Minimizing Losses in Hay Storage and Feeding - MSUcares

Minimizing Losses in Hay Storage and Feeding - MSUcares

Minimizing Losses in Hay Storage and Feeding - MSUcares

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

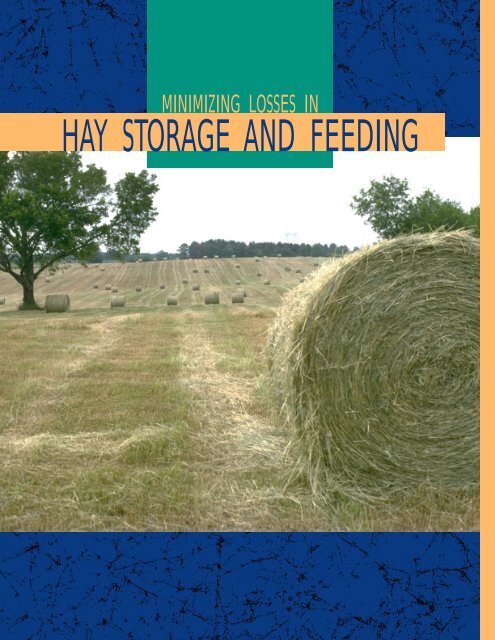

MINIMIZING LOSSES INHAY STORAGE AND FEEDING

MINIMIZING LOSSES IN HAYSTORAGE AND FEEDINGEach year more than 60 million acresof forage crops are harvested for hay <strong>in</strong>the United States. Annual productionfrom this acreage is over 150 milliontons of hay valued at more than 12billion dollars. <strong>Hay</strong> is the most widelygrown mechanically-harvested agronomiccrop <strong>in</strong> the United States.As a source of nutrition for livestock,hay offers numerous advantages.It can be made from many differentcrops; when protected from theweather it can be stored <strong>in</strong>def<strong>in</strong>itelywith little nutrient loss; package sizes<strong>and</strong> shapes can vary greatly; <strong>and</strong>harvest<strong>in</strong>g, storage, <strong>and</strong> feed<strong>in</strong>g canvary from be<strong>in</strong>g done by h<strong>and</strong> to be<strong>in</strong>gcompletely mechanized. <strong>Hay</strong> often canmeet, or almost meet, the nutrientneeds of many classes of livestock.Because of its many merits, hay isthe most commonly used stored feedon livestock farms across the nation.Unfortunately, losses of hay dur<strong>in</strong>gstorage <strong>and</strong> feed<strong>in</strong>g are often high,particularly with round bales storedoutside <strong>in</strong> high ra<strong>in</strong>fall areas such asthe eastern United States. It is estimatedthat the total value of haystorage <strong>and</strong> feed<strong>in</strong>g losses nationwideexceeds three billion dollars annually!On some farms, such losses account forover 10% of the cost of livestockproduction.These are real, <strong>and</strong> not just potential,losses (time, labor, <strong>and</strong> monetary<strong>in</strong>puts are lost along with the hay).Unfortunately, many producersprobably do not realize how large theirlosses really are, or that with relativelylittle effort or expense they could bereduced considerably. The purpose ofthis publication is to provide <strong>in</strong>formationas to how <strong>and</strong> why hay lossesoccur, <strong>and</strong> how they can be reduced.TYPES OF STORAGE LOSSES<strong>Hay</strong> storage losses vary greatly depend<strong>in</strong>gupon several factors, but storagetechnique is of utmost importance.<strong>Losses</strong> of dry hay stored <strong>in</strong>side a barnare usually of little concern. However,even for barn stored hay, losses risesharply as moisture levels <strong>in</strong>creaseabove 20%, <strong>and</strong> losses from roundbales stored outside under adverseconditions can be much larger.Dur<strong>in</strong>g storage, hay can be subject todry matter losses as well as losses offorage quality.Dry Matter <strong>Losses</strong>Dry matter losses dur<strong>in</strong>g storage resultfrom plant respiration (the cont<strong>in</strong>uationof normal plant processes),microbial activity, <strong>and</strong> weather deterioration.Even at low moisture levels(20% or less) there is some loss due torespiration <strong>and</strong> low numbers ofmicroorganisms, but this is constantacross hay types <strong>and</strong> essentiallyunavoidable.At higher moisture levels (above20%) where mold growth is likely tobe visibly detectable, dry matter lossesare greater, <strong>and</strong> significant levels ofheat<strong>in</strong>g (which can also lower foragequality) occur due to microbial activity.Although numerous bacteria arepresent <strong>in</strong> hay, fungi account for mostof the microbial growth.Heat<strong>in</strong>g of hay is related to moisturecontent. Peak temperature is oftenreached with<strong>in</strong> a week after bal<strong>in</strong>g, butwith higher moisture hay <strong>and</strong> conditionswhich limit heat escape, it maytake as much as three weeks. At safemoisture levels (less than: 20% forrectangular bales; 18% for round bales;<strong>and</strong> 16% for large rectangular packages)<strong>in</strong>side storage losses are typicallyaround 5% of dry matter, but lossesseveral times higher have been reportedfor extremely moist hay.“Weather<strong>in</strong>g” (the term which iscommonly used to refer to the effects2which climatic conditions have on hay)is partially a physical process. Some ofthe dry matter loss which occursdur<strong>in</strong>g outside storage is caused byleach<strong>in</strong>g, which refers to the dissolv<strong>in</strong>g<strong>and</strong> removal of nutrients by the passageof ra<strong>in</strong> water over the surface of, <strong>and</strong>through, the bale. The more digestiblenutrients are, the more soluble theyare, <strong>and</strong> thus the more likely they areto be removed by leach<strong>in</strong>g.The switch from small rectangularbales to large round bales on most U.S.farms has resulted <strong>in</strong> higher storagelosses (<strong>in</strong> many cases, several timeshigher). Round bales are not <strong>in</strong>herentlysubject to greater losses, but they aremuch more likely to be subjected toadverse storage conditions, oftenrema<strong>in</strong><strong>in</strong>g outside with no protectionbetween bal<strong>in</strong>g <strong>and</strong> feed<strong>in</strong>g. Feed<strong>in</strong>glosses are usually sharply higher withround bales as well, partly because biground bales are generally fed on sodwhile rectangular bales are often fed<strong>in</strong> bunks.The extent of weather<strong>in</strong>g damagedur<strong>in</strong>g outside storage varies ma<strong>in</strong>lywith climatic factors <strong>and</strong> with foragespecies. Weather<strong>in</strong>g primarily affectshay <strong>in</strong> the outside circumference of alarge round bale rather than <strong>in</strong> theends. Consequently, package size(ma<strong>in</strong>ly the diameter) affects theproportion of the bale conta<strong>in</strong>ed <strong>in</strong> thesurface layer, <strong>and</strong> thus the magnitudeof losses (Figure 1).Figure 1. Dry matter loss vs. average spoilage depth <strong>in</strong>round bales of various diameters.*50%40%30%20%10%0%Bale diameter = 3 ft.4 ft.5 ft.6 ft.1 2 3 4 5 6Average spoilage depth (<strong>in</strong>ches)*SOURCE: Buckmaster, D.R., 1993. Evaluator for Round<strong>Hay</strong> Bale <strong>Storage</strong>. J. Prod. Agric., 6:378-385.

