high performance - The Schulich School of Engineering - University ...

high performance - The Schulich School of Engineering - University ...

high performance - The Schulich School of Engineering - University ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

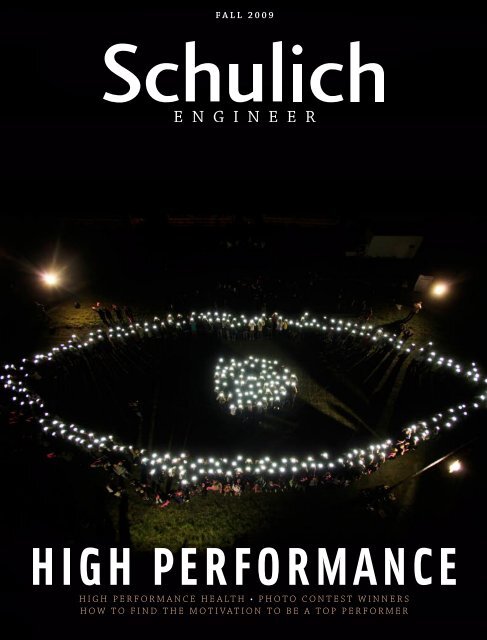

FALL 2009HIGH PERFORMANCEHIGH PERFORMANCE HEALTH • PHOTO CONTEST WINNERSHOW TO FIND THE MOTIVATION TO BE A TOP PERFORMER

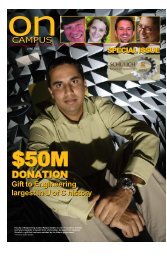

WINNER OF THE 2009 CANADIANENGINEERING LEADER AWARD<strong>Schulich</strong>ENGINEERFALL 2009Permission to reproduce any part <strong>of</strong> thispublication for commercial purposes shouldbe obtained by writing to the address below.Reproduction for other purposes shouldacknowledge the source.DeanElizabeth CannonVIEWPOINTGetting to the Olympicsthe old-school wayBy Arne DankersPAGE 2CONTENTSDon Taylor is chief executive <strong>of</strong>ficer <strong>of</strong> EngineeredAir, a Calgary company he joined in 1967. He builtthe firm into one <strong>of</strong> Canada’s leaders in the heating,ventilating and air conditioning (HVAC) industry.Engineered Air is recognized as one <strong>of</strong> Canada’s50 Best Managed Companies. In 2008, Taylor wasinducted into the Calgary Business Hall <strong>of</strong> Fame.Don Taylor graduated in 1958 with a bachelor’sdegree in civil engineering and a master’s degreein 1960, both from the <strong>University</strong> <strong>of</strong> Alberta. Hiscommitment to supporting education and researchis apparent in his long history <strong>of</strong> donations totechnical schools and universities. He has providedfunding for cancer treatment and research,women’s shelters and youth programs acrossCanada. Taylor’s company is also the corporatesponsor <strong>of</strong> the Engineered Air <strong>The</strong>atre at the EpcorCentre for the Performing Arts in Calgary.Don Taylor, PEng, is the2009 recipient <strong>of</strong> the Canadian<strong>Engineering</strong> Leader Award.<strong>The</strong> Taylor family’s most recent contribution tothe <strong>University</strong> <strong>of</strong> Calgary is $25 million towards theTaylor Family Digital Library. <strong>The</strong> library, scheduledfor completion in late 2010, will house the latesttechnology to enhance education and research:wireless capabilities, multimedia rooms, editingsuites and a 3D visualization lab.Every year, the <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>recognizes an engineer who has achievedpr<strong>of</strong>essional excellence while giving back tothe community and serving as an inspirationalrole model to future engineers. <strong>The</strong> Canadian<strong>Engineering</strong> Leader Award is presented annuallyat the <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong> Dean’sHoliday Reception in Calgary.Editorial TeamMary Anne MoserDirector <strong>of</strong> CommunicationsJennifer SowaMedia Relations OfficerAmy DowdCommunications OfficerContributorsPeter Calamai, Arne Dankers, Don McSwiney,Carolina Romeo, Jennifer SowaPhotographyDebby Armstrong, Darryl Augustine,Ken Bendiktsen, Chris Bolin, Karen Denny,David Moll, Ewan Nicholson, Greg Fulmes,Matt Sattlegger, Jennifer Sowa, Jason StangDesignID8 Design GroupContact informationJennifer Sowa, Managing Editor<strong>Schulich</strong> EngineerDean’s Office, EN C202<strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>2500 <strong>University</strong> Drive NWCalgary, AlbertaT2N 1N4Email: magazine@schulich.ucalgary.caWebsite: www.schulich.ucalgary.caOn the cover:A winking eye was part <strong>of</strong> a light message sentby U <strong>of</strong> C students to graduate Dr. RobertThirsk on the International Space Station inSeptember 2009.Photo by Greg FulmesFEATURESH I G H E RFinding the motivationto be a top performerBy Dr. James E. Loehrand Peter J. McLaughlinPAGE 4F A S T E RMay the athlete withthe best equipment winBy Don McSwineyPAGE 10S T R O N G E RStructures that outperformBy Jennifer SowaPAGE 21H E A L T H I E RHigh <strong>performance</strong> healthBy Peter CalamaiPAGE 29Y O U N G E RCanada’s top 20 under 20By Carolina RomeoPAGE 36A R T S I E RAnnual engineeringinternship photo contestwinnersPAGE 38DID YOU KNOW?<strong>The</strong> word “gymnasium” comesfrom the Greek root “gymnos”meaning nude; the literal meaning<strong>of</strong> “gymnasium” is “school for nakedexercise.” Athletes in the ancientOlympic Games would participatein the nude.Source: Interesting Olympic Facts,www.about.comDEPARTMENTSIn conversationwith Bruce JamiesonPAGE 8In conversationwith Hany MichaelPAGE 28In the communityPAGE 46NewsPAGE 47Donor storiesPAGE 50Reverse engineeringPAGE 52

