Download - Skanska

Download - Skanska

Download - Skanska

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TargetingZeroAccidentsTank StorageDos & Don'tsAttaining zero accidents is areachable goal, one the RockyMountain District proves is possibleto achieve. For more than sevenyears, the division has gone withouta single lost time accident.Do!Separate oxygen and acetylenetanks by at least 20 feet while notin use. Ensure they’re stored in theupright position, secured with aninsulated chain or non-conductivebelt and protected from contactwith the ground.What’s the trick to being safe? Year after year, the team remainsfocused on minimizing risk through committed leadership, pre-taskplanning and people training.Making gains“The awareness and commitment of the people out in the field is mostimportant,” explains Senior Vice President Curtis Broughton. “We’veempowered our people to stop, rethink and find better, safer ways toconduct a task if they feel there’s a risk that could jeopardize safety. We set"We set high expectationsand lower the threshold ofacceptance for risk-taking.And there are no repercussionswhen someone stops work forsafety reasons."high expectations and lower the threshold of acceptance for risk-taking.And there are no repercussions when someone stops work for safetyreasons. What’s learned from these incidents is transferred from crew tocrew, so there’s a strong sense of responsibility.”This culture of responsibility is something the Rocky Mountain Districthas cultivated, with the help of its clients, over the last two decades.“A lot of our safety processes 20 years ago were driven by the clients –oil, gas and mining guys with sophisticated safety cultures,” Curtis says.“So if you look at our incident rates from back then, you’ll notice that’swhen big gains were made. We’ve maintained this level of performancebecause of the clients’ standards and demands as well as our commitmentto a strong safety culture.”According to Curtis, that’s not all it takes to sustain such aconsistent record.“It’s also crucial to appoint the right resources. We have six peoplewho are wholly dedicated to safety work.”Taking it day by day“Moving forward, some of our biggest risks are complacency andmanaging our growth and the new people coming into our organization,”reveals EHS Director Clark Peterson. “If you were to ask employeeswhen the Rocky Mountain District’s last lost time occurred, their answerwould be, ‘It doesn’t matter.’ We have to be focusedon the one we prevent today and tomorrow. It’ll takeleadership setting clear expectations, along with clearand consistent systems and processes, to manage thegrowth of our organization in the Rocky MountainDistrict while maintaining our safety.”Once these expectations and processes leavemanagement’s hands, Clark says it’s up to employeesto put them into play.“Any safety system is ultimately depending onhuman beings who are affected by beliefs, values,misperceptions and communication. We must helpour employees make the right decisions by praising theright things, being a consistent leader and making surethey’re involved. That enables them to have ownershipover their own safety.One thing I’ve always preached is that if we executeand go zero today, then we can do it forever. We musttake every day as a new day and go out and execute.The safety record doesn’t save us. Just because we weresafe yesterday, doesn’t mean we’re safe today. We haveto be on our toes every day,” concludes Clark. ◆Safety FirstCurtis Broughtonwill serve as a U.S.representative onthe global SafetyLeadership Teamalongside Chief EHSOfficer Hendrik “Van”Brenk. The team willwork over the nextyear to improvesafety processesthroughout <strong>Skanska</strong>.Don’t!Acetylene, an inflammable gas,shouldn’t be stored next to oxygentanks because acetylene and airform an explosive mixture.Improper storage can lead to seriousfires, explosions or reactivity withother materials.2 coast to coast coast to coast 3

EditorialA ChanceEncounterWhen I returned home from Iraq in 2006, I wasn’t sureof the road that lay ahead of me.I was serving in the U.S. Army as asergeant of a general constructionplatoon in Iraq when I was injuredand had to return home for medicaltreatment. I began my treatment atWalter Reed Army Medical Center,but in an effort to be closer to homein Arizona, I transferred to the Centerfor the Intrepid in San Antonio.It was at the grand opening of theCenter for the Intrepid that I first learnedabout <strong>Skanska</strong>. The company had beenthe construction manager for the newfacility where I was about to continuemy treatment, and the project team wasin attendance for the ceremony. I spoketo several team members and shared myexperience with the Corps of Engineersand previous work with contractors.I was given