High Quality Jeantil Slurry Tankers Product Information ... - Fatcow

High Quality Jeantil Slurry Tankers Product Information ... - Fatcow

High Quality Jeantil Slurry Tankers Product Information ... - Fatcow

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Slurry</strong> tanker2010-2011

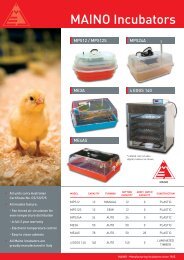

Gti 4500Complete rangefrom 4 500 to 24 000 litresGti 6500Gti 8500GT 11500GT 12500GT 15500Design and manufacture 100% <strong>Jeantil</strong>GT 20500Spot welded girdersHot-dip galvanisationDESP tank calculationGT 240002

Expertise and design 100% JEANTILStrong innovative construction- Tank resting on 2 girders stud weldedthroughout its length- Continuous welded girders- Edge to edge welded ferrules- Optimised tank weight for transportof liquid only- Wheels flush fitted into the tank<strong>Quality</strong> of manufacture- Manufacture 100% JEANTIL- Continuous mechanically weldedunit inside and outside- Conformity to the DESP 97/23 CE (1)- Automatic welding of ferrules- Continuous quality controlComplete emptying of allproducts- Drop frame spot welded rear- Pneumatic interior mixer- Smooth tank floor with natural slope- Mountain emptying- Top rear outlet with sumpBetter filling- Large volume filling security- optimisation of suction Ø- Submerged pumping turbine withventMulti-purpose use- Mountain emptying- Interior paint protection for transportof specific products- Tank exterior protection paint- Tank partitioned clean water forpressure washingSafety of use- Interior baffle partitions- Overpressure safety devices- 2nd filling security- Self-cleaning detritus chamberSimplified cleaning- Hot-dip galvanised tank- Rear door Ø900 or side Ø600- Smooth tank floor for no retention- Baffle partition with through access(1) DESP : Pressurised EquipmentDirective > 0,5bDouble filling securityPneumatic interior mixerRear door Ø900Weight transfer partitionProtection paintRange Gti4500 to 10500Mountain emptying on a downwards slopeRange GT10500 to 15500Interior baffle partitionSide door Ø600Range GT18500 to 24000Volume to treat 5000m3/year+ ++ +++Distance from fosse tofield >2.5 km+ ++ +++Pumping by manual valve +++ +++ +++Pumping with receptioncone+++ +++ +++Direct pumping into thefosse+++ +++Spreading with nozzle onbare ground+++ +++ +++Spreading on crops ++ +++ +++Injection of slurry +++ ++++ Possible++ Favourable+++ Very favourable3

Single axleBogieTandemComplete rangeof slurry tankers1, 2 and 3 axlesTridemHydraulic suspensionFollowing axleHydraulic suspensionSteering axleBrakesGT range independent chassisGTi range integral chassisPerformances and behavious Single axleBogie suspension Tandem suspension Tridem suspension Hydraulic suspensionNormal Reversed Normal Reversed Normal Reversed2 – 3 axlesTransport + ++ ++ +++ +++ +++ +++ +++Spreading +++ ++ +++ ++ +++ ++ ++ +++Clearance + ++ +++ ++ +++ ++ ++ +++Handling +++ +++ (1) +++ (1) +++ (1) +++ (1) ++ (1) ++ (1) +++ (1)Maintenance and long life +++ +++ +++ +++ +++ +++ +++ ++4+ Possible ++ Favourable +++ Very favourable(1) With following or drive axles

Performance and maximum comfort in all conditionsBetter stability- Possible fitting of large Ø wheels- Drop frame bogie, tandem andtridem axle- Wheels flush fitted into the tank- Hydraulic suspensionRespect for soils- 1, 2 or 3 axles- Low pressure tyre up to 800 mm wide- Optimised dead weight thanks toindependent chassis- Remote inflation to adjust the tyrepressure at work and on the roadRobust, reliable design- Tubular chassis- Chassis tank connection by bracketson GT- Oversized running gear- Drawbar pin 500 mm greasedbushing- Drawbar main section in HLE steel- Ring welded or bolted on the drawbar- Bolted axlesHandling- Following axle on bogie, tandem,tridem- Steering axle on bogie, tandem,tridem- 2 following axles on tridem- 2 steering axles on tridemOptimised need for power- Weight transfer partition on the frontof the tanker- Drop frame axle- Weight transfer on hydraulicsuspension- Possible fitting of large Ø wheelsComfort of use- Spring draw bar suspension- Adjustable drawbar height- Hydraulic or mechanical stand- Pneumatic braking proportional tothe loadCompliant for road use- Protected double lighting- side lights- DREAL France approval 25 km/h and40 km/hDouble lamp protected lightingProportional braking40 km/hMechanical standHydraulic standWelded ring Bolted ring Ø50 Bolted ring coupling ball Ø 80Gti4500Gti5500Gti6500Gti8500Gti10500Integral chassis Single axle Flush fitting Fixed drawbar Spring drawbar Welded ring Bolted ring Ø50 Ring coupling ball K80 Authorisation 25km/h GT10500GT11500GT10500GT12500GT14000GT15500GT18500GT20500GT24000Independent chassis Single axle Bogie Tandem Tridem Hydraulic suspension Following axle Steering axle 2 following axles ontridem 2 steering axles ontridem Flush fitting Spring drawbar Welded ring Bolted ring Ø50 Ring coupling ballK80 Authorisation 25km/h Authorisation40km/h standard option(1) Tandem or Tridem according to PTAC with pneumatic braking proportional to the load5

Side valveCoupling systemComplete range of loadingsolutionsCentral armUnderground pitGeo-membrane pitUpper loading hoistVirgule armTurbo armOutside pitWellLagoonPumping acceleratorFilling coneHydraulic top openingManualvalve Ø150ManualvalveØ200Centralarm Ø150CentralarmØ200VirgulearmØ200TurboarmØ200Gti range GT range Type of slurry <strong>Slurry</strong> < 5% Dry Matter ++ +++ ++ +++ +++ +++<strong>Slurry</strong> 5 to 10% DM ++ ++ ++ +++ +++ +++<strong>Slurry</strong> 10 to 15% DM + ++ + +++(1) +++(1) +++(1)Type of pit Lagoon ++ ++ ++ ++ +++ +++Geo-membrane pit ++ ++ +++ +++ ++ ++Underground pit ++ ++ ++ ++ +++ +++Outside pit + + ++ ++ ++ ++Well ++ ++ ++ ++ ++ +++Altitude > 600m + ++ + +++(1) +++(1) +++(1)Pumping Pumping on reception cone +++ +++ +++ +++solutionPumping direct pit +++ +++Pumping accelerator Pumping turbine up to 6 m3 /min Pumping turbine up to 10 m3 /min Pumping without compressor Option + Possible ++ Favourable +++ Very favourable (1) With pumping accelerator and GT security6