In the eastern United States it is notunusual for 4 to 8 or more <strong>in</strong>ches ofspoilage to occur on the outside oflarge round bales stored outside withno protection. A weathered layer 6<strong>in</strong>ches <strong>in</strong> depth on a 5.6 foot x 5.6 footbale conta<strong>in</strong>s about one-third of thepackage volume. Other th<strong>in</strong>gs be<strong>in</strong>gequal, the percentage of hay lostdecreases as bale size <strong>in</strong>creases because asmaller proportion of the bale volumeis conta<strong>in</strong>ed <strong>in</strong> the surface layer. Thishas important implications regard<strong>in</strong>gbaler purchase decisions.Forage Quality <strong>Losses</strong><strong>Storage</strong> conditions can also have adramatic effect on hay chemicalcomposition <strong>and</strong> feed<strong>in</strong>g value. Typicaleffects on the <strong>in</strong>terior (unweathered)<strong>and</strong> exterior (weathered) portions ofbales on crude prote<strong>in</strong>, acid detergentfiber (ADF), <strong>and</strong> <strong>in</strong> vitro digestible drymatter (IVDDM) are shown <strong>in</strong> Table1. Even if there were no dry matterlosses or additional feed<strong>in</strong>g losses withweathered hay, changes <strong>in</strong> foragequality would be of great concern.Total crude prote<strong>in</strong> decl<strong>in</strong>es withweather<strong>in</strong>g, but the percentage ofcrude prote<strong>in</strong> may <strong>in</strong>crease due to drymatter losses (a phenomenon whichhas been reported to also occur withra<strong>in</strong> damage of field-cur<strong>in</strong>g hay). ThisSampl<strong>in</strong>g each lot of hay for nutritive analysis isnecessary if hay is to be fed <strong>in</strong> an efficient manner.is because prote<strong>in</strong> is less subject thanother plant constituents to weather<strong>in</strong>gloss. However, the proportion ofdigestible crude prote<strong>in</strong> may decrease,especially if the hay undergoes heat<strong>in</strong>gdue to excessive moisture.Soluble carbohydrates, which arehighly digestible, decl<strong>in</strong>e dur<strong>in</strong>gweather<strong>in</strong>g as shown by <strong>in</strong>creases <strong>in</strong>Table 1. Forage quality of the <strong>in</strong>terior <strong>and</strong> exterior portions of alfalfa roundbales stored outside.*Portions Crude Acid detergentOf Bales prote<strong>in</strong> fiber IVDDM_____________________________________________________________- - - - - - - - % of dry weight - - - - - -Interior 18.9 38.6 61.4Exterior 19.4 45.8 46.9_____________________________________________________________*SOURCE: Anderson, P.M., W.L. Kjelgaard, L.D. Hoffman, L.L. Wilson, <strong>and</strong> H.W. Harpster. 1981. Harvest<strong>in</strong>gpractices <strong>and</strong> round bale losses. Trans. ASAE.24:841-842.ADF <strong>and</strong> decreases <strong>in</strong> IVDDM; thuscarbohydrate levels differ greatlybetween the weathered <strong>and</strong> unweatheredportions of round bales. Decl<strong>in</strong>es<strong>in</strong> hay quality from weather<strong>in</strong>g areHAY QUALITY- THE KEY TOANIMAL PERFORMANCE<strong>Hay</strong> quality is critically important, especially for animals hav<strong>in</strong>ghigh nutritional requirements, <strong>and</strong> the ultimate test of hay qualityis animal performance. <strong>Hay</strong> quality is considered satisfactory whenanimals consum<strong>in</strong>g it perform as desired. For anyone who isproduc<strong>in</strong>g, feed<strong>in</strong>g, buy<strong>in</strong>g, or sell<strong>in</strong>g hay, forage quality should bea major consideration.Factors which affect hay quality <strong>in</strong>clude: grow<strong>in</strong>g conditions,fertility, species, varieties, pests, presence of weeds, harvest<strong>in</strong>g,cur<strong>in</strong>g, h<strong>and</strong>l<strong>in</strong>g, <strong>and</strong> storage. However, the stage of maturity whenharvested is the most important factor, <strong>and</strong> the one wheremanagement can have the greatest impact.As plants advance from the vegetative to the reproductivestages, fiber <strong>and</strong> lign<strong>in</strong> <strong>in</strong>crease, while prote<strong>in</strong>, digestibility,metabolizable energy, <strong>and</strong> acceptability to livestock decrease. Earlycut hay makes a more desirable feed because it conta<strong>in</strong>s morenutrients. <strong>Hay</strong> cut at an early stage of maturity is also morepalatable <strong>and</strong> is more readily consumed by livestock.Evaluat<strong>in</strong>g <strong>Hay</strong> QualitySeveral methods exist for evaluat<strong>in</strong>g hay quality: visual, chemical,near <strong>in</strong>frared reflectance spectroscopy (NIRS), <strong>and</strong> animalperformance. Visual estimates can help, but vary considerably.Descriptions based on these estimates show high quality hay to beearly cut, leafy, soft, free of mold <strong>and</strong> foreign material, <strong>and</strong> hav<strong>in</strong>ga pleasant odor. Color can be mislead<strong>in</strong>g, because hay hav<strong>in</strong>g abright green color may be mature <strong>and</strong> fibrous, while faded haymay often have excellent nutritional value.The most precise way to determ<strong>in</strong>e the nutrient content ofhay is through laboratory analysis. If a representative sample istaken <strong>and</strong> analyzed for nutritive content, the results can helpdeterm<strong>in</strong>e how much <strong>and</strong> what type of supplementation, if any, isneeded <strong>in</strong> order to meet the nutrient requirements of the animalsbe<strong>in</strong>g fed, <strong>and</strong> to obta<strong>in</strong> the level of performance desired. Thisleads to efficient <strong>and</strong> economical feed<strong>in</strong>g programs.Sampl<strong>in</strong>g For Forage Quality AnalysesWhen hay is tested, a r<strong>and</strong>om, representative sample must beobta<strong>in</strong>ed because laboratory results will be only as accurate as thesample submitted. A sample should be taken for each lot of hay. A“lot” represents a group of bales of hay which were grown <strong>in</strong> thesame field, harvested under the same conditions <strong>and</strong> at the sametime, <strong>and</strong> stored <strong>in</strong> the same way.When collect<strong>in</strong>g samples, a hay probe should be used whichhas a m<strong>in</strong>imum cutt<strong>in</strong>g diameter of 1/2 <strong>in</strong>ch <strong>and</strong> a m<strong>in</strong>imumlength of 12 <strong>in</strong>ches. Samples should be taken from the ends ofconventional rectangular bales or from the radial sides of largeround bales, with 15 to 20 probe samples be<strong>in</strong>g composited <strong>and</strong>then submitted for analysis from each lot of hay. Samples shouldbe stored <strong>in</strong> an airtight bag for shipment to the laboratory.Sampl<strong>in</strong>g of weathered hay for nutritive value is more complexthan sampl<strong>in</strong>g unweathered hay. Ideally, weathered <strong>and</strong>unweathered portions of bales should be sampled separately <strong>and</strong>the analysis results from the two fractions weighted accord<strong>in</strong>g totheir relative contributions to entire bales.3

Table 2. <strong>Losses</strong> of forage quality dur<strong>in</strong>g storage of round-baledgrass <strong>and</strong> grass-legume hay.*___________________________________________________________________________<strong>in</strong> vitro Relative $ valueCrude digestible feed<strong>Hay</strong> type Fraction prote<strong>in</strong> dry matter value loss___________________________________________________________________________- - - % of dry wt. - - - <strong>in</strong>dex $/TGrass unweathered 13.5 58.8 72 —weathered 16.4 42.5 75 9.72Alfalfa unweathered 14.2 56.5 86 —weathered 16.9 34.2 79 22.68____________________________________________________________________________*SOURCE: Lechtenberg, V.L., K.S. Hendrix, D.C. Petritz, <strong>and</strong> S.D. Parsons. 1979. Compositional changes <strong>and</strong> losses<strong>in</strong> large hay bales dur<strong>in</strong>g outside storage. pp. 11-14 In Proc. Purdue Cow-Calf Res. Day. West Lafayette, IN, 5Apr. 1979. Purdue Univ. Agric. Exp. Stn. West Lafayette, IN.1 <strong>Hay</strong> value determ<strong>in</strong>ed: Y = (0.81 x RFV <strong>in</strong>dex) - 14.8 where Y = $/ton of hay. M<strong>in</strong>nesota Quality-Tested<strong>Hay</strong> Auction Data. SOURCE: Mart<strong>in</strong>, N.R., & Duane Schriever. 1996. M<strong>in</strong>nesota forage update Vol. XXI, No. 2, p. 5.usually greater for legumes than forgrasses (Table 2).Some heat<strong>in</strong>g of hay is normal, butextreme heat<strong>in</strong>g (above 120 o F) lowersforage quality along with dry matter.Microbial activity associated withheat<strong>in</strong>g uses soluble carbohydrates,which reduces digestibility <strong>and</strong><strong>in</strong>creases fiber levels. A reduction <strong>in</strong>voluntary <strong>in</strong>take accompanies excessive<strong>in</strong>creases <strong>in</strong> NDF.In addition to caus<strong>in</strong>g huge dry matter losses,weather<strong>in</strong>g lowers forage quality, reduces palatability<strong>and</strong> <strong>in</strong>take, <strong>and</strong> <strong>in</strong>creases feed<strong>in</strong>g losses due toanimal refusal. Cattle ate only the center portion ofthis highly weathered bale.UNDERSTANDING THEWEATHERING PROCESSFrom the preced<strong>in</strong>g discussion, itshould be obvious that most of the haystorage losses which occur are associatedwith hay be<strong>in</strong>g stored outside <strong>in</strong> asituation <strong>in</strong> which it is exposed to theelements, result<strong>in</strong>g <strong>in</strong> weather<strong>in</strong>g. Thelonger hay is exposed to unfavorableweather conditions, the greater losseswill be.How Weather<strong>in</strong>g OccursBales stored outside on the groundwithout covers <strong>in</strong>crease sharply <strong>in</strong>moisture content dur<strong>in</strong>g storage. Thisis especially true for the outer 2 to 3<strong>in</strong>ches of the bale <strong>in</strong> which moisturemay <strong>in</strong>crease by as much as 120%.Weather<strong>in</strong>g beg<strong>in</strong>s slowly, but thenaccelerates because weathered hay ismore easily penetrated by ra<strong>in</strong>, <strong>and</strong>doesn’t dry as rapidly thereafter.In areas of high <strong>and</strong>/or frequentra<strong>in</strong>fall, or with hay which does notshed water readily, the method ofstorage can make the differencebetween less than 5%, or more than50%, dry matter loss from weather<strong>in</strong>g!Furthermore, losses of more than 14%of the total crude prote<strong>in</strong> <strong>and</strong> morethan 25% of the total digestiblenutrients can occur <strong>in</strong> the most highlyweathered portions of a bale. Animportant associated factor is that thepalatability of weathered portions ofbales is decreased, which lowers <strong>in</strong>take<strong>and</strong> <strong>in</strong>creases refusal.Thatch FormationIn theory, a round bale should form athatch that will, at least <strong>in</strong>itially, shedalmost all of the ra<strong>in</strong> which falls on thetop of the bale, but any of severalfactors may prevent this from occurr<strong>in</strong>g.Examples of forage crops whichhave the potential to thatch well whenpackaged <strong>in</strong> a uniform, dense bale aref<strong>in</strong>e-stemmed, leafy, weed-freebermudagrass or tall fescue.<strong>Hay</strong> made from coarse-stemmedforage crops will not thatch well. Thisis due to large stems, hollow stems, orother physical factors which do notallow thatch formation. For example,water can easily penetrate the tops ofbales of many summer annual grasses,thus quickly beg<strong>in</strong>n<strong>in</strong>g the weather<strong>in</strong>gprocess. Coarse-stemmed weeds with<strong>in</strong>hay can also provide an avenue forwater to penetrate bales.Once a wet layer forms, a bale doesnot shed water well <strong>and</strong> moisture levels<strong>in</strong>side the bale are likely to cont<strong>in</strong>ue to<strong>in</strong>crease dur<strong>in</strong>g the storage period. Asthe wet, moldy area on the top of thebale deepens, less <strong>and</strong> less dry<strong>in</strong>goccurs between ra<strong>in</strong>s. Hence, onceweather<strong>in</strong>g gets underway, it usuallyproceeds much faster than with newlybaled hay.Underst<strong>and</strong><strong>in</strong>g the importance ofthatch formation is made easier byconsider<strong>in</strong>g the amount of water whichmust be shed dur<strong>in</strong>g storage. A 6 footlong by 6 foot diameter bale willreceive about 22 gallons of water foreach <strong>in</strong>ch of ra<strong>in</strong>. Therefore, if there4