Project Executive MartyCorrado’s contact information on thespot and was told to reach out to himwhen I was ready to look for a job after<strong>Skanska</strong> Survey: Have you enrolled in SEOP 2?Yes50.8%Not Yet26.2%Want to see your opinions represented here?Log in to the Hub Survey Page: www.skanskasurvey.comNo23.1%SEOP, the <strong>Skanska</strong> Employee Ownership Program, provides employeeswith the opportunity to directly benefit from the company’s earnings.More information on SEOP can be found under the <strong>Skanska</strong> & Me tabon One<strong>Skanska</strong>, the global intranet.my rehabilitation.I contacted Marty several monthslater, but soon found out that myrecovery was going to take a lot longerthan expected. What I thought would besix months of recuperation lasted overtwo years. But Marty checked in with mejust about every six months to see how Iwas coming along.When I finally recovered and retiredfrom the Army at the end of 2010,<strong>Skanska</strong> welcomed me with open arms.I’m now a quality control manager onthe Texas A&M Liberal Arts Buildingproject in College Station.I enjoy the challenge of learning thenuance of working in the state of Texas,and being back in the field with a greatcompany like <strong>Skanska</strong>. ◆<strong>Skanska</strong> Employee Ownership ProgramJoin in as an ownerof our company—Sandra SmithQuality Control Manager in College Station, T.X.Your SEOP contactName and phone:http://one.skanska/seopA Day in the Life…Jeff SmithSenior Project Manager, Los Angeles, C.A.4:00 am Wake up and take a walk through my neighborhood.5:30 am Commute to work.6:30 am Arrive at the office, review yesterday’s tasks and organize the day’s to-do list.7:00 am Plan the pursuit for the Metro Gold Line Foothill 2A design-build project,an 11.5 mile expansion of the light rail line from Pasadena to Azusa.8:00 am Morning staff meeting to provide an open forum for the pursuit team andto get status updates from the proposal, operations and estimating teams.9:00 am Review and respond to morning emails.10:00 am Evaluate the design-build contract documents for the Foothill 2A projectand then coordinate with my staff, legal, insurance and executives. Followup these meetings by writing down questions and comments to use whenediting the contract documents. Then shoot an email to the client with astatus update on the project.11:30 am Lunchtime.12:30 pm Review and respond to late morning emails.1:00 pm Map design-build contract documents for indirect cost and schedule impactsby creating a spreadsheet to identify cost drivers and schedule driversspecific to the Foothill 2A project. Then email this information to theestimating team.2:00 pm Coordinate the designers’ preliminary engineering plan to support thedesign-build estimate by defining the scope and prioritization.3:00 pm Develop, maintain and share our construction approach, winning strategypoints, management and staffing plan, risk register and action items listwith the pursuit team.4:30 pm Review and respond to afternoon emails and organize and file theday’s activities.5:00 pm Return calls while leaving the office.6:30 pm Dinner with the family to catch up with my wife and kids.7:00 pm Attend a Boy Scout meeting with my son.8:30 pm Spend quality time with my two daughters before bed.9:30 pm Time to hit the sack.How is your team supportingzero environmental incidents?On the LyndonB. Johnson GeneralHospital project,we’re supporting zero environmentalincidents throughtraining and monitoring.Every subcontractor and employeegoes through jobsiteorientation, which includes asection on our ISO 14001 andOSHA 18001 systems. We also have labels filled outfor our personnel on site, which includes a checklistof our environmental aspects that are reviewed duringthe orientation.—Charles GriffithsProject Manager, Houston, T.X.We have twoDelaware certifiedconstructionreviewers on the IndianRiver Inlet Bridge projectwho ensure that our erosionand sediment controls arein place and effective. Theyinspect the site weekly withthe client and after any major weather event.Deficiencies found in our controls are repairedimmediately.We also use special netting toprevent construction debris or tools from fallinginto the inlet.—Cheryl R. KingBusiness Manager, Rehoboth Beach, D.E.6 coast to coast coast to coast7QAConstruction onOregon Health &Science Universityrequired that we work outsidepatient rooms and critical areaswhile the hospital remainedopen. Scope included noisessuch as drilling, demolitionand replacement with metalpanels. Our first priority wasto quell the noise pollution by eliminating use ofimpact tools, drills and power-actuated tools. If thatwas not possible, we instituted noise testing and acommunication plan.—Katie ReiffProject Engineer, Beaverton, O.R.