Performance and multiple use adaptedto the needs of each userOptimised pumping time- Pumping rate up to 13 m3/mn- Large rate pumping accelerator- Pumping with or without lowpressure- Pumping arm Ø 200- <strong>Slurry</strong> mixing and grinding with theTurbo MixBetter filling rate- Large volume raised pumpingsecurity- 2nd security with large volumedetritus chamber- Pumping without low pressure withslurry/foam return circuit towardsthe pit- <strong>Slurry</strong> preparation with the Turbo MixPumping turbine 10m3/minPump accelerator 6m 3 /minInnovative loading solutionsadapted to livestock farms- Filling cone Ø200 and vent Ø150- Hydraulic top opening Ø600- Pumping accelerator- Pumping arm Ø200Filling without compressorPump flow rate according to configurationMulti-purpose pumpingsystems- Pumping direct or on cone withVirgule and Turbo arm- Pumping by side valve Ø150 or 200- Reception cone with remote controlopeningComfort of use- Semi-automatic system for couplingthe pumping hose- Sequential control of the central arm- Electrical control for Virgule andTurbo arm- Reception cone with remote controlopeningReliability and very long life- Galvanisation of all parts in contactwith the slurryTurbo mixer- Mixing and grinding by Ø700 screwthread 600- 2 cutters and 1 counter-cutter- 5.5m model for pit up to 2.5 m indepth- 7m model for pit up to 3.5 m in depthCompressor DL200 + Turbine 10 m 3 /minCompressor + accelerator + arm Ø 200mmCompressor + arm or valve Ø 200mm With hydraulic flowrate of 80 to 120 l/min at 200b for TurbinePumping turbine 10 m 3 /min + arm Ø 200mmPumping turbine 6 m 3 /min + arm Ø 200mmCompressor + arm or valve Ø 150mm Turbo Mix 5.50mØ700 paddle propeller7

Exact nozzleComplete range of spreadingsolutionsExact Té bi-nozzlesRE 248NozzleTé bi-nozzlesSpade rampRB 303RP 12-40Disc injectorNozzle rampEDV 45-15EDS 48-8Tine injectorHanging rampEDD 57-198

Performance and multiple use adaptedto the needs of each userOptimised work rate- Spreading up to 30 m in one run- Emptying rate uo to 9 m3/mn- Outlet Ø150 or 200- Emptying accelerator on top outletØ150Respect for environmentalconstraints- Automatic spreading control in m3/ha- Large width slurry injection on bareearth and meadow- <strong>Slurry</strong> deposit in line using hangingramp- Reduction of smells- Maximum use of slurry fertilisingelements- Output curve for each device toadjust its doseEconomies at all levels- Use of slurry instead of mineralfertiliser on cereals- Reduction of nitrogen losses withinjector and ramps- Work rate > than 100 m3 spread perhour- Spreading and injection in just onerun<strong>Quality</strong> of spreading- Ramp and injector with variation oftransversal distribution

<strong>Slurry</strong> tanker integralchassis 1 axleGti 4500, 5500, 6500, 8500, 10500Gti 8500 inset pumping armGti 6500 spreadingGti 8500 inset10

The multi-purpose, economical and easyto handle slurry tankerComplete emptying of allproducts- Smooth tank floor for no retention- Spot-welded rear drop frame Ø150 or200- Pneumatic interior mixer Ø80- Mountain emptying- SE hydraulic bronze rear valve- Industrial valve DE Ø150 or 200 forslurry with strawMulti-purpose use andperformance- Low centre of gravity with integralchassis- Wheels flush fitted up to Ø1850- Pre-equipment front outlet Ø150- Manual valve pumping Ø150 or 200- Central pumping arm Ø150 or 200- Spreading with nozzle or té bi-nozzles- Drawbar ring welded or bolted- GT security and large volume detrituschamberSimplified cleaning- Entirely galvanised monobloc unit- Rear door Ø900- Smooth tank floor for no retentionSafety of use- Sealed pressure safety valve- Baffle partition according to model- <strong>High</strong>er safety of ball valve filling- Front detritus chamber- GT security and large volume detrituschamber- Pressure and low pressure controlmanometer<strong>Quality</strong> of manufacture- Tube girders integral to the tank- Continuous mechanically weldedunit inside and outside- Conformity to the DESP 97/23 CE- Automatic welding of ferrules- Continuous quality controlComfort of use- 1 or 2 level warning lights accordingto model- Column level warning light- Mechanical or hydraulic standCompliant for road use- Double lamps protected lighting- Approved brakingRear door Ø900 and industrial valveBronze valve as standardFixed drawbarGT securityDouble safety filling asstandardLevel indicatorsColumn level indicatorsBaffleSpring drawbarCompressor oil canCharacteristics in basic version Gti 4500 Gti 5500 Gti 6500 Gti 8500 Gti 10500Tank volume (lt) * 4220 5530 6840 8600 10623PTAC (kg) ** 5765 7335 8795 11200 13400Empty weight (kg) 1540 2060 1995 2520 3100Tank Ø (mm) 1500 1500 1500 1600 1600Baffle 1 1 2Level indicators 1 1 1 2 2Front valve piquage G G G G GBasic wheels 15x22,5 15x22,5 15x22,5 15x22,5 16x22,5Standard version dimensionsTank length 2518 3268 4018 4556 5456Overall length 4450 5200 5950 6450 7350Overall width 2300 2300 2300 2300 2350Overall height 2650 2700 2700 2800 2850(*) Loss of volume with flush fitting(**) The actual on-road load corresponds to a basic material and reduces according to options11

<strong>Slurry</strong> tankers Independenttank and chassis 1,2 or 3 AxlesGT10500, 11500, 12500, 14000, 15500, 18500, 20500, 24000GT 20500 flush fittedGT 15500GT 1150012

