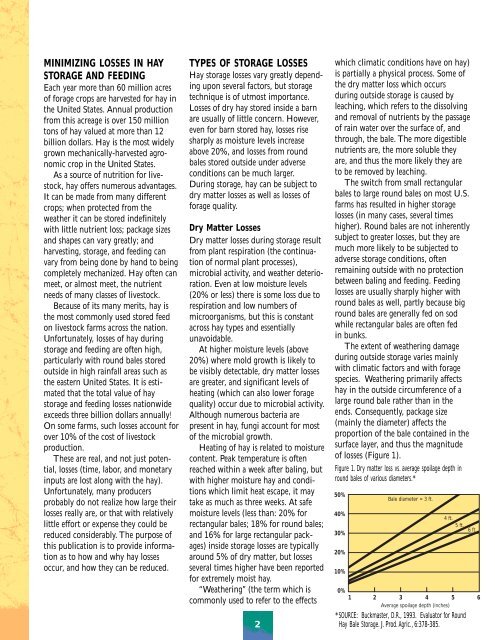

MINIMIZING LOSSES IN HAYSTORAGE AND FEEDINGEach year more than 60 million acresof forage crops are harvested for hay <strong>in</strong>the United States. Annual productionfrom this acreage is over 150 milliontons of hay valued at more than 12billion dollars. <strong>Hay</strong> is the most widelygrown mechanically-harvested agronomiccrop <strong>in</strong> the United States.As a source of nutrition for livestock,hay offers numerous advantages.It can be made from many differentcrops; when protected from theweather it can be stored <strong>in</strong>def<strong>in</strong>itelywith little nutrient loss; package sizes<strong>and</strong> shapes can vary greatly; <strong>and</strong>harvest<strong>in</strong>g, storage, <strong>and</strong> feed<strong>in</strong>g canvary from be<strong>in</strong>g done by h<strong>and</strong> to be<strong>in</strong>gcompletely mechanized. <strong>Hay</strong> often canmeet, or almost meet, the nutrientneeds of many classes of livestock.Because of its many merits, hay isthe most commonly used stored feedon livestock farms across the nation.Unfortunately, losses of hay dur<strong>in</strong>gstorage <strong>and</strong> feed<strong>in</strong>g are often high,particularly with round bales storedoutside <strong>in</strong> high ra<strong>in</strong>fall areas such asthe eastern United States. It is estimatedthat the total value of haystorage <strong>and</strong> feed<strong>in</strong>g losses nationwideexceeds three billion dollars annually!On some farms, such losses account forover 10% of the cost of livestockproduction.These are real, <strong>and</strong> not just potential,losses (time, labor, <strong>and</strong> monetary<strong>in</strong>puts are lost along with the hay).Unfortunately, many producersprobably do not realize how large theirlosses really are, or that with relativelylittle effort or expense they could bereduced considerably. The purpose ofthis publication is to provide <strong>in</strong>formationas to how <strong>and</strong> why hay lossesoccur, <strong>and</strong> how they can be reduced.TYPES OF STORAGE LOSSES<strong>Hay</strong> storage losses vary greatly depend<strong>in</strong>gupon several factors, but storagetechnique is of utmost importance.<strong>Losses</strong> of dry hay stored <strong>in</strong>side a barnare usually of little concern. However,even for barn stored hay, losses risesharply as moisture levels <strong>in</strong>creaseabove 20%, <strong>and</strong> losses from roundbales stored outside under adverseconditions can be much larger.Dur<strong>in</strong>g storage, hay can be subject todry matter losses as well as losses offorage quality.Dry Matter <strong>Losses</strong>Dry matter losses dur<strong>in</strong>g storage resultfrom plant respiration (the cont<strong>in</strong>uationof normal plant processes),microbial activity, <strong>and</strong> weather deterioration.Even at low moisture levels(20% or less) there is some loss due torespiration <strong>and</strong> low numbers ofmicroorganisms, but this is constantacross hay types <strong>and</strong> essentiallyunavoidable.At higher moisture levels (above20%) where mold growth is likely tobe visibly detectable, dry matter lossesare greater, <strong>and</strong> significant levels ofheat<strong>in</strong>g (which can also lower foragequality) occur due to microbial activity.Although numerous bacteria arepresent <strong>in</strong> hay, fungi account for mostof the microbial growth.Heat<strong>in</strong>g of hay is related to moisturecontent. Peak temperature is oftenreached with<strong>in</strong> a week after bal<strong>in</strong>g, butwith higher moisture hay <strong>and</strong> conditionswhich limit heat escape, it maytake as much as three weeks. At safemoisture levels (less than: 20% forrectangular bales; 18% for round bales;<strong>and</strong> 16% for large rectangular packages)<strong>in</strong>side storage losses are typicallyaround 5% of dry matter, but lossesseveral times higher have been reportedfor extremely moist hay.