In the eastern United States, stor<strong>in</strong>g bales outsideunprotected for several months will typically result<strong>in</strong> at least 5 or 6 <strong>in</strong>ches of hay around the top<strong>and</strong> sides which has essentially no feed<strong>in</strong>g value.<strong>Losses</strong> on the bottoms of bales are usually evengreater due to contact with wet soil.are 30 <strong>in</strong>ches of ra<strong>in</strong>fall dur<strong>in</strong>g thestorage period, a bale will receive 660gallons of water.Location Of Weather<strong>in</strong>gFor hay harvested at a low moisturelevel, weather<strong>in</strong>g usually occurs <strong>in</strong>three layers. The outside is typicallywet, dark, <strong>and</strong> rotten <strong>and</strong> has nofeed<strong>in</strong>g value. Underneath is a th<strong>in</strong>nerlayer of moist <strong>and</strong> heavily molded haywhich is of relatively low quality. Athird transition layer, which mayexhibit light mold <strong>and</strong> have a highermoisture content than the outer surfacelayers, usually surrounds the unweathered<strong>in</strong>terior.The sides of round bales shed waterbetter than the tops because less surfaceis directly exposed to ra<strong>in</strong>. Therefore,an isolated uncovered bale should haveless weather<strong>in</strong>g on the sides than onthe top. However, moisture can betrapped where bales touch on therounded sides, <strong>and</strong> this trappedmoisture delays dry<strong>in</strong>g <strong>and</strong> thus results<strong>in</strong> greater weather<strong>in</strong>g dur<strong>in</strong>g storage.Data suggest that often 50% ormore of the storage losses associatedwith outside storage occur <strong>in</strong> thevic<strong>in</strong>ity of the bale/soil <strong>in</strong>terface (thatis, at the bottom of the bale). Dry haytouch<strong>in</strong>g damp soil draws moisture<strong>in</strong>to the bale. Hence, if hay <strong>and</strong> soil are<strong>in</strong> contact, large weather<strong>in</strong>g lossesoccur on the bottoms of bales evenwhen they are stored on a well-dra<strong>in</strong>edsite. As a bale beg<strong>in</strong>s to weather on thebottom, it will flatten <strong>and</strong> allow evenmore hay/soil contact, <strong>and</strong> more toparea will be horizontally exposed tora<strong>in</strong>fall, each of which <strong>in</strong>creases theamount <strong>and</strong> rate of weather<strong>in</strong>g.FACTORS AFFECTING OUTSIDESTORAGE LOSSESIn research trials <strong>in</strong> the eastern UnitedStates <strong>in</strong> which large round bales havebeen stored outside without protectionfor six months or more, dry matterlosses of 30% or greater have beencommon. Some of the most importantfactors relat<strong>in</strong>g to the extent <strong>and</strong> dollarvalue of outside storage losses areas follows:Bale DensityIn general, the denser or more tightlyhay is baled, the lower the amount ofspoilage that will occur, assum<strong>in</strong>g haymoisture at bal<strong>in</strong>g is 18 to 20% orlower. Bale density is affected greatly bythe type of baler be<strong>in</strong>g used, with somelarge round balers provid<strong>in</strong>g a densityup to twice as great as other balers. Theaverage density of a bale is less criticalthan the density on the outer surface.Other factors may also affect baledensity. By mak<strong>in</strong>g proper baleradjustments <strong>and</strong> tak<strong>in</strong>g time to do agood job, an experienced baler operatorcan often produce bales which aremuch tighter than those someone elsemight produce us<strong>in</strong>g the same equipment.Some f<strong>in</strong>e-stemmed hays such asbermudagrass naturally tend to producea tight bale which sheds watermuch better than coarse-stemmed hayssuch as johnsongrass, pearl millet, orsorghum-sudangrass.Hav<strong>in</strong>g well-formed, tight bales isan important factor <strong>in</strong> reduc<strong>in</strong>g storagelosses. Most hay<strong>in</strong>g equipment companiescan provide <strong>in</strong>formation thatdiscusses the steps (or tricks) required toproduce dense, uniform bales whenus<strong>in</strong>g their products. The density ofround bales (at least <strong>in</strong> the outer few<strong>in</strong>ches) should be a m<strong>in</strong>imum of 10pounds of hay/cubic foot.While <strong>in</strong>creased bale densityreduces spoilage by reduc<strong>in</strong>g moisturepenetration, it also reduces the rate atwhich moisture <strong>and</strong> heat can escapefrom a bale.Thus, as density <strong>in</strong>creases, it becomes<strong>in</strong>creas<strong>in</strong>gly important to make certa<strong>in</strong>that hay is <strong>in</strong> a safe moisture range forbal<strong>in</strong>g. Unfortunately, leaf shatter fromlegume hays also <strong>in</strong>creases with decreas<strong>in</strong>ghay moisture levels.A low moisture content, use of a forage crop withstems f<strong>in</strong>e enough to form a thatch, <strong>and</strong> a baledensity of at least 10 pounds/cubic foot <strong>in</strong> theouter portions of bales are important factorsaffect<strong>in</strong>g resistance to weather<strong>in</strong>g dur<strong>in</strong>g outsidestorage.Other Field OperationsOr TechniquesReduction of storage losses can beg<strong>in</strong>with the formation of the hay swathprior to bal<strong>in</strong>g. A uniform swath ofproper size for the baler be<strong>in</strong>g used willhelp to produce a dense, uniform bale.Other th<strong>in</strong>gs be<strong>in</strong>g equal, smallerw<strong>in</strong>drows facilitate dense bales becausethey result <strong>in</strong> more layers per roll;however, leaf shatter of legumes, as wellas bal<strong>in</strong>g time, may be <strong>in</strong>creased.Operat<strong>in</strong>g rakes, tedders, <strong>and</strong> balers <strong>in</strong>the same direction as hay was cut mayalso help make a tighter bale.5