The benchmark for performanceand multi-purpose useComplete emptying of all products- Drop frame rear outlet Ø150 or 200- Top outlet with stone sorter- Pneumatic mixer Ø80- Mountain emptying- SE hydraulic bronze rear valve- Industrial valve DE Ø150 or 200 for slurrywith strawBetter filling- Large capacity high security- Large volume front detritus chamber- Accelerator on pumping arm- Turbine on pumping arm with air ventStrong innovative construction- Independent galvanised tubular chassis- Tank bolted onto the chassis- Rear door Ø900 or side Ø600- Chassis pre-equipment for lifting- Drawbar pin 500 mm greased bushing- Bolted ring as of GT 18500Multi-purpose use- Flush fitted wheels up to Ø1850- Direct pumping Ø150 or 200- Central, virgule or turbo pumping arm- Spreading with nozzle or té bi-nozzlesComfort of use- Electrical controls and automaticmanagement of spreading- Column level indicators- Hydraulic stand- Sequential controls on arm and rampsSafety of use- 2 sealed pressure safety valves- Baffle partitions- <strong>High</strong>er safety of ball valve filling- Large volume front detritus chamber- Control manometer- Large volume stone trap<strong>Quality</strong> of manufacture- Bolted tank-chassis connection- Continuous mechanically welded unitinside and outside- Conformity to the DESP 97/23 CE (1)- Automatic welding of ferrulesCompliant for road use- Approved hydraulic braking- Pneumatic or mixed pneumatic-hydraulicbraking- Double lamps protected lighting- Flashing beacon support base(1) DESR : Equipment Under Pressure Directive > 0,5bGT24000 injector with tinesDouble filling securityIndustrial valveCharacteristics inbasic versionGT10500Lifting pre-equipmentStone sorter under tankHydraulic standGT10500BogieGT11500GT12500GT14000GT15500Side doorBronze valve as standardCompressor oil canGT18500GT 20500 GT 24000Tank volume (lt) * 10623 10623 12359 12648 14164 15681 18656 20737 23859Total admissibleweight (kg) **15600 16200 15600 17100 19090 20120 23860 28265 31960Empty weight (kg) 4780 4820 5120 4875 4970 5120 6360 7520 9545Tank Ø (mm) 1600 1600 1800 1800 1800 1800 1900 2000 2000Tank thickness (mm) 6 6 6 6 6 6 6 6 6Baffle 1 2 1 2 2 2 3 3 3Level indicators Column Column Column Column Column Column Column Column ColumnFront valve holesD andGD andGD andGD andGD andGD andGD andGD and GD and GBase wheels 18x22,5 15x22,5 30,5R32 16x22,5 18x22,5 18x22,5 18x22,5 560/60R22,5 560/60R22,5Standard version dimensionsTank length 5456 5456 5184 5184 5784 6384 6822 6862 7862Overall length 7990 7990 7640 7640 8240 8840 9240 9240 10240Overall width 2370 2300 2550 2350 2370 2370 2370 2550 2550Overall height 3100 3055 3530 3450 3530 3530 3705 3795 3755(*) Loss of volume with flush fitting(**) The actual on-road load corresponds to a basic material and reduces according to options13

Continuous reliability and performanceCompressorwith 5 000 to 20 000 l/mnand pumping securityMEC vane compressor- Nominal rate 5 000 to 7 300 l/min- Adjustable drip forced lubrication- Air cooling- 540 rpm drive- Kevlar pallets twice as resistant(option)- Pallet wear inspection plugSTAR vane compressor- Recommended for intensive use- nominal rate 8 250 to 10 700 l/min- Kevlar pallets twice as resistant- Automatic lubrication for betterdistribution- Low pressure security- Pallet wear inspection plugWPT vane compressor- Adapted to extreme conditions- Nominal rate 10 625 and 12 785 l/min- Kevlar pallets twice as resistant- Automatic lubrication for betterdistribution- Liquid cooling with circulation pump- Electro-ventilator with temperaturesensor- Low pressure security- Pallet wear inspection plugDL200 lobe compressor- Adapted to extreme conditions- Maximum work rate- Reduction of maintenance cost- Nominal rate 20 830 l/min- 2 rotors 3 lobes- Without lubrication- Cooling by air injection- Suction filter with strainer- Overheating alarm- <strong>High</strong> silent air intakeMEC compressorSTAR compressorCompressor WPT720Forced lubricationPressure and low pressure securityRadiator WPTCompressor DL 200Lobe diagram DL200Nominalrate l/minHose Ø Gti 4500 Gti 5500 Gti 6500 Gti 8500 Gti 10500 GT 10500 GT 11500 GT 12500 GT 14000 GT 15500 GT 18500 GT 20500 GT 24000MEC 5000 LF 5 000 60 MEC 6500 LF 6 300 60 MEC 8000 LF 7 300 80 (1) (1) (1) ST 60 LA 8 250 80 (1) (1) ST 72 LA 9 650 100 ST 84 LA 10 700 100 WPT 600 DR 10 625 100 WPT 720 DR 12 785 100 DL 200 20 830 120 Standard Option (1) Possible with Security GT14

Performances and multiple useHydraulic generatorPerformance- Output from 75 to 130l/min at 180b- Gain in power- Electrical controlsMulti-purpose use- Autonomous machine- Accelerator and grinder drive andmachine hydraulic functions- 2 pump generator for independentcompressor driveHydraulic generatorSafety of use- No oil mixture- Oil filtering- Radiator for intensive useHydraulic radiatorHydraulic compressor driveOil tankCombined pumpinggenerator : pump /compressorMulti-purpose use- Pumping with the compressor- Spreading with compressor orcentrifugal pump- Fitting of different compressorspossible- <strong>High</strong> pressure 200b cleaner pumpinstead of centrifuge pumpPerformance- Centrifugal pump 6500 l/min at 6bwhen emptying- Spreading range 40 to 60 m withspreading jetComfort of use- Rotation and hydraulic oscillation ofthe jet- Output adjustment valveCompressor accessories- <strong>High</strong> air intake and oil collector MEC– ST - WPT- Oil can and support supplied witheach machineSpreading jetCompressor oil canGarda group 6500Compressor MECMEC5000LFMEC6500LFMEC8000LFST 60 ST 72 ST 84 WPT600DRWPT720DRPto 540 rpm Pto 1000 rpm Kevlar vanes Lubrication forced forced forced auto auto auto auto auto withoutCooling Air Air Air Air Air Air Liquid Liquid AirinjectionHydraulic generator 1000 rpm2 pump generator 1000 rpm Hydraulic compressor drive GARDA generator 6500l/mn - compressor<strong>High</strong> air intake and oil collectorFreewheel on transmission Homokinetic transmission Friction limiter transmission1000rpm 15 StandardDL200 Option

Central pumping arm Ø150or Ø200 and reception cone,sequential controlsGT 12500 central arm Ø200 acceleratorGT 20500 central arm Ø200 acceleratorGti 8500 central arm Ø15016