“Weather<strong>in</strong>g” (the term which iscommonly used to refer to the effects2which climatic conditions have on hay)is partially a physical process. Some ofthe dry matter loss which occursdur<strong>in</strong>g outside storage is caused byleach<strong>in</strong>g, which refers to the dissolv<strong>in</strong>g<strong>and</strong> removal of nutrients by the passageof ra<strong>in</strong> water over the surface of, <strong>and</strong>through, the bale. The more digestiblenutrients are, the more soluble theyare, <strong>and</strong> thus the more likely they areto be removed by leach<strong>in</strong>g.The switch from small rectangularbales to large round bales on most U.S.farms has resulted <strong>in</strong> higher storagelosses (<strong>in</strong> many cases, several timeshigher). Round bales are not <strong>in</strong>herentlysubject to greater losses, but they aremuch more likely to be subjected toadverse storage conditions, oftenrema<strong>in</strong><strong>in</strong>g outside with no protectionbetween bal<strong>in</strong>g <strong>and</strong> feed<strong>in</strong>g. Feed<strong>in</strong>glosses are usually sharply higher withround bales as well, partly because biground bales are generally fed on sodwhile rectangular bales are often fed<strong>in</strong> bunks.The extent of weather<strong>in</strong>g damagedur<strong>in</strong>g outside storage varies ma<strong>in</strong>lywith climatic factors <strong>and</strong> with foragespecies. Weather<strong>in</strong>g primarily affectshay <strong>in</strong> the outside circumference of alarge round bale rather than <strong>in</strong> theends. Consequently, package size(ma<strong>in</strong>ly the diameter) affects theproportion of the bale conta<strong>in</strong>ed <strong>in</strong> thesurface layer, <strong>and</strong> thus the magnitudeof losses (Figure 1).Figure 1. Dry matter loss vs. average spoilage depth <strong>in</strong>round bales of various diameters.*50%40%30%20%10%0%Bale diameter = 3 ft.4 ft.5 ft.6 ft.1 2 3 4 5 6Average spoilage depth (<strong>in</strong>ches)*SOURCE: Buckmaster, D.R., 1993. Evaluator for Round<strong>Hay</strong> Bale <strong>Storage</strong>. J. Prod. Agric., 6:378-385.

In the eastern United States it is notunusual for 4 to 8 or more <strong>in</strong>ches ofspoilage to occur on the outside oflarge round bales stored outside withno protection. A weathered layer 6<strong>in</strong>ches <strong>in</strong> depth on a 5.6 foot x 5.6 footbale conta<strong>in</strong>s about one-third of thepackage volume. Other th<strong>in</strong>gs be<strong>in</strong>gequal, the percentage of hay lostdecreases as bale size <strong>in</strong>creases because asmaller proportion of the bale volumeis conta<strong>in</strong>ed <strong>in</strong> the surface layer. Thishas important implications regard<strong>in</strong>gbaler purchase decisions.Forage Quality <strong>Losses</strong><strong>Storage</strong> conditions can also have adramatic effect on hay chemicalcomposition <strong>and</strong> feed<strong>in</strong>g value. Typicaleffects on the <strong>in</strong>terior (unweathered)<strong>and</strong> exterior (weathered) portions ofbales on crude prote<strong>in</strong>, acid detergentfiber (ADF), <strong>and</strong> <strong>in</strong> vitro digestible drymatter (IVDDM) are shown <strong>in</strong> Table1. Even if there were no dry matterlosses or additional feed<strong>in</strong>g losses withweathered hay, changes <strong>in</strong> foragequality would be of great concern.Total crude prote<strong>in</strong> decl<strong>in</strong>es withweather<strong>in</strong>g, but the percentage ofcrude prote<strong>in</strong> may <strong>in</strong>crease due to drymatter losses (a phenomenon whichhas been reported to also occur withra<strong>in</strong> damage of field-cur<strong>in</strong>g hay). ThisSampl<strong>in</strong>g each lot of hay for nutritive analysis isnecessary if hay is to be fed <strong>in</strong> an efficient manner.is because prote<strong>in</strong> is less subject thanother plant constituents to weather<strong>in</strong>gloss. However, the proportion ofdigestible crude prote<strong>in</strong> may decrease,especially if the hay undergoes heat<strong>in</strong>gdue to excessive moisture.Soluble carbohydrates, which arehighly digestible, decl<strong>in</strong>e dur<strong>in</strong>gweather<strong>in</strong>g as shown by <strong>in</strong>creases <strong>in</strong>Table 1. Forage quality of the <strong>in</strong>terior <strong>and</strong> exterior portions of alfalfa roundbales stored outside.*Portions Crude Acid detergentOf Bales prote<strong>in</strong> fiber IVDDM_____________________________________________________________- - - - - - - - % of dry weight - - - - - -Interior 18.9 38.6 61.4Exterior 19.4 45.8 46.9_____________________________________________________________*SOURCE: Anderson, P.M., W.L. Kjelgaard, L.D. Hoffman, L.L. Wilson, <strong>and</strong> H.W. Harpster. 