When you are motivated solely by theoutcome, you are relying on something formotivation that you cannot control. It’sexternal. You don’t determine who getspay raises or promotions; if that’s all thatmotivates you, then you are bound to bedisappointed sometimes. An athlete canplay an outstanding game and still lose.As the Bible puts it, “<strong>The</strong> race is not alwaysto the swift, nor the battle to the strong.”No matter how swift and strong you are,you won’t always emerge on top. If that’syour sole motivation, you will eventuallylose it. And without motivation, you can’tperform at all.Another motivation is fear – fear <strong>of</strong> theconsequences <strong>of</strong> a <strong>performance</strong>. You’renot playing to win; you’re playing to “notlose.” You are worried about what willhappen if something goes wrong duringyour <strong>performance</strong>. This can take manyforms, from choking to covering your assby making sure that there are plenty <strong>of</strong>plausible excuses for failure. And you’llprobably need them.In any case, the focus during the<strong>performance</strong> is on something negative – theconsequences <strong>of</strong> failure. And so your goalis not to perform well, but to avoid failure.Eventually, you figure out that the easiestway to avoid failing is to avoid performing.It’s safer to sit on the bench, where nothingcan go wrong, than to get into the game,where you might fumble. You’ve lost yourmotivation; you don’t perform.That’s why you cannot be a top performerif you rely on external motivations topropel your <strong>performance</strong>. <strong>The</strong>re will alwayscome a time when they disappoint you ordepress you.To be a top performer, you must love thebattle more than the outcome.DEVELOPING PERFORMANCE MOTIVATIONWhat motivates top <strong>performance</strong> isnot the reward or the outcome, but the<strong>performance</strong> itself. To put it another way,you must love what you’re doing whenyou perform. If you don’t, it won’t holdyour interest, and you won’t perform atyour best.Generally, the strategy that works best ischanging your focus. Instead <strong>of</strong> worryingabout the consequences or anticipatingthe outcome, becoming distracted orworrying about flaws, focus on the<strong>performance</strong> itself. <strong>The</strong>re is a time toconsider the consequences or the outcome,and that time is before, not during, the<strong>performance</strong>.By focusing on the moment, on whatyou’re doing at that time, you bring yourfull attention to the <strong>performance</strong> – and itwill improve.This shift in focus is sometimes difficult toachieve because we live in a goal-directedsociety. Setting goals is vital because thatdetermines the direction. Without goals,you’re treading water, expending energybut getting nowhere.Once the goals are set, though, thenthe process becomes most important.Focusing on the process then makes thosegoals more attainable.No matter what you try, from real-estatespeculation to freelance writing, you aremost likely to reach the top when youfocus on the <strong>performance</strong> itself and drawyour rewards from its intrinsic nature.Any other rewards that come along – thesatisfaction <strong>of</strong> sitting at the summit, thepr<strong>of</strong>its <strong>of</strong> a leveraged investment, or thepride in seeing one’s byline in a nationalmagazine – are mere enhancements.Welcome enhancements, to be sure, butstill enhancements.Reprinted with permission from MentallyTough: <strong>The</strong> Principles <strong>of</strong> Winning atSports Applied to Winning in Business byDr. James E. Loehr and Peter J. McLaughlin.Copyright © 1986, published by M. Evansand Company, Inc., New York.Instead <strong>of</strong> worryingabout the consequences oranticipating the outcome,becoming distracted orworrying about flaws,focus on the <strong>performance</strong>itself. <strong>The</strong>re is a time toconsider the consequencesor the outcome, and thattime is before, not during,the <strong>performance</strong>.SCHULICH06ENGINEER