Simplicity and work rate at the serviceof comfort of useOptimised work rate- Arm section Ø150 or 200- Pumping accelerator- Reduced setting up time- No more hose handlingInnovation and multi-purposeuse- Sequential control of all functions- Ø200 arm locking right and left- Reception cone with remote controlclosure for external pit- Hydraulic vent for arm low pressureSimplicity of use- Sequential control by 1 DE- Rapid reversal for pumping to theright or left- Cone stand on machineSafety in transport- Mechanical locking with hydraulicopening on Ø200 arm- Controlled safety valve on arm jackØ150 and 200<strong>Quality</strong> construction- Arm entirely galvanised- Pre-equipment on GT rangeUpkeep and reliability- Arm entirely galvanised- Swivel joint with grease nipple- Industrial valve stainless steel blade- Fixed air vent on tankGT 24000 central armIndustrial valve androtating jointØ200 arm transport lockingSequential blocØ200 arm hydraulic lockCone support standRemote control receptionconeCentral arm Ø150 Central arm Ø200Right pumping Left pumping Reception cone Ø150Reception cone Ø200Hoses Ø150 (1 flexible + 1 rigid) Hoses Ø200 (1 flexible + 1 rigid)Reception cone remote control closure Ø150Reception cone remote control closure Ø200Transport lockingPumping accelerator Standard Option17

Plunging pump arm Virgule®Ø200 right or left,hydraulic lockingGT 18500 arm Virgule Ø200 acceleratorGT 15500 arm Virgule Ø200 acceleratorGT 20500 arm Virgule Ø200 left18

Performance and multiple useto optimise your workWork rate- Direct pumping into the pits- Ø200 suction tube- Optimised arm opening/closing time- Pumping accelerator not submerged- Submerged filling turbine 10 m3/minMulti-purpose use- Pumping on reception cone withadapter- Independent control of each function- Pumping with or without compressor- Industrial valve for straw slurryComfort of use- Dual articulation- Independent control of each function- Compressor inversion by electricaljack- In cab electrical control- Valve opening coupled with air ventSafety in transport- Mechanical locking with hydraulicopening- Safety valve controlled on the jack<strong>Quality</strong> construction- Attachment of the arm on the chassis- Bearing on primary articulation- Arm isolated from the tank bybellowsUpkeep and reliability- Arm entirely galvanised- Swivel joint with grease nipple- Industrial valve stainless steel bladeVisibility of workPumping on coneTransport lockingBearingArm virgule Ø200leftArm isolated from the tankArm virgule Ø200rightRight pumpingLeft pumpingA: pumping depth according to machine Up to 3.0 m Up to 3.0 mB : side offset 3.0 m 3.0 mC : chassis height 0,8 à 1m 0,8 à 1mPumping on reception cone Ø150 Pumping on reception cone Ø 200 Pumping on remote control cone Ø150 Pumping on remote control cone Ø200 Transport locking Pumping accelerator Pumping turbine and vent Standard Option19

Upper pumping armTurbomax® Ø200,rotation up to 320°GT 20500GT 18500 Turbo armTurbo arm clearance20

One single arm to adapt to all situationsWork rate- Direct pumping into the pits- Suction hose Ø200- Rapidity and precision of arm withmotorised rotation- Pumping accelerator not submerged- Filling up to 13 m3/min incombinationMulti-purpose use- Pumping to right or left- Rotation up to 320° depending onequipment- Turbomax longer Turret- Pumping into all types of pits- Pumping on reception cone withadapter- Emptying possible by the turret- Swivelling pumping arm endComfort of use- Arm with only two articulations- Rotation by geared motor and ring- Independent control of each function- Compressor inversion by electricaljack- In cab electrical control- Lift/drop damper by nitrogen ball- Access ladder- Vent coupled with industrial valveSafety in transport- Pumping arm support right and left- <strong>Slurry</strong> collection tank with emptyingvalve- Column level warning lightprotection<strong>Quality</strong> construction- Turret guide tube inside the tank- Wide range turning joint- Ertalon guide ring inside tank- Monobloc turretUpkeep and reliability- Arm entirely galvanised- Industrial valve stainless steel blade- Ringed articulations with greasenippleLong turretRotation by geared motorDrip tankSwivel jointTurret pumping to the right as standardTurret pumping to the left as standardA : maximum pumping depth according to machineB : side offsetC : clearance height under armPumping on reception cone Ø150Pumping on reception cone Ø 200Pumping on remote control cone Ø150Pumping on remote control cone Ø200Turbomax long turret and motorised rotationPumping acceleratorPumping turbine and ventArm supportArm guide in the tankTurbo arm Ø2003m20 to 4m3m102m8021

The simplicity and efficiency of table spreadingConical nozzle- Economical spreading- Working width 12m with 1 nozzle- Working width 16m with two nozzles- Jet height up to 4m- Spreading quality sensitive to wind- Output of 1.5 to 2.3 m3 per nozzleGround level nozzle- Multiple use and performance withall types of slurry- working width 10m with 1 nozzle- working width 15m with two nozzles- Jet height 1.5 m- output of 1.75 to 2.7 m3 per nozzleConical nozzleGround level nozzleExact nozzle- Multiple use and performance withall types of slurry- working width 10m with 1 nozzle- working width 15m with two nozzles- Jet reversed to limit drift- Interchangeable rubber end piece- output of 1.2 to 5 m3 per nozzleEZ precision nozzle- Precision and multi-purpose use- Working width 12m with 1 nozzle- Working width 16m with two nozzles- Jet height 1.5 m- Distribution plate high spreadingprecision- Interchangeable rubber end piece- output of 1.3 to 2.7 m3 per nozzleAdjust the dose per hectare- Output curve to adjust its speedsupplied with the user’s manual- 1 curve for each type of nozzle- Optimised work rate- Respect for the environmentExact nozzleDesired dose m 3 /hEZ precision nozzleFlow rate curve Nozzle Exact Ø 150mmPressure 1b, valve opening 100%, fertiliser pig slurryNozzle EZOutlet Ø45Nozzle EZOutlet Ø60Nozzle EZOutlet Ø70Nozzle EZOutlet Ø80Forward speed km/hNozzle working width = 10 mFlow rate curves given as an indication : Do the calculation again for each change of parameter (see method on the user’s manual)Exact nozzle output curveDesired dose m 3 /hFlow rate curve Té bi-nozzle Exact Ø 150mmPressure 1b, valve opening 100%, fertiliser pig slurryForward speed km/hNozzle working width = 15 mFlow rate curves given as an indication : Do the calculation again for each change of parameter (see method on the user’s manual)Nozzle EZOutlet Ø45Nozzle EZOutlet Ø60Nozzle EZOutlet Ø70Nozzle EZOutlet Ø80Exact Té bi-nozzle output curve23

