Self-Healing Technology for Gas Retention Structures ... - Team-Logic

Self-Healing Technology for Gas Retention Structures ... - Team-Logic

Self-Healing Technology for Gas Retention Structures ... - Team-Logic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

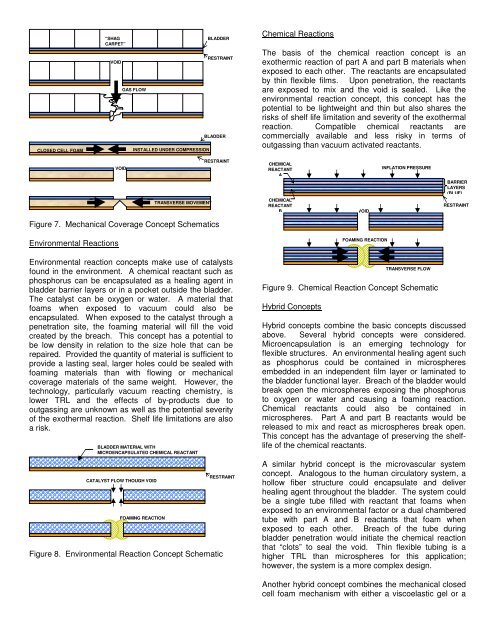

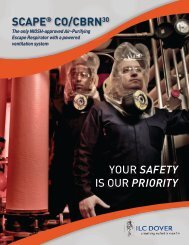

CLOSED CELL FOAM“SHAGCARPET”VOIDGAS FLOWINSTALLED UNDER COMPRESSIONBLADDERRESTRAINTBLADDERChemical ReactionsThe basis of the chemical reaction concept is anexothermic reaction of part A and part B materials whenexposed to each other. The reactants are encapsulatedby thin flexible films. Upon penetration, the reactantsare exposed to mix and the void is sealed. Like theenvironmental reaction concept, this concept has thepotential to be lightweight and thin but also shares therisks of shelf life limitation and severity of the exothermalreaction. Compatible chemical reactants arecommercially available and less risky in terms ofoutgassing than vacuum activated reactants.VOIDTRANSVERSE MOVEMENTRESTRAINTCHEMICALREACTANTACHEMICALREACTANTBVOIDINFLATION PRESSUREBARRIERLAYERS(BLUE)RESTRAINTFigure 7. Mechanical Coverage Concept SchematicsEnvironmental ReactionsEnvironmental reaction concepts make use of catalystsfound in the environment. A chemical reactant such asphosphorus can be encapsulated as a healing agent inbladder barrier layers or in a pocket outside the bladder.The catalyst can be oxygen or water. A material thatfoams when exposed to vacuum could also beencapsulated. When exposed to the catalyst through apenetration site, the foaming material will fill the voidcreated by the breach. This concept has a potential tobe low density in relation to the size hole that can berepaired. Provided the quantity of material is sufficient toprovide a lasting seal, larger holes could be sealed withfoaming materials than with flowing or mechanicalcoverage materials of the same weight. However, thetechnology, particularly vacuum reacting chemistry, islower TRL and the effects of by-products due tooutgassing are unknown as well as the potential severityof the exothermal reaction. Shelf life limitations are alsoa risk.BLADDER MATERIAL WITHMICROENCAPSULATED CHEMICAL REACTANTCATALYST FLOW THOUGH VOIDFOAMING REACTIONRESTRAINTFigure 8. Environmental Reaction Concept SchematicFigure 9. Chemical Reaction Concept SchematicHybrid ConceptsFOAMING REACTIONTRANSVERSE FLOWHybrid concepts combine the basic concepts discussedabove. Several hybrid concepts were considered.Microencapsulation is an emerging technology <strong>for</strong>flexible structures. An environmental healing agent suchas phosphorus could be contained in microspheresembedded in an independent film layer or laminated tothe bladder functional layer. Breach of the bladder wouldbreak open the microspheres exposing the phosphorusto oxygen or water and causing a foaming reaction.Chemical reactants could also be contained inmicrospheres. Part A and part B reactants would bereleased to mix and react as microspheres break open.This concept has the advantage of preserving the shelflifeof the chemical reactants.A similar hybrid concept is the microvascular systemconcept. Analogous to the human circulatory system, ahollow fiber structure could encapsulate and deliverhealing agent throughout the bladder. The system couldbe a single tube filled with reactant that foams whenexposed to an environmental factor or a dual chamberedtube with part A and B reactants that foam whenexposed to each other. Breach of the tube duringbladder penetration would initiate the chemical reactionthat “clots” to seal the void. Thin flexible tubing is ahigher TRL than microspheres <strong>for</strong> this application;however, the system is a more complex design.Another hybrid concept combines the mechanical closedcell foam mechanism with either a viscoelastic gel or a