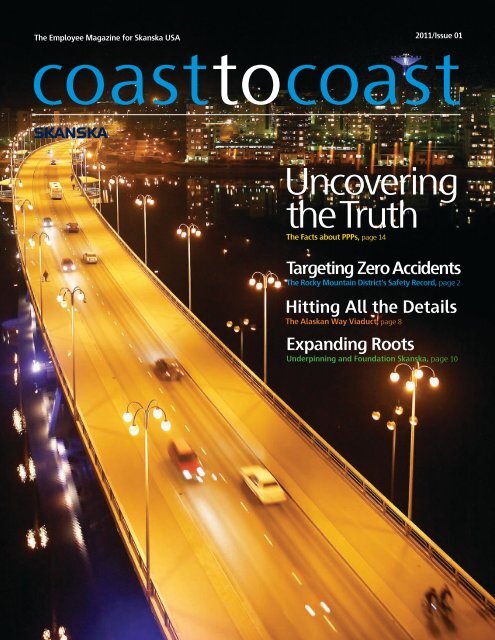

BridgingHitting All theDetails the from“H” to “K”When Civil entered the PacificNorthwest last year, it did so witha bang. Working in a joint venturewith Building, which has more than60 years of boots-on-the-groundexperience in the market, Civil’s firstwin was a big one: replacing just overa mile section of the heavily-traffickedAlaskan Way Viaduct.History in the makingDating to the 1950s, the viaduct carries Washington State Route 99 through downtownSeattle and is one of two main north-south routes through the city, the other beingInterstate 5. Aging, outmoded, and severely damaged by an earthquake 10 years ago,which left the structure susceptible to potential collapse during a future major seismicevent, the viaduct’s functional time has reached its end.<strong>Skanska</strong>’s $115 million contract is the second stage of three to complete the “HolgateStreet to King Street” phase of the viaduct replacement. The Holgate-to-King stretch– known to the project team as “H2K” – may not be the section that cuts through theheart of downtown, but it's adjacent to Safeco Field and Qwest Field, the homes ofSeattle’s three professional sports teams, as well as the Port of Seattle.Out of the ballparkAfter months of underground utility installation and replacement operations,drivers are now beginning to see the changes. On Valentine’s Day, the team movedsouthbound traffic off of the viaduct and onto a new frontage road. This cleared theway for a major milestone the following week.“On President’s Day, the first piece of the original viaductcame down,” says Project Executive Tim O’Neill. “And fromthere we’re full bore on opening a new northbound on-ramp.”That milestone means close-to-normal traffic in bothdirections and it’s a milestone the public knows about…especially if they hold Seattle Mariners season tickets.Timing for completion of the 1st Avenue-SR 99northbound on-ramp and widening is tied to theopening day of Major League Baseball in Seattle. Theseroad improvements are critical for the three stakeholdersmentioned above as well as the City of Seattle.“The deadline for getting that bit of work done has beentied to the start of baseball season since we signed the contract,”says Project Executive Dave Smith. “It’s the first thing we alwaysget asked, ‘so this will all be fine for baseball season?'"Into the futureWork will continue into 2013 on the entire project. The team has to coordinatewith a variety of partners, including the adjacent railroad and, by August 2011,with another contractor that will be building a deep-bore tunnel that starts whereour project ends.Fortunately, the crew is helped by an owner that only wants to see thingsgo well, the Washington State Department of Transportation (WSDOT).“WSDOT has been fantastic with communication,” Tim explains, “as havelocal utility companies, the stadium administrators and the surroundingbusiness community.”Despite a few weekend closures that have occurred, the impact ondrivers hasn’t been severe.H2K in the MakingGet a feel of how the H2K project works by visiting: http://wsdot.wa.gov/projects/viaduct/simulations/The chance to impress exists not only fromtraffic volume, but overall public attention. Theviaduct is a landmark and the adjacent tunnelproject has been a point of local controversy.While nearly everyone in Seattle supportsthe H2K job, the team knows that all eyes areon them.“There’s no hiding here,” Tim says, “So whynot show how good we can be? And to be sure,we’ve put signage all around the site so peopleknow who’s doing that good job.” ◆8coast to coast coast to coast9

Expanding RootsBuilding a nameFor more than 100 years,Underpinning and Foundation<strong>Skanska</strong> (Underpinning) has builta strong reputation within theconstruction community becauseof its ability to solve problems withinnovative solutions. In fact, manystate-of-the-art tools and technologieshave made their New York Citydebut on Underpinning jobsites. Forinstance, Underpinning introducedsecant pile walls in 2001 on theNewtown Creek Water PollutionControl Plant project in Brooklyn.“We’re proud of our high-profileprojects, but we bring the samepassion and commitment to all of ourwork,” Ed says.Over the years, the company hasworked on select projects outside ofthe New York Metropolitan area whenthe opportunity arose, including theBay Area Rapid Transit system inSan Francisco and the Disney WorldMonorail in Orlando. But it wasn’tuntil recently that Underpinningbegan strategically expanding itsbusiness beyond New York City.