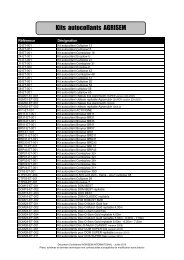

3m / 610 litres Gold DS 1100 - 3m / 1100 litres DS 1400 - Agrisem

3m / 610 litres Gold DS 1100 - 3m / 1100 litres DS 1400 - Agrisem

3m / 610 litres Gold DS 1100 - 3m / 1100 litres DS 1400 - Agrisem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Designer of equipment<br />

for sustainable agriculture<br />

The professional’s<br />

choice<br />

Seed<br />

Mulch<br />

Root

Worldwide<br />

2<br />

Chile<br />

Romania<br />

Estonia Hungary Moldavia The Netherlands<br />

Ukraine Sweden Russia<br />

Poland<br />

Denmark Slovakia Latvia Belarus France<br />

Lithuania Czech Republic Japan Belgium Switzerland<br />

Germany Bulgaria Spain New<br />

Portugal<br />

Zealand<br />

Greece Croatia Austria United<br />

Kingdom<br />

Mauriius

Strong growth<br />

For over 15 years we have been developing<br />

innovative solutions to help you<br />

save time, energy and reduce the effects<br />

of agriculture on the environment.<br />

Our aim is to provide you with robust,<br />

productive equipment to enable you to<br />

adapt your production tools to the new<br />

economical, financial, regulatory and<br />

environmental constraints. 10,000 of<br />

you have already shown confidence in<br />

us and have invested in our machines.<br />

You have taken up the challenge of<br />

having new sustainable agriculture<br />

which is even more efficient.<br />

our sustained and steady growth shows<br />

the high level of satisfaction<br />

of the farmers using our equipment<br />

AGRISEM, at your service<br />

Your satisfaction is our main concern.<br />

Thanks to our network of dealers and<br />

importers, you will find someone at your<br />

disposal not far from you.<br />

Turnover in Millions of euros<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0,15<br />

0,24<br />

0,47 0,84<br />

1,39<br />

1,85 2,34<br />

3,4<br />

1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008<br />

To cope with the growing number of customers,<br />

we also tripled the surface area of<br />

our spare parts warehouse in 2008, so that<br />

whatever you need is always available.<br />

12,000 machines<br />

currently being<br />

used<br />

5,03<br />

4,43<br />

7,22<br />

Our headquarters in Ligné<br />

(Loire Atlantique) France<br />

8,77 9,14<br />

10,31<br />

11,1<br />

15,6<br />

3

3 main areas of development<br />

Agronomy<br />

Germination and root-taking<br />

After sowing, the seed has to germinate<br />

and then take root. These two<br />

stages concern two different soil<br />

horizons. Germination occurs in top<br />

layer soil whereas root-taking requires<br />

more depth. Moreover, these two<br />

soil horizons do not have the same<br />

agronomical requirements.<br />

These observations have led us to<br />

develop an independent disc to work<br />

the top layer soil and a blade with<br />

retracted point for root development.<br />

Multipurpose modules for progressive adaptation<br />

Do not believe in miraculous machines<br />

that promise an immediate changeover<br />

to soil conservation techniques.<br />

<strong>Agrisem</strong> International offers technical<br />

modules which can be integrated into<br />

your farming system step by step.<br />

You choose your own rate of transition<br />

4<br />

optional depending on<br />

climate and the period<br />

of covercrops<br />

• Crumbling<br />

• Stale seed-bed<br />

• Crop<br />

residue control<br />

• Depth control<br />

• Levelling-out<br />

• Fissuring without<br />

upheaval<br />

• Preparation for<br />

root-taking<br />

• Elimination of<br />

plough pan<br />

• Water drainage<br />

Germination Root taking<br />

optional depending<br />

on soil structure<br />

Stubble-breaking<br />

Loosening<br />

+ stale seed-bed<br />

Sowing<br />

• Crumbling<br />

• Stale seed-bed<br />

• 2nd stubblebreaking<br />

• Depth control<br />

• Closure of soil<br />

• Levelling-out<br />

Crumbly and<br />

warm seed bed<br />

Porous,<br />

unbroken soil,<br />

continuous<br />

structure,<br />

no large clods<br />

or hollows<br />

towards soil conservation techniques.<br />

Our equipment is modular and multipurpose<br />

since it has to suit your changing<br />

requirements from year to year.<br />

When using soil conservation techniques<br />

sowing can be done in one<br />

passage, after one or several passages<br />

• Crumbling<br />

• Stale seed-bed<br />

• Crop residue<br />

control<br />

of stubble-breaking or after soil-loosening,<br />

if necessary. Your knowledge of<br />

your own soil and your experience will<br />

lead you step by step to optimize the<br />

use of our machines.<br />

• Sowing by<br />

covering over<br />

• Sowing in rows<br />

•Levelling-out<br />

•Septh control

Environment<br />

Water quality<br />

<strong>Agrisem</strong> International's fissuring technique<br />

ensures improved productivity for<br />

the farmer and nearly eliminates runoff,<br />

erosion and pollution. An official<br />

independent trial proved it spectacularly.<br />

Results measured after rainfall of 26<br />

mm (during a storm). Comparison between<br />

different cultivation techniques<br />

on silty/sandy soil with a 6% slope<br />

(maize) including a control plot which<br />

was ploughed traditionally and a plot<br />

worked with an <strong>Agrisem</strong> Combiplow.<br />

114 hours<br />

1 094 <strong>litres</strong><br />

7 167 euros<br />

Official experimental trials at Kerguehennec (56 - France)<br />

(financed by Bretagne Eau-Pure, carried out in partnership with Brittany Chamber of Agriculture,<br />