DEFINITION OF SELECTEDFORAGE QUALITY TERMSCRUDE PROTEIN (CP)The total quantity of true prote<strong>in</strong> <strong>and</strong> nonprote<strong>in</strong> nitrogenpresent <strong>in</strong> plant tissue. This can be calculated by multiply<strong>in</strong>gthe nitrogen fraction by 6.25.DRY MATTER (DM)The percentage of a plant sample which rema<strong>in</strong>s after allwater has been removed.NEUTRAL DETERGENT FIBER (NDF)The percentage of cell walls or other plant structuralmaterial present. This constituent is only partially digestibleby animals. Lower NDF levels are generally associated withhigher animal <strong>in</strong>take.ACID DETERGENT FIBER (ADF)The percentage of highly <strong>in</strong>digestible plant material. HigherADF levels are generally associated with lower digestibility.DIGESTIBLE DRY MATTER (DDM)The percentage of a sample which is digestible. DDM is acalculated estimate based on feed<strong>in</strong>g trials <strong>and</strong> from themeasured ADF concentration.IN VITRO DIGESTIBLE DRY MATTER(IVDDM)is a similar term which <strong>in</strong>dicates that the digestibility levelwas determ<strong>in</strong>ed via a laboratory test as opposed to onewhich utilized live animals fitted with a port open to therumen which allows digestion of small samples <strong>in</strong>sidethe animal.DRY MATTER INTAKE (DMI)This is the amount of forage an animal will eat <strong>in</strong> a givenperiod of time. Estimates of DMI are based on results fromanimal feed<strong>in</strong>g trials <strong>and</strong> the measured NDF concentrationof a forage or feed.DIGESTIBLE DRY MATTER INTAKE (DDMI)An estimate of how much DDM an animal will consume <strong>in</strong> agiven period of time. It is calculated as follows:DDM X DMI/100.RELATIVE FEED VALUE (RFV)A measure of a forage’s <strong>in</strong>take <strong>and</strong> energy value. Itcompares one forage to another accord<strong>in</strong>g to therelationship DDM X DMI/100 divided by a constant. RFV isexpressed as percent compared to full bloom alfalfa whichhas an RFV of 100. In most cases, as RFV <strong>in</strong>creases foragequality also <strong>in</strong>creases.Moisture content at bal<strong>in</strong>g can be animportant consideration, <strong>and</strong> this isespecially true <strong>in</strong> the case of large haypackages. Some studies have shownthat hay baled at only 2 to 3% highermoisture than other hay from the samefield will ma<strong>in</strong>ta<strong>in</strong> a higher moisturecontent for several months thereafter,thus favor<strong>in</strong>g microorganism growth.Because large hay packages haverestricted ability to lose moisture, evenrelatively small differences <strong>in</strong> moisturelevel can have a measurable negativeimpact (lower total <strong>and</strong> digestible drymatter <strong>and</strong> higher fiber).Bale wrapp<strong>in</strong>g has some <strong>in</strong>fluenceon storage losses of large round balesstored outside. A Missouri studyshowed weather<strong>in</strong>g losses <strong>in</strong>creased asthe spac<strong>in</strong>g between the tw<strong>in</strong>e on bales<strong>in</strong>creased from 2 to 8 <strong>in</strong>ches. However,wrapp<strong>in</strong>g bales with tw<strong>in</strong>e spacedclosely together <strong>in</strong>creases costs becausemore tw<strong>in</strong>e is used <strong>and</strong> more time isrequired for wrapp<strong>in</strong>g.Most studies have shown net wrapto be slightly better than tw<strong>in</strong>e <strong>in</strong>prevent<strong>in</strong>g storage losses. Producerswho use net wrap have also <strong>in</strong>dicatedthat they can wrap a bale with only twoto three revolutions <strong>and</strong> produce morebales per hour than with tw<strong>in</strong>e. Netwrap has the additional advantage ofstabiliz<strong>in</strong>g bales better than tw<strong>in</strong>e, thusmak<strong>in</strong>g bale h<strong>and</strong>l<strong>in</strong>g <strong>and</strong> storageeasier, but it also <strong>in</strong>creases cost.Though not a storage procedure perse, a preservative is sometimes appliedto the swath or to forage as it enters thebaler. The preservative is often abuffered acid which decreases mold<strong>and</strong> mildew growth. This allows hay tobe baled at a higher moisture levelwhich may <strong>in</strong>crease leaf retention oflegume hays, thus slightly improv<strong>in</strong>gharvest yield <strong>and</strong> forage quality, aswell as hasten<strong>in</strong>g bal<strong>in</strong>g by one-halfto one day, thus reduc<strong>in</strong>g the risk ofra<strong>in</strong> damage.Acid-treated hay which is protectedfrom ra<strong>in</strong> dur<strong>in</strong>g storage may haveslightly lower storage losses thanuntreated hay if stored for only a fewmonths, but after storage for as long assix months, there may be no differencebetween treated <strong>and</strong> untreated hay.Acid treatment does not appear toretard the weather<strong>in</strong>g process with haystored outside, however. Furthermore,acids can result <strong>in</strong> corrosion ofhay equipment.Inject<strong>in</strong>g hay with anhydrousammonia <strong>in</strong>creases crude prote<strong>in</strong> byadd<strong>in</strong>g nonprote<strong>in</strong> nitrogen. It has alsobeen shown to <strong>in</strong>crease digestibility ofgrass hay, <strong>and</strong> can be quite effective <strong>in</strong>reduc<strong>in</strong>g or elim<strong>in</strong>at<strong>in</strong>g mold growth<strong>and</strong> heat<strong>in</strong>g. In addition, because<strong>in</strong>jected bales must be sealed airtight toavoid ammonia loss, weather<strong>in</strong>g loss isavoided. However, the caustic nature ofthis product creates danger to humans,<strong>and</strong> has occasionally caused hay to betoxic to animals (particularly with highmoisture, high quality hays).As fields are cut, baled, <strong>and</strong> stored,some system for identify<strong>in</strong>g hay as tofield <strong>and</strong> cutt<strong>in</strong>g date should beimplemented. This <strong>in</strong>formation isuseful <strong>in</strong> determ<strong>in</strong><strong>in</strong>g the effect ofmanagement practices on foragequality <strong>and</strong>/or animal performance,<strong>and</strong> <strong>in</strong> test<strong>in</strong>g the nutritive quality ofhay to allow the formulation of rationswhich efficiently meet animal nutritionalrequirements.Climatic InfluencesClimatic conditions obviously play animportant role <strong>in</strong> determ<strong>in</strong><strong>in</strong>g theextent of spoilage loss of hay storedoutside. In general, the higher thera<strong>in</strong>fall dur<strong>in</strong>g outside storage, thegreater the amount of storage losswhich will occur. However, ra<strong>in</strong>falldistribution also has an <strong>in</strong>fluence (<strong>in</strong>fact, results from some studies haveimplied that ra<strong>in</strong>fall distribution can be6

considerably more important thanra<strong>in</strong>fall amount). To illustrate, ara<strong>in</strong>storm which results <strong>in</strong> 2 <strong>in</strong>ches ofra<strong>in</strong> fall<strong>in</strong>g very quickly is likely tohave much less impact than the samera<strong>in</strong>fall com<strong>in</strong>g <strong>in</strong> small amounts everyother day over a period of two weeks.Other climatic factors such as highhumidity, which slows dry<strong>in</strong>g of wethay, likewise enhance storage losses.Temperature also has an effect, becausemicrobial activity with<strong>in</strong> the bale isfavored when warm, humid, overcastconditions prevail. <strong>Hay</strong> which is stored<strong>in</strong> a sunny area which receives thebenefit of unobstructed breezes driesmore quickly <strong>and</strong> tends to have lowerspoilage losses than hay stored <strong>in</strong> shady<strong>and</strong>/or less well-ventilated areas.Outside storage of hay normallypresents little or no problem <strong>in</strong> the aridwestern United States, so <strong>in</strong> this arealarge stacks of hay are often storedoutside totally unprotected from theelements. However, <strong>in</strong> high ra<strong>in</strong>fall/high humidity areas, outside storagelosses can be extensive <strong>and</strong> quite costly.Site SelectionIf hay is to be stored outside, it isdesirable to locate the storage site closeto the feed<strong>in</strong>g area because balesbecome more difficult to h<strong>and</strong>le asthey weather. It is easier to move thema greater distance when they are new<strong>and</strong> tightly wrapped.Well-dra<strong>in</strong>ed upl<strong>and</strong> storage sites arebest. Bottom areas should generally beavoided as they tend to be heavier soils.Also, many bottom areas are prone toflood<strong>in</strong>g, which is detrimental to hay<strong>and</strong> may limit vehicle access dur<strong>in</strong>gra<strong>in</strong>y periods. <strong>Hay</strong>/soil contact shouldbe avoided if at all possible, but if haymust touch the soil, a s<strong>and</strong>y, welldra<strong>in</strong>edarea is greatly preferable to aheavy soil <strong>and</strong>/or a poorly dra<strong>in</strong>ed site.It is also advisable to select a storagesite where the danger of fire is m<strong>in</strong>imized.Several steps which can betaken to reduce the likelihood of fireare discussed <strong>in</strong> a later section titled“Reduc<strong>in</strong>g Fire Risk.”Bale Orientation/PlacementOnce the storage site has been located,attention should be given to baleplacement <strong>and</strong> orientation. Exceptwhen multiple-bale covers are used,large round bales should be stored <strong>in</strong>rows with sides not touch<strong>in</strong>g so as toavoid creat<strong>in</strong>g a moisture-hold<strong>in</strong>g areabetween sides. However, the flat endsof bales should be firmly butted aga<strong>in</strong>stone another. This conserves space <strong>and</strong>may help protect the bottoms of bales(other than the one on the upper sideof the slope) from water flow<strong>in</strong>g downthe slope. Properly done, this protectsthe ends almost as well as if they werepart of one cont<strong>in</strong>uous bale.If possible, rows should run north<strong>and</strong> south so as to allow maximumexposure of the rounded sides to thesun. This <strong>in</strong>creases dry<strong>in</strong>g of therounded surface of bales dur<strong>in</strong>gthe day. At least 3 feet should beleft between bale rows to ensuresunlight penetration <strong>and</strong> allow goodair circulation.If direct hay/soil contact cannot beavoided, tak<strong>in</strong>g steps to m<strong>in</strong>imize theamount of water reach<strong>in</strong>g the bales,<strong>and</strong> the length of time they stay wet,will at least help. A gently slop<strong>in</strong>g site(preferably with a southern exposure tomaximize solar dry<strong>in</strong>g) will allow waterto quickly dra<strong>in</strong> away from the hay.Bales should be oriented up <strong>and</strong> downthe slope so that they will not create adam for surface water, <strong>and</strong> placed nearthe top of the slope to m<strong>in</strong>imize theamount of water flow<strong>in</strong>g aroundthe hay.Protect<strong>in</strong>g The Tops Of BalesThere are numerous types of commerciallyavailable cover<strong>in</strong>gs for largeround hay bales, <strong>and</strong> they vary <strong>in</strong> botheffectiveness <strong>and</strong> cost. These <strong>in</strong>cludesmall “caps” which are staked orp<strong>in</strong>ned to the bale <strong>and</strong> which cover thetop third to half of the bale. If h<strong>and</strong>ledcarefully, such products often can beused more than one season, whichmakes them less expensive <strong>and</strong> thereforemore feasible to use. Some <strong>in</strong>dividualbale covers may be difficult tokeep securely <strong>in</strong> place for an extendedperiod of time.One can also buy a large roll ofplastic sheet<strong>in</strong>g <strong>and</strong> cut <strong>in</strong>dividual balecovers, although experience has proventhis method to be time consum<strong>in</strong>g <strong>and</strong>the pieces somewhat awkward toh<strong>and</strong>le. If plastic sheet<strong>in</strong>g is used, itshould be at least 6 mil thick.Individual bale covers are most suitablefor producers who use relativelysmall quantities of hay <strong>in</strong> a givenfeed<strong>in</strong>g season.The expense of a tarp, plasticsheet<strong>in</strong>g, or other fabric cover<strong>in</strong>g, aswell as the labor <strong>in</strong>volved to cover hay,can be reduced by plac<strong>in</strong>g a group ofbales under one cover. Often bale rowsare stacked <strong>in</strong> a triangular fashion withtwo or three rows form<strong>in</strong>g the base.This gives either three or five rows ofhay per stack, with the total numberof bales vary<strong>in</strong>g with the length ofthe stack.A cover must be secured firmly toprevent w<strong>in</strong>d from blow<strong>in</strong>g it offdur<strong>in</strong>g storage. It is desirable to leavethe flat ends of the outside balesuncovered <strong>and</strong> to leave a few <strong>in</strong>chesuncovered along the sides of the rowsto allow moisture to escape <strong>and</strong> air tocirculate under the bales. However,w<strong>in</strong>ds of only 15 to 20 mph can exert aconsiderable lift<strong>in</strong>g force as it blowsacross the top of a plastic or tarp, <strong>and</strong>even a slight breeze may lift a looseedge of a poorly secured cover.7