“We're expanding our scope ofservices beyond what we've everdone before and we're excited togrow our business in new markets,”Ed explains. “Part of <strong>Skanska</strong>’s planfor profitable growth for the nextfive years includes expanding intonew markets, so we’ll continue toexplore our options with new clientsin markets where it makes sense.”Underpinning and Foundation <strong>Skanska</strong> has deep roots inNew York City. Founded in 1897, the heavy foundationspecialty contractor has worked on some of the most iconicbuildings in the city, including the New York Stock Exchange,the World Trade Center and the new Yankee Stadium.“As one of America's oldest and most experienceddeep foundation specialists, we build supportingstructures for all types of projects on all types ofsites,” says Ed Forte, president of Underpinning andFoundation <strong>Skanska</strong>, “from single-story buildingsto high-rise structures on rock or soft soil, frommunicipal infrastructure projects to wide-spanbridges and piers in harsh environments. Unlike othercompanies, we really understand the complexities ofconstruction in densely developed urban sites.”Developing new businessUnderpinning currently has twoprojects underway in New Jersey,marking its first time workingfor Union Paving and performinglarge diameter wet hole drilling.In addition, the company hasfive projects under contract inConnecticut, which include work atthe New Haven Rail Yard Facilitiesand the West Haven Railroad Station.Estimators at Underpinning arealso looking into opportunities inWashington, D.C., California andUpstate New York. ◆New Market ContractsNew Jersey Department of Transportation’sRoute 3 Passaic River CrossingClifton, N.J.$10.6 millionNew Jersey Turnpike InterchangesBurlington County, N.J.$5.2 millionReplacement of Amtrak Railroad BridgeBrandford, C.T.$553,255New Haven Rail Yard FacilitiesNew Haven, C.T.$805,150West Haven Railroad StationWest Haven, C.T.$1.4 millionHartford Water PollutionControl FacilityHartford, C.T.$1.6 million10 coast to coast coast to coast11

WaterUnder theBridgeContending with water as deep as 100feet and currents that reach up to 8feet per second, Civil Southeast’s teamon the Indian River Inlet Bridge (IRIB)project in Rehoboth Beach, D.E, washard-pressed to find a way to constructa 2,600-foot-long cable stay bridge thatincludes a 900-foot span over the inlet.The solution came in the form of twothree level, moving pieces of equipmentknown as form travelers.Cortez Flips the SwitchAt more than 6,100 feet of elevation and averaging less than 13 inches of rain every year, the Cortezoffice sees plenty of sun. Now it’s begun to harness some of that solar energy.<strong>Skanska</strong>’s property in Cortez is now sporting a $1.5 million, 258 kilowatt photovoltaicsolar array, set in 15 rows and comprising 1,260 individual photovoltaic panels. Theinstallation is on 2.5 acres, adjacent to the office and equipment shop.“Our system includes GPS telemetry that will allow each panel to pivot to followthe sun across the sky,” says Estimator Keenan Willbanks, who served as projectmanager for the installation. “That makes the panels 30 percent more efficient than ifthey didn’t move.”While designed and engineered by an outside solar firm, the Cortez team did all ofthe construction work, from initial site work to installing the posts and panels.“There is the obvious green aspect to the project,” says Vice President David Sitton,“but there’s also a strong business purpose. We want potential clients to know that thisis work we not only say we can perform, but have the résumé and skill set to execute.This has already opened some doors to potential clients and projects.”When the facilities are using less power than what’s generated by the array, poweris fed into the local grid. Similarly, the office taps into the grid to account for neededpower in times of high demand. Safety fail-safes ensure that if the grid blacks out, thearray powers down to avoid electrocuting utility linemen making grid repairs.The end result will be a significant energy savings over baseline –and to the bottom line.