Inra-Ensa in Rennes and ITCF)<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

Run-off (<strong>litres</strong>/300 m 2 ) Soil erosion (kg/ha) Atrazin flow (mg/ha)<br />

496<br />

15 times less<br />

run-off !<br />

34<br />

Ploughed<br />

control plot <strong>Agrisem</strong><br />

Technique<br />

100<br />

yearly savings :<br />

80<br />

60<br />

40<br />

20<br />

200 hours<br />

2573 <strong>litres</strong><br />

12220 euros<br />

0<br />

90<br />

25 times less<br />

erosion !<br />

3,4<br />

Ploughed<br />

control plot <strong>Agrisem</strong><br />

Technique<br />

15000<br />

12000<br />

9000<br />

6000<br />

3000<br />

0<br />

13492<br />

412 hours<br />

4145 <strong>litres</strong><br />

28980 euros<br />

65 times less<br />

pollution !*<br />

205<br />

Ploughed<br />

control plot <strong>Agrisem</strong><br />

Technique<br />

* please note that in this trial, the pollution due to run-off was halved (102mg/l) in presence of<br />

surface mulch when using the <strong>Agrisem</strong> technique.<br />

Savings<br />

Comparison: standard system/<strong>Agrisem</strong> technique<br />

Our equipment allows to halve the working time. With a doubled productivity<br />

your farm will be ready to face the future with equanimity.<br />

(70 ha farm) (50 ha farm) (350 ha farm)<br />

5

Blade<br />

The patented wave<br />

Controlling your crops' root-taking<br />

To encourage good root development, it is<br />

essential to restore soil porosity without<br />

too much upheaval so as to preserve soil<br />

structure and prevent the dilution of<br />

organic matter.<br />

6<br />

Capillarity<br />

Root development,<br />

water supply<br />

<strong>Agrisem</strong> International's patented solution<br />

is to fold-over the soil in a wave-like<br />

movement.<br />

Drainage<br />

Direct closure of the wave<br />

to preserve the carbon<br />

and organic matter.<br />

A successful graft!<br />

The graft is at one with the subsoil.<br />

Lifting is achieved by wrenchingout<br />

the soil in order to eliminate<br />

the risk of smoothing-out. The<br />

band of soil is then put back into<br />

place without disturbance thus<br />

ensuring perfect structural continuity<br />

and guaranteeing efficient<br />

capillarity and good root development<br />

at depth.<br />

Homogenous soil loosening over the entire working width<br />

Fissuring<br />

When folding a friable material<br />

you efficiently cause fissuring<br />

without upheaval. It is like<br />

when you fold a welding rod,<br />

the coating crackles and fissures.