Work rate and precision in inputsin all products up to 24 m wideSpade spreading rampsRE124, RE126, RE128, RE155, RE186, RE189, RE217, RE248Work rate- Emptying rate up to 9 m3/min- Feed Ø150 up to 6 spades- <strong>High</strong> feed Ø200 advised as from 7spades- Emptying accelerator on top outletØ150- Ø60 hoses- Output curve for each model<strong>Quality</strong> of work- Transversal distribution of qualityover 15 m3/ha- Dosimat grinder- distributor Ø60horizontal cutting axis- Exacut Ø60 grinder- distributor 2horizontal cutting axes- Adjustment of spade angle- Adjustment of spade height inrelation to the ground- Micrometric dosing valve oncylindrical distributor- Electrical setting on rear valve- Regulation of the spreading pressure- DPA with flowmeter for Ø150<strong>Quality</strong> construction- Fixed ramp frame on chassis- Hydraulic lifting for setting workingheight- Hydraulic slope corrector- Stone trap on rear outlet- Stone trap on ExacutReliability and long life- Unit entirely galvanised- Galvanised distributor with lidSafety- Ramp end retractable according tomodel- Mechanical transport locking withhydraulic control- End spades retractableRE 248Emptying rateRE 128Setting spreading pressureRamp lockingRE 124 RE 126 RE 128 RE 155 RE 186 RE 189 RE 217 RE 248Working width (m) 12 12 12 15 18 18 2115-18-21-24Number of spades 4 6 8 5 6 9 7 8Maximum dose at 6 km/h 20 30 40 20 25 35 33 32Flow spreader with micrometricdosage valve Dosimat grinder and flowspreader Exacut grinder and flowspreader Slope corrector Feed Ø150 Feed Ø200 (1) (1) (1) (1) Standard Option (1) Fitting advised for maximum output24

Simplicity and precision of spreading very large widthSpreading ramps with EZprecision nozzles:RB212, RB242, RB283, RB303Work rate- Working width up to 30 m- Emptying rate up to 7.5 m3/min- Rear outlet Ø150 up to 24 m- Rear outlet Ø200 from 21 to 30 m<strong>Quality</strong> of work- Transversal distribution of qualityover 15 m3/ha- EZ precision nozzles- Adjustable nozzle plate- Reduced number of runs- Setting the spreading pressureRB 303 30m<strong>Quality</strong> construction- Tube chassis for slurry transport- Slope corrector- Feed cut-off nozzle by nozzle- Ramp 21 m can extend to 24 mReliability and long life- Unit entirely galvanised- Monobloc armSafety-- Mechanical transport locking withhydraulic control- Stone trap on outletRB 242 24mEmptying rateRamp lockingSetting spreading pressureDesired dose m 3 /hFlow rate curve RB303Flow rate curve RB303 – 30m 3 nozzlesalim.Ø200, Pressure 1b, valve opening 100%, fertiliser pig slurryRB 283NozzleOutlet Ø50RB 283NozzleOutlet Ø60RB 283NozzleOutlet Ø70Forward speed km/hFlow rate curves given as an indication : Do the calculation again for each change of parameter (see method on the user’s manual)RB 212 RB 242 RB 283 RB 303Working width 21 24 28 30Number of nozzles 2 2 3 3Maximum dose at 6 km/h 25 22 28 26Slope corrector Feed Ø150 Feed Ø200 (1) (1)Cut off nozzle by nozzle Standard Option (1) Fitting advised for maximum output25

Precision spreading and work ratein all productsHanging spreading ramps:RP12-40, RP12-48, RP16-48, RP18-48Work rate- Emptying rate up to 8m3 /min- Feed Ø150 or 200- Emptying accelerator on top outletØ150- 40 or 48 outlets Ø40- 1 or 2 grinder distributors<strong>Quality</strong> of work- <strong>Quality</strong> transversal distribution from10 m3/hectare- Reduced smells- DPA with inductive flowmeter- Grinder distributor with 2 verticalcutting axes (Exacut)- Work possible on all types of crops- Hydraulic anti-drip system- Each hose guided to the soil by 2spring rods- Constant space between hoses- Setting the spreading pressure<strong>Quality</strong> construction- 120 x 60 section ramp arm- Hydraulic slope corrector- Doubled ramp frame- Sequential control arm opening andanti-drip- Set of stands for winter storageReliability and long life- Unit entirely galvanised- Anti-drip rotation on ertalon ring- Hoses protected in the ramp chassisSafety- Retractable ramp end- Mechanical transport locking withhydraulic control- Stone trap on outlet and on grinderRP 16 48Anti-drip jackSetting spreading pressureRP 12 40Traffic signsRP12 40RP12 48Security for endsRamp lockingRP16 48RP18 48Working width (m) 12 12 12 15Number of outlets Ø40 4 6 8 5Maximum dose at 6km/h (Ø150) 30 38 28 25Exacut grinder and flow spreader Option 2 Exacut 30s Slope corrector Feed Ø150 Feed Ø200 Standard Option26

Optimised mechanisation costsand reduced fertiliser inputInjector with square tines orvibroflex:EDC33-11, EDC33-13, EDV 39-13, EDV45-15, EDV51-17, EDV57-19Work rate- Emptying rate up to 5m3 /min- Feed Ø150- Up to 5.7 m of working width- Power of 8-10CV needed per metre<strong>Quality</strong> of work- <strong>Quality</strong> transversal distribution at10m3/ha- Better distribution with 3 cm interrow- Automatic control of the dose spread- Elimination of smells and nitrogenlosses- Distributor and micrometric dosagevalve as standard- Double effect lifting with nitrogenballs to follow the terrain- Depth control by gauge wheels orrollers- Depth gauge at front of tank- Dosimat Ø60 grinder distributor- Exacut Ø60 grinder distributor<strong>Quality</strong> construction- Tube chassis 100 x 100 x 8- Galvanised chassis- hydraulic folding- <strong>Slurry</strong> injector bit integral to the tine- Tines spread over 2 rows- Large clearance under chassis- Inter-row of 80 cm front and rearReliability and long life- Square tines 25 mm for deep work- Vibroflex tines for surface workSafety- Transport traffic signs- System for automatic reversal ofrotation if there is a blockageEDV 51-17Injector with vibroflex tines + rollerMicrometric dosage valveEDV tine workSquare tine 35EDC 33-11 EDC 33-13 EDV 39-13 EDV 45-15 EDV 51-17 EDV 57-19 EDV 65-13Working width (m) 3,3 3,3 3,9 4,5 5,1 5,7 6,5Number of tines 11 13 13 15 17 19 13Inter row (m) 0,3 0,25 0,3 0,3 0,3 0,3 0,5Square tines 35 Vibroflex tines Metallic gauge wheels 2 2 2 2 4 4 -Bar roller Ø500 Flow spreader with micrometric dosagevalve Dosimat grinder and flow spreader (1) (1) (1) (1)Exacut grinder and flow spreader (1) (1) (1) (1) Standard Option (1) Fitting advised for good distribution27