Another disadvantage of us<strong>in</strong>gplastic sheets is that condensation mayoccur under the bales if hay was moistwhen stored or if water gets under, <strong>and</strong><strong>in</strong>to, the bales. The result is that asignificant amount of spoilage mayoccur next to the plastic even thoughra<strong>in</strong> cannot reach the hay. (This makesa strong case for mak<strong>in</strong>g certa<strong>in</strong> anyhay stored us<strong>in</strong>g this technique is quitedry, preferably 18% moisture or less,before be<strong>in</strong>g covered <strong>and</strong> is not <strong>in</strong>contact with the soil.) In addition,disposal of plastic after use may bea problem.At least one commercially availablehay cover is made from a slightlyporous fabric. It is marketed <strong>in</strong> largetarp-sized sheets, <strong>and</strong> can be used tocover several bales at a time, usuallywith one row of bales stacked on top oftwo other rows <strong>in</strong> triangular fashion.This reusable product offers theadvantage of shedd<strong>in</strong>g a high percentageof ra<strong>in</strong> water while still allow<strong>in</strong>gmoisture to escape dur<strong>in</strong>g sunny,dry<strong>in</strong>g days. However, bottom spoilagemay occur on bales which touch theground unless steps are taken toprevent it.If a cover is used (particularly aplastic cover), it may be desirable torelate the size of <strong>in</strong>dividual stacks tothe rate at which hay is to be fed. Oncea row end is uncovered <strong>and</strong> bales areremoved for feed<strong>in</strong>g, covers are seldomplaced back as securely as they were<strong>in</strong>itially. The result is that w<strong>in</strong>d mayblow a cover off, or partially off,result<strong>in</strong>g <strong>in</strong> some weather<strong>in</strong>g of theUse of a rock pad is one effective yet <strong>in</strong>expensiveway to elim<strong>in</strong>ate hay/soil contact.rema<strong>in</strong><strong>in</strong>g hay. Therefore, m<strong>in</strong>imiz<strong>in</strong>gthe amount of hay stored under onecover may help reduce weather<strong>in</strong>glosses <strong>in</strong> some situations.Other companies market equipmentwhich places either <strong>in</strong>dividual bales orseveral bales <strong>in</strong>side plastic “sleeves.”This approach effectively protects thetops <strong>and</strong> sides of bales, but it is quiteimportant to make certa<strong>in</strong> that the hayis dry when baled <strong>and</strong> to make certa<strong>in</strong>there is no way for moisture to enterthe bales or for condensation to “pool”at the bottom of the plastic dur<strong>in</strong>gstorage. Otherwise, there may be highspoilage losses on the bottoms of bales.When each sleeve covers only one bale,the sleeve should be tight. Despite theplastic on the bale bottoms, <strong>in</strong>dividuallysleeved bales should not be storeddirectly on the ground.Some companies produce equipmentwhich completely wraps or seals<strong>in</strong>dividual bales <strong>in</strong> stretch plastic. Donecorrectly, this may be the most effectiveway to elim<strong>in</strong>ate weather<strong>in</strong>g losses withoutside storage. However, depend<strong>in</strong>gon the equipment design, this may beexpensive <strong>in</strong> terms of labor, equipment,<strong>and</strong> plastic, plus disposal of plastic afterfeed<strong>in</strong>g is required.Several research studies have <strong>in</strong>volvedspray<strong>in</strong>g bales with waterrepellent substances. Hydrogenatedanimal fats <strong>and</strong> plant oils have beenused most frequently, <strong>and</strong> offer theattributes of be<strong>in</strong>g natural, environmentallyfriendly, <strong>and</strong> biodegradable.With most such products, animalrefusal of treated hay does notappear to be a problem, but the fat oroil may attract <strong>in</strong>sects, which can<strong>in</strong>clude fire ants <strong>in</strong> areas where theyare present. Additional research isneeded to determ<strong>in</strong>e the feasibility ofthis approach.Protect<strong>in</strong>g The Bottoms Of BalesSeveral studies have shown that it canbe more important to protect thebottoms, as opposed to the tops, ofbales. The bottoms of bales can beprotected <strong>in</strong> countless ways, limitedonly by imag<strong>in</strong>ation <strong>and</strong> <strong>in</strong>genuity.The bale bottom is protected when it isheld off the ground by someth<strong>in</strong>g thatdoes not trap <strong>and</strong> hold water. Forexample, wooden pallets, telephoneposts, scrap pipe, <strong>and</strong> cross ties have allbeen successfully used <strong>in</strong> hay storage.The most important po<strong>in</strong>t is to preventhay/soil contact, but provid<strong>in</strong>g someair flow under the hay is also desirable.Wooden pallets offer an <strong>in</strong>expensivemethod of elim<strong>in</strong>at<strong>in</strong>g hay/soil contact,but are labor <strong>in</strong>tensive as they need tobe moved as hay is used. They make iteasy to change storage location(s) fromyear to year because they have to bemoved anyway. However, palletsconta<strong>in</strong> nails which can puncture tiresor cause other damage.Another relatively <strong>in</strong>expensive <strong>and</strong>effective storage technique is to placehay on rock pads. A good rock padkeeps bales off the soil, <strong>and</strong> alsoprovides all weather support forequipment. Rocks 1 to 3 <strong>in</strong>ches <strong>in</strong>diameter should be piled 4 to 8 <strong>in</strong>chesdeep, depend<strong>in</strong>g on the soil type <strong>and</strong>the weight of the equipment to beused. This size rock traps no water <strong>and</strong>effectively channels water away.Rock pads last for many seasons <strong>and</strong>can easily be repaired if damaged. Anerosion cloth can be placed below therock pad to help slow the rate at whichheavy equipment may push rocksdown <strong>in</strong>to the soil <strong>and</strong> therefore<strong>in</strong>crease the life of the pad (which canbe ten years or more).COSTS VERSUS BENEFITS OFHAY STORAGEMany producers probably do not fullyrealize the economic importance ofstorage losses because the amount ofloss is difficult to determ<strong>in</strong>e on a farm,<strong>and</strong> total hay costs are considerablyhigher than out-of-pocket expenses.8

Before mak<strong>in</strong>g decisions regard<strong>in</strong>ghay storage, a producer shouldobta<strong>in</strong> <strong>and</strong> study hay budgets todeterm<strong>in</strong>e the actual cost of hayproduction <strong>and</strong> the dollar value ofhay storage losses. Budgets are usuallyavailable from County AgriculturalExtension Agents.Cost Of <strong>Hay</strong> <strong>Losses</strong>Proper hay storage has a cost <strong>in</strong> termsof both time <strong>and</strong> effort, <strong>and</strong> this mustbe considered by producers seek<strong>in</strong>g toreduce losses. Material <strong>and</strong> labor costsexpended to store hay, as well as thenutritional value of hay, dictate whichstorage techniques are most costeffective. The higher the quality of thehay, the greater the economic cost ofstorage <strong>and</strong> feed<strong>in</strong>g losses (Table 3).<strong>Storage</strong> losses <strong>in</strong>crease the quantityof hay needed, plus they may lowerforage quality of the rema<strong>in</strong><strong>in</strong>g hayenough that additional supplementationof animal diets is required. Thecost of storage losses can readily becalculated based on the sell<strong>in</strong>g price ofhay of various qualities. The economicvalues of dry matter losses provided <strong>in</strong>Table 4 were calculated us<strong>in</strong>gM<strong>in</strong>nesota quality-tested hay auctionprices. This <strong>in</strong>formation can be used tocalculate how much one can afford tospend <strong>in</strong> construct<strong>in</strong>g overhead storageor <strong>in</strong> improv<strong>in</strong>g site dra<strong>in</strong>age.Table 4 illustrates that as hay value<strong>in</strong>creases, a greater <strong>in</strong>vestment <strong>in</strong> time,energy, <strong>and</strong> money can be justified toreduce losses. Furthermore, <strong>in</strong> additionto the value which is lost due toweather<strong>in</strong>g, the lost hay must then bereplaced. For example, dry matterlosses of 15 to 20% require a livestockTable 4. Economic value of loss (storage <strong>and</strong> feed<strong>in</strong>g) of hay by quality test.___________________________________________________________________________Average quality Value of loss 2Test st<strong>and</strong>ard RFV 1 Price 5% 10% 20% 40%___________________________________________________________________________<strong>in</strong>dex - - - - - - - - - - - - -- - - - $/T - - - - - - - - - - - - - - -Prime 168 121 6.05 12.10 24.20 48.401 138 97 4.85 9.70 19.40 38.802 115 78 3.90 7.80 15.60 31.203 97 64 3.20 6.40 12.80 25.604 81 51 2.55 5.10 10.20 20.405 60 34 1.70 3.40 6.80 13.60_________________________________________________________________1Represents the mean test values from 11 years of quality test auction data <strong>in</strong> M<strong>in</strong>nesota.2Y = (0.81 x RFV <strong>in</strong>dex) - 14.8, where Y = $/ton of hay. This calculated loss value assumes a 4 <strong>in</strong>chweather<strong>in</strong>g loss <strong>and</strong> 5 foot diameter bales (25% of the hay volume).Table 3. Cost of hay consumed as affected by storage <strong>and</strong> feed<strong>in</strong>g losses.———————————————————————————————Beg<strong>in</strong>n<strong>in</strong>g hay value, $/ton 1———————————————————————————————% Loss 50 70 80———————————————————————————————5 52.69 73.68 94.7410 55.55 77.78 100.0015 58.87 82.35 105.8820 62.50 87.50 112.5025 66.68 93.33 120.00———————————————————————————————1Numbers listed under a given beg<strong>in</strong>n<strong>in</strong>g hay value represent the cost of unweathered hay fed (that is,losses due to storage <strong>and</strong> feed<strong>in</strong>g, <strong>in</strong> essence, <strong>in</strong>crease the cost of hay).9producer to harvest 15 to 20% morehay, which further adds to the costs ofproduction, harvest<strong>in</strong>g, <strong>and</strong> storage.Barn <strong>Storage</strong>Barn storage is usually considered to bea consistently highly effective methodof stor<strong>in</strong>g hay, so it is often used as thest<strong>and</strong>ard aga<strong>in</strong>st which other techniquesare compared. When the typicaldry matter storage loss of dry haydur<strong>in</strong>g <strong>in</strong>side storage (usually around5%) is compared to the 30% or morecommon with hay stored outside <strong>in</strong>the humid portions of the UnitedStates, it isn’t difficult to see thatreduced losses can often providepayback on barn construction with<strong>in</strong> afew years. The more valuable or porousthe hay, the higher <strong>and</strong>/or morefrequent the ra<strong>in</strong>fall, <strong>and</strong>/or the longerthe period of storage, the more easilybarn construction can be justified.For commercial hay producers theremay also be considerable benefit fromthe improved appearance which resultsfrom barn storage. Outside storagehurts the appearance of hay even whenactual losses are m<strong>in</strong>imal. Appearanceis not closely l<strong>in</strong>ked to nutrientcontent or feed<strong>in</strong>g value, but it is oftenimportant <strong>in</strong> market<strong>in</strong>g, <strong>and</strong> mayjustify barn storage even <strong>in</strong> relativelylow ra<strong>in</strong>fall climates.