The new generation of loosening blades<br />

Fluidity<br />

• Lower power requirement and improved<br />

penetration of the blade.<br />

• No blade leg: the life of the ploughshare<br />

is increased.<br />

• Mass-produced coated ploughshares<br />

and leading edges.<br />

• Same leading edges as those used on<br />

previous <strong>Agrisem</strong> blades.<br />

Retracted point blade and sloped prop<br />

Thanks to the retracted point, the lifting<br />

force is located just under the centre of<br />

gravity of the block of soil to<br />

be loosened. The lining up<br />

of forces and counter forces<br />

optimize the power requirement<br />

needed to lift the soil.<br />

PATENTED<br />

Balanced lifting<br />

Save fuel with <strong>Agrisem</strong><br />

By loosening your soil with a Combiplow<br />

or Cultiplow, you will achieve<br />

incomparable fissuring, which is,<br />

as yet, unequalled. You obtain a homogeneous<br />

result while using 30% less<br />

power than a traditional soil loosener.<br />

This performance is the consequence<br />

of several years of research and<br />

development. This research has resulted<br />

in the creation of a unique blade,<br />

protected by several international<br />

patents.<br />

by using a dynamometer, the technicians<br />

were able to measure the necessary traction<br />

effort for each working part under the same<br />

conditions.<br />

PATENTED<br />

Boosting effect<br />

The exclusive design<br />

of the ploughshare<br />

increases the possible<br />

conditions for use with<br />

improved soil fissuring<br />

(patented technique).<br />

The blade leg is not straight but inclined<br />

at 10° so as to facilitate lifting<br />

and avoid deformation. All the “pans”<br />

have inclined edges to make the turning<br />

easier thus lifting the material<br />

without causing disturbance.<br />

4 sizes of blade<br />

A blade suitable<br />

for every kind of<br />

job<br />

45<br />

40<br />

35<br />

30<br />

25<br />

Only 4 blades over a 3 m width<br />

Thanks to equipment with roughly 75<br />

cm clearance between the blades, the<br />

<strong>Agrisem</strong> blade is the only one on the<br />

market able to work over a 3 m width,<br />

enabling uniform<br />

soil loosening<br />

over the entire<br />

width<br />

with just 4<br />

blades.<br />

Curved<br />

blade<br />

550 650 750 850<br />

Results of the trials carried out by<br />

Derval Secondary School<br />

Power requirement for a 3 m wide soil<br />

loosener working at a depth of 30 cm.<br />

Indice 138<br />

(41,5 Kw)<br />

Indice 128<br />

(38,5 Kw)<br />

Straight<br />

blade<br />

Indice 100<br />

(30 Kw)<br />

Straight winged tines Curved blades AGRISEM BLADES<br />

(with retracted points)<br />

Results of the trials carried out by Derval<br />

Secondary School in November 2004<br />

7

Blade<br />

Invented by <strong>Agrisem</strong> International,<br />

today, the Combiplow is the acknowledged<br />

and uncontested reference on<br />

the market. The uniqueness of the<br />

blade with its retracted point, as well as<br />

the optimized compact frame, enable<br />

the Combiplow to meet the require-<br />

8<br />

ments of the most demanding farmers<br />

and contractors. With over 8,000 soil<br />

looseners in service, <strong>Agrisem</strong> International<br />

offers a range of suitable<br />

adapted and optimized tools.<br />

Saving fuel and time Use of the existing power<br />

harrow available<br />

13l/ha *<br />

1driver<br />

1 passage<br />

1 tractor<br />

*Average fuel consumption may vary<br />

according to soil type, the topography<br />

and the capacity of the tractor<br />

2 drivers<br />

2 passages<br />

2 tractors<br />

=<br />

You will save roughly 35 €/ha<br />

while ensuring the successful<br />

root-taking of your crops.<br />

12 l / ha *<br />

27 l / ha *<br />

+<br />

15 l / ha *<br />

Sowing in only one passage<br />

on the farm<br />

The Combiplow enables the use of the<br />

traditional combined seed drill that is<br />

already present on the farm.

Bridged framework:<br />

wide passage for PTO<br />

Retractability<br />

Combiplow 36+<br />

Retractable Combiplow, working width<br />

up to 4 m with a transport width of 3 m.<br />

Compactness of coupling<br />

(retractable)<br />

Compact for<br />

transportation<br />

Combiplow 38 - Non-stop<br />

mechanical security system Stabilizing wheels<br />

The Combiplow can be<br />

used alone by adapting<br />

aroller.<br />

Clearance at work<br />

Standard Super<br />

The ideal complement<br />

to the Combiplow !<br />

9

Blade<br />

The Cultiplow is used alone. Today this<br />

loosener is acknowledged as being the<br />

best agro-economic solution by numerous<br />

agronomists all over the world.<br />

Vineyards, orchards, market gardening<br />

We have a specific range for working in<br />

reduced widths from 1 to 3 m. Market<br />

gardeners appreciate the <strong>Agrisem</strong><br />

technique since it leaves the soil even<br />

and does not disturb the rows of vegetables.<br />

Wine growers and arboricultu-<br />

Loosening without destroying the vegetation<br />

The <strong>Agrisem</strong> blade does not destroy<br />

existing cover and allows soil loosening<br />

under a grassy surface. Unique in the<br />

world, this blade can loosen the soil without<br />

breaking its underlying “framework”.<br />

10<br />

The blades with their retracted point<br />

displace a homogeneous wave of soil<br />

and save roughly 30% of your energy<br />

consumption compared with straight or<br />

curved blades.<br />

rists choose the Cultiplow for its exceptional<br />

capacity for levelling-out, its low<br />

power requirement and the delicacy of<br />

its performance.<br />

An opening disc and a tyre-roller leave<br />

the cover vegetation intact, like the Cultigreen<br />

used for sports grounds or the<br />

“meadow” Cultiplow.

