02) 9894 4240www.aussiepumps.com.auinfo@aussiepumps.com.au