“Using models where we assume the price of electricity stays the same, this shouldpay for itself in six years,” David says. “Of course if prices for power go up, it’ll pay foritself much sooner.” ◆Annually, powergenerated from theproject is forecastto be equivalentto saving:45,000 gallons of gasoline400 tons of carbon dioxide1,000 trees“The current in the inlet is so fast that using a barge tolift segments into place wasn’t a viable option,” explainsEngineer Frank Spalt. “But with the travelers, everything iscompletely supported by the bridge itself.”The travelers clamp to the bridge using a system ofrollers and bogies to keep it balanced while moving. Whenin casting position, the travelers cantilever out, providinga platform on which forms can be constructed. While theyremain stabilized during the launching process and move ata slow pace, the team instituted certain safety precautions.“When moving the travelers forward, the handrails areremoved from the bridge deck and the equipment dropsabout 7 feet,” says Construction Manager Peo Halvarsson.“This exposure requires worker to wear fall protection,and crew communication is key since people are workingwithin the structure as well as on top of it.”But the benefits outweigh the risks.“The travelers dictate the cable stay installation. It’s abalancing act because once the travelers move to the nextsegment of the bridge, they must be counterbalanced frombehind with the installation of the cable,” Frank says.In all, nine cable stays on each side of the four pylontowers have been installed and four more are on their wayin to help the travelers complete their current segments. Intotal, 76 out of 152 stay cables are in place.The project team has begun casting the bridgeover the inlet, and with approximately 500 feet left togo, the travelers will certainly play a huge role in thisfinal phase of construction. ◆12 coast to coast coast to coast13

States with Legislation for Transportation PPPsUncoveringthe TruthA public-private partnership(PPP) is a partnership between apublic authority – usually a stategovernment agency - and a privateentity. While PPPs have beenaround for more than 20 years,they remain shrouded in mystery.Here, Coast to Coast separates themyths from the facts.The factsPPPs are a viable option for delivering critical infrastructurethat would otherwise be unfunded.As part of a PPP, the private entity is responsible fordeveloping, funding, designing, constructing, operating andmaintaining some form of public infrastructure througha performance contract for a set period of time, normally30 - 50 years. The PPP model can be applied to newhighways, bridges, power plants, schools, hospitals and evenmunicipal street lighting districts. As payment, the privateentity receives either user fees (such as tolls) or a regularavailability payment from the public authority.<strong>Skanska</strong> ID specializes in developing, investing in,operating, and divesting PPPs across the <strong>Skanska</strong> footprint.To date, <strong>Skanska</strong> ID has successfully developed 19projects and is actively developing several U.S. PPP projects,including:Midtown Tunnel – VirginiaHampton Roads Bridge Tunnel – VirginiaGoethals Bridge – New York/New Jersey• Ronald Reagan Parkway Extension/I-85Interface – GeorgiaMyth bustingSome common myths about PPPs are that governmentsgive away control of projects developed via PPP or thatgovernment projects are cheaper than PPPs. Some of thesefalsehoods can now be dispelled.Myth: The only benefit of a PPP is the private financing.FactWhile private financing can be an advantage, there are manyother benefits to PPPs that are often overlooked. PPPs can:Infuse needed capital into the Broad infrastructure enabling legislationsystemLimited/project specific legislationSpur economic growth by generating Legislation new largely projectsexpired in 2009Authorization by regulationReduce need for tax hikesNo legislationTransfer project risks to the private sectorSource: National Conference of State Legislators, December 2010Minimize lifecycle costs through efficient design,construction, operations and maintenanceAchieve projects on time, on budget with anyoverages borne by the private partnersEnsure high environmental and safetyperformanceMyth: PPPs are really privatizations.FactPPP is not privatization. The government plays a central rolein PPPs during every step of the project lifecycle. A concessionagreement always provides a strict performance regime forprovided services, so the public sector never forfeits control.If metrics are not met, the public authority can react and adjustscope and services. The private partner has every reason tooutperform in delivering a quality project over the long-term.If the project somehow fails, it’s the private partner who has themost to lose.Myth: You can’t trust Wall Street to deliver PPPs.FactWall Street is only part of the funding equation for