Non-stop security system,<br />

unequalled clearance<br />

The generously-sized spring security<br />

system allows you to work in the most<br />

difficult of conditions. The kinematics<br />

of the blade holder enables complete<br />

clearance by lifting-up when the blade<br />

comes into contact with an obstacle.<br />

The springs react immediately even<br />

when working at high speed contrary to<br />

a hydraulic security system that will<br />

tend to block if the speed is high or if<br />

several blades simultaneously come<br />

into contact with an obstacle (bicycle<br />

pump effect).<br />

The ideal complement<br />

to the CULTIPLOW<br />

NEW<br />

NEW PRODUCT Cultiplow 68<br />

5m-6,5m-8m<br />

11

Blade<br />

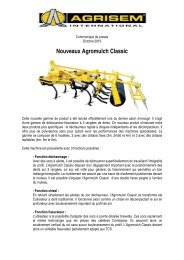

The 3 principles of the Agromulch<br />

Gain 33% power<br />

The Agromulch is used for fissuring the<br />

soil; it is made up of 2 rows of 550 mm<br />

blades and a control roller. It allows you<br />

to homogenously loosen from 10 to<br />

20 cm without any upheaval. Available<br />

in widths ranging from 3 to 12 m,<br />

this tool is the natural result of the<br />

Cultiplow. It can be used for fissuring<br />

the soil during the summer and for<br />

opening the soil in spring.<br />

Warming up without drying out<br />

12<br />

Fissuring without upheaval<br />

Germination<br />

ensured<br />

Uniform lifting<br />

No disturbance<br />

and flat work<br />

foundations<br />

Seeds<br />

Patented blade<br />

Chisel type tine cultivator<br />

Drying-out of soil horizon.<br />

Build up of clods and hollows.<br />

Seeds<br />

Chisel type tine<br />

cultivator<br />

* Reduction by 33%ofthe<br />

power required compared<br />

with a Chisel type cultivator<br />

Chisel type tine cultivator<br />

Poor<br />

germination<br />

Lifting of clods and<br />

stones,<br />

uneven profile

Modular and adaptable<br />

The Actimulch is created from the<br />

association of 2 existing machines: a<br />

stubble breaker with independent discs<br />

and a machine used for fissuring the<br />

soil<br />

The user decides if he wishes to place<br />

the fissuring mechanism in front of the<br />

discs or not. If there are crop residues,<br />

we recommend you to place the discs<br />

in front, followed by the fissuring<br />

blades. After the passage of these<br />

2 pieces of equipment, a large independent<br />

tyre roller will close the soil.<br />

Besides the possibility of changing the<br />

position of the 2 machines, you can also<br />

use each of them separately. The Actimulch<br />

can then become a stubble<br />

breaker with independent discs<br />

(Disc-O-Mulch) or an implement for<br />

fissuring the soil with a double row of<br />

blades (Agromulch).<br />

the Actimulch is available<br />

in<strong>3m</strong>,4mand5m.<br />

1 machine<br />

4 solutions<br />

13

Disc<br />

The independent disc with pan angle<br />

The aim of superficial soil work is to<br />

deal with crop residues and facilitate<br />

the germination of a stale seed bed.<br />

The disc offers the advantage of being<br />

self driven and does not require the use<br />

of power (power take-off). It wears out<br />

much slower than a tine and it works<br />

well in the presence of crop residues<br />

with no risk of windrowing.<br />

In 1998 <strong>Agrisem</strong> invented the independent,<br />

retractable disc. At that time, the<br />

disc had an opening angle and above all<br />

a positive pan angle. Compared to a<br />

traditional disc, the Disc-O-Mulch<br />

throws a flow of earth into the air. Since<br />

it is combined with a clod breaking<br />

board, the mixing of the residues is<br />

14<br />

Un déchaumeur à grande<br />

vitesse<br />

A high speed stubble breaker<br />

Un broyeur de résidus<br />

de récolte<br />

A maize mulcher<br />

A mechanical weed-killer<br />

With<br />

With pan angle and working angle<br />

• Earth thrown into the air<br />

• Perfect mix of earth-straw: mulch<br />

• Better penetration<br />

• Reduced energy requirement<br />

pan<br />

angle<br />

excellent, the seed bed is refined efficiently<br />

and the soil remains even.<br />

Finally, since the disc is a rolling element,<br />

the working speed can be very<br />

Without<br />

high as long as the implement is equipped<br />

with a board regulating the flow of<br />

earth in order to avoid any jamming in<br />

the second row of discs.<br />

Un broyeur à engrais verts<br />

An incomparable implement for levelling-out<br />

Un désherbant mécanique<br />

A crop residue chopper<br />

Un niveleur incomparable<br />

A cover crop chopper<br />

Cover-crop<br />

• Absence of pan angle<br />

• Soil moved sideways<br />

• Poor mixing, poor refining<br />

• High absorption of power<br />

• Smoothing-out of soil<br />

90°

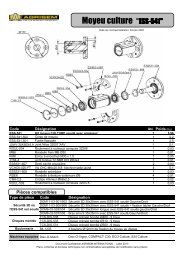

The 3D security system<br />

<strong>Agrisem</strong> International initiated the<br />

principle of the stubble breaker with independent,<br />

retractable discs. After<br />

having developed a 2D system, we understood<br />

the benefits of having a 3Dsecurity<br />

system to protect the hub and<br />

generate a vibrating effect which would<br />

save energy, improve penetration and<br />

ensure a flat working surface.<br />

This vibrating effect can only operate<br />

when the spring security system works<br />

“spiral against spiral” with the hub positioned<br />

inside the disc. Otherwise the<br />

spirals open with little resistance.<br />

The ideal size for going fast<br />

Heavy duty bearings<br />

Speed is not enough, your equipment has to enable you to<br />

work on a quick and long-lasting way. Therefore the size of<br />

the mechanical elements on the machine is of the utmost<br />

importance. The wear and tear of a mechanical part is mathematically<br />

proportional to the speed! When you double the<br />

working speed, you have to multiply the machine's resistance<br />

by four. This is why some elements on our machines<br />

may appear oversized but in fact they are necessarily so.<br />