Photo by David MollMAY THE ATHLETEWITH THE BESTEQUIPMENT WINBY DON MCSWINEYVICTORY OFTEN COMES DOWNTO THE SMALLEST DETAILS.NEW TECHNOLOGIES BECOMEINCREASINGLY IMPORTANT,AND CANADIAN ATHLETES ANDCOACHES ARE LOOKING TOSCIENCE TO HELP THEM CROSSTHAT FINISH LINE A BLINKBEFORE THE COMPETITION.When the rest <strong>of</strong> Canada began theVancouver 2010 countdown fouryears ago, engineers were already engagedin finding ways to help Canadian athletestrain more efficiently, more safely and insome cases, in finding ways <strong>of</strong> improving<strong>performance</strong>. It was a process that beganshortly after the disappointing 2002 SaltLake City Olympics.“Everyone knew that the equipment wewere competing with in 2002 in Salt LakeCity was inferior. Skates, skis, suits … ourequipment was simply not up to the levelbeing used by the rest <strong>of</strong> the world,” saysRoger Jackson, head <strong>of</strong> Canada’s ambitiousOwn the Podium project. Jackson isa former Olympian, former dean <strong>of</strong>kinesiology at the <strong>University</strong> <strong>of</strong> Calgaryand lynchpin <strong>of</strong> the 1988 Calgary Olympics.Own the Podium has a simple mandate– to help Canadian athletes consistentlycompete with the world’s best. This entailsmany different strategies, but one <strong>of</strong> themost important is to make sure Canadauses cutting-edge science to stay currentwith the rest <strong>of</strong> the world and in thecase <strong>of</strong> a <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>geomatics engineering project for AlpineCanada Alpin (ACA), to get way in front <strong>of</strong>the rest <strong>of</strong> the world.Alpine skiing is an intensely technicalsport that marries the best technologywith elite athletic <strong>performance</strong>. It’s alsoone <strong>of</strong> those sports where first place andlast place can come down to hundredths<strong>of</strong> a second. Athletes reach speeds over150 km an hour and need to keep to anearly perfect ‘line’ to have any chance <strong>of</strong>finishing on the podium.“<strong>The</strong> perfect line,” explains biomechanicsresearcher Gerald Cole, “is the line thatallows a skier to come out <strong>of</strong> a turn in perfectposition to make the next turn.” GeraldCole, who works with the <strong>Schulich</strong> <strong>School</strong> <strong>of</strong><strong>Engineering</strong> and the Faculty <strong>of</strong> Kinesiologyat the <strong>University</strong> <strong>of</strong> Calgary, was brought inby ACA as a consultant to help them excelin areas <strong>of</strong> biomechanics and engineering.When ACA coaching staff brought upthe need for a viable GPS training device,Cole knew just where to turn – Pr<strong>of</strong>essorGérard Lachapelle, Canada Research Chair/Informatics Circle <strong>of</strong> Research Excellence(iCORE) Chair in Wireless Location, andhis world-leading research group at the<strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>. Under ajoint sponsorship <strong>of</strong> the <strong>Schulich</strong> <strong>School</strong>,iCORE, Own the Podium and Calgary-basedNovAtel Inc. – which provided some <strong>of</strong> the<strong>high</strong> <strong>performance</strong> hardware – his team wenton to solve the problem in fall 2006. >>SCHULICH10 ENGINEERSCHULICH 11 ENGINEER

This will shake theworld <strong>of</strong> sports.We are first finally.Not second. We arequite excited with this.Canadian Alpine Ski Team member Jan Hudecshowing <strong>of</strong>f STEALTH, a training system thatshows skiers exactly what their run down a hilllooked like and how fast they were going.Photo by Chris Bolin