Injector with oblique disksØ630 mixed or special forgrasslandEDS24-4, EDS36-6, EDS48-8, EDS60-10, EDD33-11, EDD39-13, EDD45-15, EDD51-17, EDD57-19EDD 57-19 WorkEDS 48-8 WorkSoil cross-section after injection28

The limits of disc injection pushed to the extremeWork rate- Emptying rate up to 5m3 /min- Feed Ø150- Work up to 6m wide- Power of 5-6CV needed per metre- Non-stop security per element- Large clearance under chassis<strong>Quality</strong> of work- Side distribution of slurry up to 15 cm- Swivel drawbar for follow-through ina bend- Work depth from 6 to 10 cm- <strong>Quality</strong> transversal distribution from10m3 /ha- 30 cm inter-row special for grassland- 60 cm inter-row for mixed grasslandand stubble- No slurry run-off on slopes- Automatic control of the dose spread- Elimination of smells and nitrogenlosses- Standard distributor and micrometricdosage valve- Dosimat grinder- distributor Ø60horizontal cutting axis- Exacut Ø60 grinder- distributor 2horizontal cutting axes- Setting the spreading pressure- Output curve to adjust its dose<strong>Quality</strong> construction- Tube chassis 100 x 100 x 8- Hydraulic folding- 1 or 2 rows of discs- Double effect lifting with nitrogenballs to follow the terrain- Floating position on lifting- Depth control by 2 or 4 gauge wheels- Soil depth indicator at front of tankReliability and long life- Galvanised chassis- Ring axles with grease points- Disc hubs 2 conical bearings- Rubbing parts on down tube made ofanti-wear steel- Galvanised distributor with lidSafety- Transport traffic signs- System for automatic reversal ofrotation if there is a blockage- Non-stop security per elementSoil after injectionCrop profileTraffic signs Soil depth indicator Setting spreading pressureEDS output curveDesired dose m 3 /hFlow rate curve 1 row Disc InjectorsAlim.Ø150, Pressure 1b, valve opening 100%, fertiliser pig slurryMicrometric dosage valveForward speed km/hEDS24-4EDS36-6EDS48-8Hydraulic foldingEDS60-10EDD33-11EDD39-13EDD45-15EDD51-17Working width (m) 2,4 3,6 4,8 6 3,3 3,9 4,5 5,1 5,7Number of disc 4 6 8 10 11 13 15 17 19Inter row (m) 0,6 0,6 0,6 0,6 0,3 0,3 0,3 0,3 0,3Hydraulic folding Metallic gauge wheels 2 2 2 2 2 2 2 4 4Distributor with micrometric dosage valve Dosimat grinder distributor (1) (1) (1) (1) (1) Exacut grinder distributor (1) (1) (1) (1) (1) Swivel drawbar (follow-through in a bend) Standard Option(1) Fitting advised for good distributionEDS 24 4EDS 36 6EDS 48 8EDS 60 10Maximumvalues : Flowrate reductionpossible withpressure andvalve openingFlow rate curves given as an indication : Do the calculation again for each change of parameter (see method on the user’s manual)EDD57-1929

DPAE with inductive flowmeter Ø150Precision of inputs- Automatic management of dose / haspread- Variation < 5% in relation to theprogrammed dose- Output regulation independentof pressure in the tank and type ofslurry- Instantaneous flow control byinductive flowmeter- Speed sensor on tanker wheel- Grinder-distributor speed sensor- Compressor speed sensor- Very good longitudinal distributionInnovation- Compatible with precision farming- Coupling possible with GPS guide bar- Automatic cut-off of rear valve orsections by GPSDriving comfort- Instant display of the dose / haspread- 2 instructions only to record :workingwidth and desired dose per hectare- Low / high speed alarm- Grinder –distributor blockage alarm- Simple intuitive use of the box- Use in manual for nozzle spreadingTraceability- 10 customer files can be recorded(Name, M3 spread, Time, Distance,Surface)- Data can be exported in excel or htmlformat- Printer in cab- Automatic cut-off of rear valve orsections by GPSReliability and long life- Unit galvanised and integrated intothe tank- Flowmeter Ø150 protected in thetank- Manual control of the selected valve- Flowmeter in non-corrosive materialsFlowmeter integrated into the tankSMART Control control box Simple control boxInductive flowmeter Flowmeter operationMeter N° Name Volume [m 3 ] Surface [ha] : Distance [km] Duration1 Customer 1 153,5 5,15 12,5 0.412 Customer 2 439,24 17,56 53,12 1.043 Customer 3 0 0 0 04 Customer 4 0 0 0 05 Customer 5 0 0 0 06 Customer 6 0 0 0 07 Customer 7 0 0 0 08 Customer 8 0 0 0 09 Customer 9 0 0 0 010 Customer 10 0 0 0 0CompteurtotalVolume [m 3 ] Surface [ha] : Duration12823,5 427,53 248,23Meter data exported30