The clod breaking board so you can work faster ...<br />

Without a clod<br />

breaking board<br />

With a grid<br />

8to20km/h<br />

2D security system<br />

(First security system installed by <strong>Agrisem</strong>)<br />

At work<br />

the shaft absorbs<br />

shocks:<br />

loosening<br />

(lubricator)<br />

Lateral<br />

stress on<br />

the disc<br />

VIBRATING<br />

EFFECT<br />

Our competitors<br />

It is necessary to have a device regulating<br />

the earth flow in order to work fast<br />

and prepare the seed bed<br />

Without a clod breaking board, the first<br />

row of discs throws a flow of earth into<br />

the second row. There is a high risk of<br />

blockage and the machine slows down.<br />

(GOLD SRE)<br />

Shift: spiral stress large<br />

overall size.<br />

22 Discs over 3 m<br />

3D<br />

security<br />

system<br />

At work<br />

spiral against spiral<br />

SHOCK EFFECT<br />

Line-up and overall<br />

size reduced .<br />

24 Discs over 3 m.<br />

PATENTED<br />

Hub positioned<br />

inside disc<br />

Inverted hub<br />

Hub<br />

positioned<br />

outside disc<br />

The security<br />

spring opens:<br />

distortion,<br />

breakage and<br />

irregular<br />

working angle<br />

Lateral<br />

stress on<br />

the disc.<br />

The earth flow regulation devices in the<br />

form of a grid have a sieving effect,<br />

which is adverse for germination. The<br />

seed finds itself in contact with straw<br />

and coarse clods. In addition, the fine<br />

earth on the surface may suffer from<br />

surface-capping.<br />

15

Disc<br />

Maintain stability while working at high speed<br />

The patented flexi-pack roller ensures perfect regularity<br />

when working at high speed. With a traditional roller, the<br />

machine lifts up when the roller comes into contact with an<br />

obstacle.<br />

Ø <strong>610</strong> discs on the front and Ø 560 at the rear<br />

On the Disc-o-Mulch <strong>Gold</strong> SRE the front<br />

discs have a larger diameter. This patented<br />

principle provides homogeneous<br />

wear and tear of the two rows of discs.<br />

The machine works better in crop residue.<br />

Choose your roller<br />

The cage roller is perfectly adapted for<br />

the work of the Disc-o-Mulch since it is<br />

simple and robust. When used for stubble<br />

breaking it refines the mulch. The<br />

flexi-pack is preferable for late sowing<br />

in sticky soils as well as for sowing<br />

after ploughing or in loose soil.<br />

Reduce the number of parts and lubricators so you can work faster<br />

The time spent on the maintenance of<br />

the Disc-o-Mulch is very limited as the<br />

number of lubricators is reduced to a<br />

minimum (between 0 and 5 depending<br />

on the model). You will not waste your<br />

Guaranteed speed and high output<br />

With working speed ranging from 8 to<br />

20 Km/h the Disc-o-Mulch will ensure<br />

unequalled output.<br />

Output of a Disc-O-Mulch/<br />

Disc-O-Sem for an average<br />

speed of 12 km/h.<br />

16<br />

The second row of discs has a higher<br />

speed of rotation which generates better<br />

refining. This simple idea makes the<br />

Disc-o-Mulch even more efficient.<br />

Cage<br />

Flexi-Sem ®<br />

time crawling under the machine to<br />

grease each disc or every single articulation.<br />

Fewer parts and articulations<br />

also mean durability and reliability for<br />

work at high speed.<br />

3,6 ha/h 4,2 ha/h 4,8 ha/h<br />

6 ha/h<br />

7,2 ha/h<br />

With Flexi-Pack ®<br />

Higher speed<br />

improved refining<br />

There are fewer parts but each of them<br />

is larger and stronger.<br />

9ha/h<br />

Better clearance<br />

less wear and tear.<br />

10,8 ha/h<br />

14,4 ha/h<br />

3 m 3,5 m 4 m 5 m 6 m 7,5 m 9 m 12 m<br />

Required<br />

power 90 hp 130 hp 150 hp 180 hp 200 hp 250 hp 350 hp 400 hp 550 hp<br />

Agrix ®<br />

Flexi-Pack ®<br />

Without Flexi-Pack ®<br />

PATENTED<br />

Ø 560 Ø <strong>610</strong><br />

NEW<br />

Flexi-Roll ®

The Best works at a speed between<br />

6 and 12 km/h. It is suitable for small<br />

tractors with a requirement of 25 to<br />

35 hp per meter. Optionally, the flow<br />

of soil is regulated by individual clod<br />

Discs<br />

Ø 460<br />

Best<br />

breaking boards fixed to the rear hubs.<br />

It has the same technology as the<br />

larger machine, Disc-O-Mulch: maintenance-free<br />

hubs, patented 3D security<br />

system, depth control with a roller<br />

Individual clod breaking boards Folding 2,50 m model<br />

and the possibility of adapting a<br />

mechanical seeddrill in order to<br />

obtain Disc-O-Sem.<br />

17

Disc<br />

18<br />

NEW<br />

NEW<br />

3,50 m<br />

Towed cage roller<br />

Towed Disc-O-Mulch<br />

<strong>Gold</strong><br />

The GOLD model is the reference on<br />

the market. This product comes from<br />

10 years of research and development<br />

following the first Disc-O-Mulch<br />

created in 1998.<br />

It has been designed to<br />

work in difficult<br />

conditions and<br />

has pro-<br />

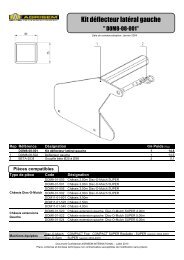

Deflectors<br />

Two lateral deflectors<br />

avoid excess soil at<br />

the sides. The left<br />

deflector is standard<br />

and the right one<br />

is optional.<br />

ved its capacity and efficiency on the<br />

plains of Eastern Europe. It is 'THE'<br />

machine for use on large farms and for<br />

contractors.<br />

This range of Disc-O-Mulch is designed<br />

for transformation into a seed drill<br />

(Disc-O-Sem). The GOLD is available in<br />

two models, depending on the intensity<br />

of the work: the S or the SRE.<br />

Width<br />

Disc-O-Mulch <strong>Gold</strong> fixe<br />

2,5 m - 3 m - 3,50 m - 4 m<br />

The multi-stop security system<br />

Adjustment of<br />

depth control<br />

Possibility of<br />

adjustment of distance<br />

with the second<br />

row of discs<br />

Adjustment of<br />

the lower stop<br />

Standard draw-bar<br />

standard on the <strong>3m</strong> and 4m<br />

Disc-O-Mulch.

