rheda 2000® ballastless track system - RAIL.ONE GmbH

rheda 2000® ballastless track system - RAIL.ONE GmbH

rheda 2000® ballastless track system - RAIL.ONE GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

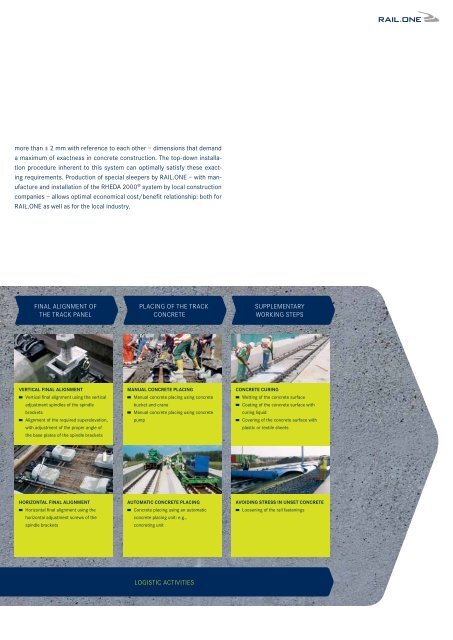

more than ± 2 mm with reference to each other – dimensions that demanda maximum of exactness in concrete construction. The top-down installationprocedure inherent to this <strong>system</strong> can optimally satisfy these exactingrequirements. Production of special sleepers by <strong>RAIL</strong>.<strong>ONE</strong> – with manufactureand installation of the RHEDA <strong>2000®</strong> <strong>system</strong> by local constructioncompanies – allows optimal economical cost/benefit relationship: both for<strong>RAIL</strong>.<strong>ONE</strong> as well as for the local industry.Final alignment ofthe <strong>track</strong> panelPlacing of the <strong>track</strong>concreteSupplementaryworking stepsVertical final alignmentVertical final alignment using the verticaladjustment spindles of the spindlebracketsAlignment of the required superelevation,with adjustment of the proper angle ofthe base plates of the spindle bracketsManual concrete placingManual concrete placing using concretebucket and craneManual concrete placing using concretepumpConcrete curingWetting of the concrete surfaceCoating of the concrete surface withcuring liquidCovering of the concrete surface withplastic or textile sheetsHorizontal final alignmentHorizontal final alignment using thehorizontal adjustment screws of thespindle bracketsAutomatic concrete placingConcrete placing using an automaticconcrete placing unit: e.g.,concreting unitAvoiding stress in unset concreteLoosening of the rail fasteningsLOGISTIC ACTIVITIES