How to choose your controls on a slurry tankerAs standard: control of the spreading valve and of the reversing of the compressor direct from the tractor.Table of needs:Description of hydraulic functionsRequired flowrateDirect tractorcouplingJack functions 45-20 l/minElectro-hydraulic distributorEngine functions up to130l / minBronze rear valve Single effect jack SE 20 l/min 1 1 XRear industrial valve Double effect jack DE 20 l/min 1 1 XFront central arm Ø 150 or 200VIRGULE arm Ø200Compressor inversionArmValve + ventElectric compressorinversionValve + ventArm articulationPlunger articulationElectric compressorinversionDE 20 l/min 1 1 XDE 20 l/min X 3 XValve + ventTurbo arm Ø200Arm rotationDE 20 l/min X 4 XArm lifting/loweringPlunger articulationPumping accelerator Engine SE 70 l/min 1 X 1Pumping turbine 6 m3/min Engine SE 70 l/min 1 X 1Pumping turbine 10 m3/min Engine SE 120 l/min X X 1Grinder-Distributor (Dosimat/Exacut) 2 stroke engine DE 60 l/min 1 X 1Upper loading cone Valve + vent DE 20 l/min 1 1 XHydraulic opening Ø600 Jacks DE 20 l/min 1 1 XMountain emptying Bronze valve DE 20 l/min 1 1 XLifting Jacks DE 20 l/min 1 1 XSpade ramp Folding + locking DE 20 l/min 1 1 XNozzle ramp Folding + locking DE 20 l/min 1 1 XHanging ramp (Do not forget enginefunction for Exacut)Folding + locking DE 20 l/min 1 1 XRamp drift corrector Oscillation jack DE 20 l/min 1 1 XInjector folding body Folding DE 20 l/min 1 1 XSpreading jetRotation (engine)OscillationDE 20 l/min 2 2 XFollowing axle Locking jacks SE ou DE 20 l/min 1 X XTotal *DE = Double Effect FunctionSE = Single Effect FunctionX = Impossible* = prévoir 1 SE supplémentaire sur le tracteur si distributeur électro-hydraulique2 distribution blocks with electric controls:- from 2 to 6 hydraulic cylinder functions with a maximum oil flow rate of 45 l/m- from 2 to 11 hydraulic cylinder functions with a maximum oil flow rate of 45 l/m plus 1 or 2 engine functions with amaximum oil flow rate of 130 l/m2 electric controls boxes are available BASIC or SMART:The BASIC control box allowsto control the totalityof the tanker from thetractor cab. Available from2 to 13 electrohydraulicfunctions including 2 highflow functionsThe SMART controls includea DPA system as well as adisplay with informations oftime, surface, total volume,volume per hectare, andkilometres driven. The SMARTcontrols features all the BASICcontrol functionsBASIC control boxSMART control box31

AccessoriesLoading cone- Valve Ø200 for load- Valve Ø150 for air vent- Hydraulic simultaneous control- Access ladderTop opening Ø600- Hydraulic opening / closing- Drop frame loading height- Access ladder<strong>High</strong> emptying arm- Hydraulic rotation 360°- Hydraulic valve Ø150 or 200- Drip tankLoading coneDosimat- Grinder 1 horizontal cutting side- Regular distribution of slurry- Air suction shutter to stop pulsations- Special rotor for injector- Special rotor for spade ramp- Outlets Ø60- Feed Ø150 on LV9- Feed Ø150 or 200 on LV13-LV24- System for automatic reversal ofrotation if there is a blockage (option)Top opening Ø600Exacut- Grinder 2 vertical cutting sides- Suitable for slurry with straw orfeathers- Air suction shutter to stop pulsations- Regular distribution of slurry- Feed Ø150 or 200- Special counter blades for injector- Special counter blades for ramp- Outlets Ø40 (hanging) or Ø60(injectors-spade ramps)- Integral stone trap- System for automatic reversal ofrotation if there is a blockage (option)Top opening Ø600<strong>High</strong> emptying armDrip tankDosimatExacut outlets Ø60Exacut outlets Ø40Hydraulic connection rear32

AccessoriesSemi-automatic manualcoupling- Handle with easy grab coupling- Ø150 or 200Suction strainer- Avoids sucking up foreign bodies- Advised with ramp and injector- Ø150 or 200Direct spreading bend- Spreading at the nozzle withoutuncoupling the injector- Bend Ø150 with angle adjustmentSemi-automatic couplingSuction strainerStone sorter under tank- Large volume 14l- Plug Ø200 or drain valveStone sorter on rear outlet- Drain plug Ø150pneumatic interior mixer- Ø80 for MEC8000 and ST60- Ø100 for ST72 and more- <strong>High</strong> performance mixing of slurry- <strong>Slurry</strong> homogenised duringspreading- Tank walls swept by expulsion ofcompressor airStone trap on rear outletDirect spreading bendStone sorter under tankWeight transfer partition- Keeps weight at the front of the tankuntil spreading ends- Automatic starting systemGalvanised mudguard- 1, 2 or 3 axles- Integral hose support basePneumatic interior mixerHose support under chassis- For tanker flush fitting axleWeight transfer partitionHose support under chassisGalvanised mudguards33

AccessoriesWorking headlight supportbase- Dual lighting- Top of tank or on injector as optionSide lights- 4 lights front and rearBull bars- Galvanised (for Export)Meter- Compressor rotation time- KilometricWaterproof tool box- 600 x 400 x 500 polypropylene- 2 handles with key lockingHand-washing can- 30l with pump for soapCleaning kit- 5 m of hose Ø60- Connection on valve Ø150- Cleaning tube with 1/4 turn valve<strong>High</strong> pressure jet washingequipment- Wide choice of equipment available- Equipment on Gti and GT ranges- Partitioned tank clean water / slurrymud- Hydraulic winder for hose Ø60 or Ø80- HP hose winder- Flexible cleaning cable- GardaJet <strong>High</strong> Pressure unit 136l/mn-200b mechanical drive- Remote control 1 to 10 functions(valve, winder, etc)Support base for working headlightsRemote controlSide marker lights frontBull barsTime meter10 remote control functionsSide marker lights rearKilometric meterToolboxHand-washing canCleaning kitDual lightingDesign of power jet washing machineHydraulic winder34