Folding Disc-O-Mulch <strong>Gold</strong><br />

Width<br />

Folding Disc-O-Mulch <strong>Gold</strong>4m-<br />

5 m - 6 m - 7,50 m<br />

Super draw-bar<br />

Standard on the towed 5m, 6m and<br />

7,5m Disc-O-Mulch. Optional on smaller<br />

widths.<br />

Good stability at field ends<br />

Turning circle facilitated.<br />

Hydraulic folding<br />

Hydraulically locked for transport.<br />

Options<br />

Stabilizing wheels<br />

Depth control wheels<br />

19

Disc<br />

The 12m Disc-O-Mulch is a tool-support<br />

machine. Its central structure has<br />

3 coupling points for attaching two <strong>3m</strong><br />

Disc-O-Mulch onto the extensions and<br />

one 6m Disc-O-Mulch at the rear.<br />

The two lateral extensions are retractable<br />

to ensure a height of 4,10m for<br />

transport.<br />

Folding<br />

20<br />

12 m<br />

12 m<br />

Height 4,10m in<br />

transport position<br />

Hydraulically locked<br />

for transport

Sowing<br />

The Disc-O-Mulch becomes a seed drill!<br />

Reduction of mechanisation costs<br />

In optimizing your machines and in<br />

decreasing your labour costs, you<br />

increase your profitability.<br />

This profitability can come about<br />

without risk as the Disc-O-Sem can be<br />

progressively introduced onto your<br />

farm. Since it is so versatile, the<br />

Disc-O-Sem will be paid off quicker<br />

than forecast and will be useful on an<br />

ever growing working area, so this will<br />

decrease its cost at work.<br />

The lowest cost on the market<br />

In terms of profitability, the Disc-O-Sem<br />

is interesting for two reasons.<br />

The investment per hectare is the<br />

lowest, especially when compared to<br />

direct drills which require very specific<br />

equipment. Moreover, the cost in use<br />

per ha is much lower than the cost of a<br />

standard stubble breaker combined<br />

with a specialised SCT seed drill.<br />

* Source : Arvalis 2005<br />

{<br />

Traditional<br />

system<br />

Ploughed or not ploughed<br />

Traditional equipment<br />

3 tractors : 180, 150 and 120 hp<br />

No Ploughing<br />

Traditional or specialised equipment<br />

2 tractors 150 and 120 hp<br />

Only 1 tractor of 150 hp<br />

Standard soil<br />

conservation techniques<br />

Mechanisation costs<br />

+ Herbicide<br />

+ Labour (€/ha)<br />

210<br />

190<br />

170<br />

150<br />

130<br />

110<br />

Traditional equipment<br />

Traditional equipment<br />

Special seeddrill & disc harrow<br />

Direct seeddrill<br />

Seeddrill on stubble breaker<br />

<strong>DS</strong>F - Front hopper<br />

<strong>DS</strong>T - Huge capacity<br />

<strong>DS</strong> mechanical<br />

Sowing ramp<br />

With <strong>Agrisem</strong>,<br />

one machine<br />

is enough !<br />

Superficial ploughing<br />

Ploughing<br />

Ploughing 2years/3<br />

1000 <strong>1100</strong> 1200 1300 <strong>1400</strong> 1500 1600 1700<br />

Investment tractor + soil preparation & seeddrill<br />

Value with new machines (€/Ha)<br />

21

Sowing<br />

Sowing in rows<br />

Tradition and versatility<br />

On this model, the Disc-O-Sem is<br />

equipped with a sowing ramp with<br />

discs, at the rear of a large pneumatic<br />

roller. The sowing ramp is made up of<br />

sowing elements equipped with a<br />

simple disc and a small wheel that<br />

compacts the soil after sowing. In wet<br />

conditions, it is easy to detach the<br />

wheel. The distance between each<br />

sowing line is 12,5cm. The design of<br />

this sowing ramp originates from the<br />

simplicity and sturdiness made famous<br />

22<br />

6 to 12 km/h<br />

by the Disc-O-Mulch. This sowing ramp<br />

is maintenance-free as the hubs have<br />

no lubricators and the 3D springs,<br />

which maintain the discs, have no articulations.<br />

Obviously, you can uncouple<br />

the sowing ramp in order to use the<br />

Disc-O-mulch alone as a stubble<br />

breaker.<br />

The Disc-O-Sem for sowing in rows is<br />

only available in the pneumatic version<br />

with a front hopper and as <strong>3m</strong> and4m<br />

width models.<br />

Sowing element<br />

with disc

Sowing by covering over<br />

Productivity, sturdiness and simplicity<br />

When sowing by covering over, we do<br />

not control the depth of sowing, but the<br />

amount of soil which covers the seeds.<br />

Only an independent disc with a pan<br />

angle is able to sow by covering over.<br />

The pan angle of the disc lifts up the<br />

soil as of a speed of 8 km/h. The soil is<br />

refined thanks to the shock as it hits<br />

the board and then it covers the seed.<br />

The depth is controlled by adjusting the<br />

amount of soil which is lifted up. This<br />

amount is proportional to the working<br />

depth of the second row of discs. The<br />

rear roller maintains the discs at a<br />

constant working depth, whatever the<br />

working speed, so the sowing depth is<br />

Sowing rows of crops<br />

regular. This sowing system creates<br />

bands of crops as the seed are sown<br />

every 25cm.<br />

The Disc-O-Sem for sowing by covering<br />

over is available in mechanical or pneumatic<br />

versions. The widths available<br />

are from <strong>3m</strong> to 6m as mounted or<br />

towed models.<br />

8 to 18 km/h<br />

Mechanical seeddrills: sowing<br />

ramp with clod breaking board<br />

Pneumatic seeddrills:<br />

individual sowing elements<br />

23

Sowing<br />

Sowing by covering over<br />

Oil seed rape Wheat on wheat<br />

