Download - Skanska

Download - Skanska

Download - Skanska

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

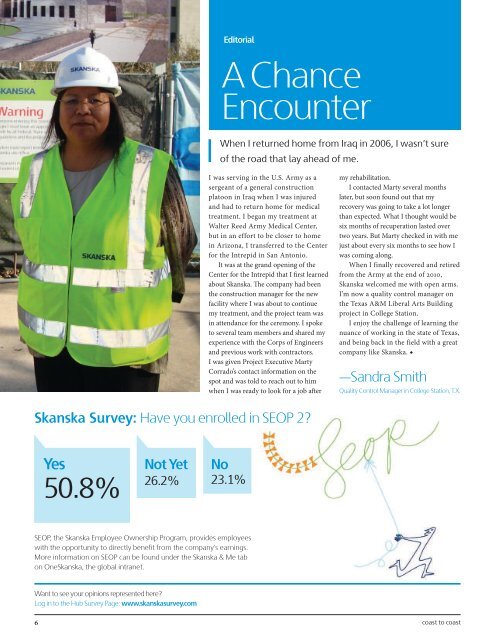

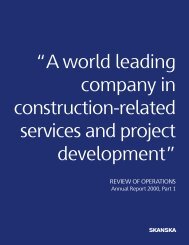

EditorialA ChanceEncounterWhen I returned home from Iraq in 2006, I wasn’t sureof the road that lay ahead of me.I was serving in the U.S. Army as asergeant of a general constructionplatoon in Iraq when I was injuredand had to return home for medicaltreatment. I began my treatment atWalter Reed Army Medical Center,but in an effort to be closer to homein Arizona, I transferred to the Centerfor the Intrepid in San Antonio.It was at the grand opening of theCenter for the Intrepid that I first learnedabout <strong>Skanska</strong>. The company had beenthe construction manager for the newfacility where I was about to continuemy treatment, and the project team wasin attendance for the ceremony. I spoketo several team members and shared myexperience with the Corps of Engineersand previous work with contractors.I was given Project Executive MartyCorrado’s contact information on thespot and was told to reach out to himwhen I was ready to look for a job after<strong>Skanska</strong> Survey: Have you enrolled in SEOP 2?Yes50.8%Not Yet26.2%Want to see your opinions represented here?Log in to the Hub Survey Page: www.skanskasurvey.comNo23.1%SEOP, the <strong>Skanska</strong> Employee Ownership Program, provides employeeswith the opportunity to directly benefit from the company’s earnings.More information on SEOP can be found under the <strong>Skanska</strong> & Me tabon One<strong>Skanska</strong>, the global intranet.my rehabilitation.I contacted Marty several monthslater, but soon found out that myrecovery was going to take a lot longerthan expected. What I thought would besix months of recuperation lasted overtwo years. But Marty checked in with mejust about every six months to see how Iwas coming along.When I finally recovered and retiredfrom the Army at the end of 2010,<strong>Skanska</strong> welcomed me with open arms.I’m now a quality control manager onthe Texas A&M Liberal Arts Buildingproject in College Station.I enjoy the challenge of learning thenuance of working in the state of Texas,and being back in the field with a greatcompany like <strong>Skanska</strong>. ◆<strong>Skanska</strong> Employee Ownership ProgramJoin in as an ownerof our company—Sandra SmithQuality Control Manager in College Station, T.X.Your SEOP contactName and phone:http://one.skanska/seopA Day in the Life…Jeff SmithSenior Project Manager, Los Angeles, C.A.4:00 am Wake up and take a walk through my neighborhood.5:30 am Commute to work.6:30 am Arrive at the office, review yesterday’s tasks and organize the day’s to-do list.7:00 am Plan the pursuit for the Metro Gold Line Foothill 2A design-build project,an 11.5 mile expansion of the light rail line from Pasadena to Azusa.8:00 am Morning staff meeting to provide an open forum for the pursuit team andto get status updates from the proposal, operations and estimating teams.9:00 am Review and respond to morning emails.10:00 am Evaluate the design-build contract documents for the Foothill 2A projectand then coordinate with my staff, legal, insurance and executives. Followup these meetings by writing down questions and comments to use whenediting the contract documents. Then shoot an email to the client with astatus update on the project.11:30 am Lunchtime.12:30 pm Review and respond to late morning emails.1:00 pm Map design-build contract documents for indirect cost and schedule impactsby creating a spreadsheet to identify cost drivers and schedule driversspecific to the Foothill 2A project. Then email this information to theestimating team.2:00 pm Coordinate the designers’ preliminary engineering plan to support thedesign-build estimate by defining the scope and prioritization.3:00 pm Develop, maintain and share our construction approach, winning strategypoints, management and staffing plan, risk register and action items listwith the pursuit team.4:30 pm Review and respond to afternoon emails and organize and file theday’s activities.5:00 pm Return calls while leaving the office.6:30 pm Dinner with the family to catch up with my wife and kids.7:00 pm Attend a Boy Scout meeting with my son.8:30 pm Spend quality time with my two daughters before bed.9:30 pm Time to hit the sack.How is your team supportingzero environmental incidents?On the LyndonB. Johnson GeneralHospital project,we’re supporting zero environmentalincidents throughtraining and monitoring.Every subcontractor and employeegoes through jobsiteorientation, which includes asection on our ISO 14001 andOSHA 18001 systems. We also have labels filled outfor our personnel on site, which includes a checklistof our environmental aspects that are reviewed duringthe orientation.—Charles GriffithsProject Manager, Houston, T.X.We have twoDelaware certifiedconstructionreviewers on the IndianRiver Inlet Bridge projectwho ensure that our erosionand sediment controls arein place and effective. Theyinspect the site weekly withthe client and after any major weather event.Deficiencies found in our controls are repairedimmediately.We also use special netting toprevent construction debris or tools from fallinginto the inlet.—Cheryl R. KingBusiness Manager, Rehoboth Beach, D.E.6 coast to coast coast to coast7QAConstruction onOregon Health &Science Universityrequired that we work outsidepatient rooms and critical areaswhile the hospital remainedopen. Scope included noisessuch as drilling, demolitionand replacement with metalpanels. Our first priority wasto quell the noise pollution by eliminating use ofimpact tools, drills and power-actuated tools. If thatwas not possible, we instituted noise testing and acommunication plan.—Katie ReiffProject Engineer, Beaverton, O.R.