PPPs.Effective developers like <strong>Skanska</strong> place at risk their balancesheets against their projects. <strong>Skanska</strong> invests significantshareholder equity to help finance PPP projects. Further,<strong>Skanska</strong> takes responsibility for performance under the designbuildconstruction contract as well as the long-term operationsand maintenance of the asset. Many national and internationalpension funds, insurance funds and labor unions invest in PPPs. ◆States with legislationfor transportation PPPsBroad enabling legislationLimited/project specific legislationLegislation largely expired in 2009Authorization by regulationNo legislationSource: National Conference of State Legislators, December 2010Another Milestone for Midtown TunnelThe team working on the Midtown Tunnel project clearedanother hurdle in January by agreeing to a term sheetwith the Virginia Department of Transportation (VDOT)that lays the important groundwork for the eventualComprehensive Agreement.“Nailing down the term sheet took alot of hard work,” explains CommercialDirector Frederick Burman, who ledthe process. “The end result is highlyencouraging and puts us on pace toachieve commercial close in 2011.”The term sheet outlines how the project will be codevelopedby VDOT and Elizabeth River Crossings andlays out risks, responsibilities and obligations of all partiesgoing forward. Signing the term sheet alsotriggers a more detailed and robust pricingand design process for the <strong>Skanska</strong>-ledconstruction joint venture.A draft of the Comprehensive Agreementwas provided by VDOT on March 14.<strong>Skanska</strong>’s Largest Project Ever: a PPPThe PPP model can be applied to more than just roads.Last year, <strong>Skanska</strong> won its largest project ever whenit secured the PPP contract for the New Karolinska Solna(NKS) hospital in Sweden. The project is the largesthealthcare PPP in the world – worth over $3 billion.To deliver the NKS bid, <strong>Skanska</strong> formed a joint bidteam with <strong>Skanska</strong> ID, <strong>Skanska</strong> UK and <strong>Skanska</strong> Sweden.Together these business units leveraged each other’sexpertise and resources to formulate the winning strategy.“The project is an outstandingexample of the One <strong>Skanska</strong>approach and what can beachieved when three <strong>Skanska</strong>business units agree on andexecute common targets andobjectives,” says Project DirectorMagnus Eriksson.14 coast to coast coast to coast15

CommunityTimelineEureka, C.A.: Christmas joyThrough the SalvationArmy’s Adopt-A-Familyprogram, the St. JosephHospital project teamprovided gifts, a Christmastree and grocery store giftcards for a family of eight.CultivatingInnovationThe way National Innovation DirectorTony Colonna sees it, <strong>Skanska</strong> isalready coming up with innovativeways to work every day. He justthinks developing the practices thattransform singular “lightning strikes”of innovation into repeatable,sustainable solutions will set <strong>Skanska</strong>apart from competitors.Want to learn more about the Innovation Grant Program?Visit: myskanska.com/usa/bldg/innovation/grants/In order to make this a companywide reality, Tony’s efforts are focused on creatingan environment that promotes innovation by facilitating collaboration, providing aforum to share ideas, supplying tangible support to develop ideas and recognizingpeople for their ideas. In fact, Tony and his team have rolled out some initiativesthat do just that.In early 2010, Building launched the Innovation Grant Program, which encouragescollaboration across jobsites and regional offices, fosters partnership with localuniversities and promotes <strong>Skanska</strong> as an innovative construction partner. Throughoutlast year, the program awarded $163,500 to fund inventive work on six projects thatincluded process studies and the development of jobsite tools, such as the DayFactsOnline Daily Superintendent Report.Tony also set his sights on the prefabrication process <strong>Skanska</strong> Shook developedon the Miami Valley Hospital project in Dayton, O.H., the first major hospitalproject in the U.S. to use prefabrication for all mechanical, electrical and plumbinginstallations. Through an innovation grant awarded to a team led by Project ExecutiveMarty Corrado and includes the University of Cincinnati, Tony hopes to developprefabrication into a core competency <strong>Skanska</strong> can market to clients.