Flax Wheat<br />

Peas<br />

Wheat after maize Barley<br />

24<br />

Wheat after sunflower only 1 passage

Sowing by covering over<br />

Why sowing by covering over instead of using a ramp<br />

with sowing elements?<br />

With a sowing element, depth control is<br />

not regular. At over 12 km/h, the element<br />

starts to vibrate. Moreover, the<br />

ramp reduces the sowing capacity of<br />

the drill when there is crop residue.<br />

Finally, with a ramp there are many<br />

small parts which increase maintenance<br />

and which could be the cause of<br />

possible technical problems…<br />

Sow rapidly in the presence of crop<br />

residue.<br />

The independent disc is able to work<br />

perfectly in crop residue without getting<br />

clogged up with straw, whereas<br />

tines rake up the residue and get<br />

blocked. The Disc-O-Sem is able to drill<br />

directly after maize, oil seed rape, sunflower<br />

or soy harvests. It saves you a<br />

passage with the chopper.<br />

Optimize germination<br />

at high speed.<br />

The germination rate with sowing by<br />

covering over is always high. We can<br />

explain this by two factors:<br />

An excellent soil/seed contact: the<br />

seeds are covered over by an energetic<br />

flow of soil and there is no risk of<br />

smoothing over the sowing line with<br />

the sowing element.<br />

The seeds are in contact with fine soil.<br />

When lifting up the soil, the second row<br />

of discs separates the fine soil from the<br />

clods and residue. The smallest elements<br />

fall first due to their density, and<br />

so are the first to be in contact with the<br />

seeds.<br />

Don't confuse broadcast sowing and<br />

sowing by covering over: With broadcast<br />

sowing, the seeds are thrown onto<br />

the soil. The sowing depth is random.<br />

With the covering over system, the seed<br />

The larger clods and the straw fall on<br />

top to make mulch and protect the surface.<br />

Excellent seed/soil contact in stony<br />

conditions.<br />

Trial by the chamber of agriculture - Department of Orne<br />

The trials were carried out by the chamber of agriculture of the<br />

Orne during the season of 2004 / 2005. The control (combination<br />

power harrow & seeddrill) and the AGRISEM seeddrill provided<br />

virtually the same results: sowing depth, regularity and germination<br />

rate.<br />

Amount of seedlings<br />

% seed germination<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

CONTROL<br />

Combined drill<br />

(PH & Drill)<br />

Stubble breaker Cultivator Tine harrow AGRISEM<br />

& croskill<br />

Sowing by<br />

covering over<br />

Broadcast sowing<br />

is placed under the flow of soil which<br />

optimizes the sowing depth, and<br />

makes it constant under all conditions,<br />

so you can control your sowing depth<br />

with precision.<br />

25

Sowing<br />

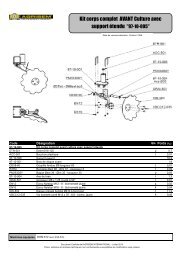

The mechanical Disc-O-Sem<br />

The mechanical Disc-O-Sem is a unique<br />

solution on the market. It is the most<br />

cost-effective and certainly the strongest<br />

SCT seed drill on the market.<br />

Since it has no hydraulic turbine, you<br />

save 10 hp and you gain in simplicity<br />

Best<br />

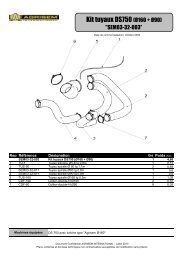

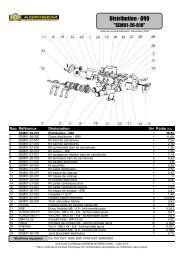

<strong>DS</strong> <strong>610</strong> - <strong>3m</strong> / <strong>610</strong> <strong>litres</strong><br />

Individual sowing elements<br />

from the mechanical seeddrill<br />

of the <strong>610</strong>L adapted to the<br />

Disc-O-Mulch Best frame.<br />

<strong>Gold</strong><br />

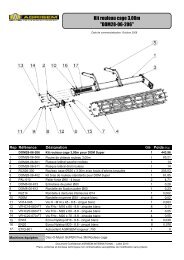

<strong>DS</strong> <strong>1100</strong> - <strong>3m</strong> / <strong>1100</strong> <strong>litres</strong><br />

<strong>DS</strong> <strong>1400</strong> - 4m / <strong>1400</strong> <strong>litres</strong><br />

Sowing ramp on the clod<br />

breaking board for the <strong>DS</strong><br />

<strong>1100</strong> / <strong>DS</strong> <strong>1400</strong><br />

26<br />

and reliability. Mechanical seed drills<br />

by gravity suffer from an old-fashioned<br />

and archaic image, whereas they are<br />

probably the best economical and<br />

technical choice for small width equipment.<br />

With no pneumatic or hydraulic<br />

Gangplank<br />

adjustment, you only have to couple-up<br />

the equipment, adjust the seed rate<br />

and off you go! These Disc-O-Sem<br />

perfectly suit co-operative use.<br />

Distribution via fluting and<br />

spurs<br />

Oil-immersed variator Hydraulic marking kit

Towed models<br />

The mounted mechanical Disc-O-<br />

Sem's are also available as towed models.<br />

We use the Flexi-Pack or another<br />

roller with a supporting axle. These<br />

machines are suitable for tractors with<br />

a low lifting capacity and insufficient<br />

hydraulic flow to drive an agricultural<br />

turbine.<br />

<strong>DS</strong>T <strong>1100</strong><br />

<strong>DS</strong>T <strong>1400</strong><br />

<strong>3m</strong><br />

<strong>1100</strong> <strong>litres</strong><br />

Towed cage roller<br />

4m<br />

<strong>1400</strong> <strong>litres</strong><br />

NOUVEAU<br />

27

Sowing<br />

The front hopper : <strong>DS</strong>F 1500<br />

The front hopper is versatile and modular. With a strong frame, it is well-adapted for use at a high working<br />

speed. The front hopper can be uncoupled quickly and easily in order to use the stubble breaker alone.<br />