Wheel characteristicsXY1 AR01 TR08 328404 380 Cargo Twin Radial421 ELS XS large 324347 360 375 390Dimensions Make ProfileN° of plys loadindexTYRE CARACTERISTICSDiameter in mmWidth in mmLoad per wheel in kg40km/hInflationpressure in Bars15x22,5 Retrad XY1 18 1090 385 4880 5,016x22,5 Retrad XY1 20 1150 425 5920 5800 5,018x22,5 Retrad XY1 20 1180 445 6440 6200 5,018R22,5 Mitas new AR-01 169 F 1150 445 7830 6670 8,0550/60x22.5 Mitas TR 08 16 1254 537 5800 4875 2,8550/60x22.5 Alliance 328 166 A8 1238 550 6310 5300 3,0560/60x22.5 Trelleborg 404 167 A8 1244 564 6485 5450 3,6560/60R22.5 Alliance 380 radial 161 E 1245 554 7400 6710 4,0560/60R22.5 Michelin Cargo radial 161 D 1251 570 7310 6290 4,0580/65R22.5 Trelleborg Twin radial radial 159 D 1300 580 6915 5950 3,2600/50x22.5 Trelleborg 404 156 A 8 1170 600 4760 4000 2,6600/55R22.5 Alliance 380 radial 162 E 1245 600 7600 6890 4,0600/55X26,5 Trelleborg 404 166 A 8 1350 600 6305 5300 2,4600/55 R26.5 Trelleborg Twin Radial radial 165 D 1341 600 8135 7100 4,0600/55R26.5 Michelin Cargo radial 165 D 1348 626 8140 7000 4,0650/55R26,5 Alliance 380 radial 167 E 1360 645 8210 6900 4,024R20.5 Michelin XS large radial 176 F 1374 604 8500 7940 4,0650/65R26.5 Nokian ELS radial 174 D 1518 650 10500 9150 4,0650/65R26.5 Alliance 380 radial 174 D 1518 650 10500 9150 4,0680/55R26.5 Trelleborg Twin radial radial 165 D 1400 680 8140 6900 3,2600/60x30.5 Trelleborg 421 171 A8 1500 600 7320 6150 3,1600/60R30.5 Michelin Cargo radial 169 D 1496 639 9160 7890 4,0710/45x26.5 Trelleborg 404 169 A8 1350 700 6900 5800 3,1710/50R26.5 Michelin Cargo radial 170 D 1405 728 9480 8160 4,0710/50R26.5 Alliance 390 radial 172 D 1390 730 9510 8570 4,0650/65R30.5 Trelleborg Twin Radial radial 176 D 1625 650 11218 9750 4,0650/65R30.5 Michelin Cargo radial 176 D 1623 650 11220 9660 4,0750/60x30.5 Trelleborg 404 radial 178 A8 1650 755 8925 7500 2,6750/60R30.5 Trelleborg Twin Radial radial 181 D 1678 756 12500 11200 4,0650/60R34 Nokian ELS radial 175D 1644 650 10950 9400 4,0710/55R34 Nokian ELS radial 177D 1645 710 11300 9750 4,0800/45x30.5 Trelleborg 404 radial 178 A8 1500 800 8925 7500 3,130,5LR32 Alliance 390 radial 181B 1800 780 11250 9490 4,018,4/15x34 Alliance 324 14 1610 470 4660 4197 3,021,3R24 Dnieproshina tracteur radial 1400 540 4850 2,823,1X26 Alliance 347 16 1605 587 5580 5031 2,8620/75R26,5 Alliance 375 radial 166 A8 1600 606 7017 6325 3,828,1R26 Dnieproshina tracteur radial 157 A6 1735 750 5720 4125 2,824,5X32 Alliance 347 160 A8 1805 650 5740 5175 2,030,5R32 Dnieproshina tracteur radial 161 A6 1830 775 6500 4625 2,830,5LR32 Alliance A 360 radial 178 A8 1820 775 9575 8625 3,735

Gti4500Gti5500Approval DREAL 25 km/h Approval DREAL40 km/h TankFlush fitting axle Rear door Ø 900 mm Side door Ø 600 mm instead of rear Spring drawbar Mudguards <strong>High</strong> volume pumping safety Column level indicator Ø 110 mm Lifting pre-equipment and central pumping arm PumpingSide front valve Ø 150 mm or Ø 200 mm Semi-automatic hooking system Central pumping arm Ø 150 mm with reception cone Central pumping arm Ø 200 mm with reception cone Front upturned pumping arm Ø 200 mm Pumping arm TURBOMAX Ø 200 mm Pump accelerator on pumping arm Ø 200 mm Submerged pumping turbine 6m3/mn + vent Submerged pumping turbine 10m3/mn + vent Upper filling cone Ø 200 mm + Ø 150 mm Hydraulic upper filling hatch Ø 600 mm Receiving cone (Ø 150 mm or Ø 200 mm) Receiving cone closing with remote control (Ø 150 mm or Ø 200 mm) Suction strainer Bend 45° (Ø 150 mm or Ø 200 mm) Bend 90° (Ø 150 mm or Ø 200 mm) Galvanised pumping tube 3m (Ø 150 mm or Ø 200 mm) Flexible pumping tube 3m (Ø 150 mm or Ø 200 mm) Hose support under chassis CompressorMEC 5000lt/mn MEC 6500lt/mn MEC 8000lt/mn STAR 60 10000lt/mn Kevlar vanes STAR 72 11870lt/mn Kevlar vanes STAR 84 14420lt/mn Kevlar vanes WPT 600 11870lt/mn Liquid cooling WPT 720 14420lt/mn Liquid cooling DL200 20000lt/mn lobe compressor Compressor group + Thrust pump unit with cannon <strong>High</strong> air intake and oil recuperator Drive shaft - with flywheel Drive shaft - friction torque limiter Drive shaft - with wide-angle joint Hydraulic compressor drive SpreadingIndustrial rear valve Ø150 or Ø200 Ground level nozzle Exact nozzle EZ precision nozzle Té bi-ground level nozzle Hydraulic hitch Rear high outlet Ø 150 or 200 mm with stone remover under the tank Stone remover (alone) with emptying plug Stone remover on rear outlet Ø 150 mm with cap Spreading booms with spades 12 to 24 m Nozzles booms 21 and 24 m Nozzles booms 28 m Nozzles booms 30 mHanging booms 12 m Hanging booms 16 m Hanging booms 18 mTines injectors up to 5,70 m Disc injectors up to 6 m Grinder-ditributor Dosimat Grinder-ditributor Exacut DPAE (electronic flow rate proportional to speed) with inductive flow metre Printer for DPAE ControlsElectric controls up to 10 functions Electric controls grinder-ditributor Option load sensing distributor (LS) On board hydraulic pump 75lt/mn Autonomous on board hydraulic pump 140lt/mn + 75lt/mn Hydraulic cooling system (intensive use) AccessoriesMechanical stand Hydraulic stand Bolted ring coupling ball K80 3 ton Time meter Side marker lights Rear support base for working headlights Cleaning kit 5m Ø60 Compressor oil can 5L with support Waterproof toolbox Hand-washing can 30l Standard OptionGti6500Gti8500Gti10500GT10500GT11500GT10500GT12500GT14000GT15500GT18500GT18500TridemGT20500GT20500TridemGT24000Photos not contractual – Except for typographical errors – the technical characteristics are given as an indication and not as a commitment, the <strong>Jeantil</strong> Company reserving the right to make all modifications, improvements and developments to them.The 1 st complete solution • Livestock • Transport • SpreadingSCM JEANTIL – Z.I. des Charmilles – 53390 SAINT AIGNAN SUR ROËTél: 0033 2 43 06 69 69 – Fax: 0033 2 43 06 69 08 – Site Website: www.jeantil.com - e-mail: scm@jeantil.com