“Prefabrication is an outstanding example of both the potential and the challengeof harnessing innovation,” he says, “The innovation at Miami Valley was recognizednationally, but we need a process that enables <strong>Skanska</strong> to replicate its success onfuture projects.”Tony plans to continue building the innovation process by enhancing My Site andthe Idea Exchange and launching innovation communities where teams with commoninterests can collaboratively solve problems and share ideas.“It takes real resources and time to actively manage the innovation process anddrive change,” Tony explains, “but <strong>Skanska</strong> is making the investment to build the toolsthat capture the best ideas and transform them from singular lightning strikes to partof <strong>Skanska</strong>’s fabric.” ◆Alexandria, V.A.: Pajama driveID Americas participated in Scholastic Book Clubs'Pajama Drive, collecting 50 pairs of pajamasand two robes, which were given to homelesschildren in the area.Hopewell Township, N.J.: Part of the causeThe Capital Health project team donatedapproximately 500 pounds of food and $180to the Mercer Street Friends Food Bank. Foodbank donors matched the donations at a rateof $8 for every $1, making the total amountcontributed $1,440.Randolph, N.J.:Walk the walkThe <strong>Skanska</strong> Work Crewattended the JuvenileDiabetes ResearchFoundation's Walk toCure Diabetes, raisingapproximately $20,000for the organization.West Palm Beach, F.L.:Race for the cureMore than 20 membersof the South Florida teamparticipated in the annualSusan G. Komen Race forthe Cure 5k, collecting$1,160 for the cause.Tampa, F.L.:Love is in the airThe office’s CommunityOutreach Committeevisited the pediatricunit at Tampa GeneralHospital to helpthe children makeValentine’s Day cards,keepsake boxes, mugsand door hangers.FEBRUARY JANUARYDECEMBERWhitestone, N.Y.: Tis the seasonCivil Northeast donated over 100 coats to the NYCares Coat Drive, dozens of toys to Toys for Totsand approximately 150 toys to New York PoliceDepartment Community Affairs.Orlando, F.L.: Food for thoughtThe Nemours Children’s Hospital project teamamassed more than 2,197 nonperishable fooditems, weighing roughly 2,300 pounds, for SecondHarvest Food Bank.Cortez, C.O.: Local goodwillThe office adopted a family with 11 children, aswell as two additional young girls, providing thekids with clothes and toys of their choice and aholiday dinner.Virginia Beach, V.A.: Holiday spiritBayshore Concrete Products employees collectedmore than 200 items for the Northampton CountySocial Services Angel Tree program.Portland, O.R.: Spell it outFollowing a table sponsorshipfor the OnPoint CommunityCredit Union’s CelebritySpelling Bee, eight employeesfrom the Beaverton officeattended the event, raisingmore than $1,800 forSchoolhouse Supplies.Houston, T.X.: Picture of healthThe local team partook in the Texas Medical Center5k, which benefitted the Harris County HospitalDistrict Foundation.Seattle, W.A.: Silver screenThe office collected more than 900 DVDs todonate to the Seattle Cancer Care Alliance.16 coast to coastcoast to coast17

coast tocoastThe Employee Magazine for <strong>Skanska</strong> in the U.S.The <strong>Skanska</strong> Top 10USA CommercialDevelopment is openfor business in Seattle,its fourth U.S. office.BlueCross BlueShield ofTennessee Cameron Hill campusin Chattanooga has beenLEED® Gold certified,making it the largest LEED Goldcorporate campus in Tennesseeand the second largest in the U.S.Marty Corrado, projectexecutive for the Nashvilleoffice, was named one ofEngineering News-Record’sTop 25 Newsmakers of 2010.The groundbreaking of1776 Wilson Boulevardin Arlington, V.A., wascelebrated by USACommercial Development.Building and Civilheld their first jointNational EnvironmentalHealth and SafetyLeadership Team meetingto optimize the sharing ofbest safety practices.The rehabilitation of theBridge of Lions in St.Augustine, F.L., was namedone of Roads & Bridgesmagazine’s best bridgeconstructions of 2010.The Houston team landeda $34 million contractto construct the Arts andHumanities Building atTexas A&M University inCollege Station, T.X.USA CommercialDevelopment closed ona development site, knownas Capitol Plaza II & III,located at First and MStreets in Washington, D.C.Crisis Managementtraining, designed to helpteams successfully workthrough a crisis whileprotecting the <strong>Skanska</strong>brand, is available through<strong>Skanska</strong> University.Earth Charter U.S.selected Building as arecipient of the 2010Sustainable BusinessAward in the largebusiness category.