Some important<br />

advantages…<br />

• The possibility of using the stubble breaker<br />

alone without carrying the sowing unit.<br />

• The front hopper allows you to use<br />

rear-mounted equipment behind the<br />

tractor. This set up makes the equipment<br />

much easier to handle and decreases<br />

compaction at the field's end,<br />

often found with towed equipment.<br />

• Constant pressure on the working and<br />

sowing equipment means constant<br />

sowing depth whatever the amount or<br />

weight of seed in the hopper.<br />

Visibility loading Versatility<br />

The shape of the polyethylene hopper<br />

was especially designed to offer perfect<br />

visibility up front. Its sloping shape<br />

offers unrivalled comfort at work.<br />

This hopper can also be used to distribute<br />

fertiliser since it is easily cleaned.<br />

28<br />

• Good distribution of the weight on the<br />

tractor. The weight is reduced by about<br />

1 Ton as the front ballast is replaced by<br />

A low loading threshold which requires<br />

no specialist equipment.<br />

Distribution of weight<br />

the hopper, and this saves about 10hp<br />

of energy.<br />

The polyethylene hopper and the stainless<br />

steel distribution system allow the<br />

<strong>DS</strong>F to be used to distribute fertiliser<br />

when sowing maize or beetroot.

The stainless steel pneumatic distribution system<br />

Most pneumatic drills were designed,<br />

regarding their size, to sow at between<br />

4 and 9 km/h. This is the reason why<br />

they are not compatible with the high<br />

speed of the Disc-O-Sem. Our distribution<br />

system has been designed for high<br />

flow distribution. This distribution<br />

system is larger and has a powerful<br />

pneumatic turbine.<br />

Markers for <strong>3m</strong>, 3,5m and 4m rigid<br />

Disc-O-Sem (folding vertically).<br />

Markers for 4m,<br />

5m and 6m folding<br />

Disc-O-Sem<br />

(folding laterally).<br />

16 outlet distribution<br />

heads<br />

Filling trapdoors<br />

24 outlet distribution<br />

heads<br />

Turbine<br />

Emptying trapdoors Seed-rate trial<br />

trapdoors<br />

Box for small seeds<br />

Electronic control<br />

box<br />

Removable box with<br />

two connections<br />

29

Sowing<br />

<strong>DS</strong>T 6000, the specialist for large farms<br />

The <strong>DS</strong>T 6000 is an exceptional<br />

machine. It has been designed to drill<br />

more than 100 Ha a day with a width of<br />

6m and a hopper capacity of 6,000 <strong>litres</strong><br />

Depending on the landscape and the<br />

working speed, the power requirement<br />

is from 250 hp to 350 hp.<br />

The towed frame has got a lifting capacity<br />

of 16 tons to which we can couple<br />

up a 6m stubble breaker.<br />

Lifting capacity of 16 T Easy loading<br />

Transportation on the road<br />

The <strong>DS</strong>T 6000 behaves like a trailer.<br />

30<br />

The rear machine is mounted which<br />

makes the <strong>DS</strong>T easy to handle.<br />

The seed drill and the stubble breaker<br />

can easily be uncoupled to use the<br />

Disc-O-Mulch alone.<br />

Hydraulic stainless steel 'worm' for filling the hopper (optional).

Highly autonomous and the possibility of mixing grains<br />

With a hopper capacity of 6,000 <strong>litres</strong>,<br />

the <strong>DS</strong>T has got autonomy of around 40<br />

ha of wheat. This capacity is divided<br />

into two individual 3,000 litre hoppers.<br />

Each has got its own distribution channel.<br />

Optionally, it is possible to incorporate<br />

fertiliser and seeds, or to mix two<br />

different varieties of seed.<br />

Sowing of wheat after corn<br />

in only one passage<br />

Regular sowing depth<br />

The hoppers are not mounted on the<br />

stubble breaker but they are up front.<br />

The amount of seed in the hoppers<br />

doesn't affect the sowing depth.<br />

7,4 m<br />

The work of the Disc-O-Mulch remains<br />

constant whatever the weight of the<br />

hoppers.<br />

<strong>3m</strong> width<br />

Hydraulic brakes<br />

<strong>3m</strong><br />

Use of the Disc-O-Mulch alone<br />

31

Everybody’s talking about us !!!<br />

AGRISEM International S.A.<br />

“Beaucé” - 44850 LIGNÉ - FRANCE<br />

Phone +33 (0) 240 77 40 48 - Fax +33 (0) 240 77 45 45<br />

E-mail : agrisem@agrisem.com - Website : www.agrisem.com<br />

RCS Nantes B 389 996 737 - Documents, photos and technical data non-contractual,<br />

susceptible to modification without notice.<br />

Printed in January 2009 - IMPRIM’lOIRE / 0240 83 14 63 -