<strong>Storage</strong> build<strong>in</strong>gs may providebenefits <strong>in</strong> addition to those whichresult from stor<strong>in</strong>g hay. For example,part of a haybarn might beused for otherpurposesdur<strong>in</strong>g aportion of theyear. Furthermore,theoverall value ofa farm should<strong>in</strong>crease withthe addition ofa hay barn.Bale densityis anotherimportantconsiderationaffect<strong>in</strong>g thecost effectivenessof barnstorage. Thedensity of small rectangular bales isusually around 9 pounds per cubicfoot, while the density of large roundbales can vary from less than 5 to morethan 10. Even when high densityround bales are used, at least a thirdless round bale hay than rectangularbale hay can be stored <strong>in</strong> a givenstorage structure due to the wastedspace between bales.When a storage facility isconstructed for round bale storage,dimensions should be based on thediameter <strong>and</strong> length of the bales thatwill be stored. For such structures, adesign which does not require <strong>in</strong>teriorroof-support<strong>in</strong>g poles is desirable sothat equipment operation will notbe impeded.Costs And Risks Of Barn <strong>Storage</strong>The cost of build<strong>in</strong>g a hay storagestructure can vary greatly. Comparisonsof structures of various types <strong>and</strong> sizesshould be made on a cost-per-squarefootbasis. Material costs are higher <strong>in</strong>some areas than others, <strong>and</strong> climatelargely determ<strong>in</strong>es sid<strong>in</strong>g costs. Even <strong>in</strong>On many farms, particularly <strong>in</strong> the eastern United States, reduced hay storage losses can providepayback on barn construction with<strong>in</strong> a few years.high ra<strong>in</strong>fall areas at least one sidemay be left open without significantadverse results.Labor costs typically account foraround 35% of the cost of erect<strong>in</strong>g ahay storage structure. Thus, a producerwho can provide most or all of thelabor for build<strong>in</strong>g a storage structurecan substantially reduce out-of-pocketconstruction expenses.Costs other than construction whichare associated with barn storage aregreater than might be expected. Beforemak<strong>in</strong>g decisions regard<strong>in</strong>g erect<strong>in</strong>gstorage facilities or pric<strong>in</strong>g hay whichhas been stored <strong>in</strong>side, the follow<strong>in</strong>gitems should be taken <strong>in</strong>toconsideration.Shr<strong>in</strong>kage- <strong>Hay</strong> which has beenstored <strong>in</strong>side for several months willtypically lose 5 to 10% of its weight ascompared to freshly baled hay due to acomb<strong>in</strong>ation of dry matter loss <strong>and</strong>moisture loss.Depreciation- The economic valueof a build<strong>in</strong>g decl<strong>in</strong>es steadily overtime. Generally, depreciation is consideredto be around 5% of the <strong>in</strong>itialvalue per year.Interest on<strong>in</strong>vestment- This is“opportunity cost”or the amount ofreturn which couldhave been madewith the moneyused to build astorage structure if ithad been <strong>in</strong>vestedelsewhere.Repairs- A goodfigure to use is thatapproximately 1 to2% of the value of abuild<strong>in</strong>g mustannually be spenton repairs. Most ofthis will occurdur<strong>in</strong>g the latterpart of its useful life.Taxes <strong>and</strong> <strong>in</strong>surance- Taxes varygreatly with location, so to determ<strong>in</strong>etax costs a producer should check withlocal officials. Hav<strong>in</strong>g <strong>in</strong>surance on astorage facility is generally advisable,but each producer must decide whetherhe needs it <strong>and</strong>, if so, how much. Somefarm policies may cover such additionalbuild<strong>in</strong>gs at little extra cost. Often thecomb<strong>in</strong>ed costs of taxes <strong>and</strong> <strong>in</strong>suranceamount to about 1% of the averagevalue of the build<strong>in</strong>g over its useful life.Other- If a barn has an earth floor,water from outside should not beallowed to run under the hay. Otherwise,spoilage will occur on the bottombales even though the hay is undershelter.Bale dimensions, how high baleswill be stacked, <strong>and</strong> the anticipatedlength of usefulness of the storagefacility will also affect the economics ofbarn storage. For example, if a build<strong>in</strong>gcosts a certa<strong>in</strong> amount per square foot10

Breakeven barn cost ($/sq. ft)to build, but bales will be stacked threehigh <strong>and</strong> the facility is expected to lastfor 20 years, the cost per square footfor bale storage per year (constructioncost only) can be determ<strong>in</strong>ed bydivid<strong>in</strong>g the construction cost by 3 <strong>and</strong>then by 20. The cost/bale/year canthen be obta<strong>in</strong>ed by multiply<strong>in</strong>g thecost per square foot by the squarefootage of the size of bales to be stored(for example, a 5 foot x 6 foot balewill occupy about 30 square feet ofstorage space).In the f<strong>in</strong>al analysis, <strong>in</strong> order todeterm<strong>in</strong>e whether it is economicallyfeasible to build a hay storage structurea producer must calculate anticipatedconstruction costs, then compare thisfigure with an estimate of the value ofhay be<strong>in</strong>g lost without it. Figure 2provides the break even costs for barnconstruction at various loss levels,costs/square foot, <strong>and</strong> hay values.252015105Outside storage loss = 25%040 50 60 70 80 90 100 110 120Average spoilage depth (<strong>in</strong>ches)Figure 2. Break even barn cost for various levels ofstorage loss <strong>and</strong> vary<strong>in</strong>g hay value at harvest.(This analysis <strong>in</strong>cludes the follow<strong>in</strong>g assumptions: <strong>in</strong>-barnaverage stack<strong>in</strong>g height of three bales, ten-year barnamortization, <strong>and</strong> construction cost of $7.50/square foot.Inputs other than storage loss <strong>and</strong> hay value arenot <strong>in</strong>cluded.)SOURCE: Buckmaster, D.R. 1993. Evaluator for Round<strong>Hay</strong> Bale <strong>Storage</strong>. J. Prod. Agric., 6:378-385.20%15%10%Table 5. Average <strong>and</strong> range of <strong>in</strong>crease of percentages of dry matter <strong>and</strong>digestible dry matter with barn storage as compared to various protectiontechniques used for hay stored outside. (Medium ra<strong>in</strong>fall areas.)*Increase With Barn <strong>Storage</strong>, % UnitsTreatment Compared To Barn <strong>Storage</strong> Dry Matter Digestible Dry MatterOn Ground Without Cover 8.7 12.7(3.6 - 14.5) 1 (3.3 - 17.2)Dra<strong>in</strong>ed Surface (Rock, Pallets, etc.) 2.4 6.8(-1.3 - 6.7) (-0.4 - 13.4)Plastic Cover On Bale Tops 3.2 3.6(0.6 - 4.6) (2.9 - 4.3)Dra<strong>in</strong>ed Surface + Plastic Cover 0.3 -1.4On Bale Tops (0.9 - 2.9) (-2.1 - 1.8)Net Wrap 1.5 —(0.6 - 1.5) —Plastic Sleeve 0.6 —(-1.4 - 2.7)Pyramid Stack + Cover On Top 3.7 —*SOURCE: Russell, Jim, <strong>and</strong> Ray Huhnke. 1997. W<strong>in</strong>ter Feed Management To M<strong>in</strong>imize Cow-Calf ProductionCosts: <strong>Hay</strong> <strong>Storage</strong> And Feed<strong>in</strong>g. The Forage Leader (a periodical published by the American Forage <strong>and</strong>Grassl<strong>and</strong> Council, Georgetown, TX). 1 Parentheses denote the range of values <strong>in</strong> tests <strong>in</strong>cluded <strong>in</strong> this summary.The costs versus the benefits ofus<strong>in</strong>g other techniques to protect hayshould be compared to: (1) hay storedoutside with no protection, <strong>and</strong> (2)build<strong>in</strong>g a hay storage facility. Experimentshave generally shown that morethan half (<strong>and</strong> sometimes nearly all)the difference <strong>in</strong> storage lossesbetween outside storage on theground with no protection <strong>and</strong>barn stored hay can be elim<strong>in</strong>atedthrough the use of variousstrategies. A summary of 12experiments compar<strong>in</strong>g storagelosses of barn stored hay tovarious other storage techniquesis provided <strong>in</strong> Table 5.Barn Safety ConsiderationsSafety considerations should be ahigh priority when plann<strong>in</strong>g barnstorage of hay. These <strong>in</strong>clude mak<strong>in</strong>gcerta<strong>in</strong> that equipment available on thefarm is capable of safely plac<strong>in</strong>g bales<strong>in</strong> stable stacks, hav<strong>in</strong>g a shield onstack<strong>in</strong>g equipment to prevent <strong>in</strong>juryto the operator if a bale falls, <strong>and</strong>mak<strong>in</strong>g certa<strong>in</strong> that excessive pressurewill not be exerted on the walls orsupports of the storage facility(stack<strong>in</strong>g bales on end reduces thelatter hazard).11REDUCING FIRE RISKEach year there are many reports of haybarns burn<strong>in</strong>g, as well as of firesoccurr<strong>in</strong>g <strong>in</strong> hay stored outside. Fire isalways a concern with hay, but it takeson even greater importance when anexpensive barn can be lost <strong>in</strong> additionto the hay.Fire <strong>in</strong> stored hay may occur fromeither external or <strong>in</strong>ternal causes.Internally started fires are a result ofhay go<strong>in</strong>g through an extreme heat.As discussed earlier, heat<strong>in</strong>g is a directresult of microorganism activity <strong>in</strong> haystored at excessively high moisturelevels. Even if excessive heat<strong>in</strong>g doesnot result <strong>in</strong> a fire, it will reduceforage quality.Combustion Due ToExtreme Heat<strong>in</strong>gThe pr<strong>in</strong>cipal way to avoid fire result<strong>in</strong>gfrom <strong>in</strong>ternal heat<strong>in</strong>g (sometimesreferred to as “spontaneous combustion,”though this term is mislead<strong>in</strong>g)is to bale hay at proper moisture levels.<strong>Hay</strong> <strong>in</strong> round bales should conta<strong>in</strong> nomore than 18% moisture when placed<strong>in</strong>side a barn, while hay <strong>in</strong> smallrectangular bales should conta<strong>in</strong> nomore than 20% moisture. <strong>Hay</strong> that is

