high performance - The Schulich School of Engineering - University ...

high performance - The Schulich School of Engineering - University ...

high performance - The Schulich School of Engineering - University ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

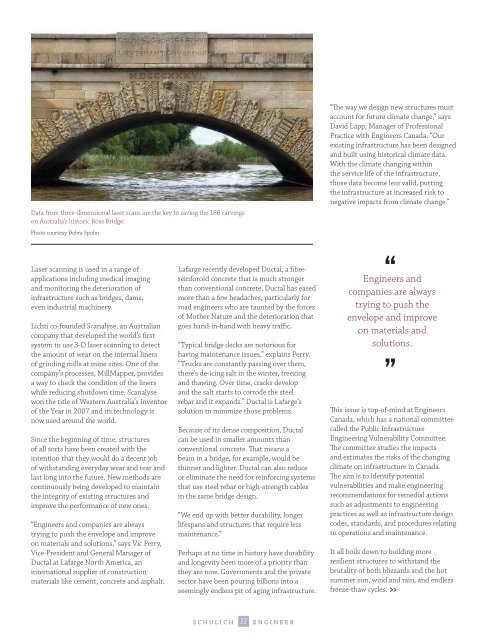

Data from three-dimensional laser scans are the key to saving the 186 carvingson Australia’s historic Ross Bridge.Photo courtesy Debra Spohn“<strong>The</strong> way we design new structures mustaccount for future climate change,” saysDavid Lapp, Manager <strong>of</strong> Pr<strong>of</strong>essionalPractice with Engineers Canada. “Ourexisting infrastructure has been designedand built using historical climate data.With the climate changing withinthe service life <strong>of</strong> the infrastructure,those data become less valid, puttingthe infrastructure at increased risk tonegative impacts from climate change.”Laser scanning is used in a range <strong>of</strong>applications including medical imagingand monitoring the deterioration <strong>of</strong>infrastructure such as bridges, dams,even industrial machinery.Lichti co-founded Scanalyse, an Australiancompany that developed the world’s firstsystem to use 3-D laser scanning to detectthe amount <strong>of</strong> wear on the internal liners<strong>of</strong> grinding mills at mine sites. One <strong>of</strong> thecompany’s processes, MillMapper, providesa way to check the condition <strong>of</strong> the linerswhile reducing shutdown time. Scanalysewon the title <strong>of</strong> Western Australia’s Inventor<strong>of</strong> the Year in 2007 and its technology isnow used around the world.Since the beginning <strong>of</strong> time, structures<strong>of</strong> all sorts have been created with theintention that they would do a decent job<strong>of</strong> withstanding everyday wear and tear andlast long into the future. New methods arecontinuously being developed to maintainthe integrity <strong>of</strong> existing structures andimprove the <strong>performance</strong> <strong>of</strong> new ones.“Engineers and companies are alwaystrying to push the envelope and improveon materials and solutions,” says Vic Perry,Vice-President and General Manager <strong>of</strong>Ductal at Lafarge North America, aninternational supplier <strong>of</strong> constructionmaterials like cement, concrete and asphalt.Lafarge recently developed Ductal, a fibrereinforcedconcrete that is much strongerthan conventional concrete. Ductal has easedmore than a few headaches, particularly forroad engineers who are taunted by the forces<strong>of</strong> Mother Nature and the deterioration thatgoes hand-in-hand with heavy traffic.“Typical bridge decks are notorious forhaving maintenance issues,” explains Perry.“Trucks are constantly passing over them,there’s de-icing salt in the winter, freezingand thawing. Over time, cracks developand the salt starts to corrode the steelrebar and it expands.” Ductal is Lafarge’ssolution to minimize those problems.Because <strong>of</strong> its dense composition, Ductalcan be used in smaller amounts thanconventional concrete. That means abeam in a bridge, for example, would bethinner and lighter. Ductal can also reduceor eliminate the need for reinforcing systemsthat use steel rebar or <strong>high</strong>-strength cablesin the same bridge design.“We end up with better durability, longerlifespans and structures that require lessmaintenance.”Perhaps at no time in history have durabilityand longevity been more <strong>of</strong> a priority thanthey are now. Governments and the privatesector have been pouring billions into aseemingly endless pit <strong>of</strong> aging infrastructure.Engineers andcompanies are alwaystrying to push theenvelope and improveon materials andsolutions.This issue is top-<strong>of</strong>-mind at EngineersCanada, which has a national committeecalled the Public Infrastructure<strong>Engineering</strong> Vulnerability Committee.<strong>The</strong> committee studies the impactsand estimates the risks <strong>of</strong> the changingclimate on infrastructure in Canada.<strong>The</strong> aim is to identify potentialvulnerabilities and make engineeringrecommendations for remedial actionssuch as adjustments to engineeringpractices as well as infrastructure designcodes, standards, and procedures relatingto operations and maintenance.It all boils down to building moreresilient structures to withstand thebrutality <strong>of</strong> both blizzards and the hotsummer sun, wind and rain, and endlessfreeze-thaw cycles. >>Raafat El-Hacha examines the damage to a masonryblock caused by a month’s worth <strong>of</strong> experiments in theenvironmental testing chamber.Photo by David MollSCHULICH22 ENGINEERSCHULICH 23 ENGINEER