1981. Harvest<strong>in</strong>gpractices <strong>and</strong> round bale losses. Trans. ASAE.24:841-842.ADF <strong>and</strong> decreases <strong>in</strong> IVDDM; thuscarbohydrate levels differ greatlybetween the weathered <strong>and</strong> unweatheredportions of round bales. Decl<strong>in</strong>es<strong>in</strong> hay quality from weather<strong>in</strong>g areHAY QUALITY- THE KEY TOANIMAL PERFORMANCE<strong>Hay</strong> quality is critically important, especially for animals hav<strong>in</strong>ghigh nutritional requirements, <strong>and</strong> the ultimate test of hay qualityis animal performance. <strong>Hay</strong> quality is considered satisfactory whenanimals consum<strong>in</strong>g it perform as desired. For anyone who isproduc<strong>in</strong>g, feed<strong>in</strong>g, buy<strong>in</strong>g, or sell<strong>in</strong>g hay, forage quality should bea major consideration.Factors which affect hay quality <strong>in</strong>clude: grow<strong>in</strong>g conditions,fertility, species, varieties, pests, presence of weeds, harvest<strong>in</strong>g,cur<strong>in</strong>g, h<strong>and</strong>l<strong>in</strong>g, <strong>and</strong> storage. However, the stage of maturity whenharvested is the most important factor, <strong>and</strong> the one wheremanagement can have the greatest impact.As plants advance from the vegetative to the reproductivestages, fiber <strong>and</strong> lign<strong>in</strong> <strong>in</strong>crease, while prote<strong>in</strong>, digestibility,metabolizable energy, <strong>and</strong> acceptability to livestock decrease. Earlycut hay makes a more desirable feed because it conta<strong>in</strong>s morenutrients. <strong>Hay</strong> cut at an early stage of maturity is also morepalatable <strong>and</strong> is more readily consumed by livestock.Evaluat<strong>in</strong>g <strong>Hay</strong> QualitySeveral methods exist for evaluat<strong>in</strong>g hay quality: visual, chemical,near <strong>in</strong>frared reflectance spectroscopy (NIRS), <strong>and</strong> animalperformance. Visual estimates can help, but vary considerably.Descriptions based on these estimates show high quality hay to beearly cut, leafy, soft, free of mold <strong>and</strong> foreign material, <strong>and</strong> hav<strong>in</strong>ga pleasant odor. Color can be mislead<strong>in</strong>g, because hay hav<strong>in</strong>g abright green color may be mature <strong>and</strong> fibrous, while faded haymay often have excellent nutritional value.The most precise way to determ<strong>in</strong>e the nutrient content ofhay is through laboratory analysis. If a representative sample istaken <strong>and</strong> analyzed for nutritive content, the results can helpdeterm<strong>in</strong>e how much <strong>and</strong> what type of supplementation, if any, isneeded <strong>in</strong> order to meet the nutrient requirements of the animalsbe<strong>in</strong>g fed, <strong>and</strong> to obta<strong>in</strong> the level of performance desired. Thisleads to efficient <strong>and</strong> economical feed<strong>in</strong>g programs.Sampl<strong>in</strong>g For Forage Quality AnalysesWhen hay is tested, a r<strong>and</strong>om, representative sample must beobta<strong>in</strong>ed because laboratory results will be only as accurate as thesample submitted. A sample should be taken for each lot of hay. A“lot” represents a group of bales of hay which were grown <strong>in</strong> thesame field, harvested under the same conditions <strong>and</strong> at the sametime, <strong>and</strong> stored <strong>in</strong> the same way.When collect<strong>in</strong>g samples, a hay probe should be used whichhas a m<strong>in</strong>imum cutt<strong>in</strong>g diameter of 1/2 <strong>in</strong>ch <strong>and</strong> a m<strong>in</strong>imumlength of 12 <strong>in</strong>ches. Samples should be taken from the ends ofconventional rectangular bales or from the radial sides of largeround bales, with 15 to 20 probe samples be<strong>in</strong>g composited <strong>and</strong>then submitted for analysis from each lot of hay. Samples shouldbe stored <strong>in</strong> an airtight bag for shipment to the laboratory.Sampl<strong>in</strong>g of weathered hay for nutritive value is more complexthan sampl<strong>in</strong>g unweathered hay. Ideally, weathered <strong>and</strong>unweathered portions of bales should be sampled separately <strong>and</strong>the analysis results from the two fractions weighted accord<strong>in</strong>g totheir relative contributions to entire bales.3