suspected of be<strong>in</strong>g too wet should bestored outside for about three weeksuntil the danger of combustion due toheat<strong>in</strong>g is past. New crop hay shouldnever be placed aga<strong>in</strong>st dry hay.The danger of fire from heat<strong>in</strong>g ofhay of higher-than-optimum moisturecan be decreased somewhat by “loosestack<strong>in</strong>g” the bales so good air movement<strong>and</strong> ventilation can occur. <strong>Hay</strong>preservatives, which reduce fungal <strong>and</strong>bacterial growth, sprayed on haydur<strong>in</strong>g the bal<strong>in</strong>g process help reduce(though do not always prevent)excessive heat<strong>in</strong>g <strong>in</strong> higher moisturehay. Bales known to conta<strong>in</strong>, orsuspected of conta<strong>in</strong><strong>in</strong>g, excessivemoisture can be temporarily looselystacked outside, then moved <strong>in</strong>sideafter the danger of fire is past.External CausesExternal fires have many causes rang<strong>in</strong>gfrom lightn<strong>in</strong>g to the m<strong>in</strong>dless toss<strong>in</strong>gof a cigarette. Common sense <strong>and</strong> analert eye can elim<strong>in</strong>ate most causes ofexternal fires. For example, it is best toavoid stack<strong>in</strong>g hay close to anyth<strong>in</strong>gthat can attract lightn<strong>in</strong>g such as powerl<strong>in</strong>es, metal fence posts, trees, or towerssuch as antennas.It is also advisable to avoid stor<strong>in</strong>ghay adjacent to vegetation that mightsupport a fire, <strong>and</strong> to ma<strong>in</strong>ta<strong>in</strong> a novegetationbuffer area around stackedhay to prevent wildfire from mov<strong>in</strong>g<strong>in</strong>to the stored hay. This is especiallytrue if the grass or other plants <strong>in</strong> thestorage area are warm season speciesthat go dormant <strong>in</strong> w<strong>in</strong>ter. Risk of hayloss from fire can further be reduced bystor<strong>in</strong>g hay <strong>in</strong> two or more sites ratherthan just one.It is a good idea to post “No Smok<strong>in</strong>g”signs <strong>in</strong> conspicuous placesaround a hay barn <strong>and</strong> to strictlyenforce this policy. A herbicide ortillage can be used to create a bareground buffer zone at least 3 feet widearound the edge of the barn to reducerisk from wildfire.If there is a need to check thetemperature of hay, it can be done byfitt<strong>in</strong>g a sharpened end on a 10-footsection of 1/2 <strong>in</strong>ch pipe, then driv<strong>in</strong>g it<strong>in</strong>to the hay, followed by lower<strong>in</strong>g athermometer <strong>in</strong>to the pipe. Temperaturesbelow 120 o F are normal, <strong>and</strong>120 o to 140 o are <strong>in</strong> the caution range.<strong>Hay</strong> heat<strong>in</strong>g to 160 o or higher is <strong>in</strong>serious danger of catch<strong>in</strong>g fire. Temperaturecan build <strong>in</strong> hay, particularlywith<strong>in</strong> the first week or two afterbal<strong>in</strong>g, <strong>and</strong> therefore periodic monitor<strong>in</strong>gof temperature until it is clear thereis no danger of fire is advisable.HAY FEEDINGOn many farms, hay feed<strong>in</strong>g losses areas high as storage losses, particularly ifhay is fed outside (This is logicalbecause as the amount of weatheredhay <strong>in</strong>creases, animal refusal also<strong>in</strong>creases). Some hay losses dur<strong>in</strong>gfeed<strong>in</strong>g can be expected with anyfeed<strong>in</strong>g system, but the amount of lossvaries with the system used. The majorobjective for any feed<strong>in</strong>g system shouldbe to keep losses to a practical m<strong>in</strong>imumlevel, thus permitt<strong>in</strong>g animals toconsume the majority of hay offeredat feed<strong>in</strong>g.Feed<strong>in</strong>g losses <strong>in</strong>clude trampl<strong>in</strong>g,leaf shatter, chemical <strong>and</strong> physicaldeterioration, fecal contam<strong>in</strong>ation, <strong>and</strong>refusal. The levels <strong>and</strong> costs of theselosses will be determ<strong>in</strong>ed by feed<strong>in</strong>gmethod, <strong>in</strong>tervals between feed<strong>in</strong>gs,amounts fed at a time, weather conditions,the number of animals be<strong>in</strong>g fed,<strong>and</strong> forage quality or hay value.In research trials, feed<strong>in</strong>g losses haveranged from less than 2% when greatcare was exercised, to more than 60%where no attempts were made toreduce loss. Feed<strong>in</strong>g losses of 3 to 6%are quite acceptable for most feed<strong>in</strong>gprograms, although such low levels ofloss are usually associated with systemswhich require high labor <strong>in</strong>puts <strong>and</strong>daily feed<strong>in</strong>g.Use Of <strong>Hay</strong> Quality Information<strong>Hay</strong> can be most efficiently fed whenseparated <strong>in</strong>to lots accord<strong>in</strong>g to quality,<strong>and</strong> when classes of animals areseparated <strong>and</strong> fed accord<strong>in</strong>g to needs.This allows hay quality to be matchedto livestock needs. For example, on acattle farm the best quality hay mightbe fed to animals hav<strong>in</strong>g high nutritionalrequirements such as youngcalves, yearl<strong>in</strong>gs, bred heifers, <strong>and</strong>lactat<strong>in</strong>g cows. Lower quality hay couldbe saved for mature, dry pregnant cows<strong>and</strong> bulls when not <strong>in</strong> breed<strong>in</strong>g season.High quality hay is early cut, leafy,pleasant smell<strong>in</strong>g, <strong>and</strong> free of foreignmaterial <strong>and</strong> toxic factors. Whenchemically analyzed, such hay willusually be high <strong>in</strong> prote<strong>in</strong> <strong>and</strong> digestibleenergy, <strong>and</strong> low <strong>in</strong> fiber. The bestquality hay will also be the mostvaluable hay <strong>and</strong> thus should be fedwith the greatest care.Feed<strong>in</strong>g MethodsIf not ground for use <strong>in</strong> formulat<strong>in</strong>g atotal mixed ration, small rectangularbales are normally stored under shelter,then are usually either moved from theshelter <strong>and</strong> placed <strong>in</strong> some type ofstructure (bunk, manger, rack, wagon,trough, etc.) or taken to an outside areawhere cattle are located. Either systemrequires a considerable amount oflabor. Most large hay packages arefed on sod whether stored <strong>in</strong>sideor outside.Feed<strong>in</strong>g hay on sod offers theadvantage of distribut<strong>in</strong>g hay onpasture l<strong>and</strong> rather than concentrat<strong>in</strong>git along a feed bunk or <strong>in</strong> a barn.When hay is fed on sod, livestockusually waste <strong>and</strong> refuse less hay <strong>in</strong>situations <strong>in</strong> which they have a solidfoot<strong>in</strong>g. Dry, well-dra<strong>in</strong>ed, or frozen12

sites should therefore be chosen forfeed<strong>in</strong>g hay outside.Feed<strong>in</strong>g <strong>in</strong> only one area permitsselection of a convenient feed<strong>in</strong>glocation which is easily accessible <strong>and</strong>which m<strong>in</strong>imizes the size of the area <strong>in</strong>which sod is killed. However, it causesexcessive sod destruction, usuallycreates muddy conditions, often results<strong>in</strong> heavy spr<strong>in</strong>g weed pressure, <strong>and</strong> canresult <strong>in</strong> soil compaction <strong>and</strong>/or ruts <strong>in</strong>the field.Some livestock producers who feed<strong>in</strong> only one area prefer to feed onconcrete or to haul <strong>in</strong> large gravel sothe hay can be placed on a solidfoundation. Also, some producersfeed the lowest quality hay first, thus<strong>in</strong>itially caus<strong>in</strong>g excessive hay wastagebut provid<strong>in</strong>g a foundation forfurther feed<strong>in</strong>g.Frequently mov<strong>in</strong>g the feed<strong>in</strong>g areaallows manure to be spread moreuniformly over the field(s) <strong>and</strong> thereforeimproves the soil fertility <strong>in</strong> bareor th<strong>in</strong> spots, while reduc<strong>in</strong>g theseverity of (though not necessarily thetotal area which susta<strong>in</strong>s) sod damage.It can also facilitate the “trampl<strong>in</strong>g <strong>in</strong>”of legume seed (usually white clover orred clover) which was broadcast over afield dur<strong>in</strong>g early w<strong>in</strong>ter. Regardlessof the approach used when feed<strong>in</strong>ghay on sod, any areas where sod killis encountered should be reseededas soon after the feed<strong>in</strong>g seasonas possible.When hay is fed on sod, the amountof hay wasted will be much less whenonly a one-day hay supply is given, <strong>and</strong>when hay is fed <strong>in</strong> such a manner thatall animals have access. However,unrestricted animal access to largeround bales or stacks will result <strong>in</strong>grossly excessive feed<strong>in</strong>g waste.If substantial quantities of hay mustbe put out at one time, erect<strong>in</strong>g abarrier between the hay <strong>and</strong> the feed<strong>in</strong>ganimals will reduce waste. The barrierPlac<strong>in</strong>g a barrier between the hay <strong>and</strong> the animals will reduce feed<strong>in</strong>g losses.can be an electric wire, feed<strong>in</strong>g racks orr<strong>in</strong>gs, panels, wagons, or gates. Feed<strong>in</strong>gracks <strong>and</strong> r<strong>in</strong>gs are available <strong>in</strong> a varietyof shapes <strong>and</strong> sizes (racks whichprevent hay from contact<strong>in</strong>g theground are particularly effective). Inaddition, bluepr<strong>in</strong>ts for home constructionof bale protectors are availablethrough many universities,<strong>in</strong>clud<strong>in</strong>g from County AgriculturalExtension Agents.When racks or panels are not used,enough animals are needed to eat theamount of hay offered <strong>in</strong> a relativelyshort period of time. Waste can bereduced by hav<strong>in</strong>g at least one cow foreach foot of outside dimension (circumference)of the hay package.Forc<strong>in</strong>g animals which have lownutritional requirements to clean uphay <strong>in</strong> feed<strong>in</strong>g areas before more hay isput out can also help reduce waste.A few producers use balers whichpackage hay <strong>in</strong> relatively small roundbale packages which are left <strong>in</strong> the field<strong>and</strong> later fed at the spot where theywere dropped from the baler. Thissystem lends itself to large hay storagelosses if hay is stored <strong>in</strong> this manner forvery long because the hay is unprotectedfrom the elements <strong>and</strong> there ishigh bale surface area exposure. Whenthis system is used, an electric wireshould be used to limit access <strong>and</strong> thusat least reduce feed<strong>in</strong>g losses.Feed<strong>in</strong>g Priority Of Various <strong>Hay</strong>sObviously, the longer hay is exposed tothe elements, the greater storage losseswill be. Therefore, hay stored outsideshould generally be fed before haystored <strong>in</strong>side. Porous hay which ishighly susceptible to damage should befed before hay which is tightly baled.Other th<strong>in</strong>gs be<strong>in</strong>g equal, the bestquality hay stored outside should befed before lower quality hay, thoughanimal nutritional requirements mayalso affect feed<strong>in</strong>g priority.Alter<strong>in</strong>g <strong>Hay</strong> Bales Before Feed<strong>in</strong>gSeveral types of equipment are availablefor gr<strong>in</strong>d<strong>in</strong>g, shredd<strong>in</strong>g, unroll<strong>in</strong>g, orcutt<strong>in</strong>g <strong>and</strong> w<strong>in</strong>drow<strong>in</strong>g large haypackages. These methods usuallyrequire additional equipment, but canwork well under proper management.Gr<strong>in</strong>d<strong>in</strong>g or shredd<strong>in</strong>g hay facilitateslimit feed<strong>in</strong>g (limit<strong>in</strong>g the amount fedat a time) <strong>and</strong> also tends to lowerfeed<strong>in</strong>g losses by reduc<strong>in</strong>g the abilityof animals to selectively consumeunweathered hay <strong>and</strong> refuseweathered material.The least expensive method is tosimply unroll the bale to enablelivestock to l<strong>in</strong>e up much like at a feedbunk. Aga<strong>in</strong>, feed<strong>in</strong>g only enoughfor one day reduces waste but<strong>in</strong>creases labor.13

<strong>M<strong>in</strong>imiz<strong>in</strong>g</strong> <strong>Hay</strong> RequirementsThe objective of any hay feed<strong>in</strong>gprogram is to provide adequatequantities of high quality hay to meetlivestock needs not be<strong>in</strong>g met bypasture. However, stored feed, <strong>in</strong>clud<strong>in</strong>ghay, is normally much moreexpensive than pasture forage, so it iseconomically advantageous to m<strong>in</strong>imizestored feed requirements to theextent possible. Examples of ways thismight be done <strong>in</strong>clude stockpil<strong>in</strong>gforage, graz<strong>in</strong>g crop residues, <strong>and</strong>lengthen<strong>in</strong>g the graz<strong>in</strong>g season bygrow<strong>in</strong>g various pasture crops whichhave differ<strong>in</strong>g periods of production.KEY CONCEPTS REGARDINGOUTSIDE HAY STORAGE1. Weather<strong>in</strong>g of hay results <strong>in</strong> lossesof dry matter, lowered foragequality, <strong>and</strong> (perhaps even lesswell recognized) reduced hay<strong>in</strong>take <strong>and</strong> greater refusal.2. The more valuable the hay, theeasier it is to justify spend<strong>in</strong>gtime <strong>and</strong> money to reducestorage losses.3. <strong>Hay</strong>/soil contact is usually themost important source of spoilageof hay stored outside <strong>and</strong>should be elim<strong>in</strong>ated if possible.This can be accomplished byplac<strong>in</strong>g bales on crushed rock, aconcrete pad, or some object suchas wooden pallets. If plac<strong>in</strong>g baleson the ground cannot be avoided,selection of a well-dra<strong>in</strong>ed area(preferably with s<strong>and</strong>y soil)6. It is preferable for bale rows to runnorth <strong>and</strong> south rather than east<strong>and</strong> west. Also, a southern, ratherthan a northern, exposure is best.7. The flat ends of bales should bebutted together, but the roundedsides should not touch. Unlessrows are put together to facilitatecover<strong>in</strong>g with sheets of plastic orsimilar material, at least 3 feet ofspace should be left between rowsto allow air circulation.8. The larger the bale, the lower thetotal percentage of weather<strong>in</strong>g ofhay stored outside. However, thereare some disadvantages associatedwith h<strong>and</strong>l<strong>in</strong>g larger bales.9. As hay density is <strong>in</strong>creased (particularly<strong>in</strong> the outer portion ofthe bale), outside storage lossesEXAMPLES OF THINGS YOU SHOULD NOT DOBales should not be allowed to be <strong>in</strong>st<strong>and</strong><strong>in</strong>g water, even on a temporarybasis.The rounded sides of bales should nottouch.should be selected.4. Water should quickly dra<strong>in</strong> awayfrom any bales stored on theground. Stor<strong>in</strong>g bales near thetop of a slop<strong>in</strong>g area reduces theamount of water flow<strong>in</strong>g aroundthem. Bale rows should run up<strong>and</strong> down a slop<strong>in</strong>g area to avoidtrapp<strong>in</strong>g surface water.5. <strong>Hay</strong> should be stored <strong>in</strong> a sunnylocation, preferably <strong>in</strong> an areawhere frequent breezes occur.<strong>Hay</strong> should never be stored undertrees or other areas where dry<strong>in</strong>gis slow.<strong>Hay</strong> should not be placed under trees.decl<strong>in</strong>e. A m<strong>in</strong>imum of 10 poundsof hay/cubic foot is recommendedfor round bales stored outside.Course-stemmed forages are morevulnerable to weather<strong>in</strong>g thanf<strong>in</strong>e-stemmed forages which forma thatch.10. The efficiency <strong>and</strong> cost of variousmethods of stor<strong>in</strong>g hay outsidevary greatly. Whether a particulartechnique or comb<strong>in</strong>ation oftechniques can be justified dependson the cost of thetechnique(s) versus the value ofhay which will otherwise be lost.14