Gérard Lachapelle connects the STEALTH hardware toCanadian Alpine Ski Team member Jan Hudec.Photo by Chris Bolin“We were given an interesting problem,and I think we came up with an interestingsolution,” says Lachapelle as he holds upan innocent looking black box, about thesize <strong>of</strong> a fat wallet with a couple <strong>of</strong> lightsand a single red button. A black wire leadsto a little antenna that resembles a giantmetal ladybug. Lachapelle hesitates as hehands me the box, “This was developed bymy team – myself and my two graduatestudents Aiden Morrison and RichardOng – and it is top secret, you understand– word <strong>of</strong> this can’t come out until the fall.”I nod assent as he somewhat reluctantlyhands me the box. In his hesitation Iinstantly get insight into what this devicemeans to the future <strong>of</strong> global navigationtechnology and hopefully Canadian sports.<strong>The</strong> gadget is named STEALTH (short forSensor for the Training <strong>of</strong> Elite Athletes)and it uses satellite tracking technology toshow skiers and their coaches exactly whata skier’s line is down a mountainside (withan accuracy better than 5 centimetres)and exactly how fast they were going atany given point in a run (up to a timingaccuracy <strong>of</strong> .1 millisecond).“Everything has to do with accuracy,” saysLachapelle. “Many people have tried tocreate a device like this – and a few yearsago some researchers were very proud<strong>of</strong> a system that delivers up to a fewdecimetres. <strong>The</strong> weight <strong>of</strong> their device isup to 2 kilograms. We are better than 5centimetres in accuracy with a unit thatweighs only 270 grams.” He pauses tolet the implications <strong>of</strong> this outrageous<strong>performance</strong> sink in before continuing.“This will shake the world <strong>of</strong> sports. Weare first – finally. Not second. We are quiteexcited with this.”Lachapelle has a right to be excited,because in many ways STEALTH is theculmination <strong>of</strong> 30 years <strong>of</strong> research. Hewas part <strong>of</strong> the first Calgary team to dooilfield GPS research with Shell Canada in1980. When Shell decided to ‘divest’ thedivision, Lachapelle and his colleaguesfound investors and created their owncompany, Nortech Surveys, in 1983. Afterthat company faded and sold its valuableGPS assets to NovAtel Inc., Lachapellebrought his expertise to <strong>Schulich</strong> in 1988,created the research group called PLAN(position, location and navigation), andthe rest, as they say, is history – and inthis case, history making.For starters, STEALTH is more thanjust GPS, because it uses data from boththe North American Global PositioningSystem (GPS) and the Russian GLONASSto achieve its unparalleled accuracy. It alsosolved every problem that has held uppractical application <strong>of</strong> GPS in these types<strong>of</strong> uses. It’s tiny, ridiculously accurate, easyto use, rugged (did I mention ridiculouslyaccurate?) and STEALTH replaces previoustechnology that was so time consumingand useless that it was rarely used.“With the new system,” says Lachapelle,“the coach goes down the slope in themorning with the same unit, but with theantennae on top <strong>of</strong> a pole and stands forless than one minute at the location <strong>of</strong>each flag or gate as they call them – in halfan hour he is done – as opposed to the oldsurvey method which could take up to twodays. Once we know the position <strong>of</strong> theflag and as they pass through each gateor beside it, we know exactly how closethey are to the gate and how fast they aregoing.”Once they’re done, the coaches can takethe data they’ve collected and give theathletes nearly instant feedback on their<strong>performance</strong> using a video interface thatallows a coach to show a skier exactly whattheir line looked like on the hill and howfast they were going.<strong>The</strong> coaches were thrilled and more than alittle relieved at how easy the system is touse, and Gerald Cole says the real successmay be in how well the project met andcatered to the needs <strong>of</strong> the skier.“<strong>The</strong>y need to maintain perfect balanceand can’t carry any excess weight,” saysCole, “so the size issue was crucial. <strong>The</strong>re’sno way elite skiers can safely go down ahill at 150 km/hour with a GPS device thesize <strong>of</strong> a frozen chicken strapped to theirback!”While the STEALTH system couldrevolutionize the way skiing is coached, it’snot the only application <strong>of</strong> the technology.One <strong>of</strong> the most important applicationswill be in the area <strong>of</strong> ski testing.When a sport comes down to the blink <strong>of</strong>an eye, every detail is important and Colesays that in ski racing, choosing the righttype <strong>of</strong> wax and the ‘fastest’ ski is absolutelyvital. To ensure they’re using the rightequipment the team does extensive skitesting – putting skis and wax to the test ina variety <strong>of</strong> environmental conditions to seewhich is fastest.“What the Canadian athletes tell me is thattesting skis is so much easier with the newsystem. <strong>The</strong>y can set up the course in notime and whip through their inventory <strong>of</strong>ski-tests in a fraction <strong>of</strong> the time that it usedto take them. That alone could make a hugedifference in Whistler, where the conditionscan change so much and so rapidly.”Conditions rarely change in the OlympicOval at the <strong>University</strong> <strong>of</strong> Calgary. It’sengineered for perfect ice and speedy<strong>performance</strong>. It’s late afternoon and thewest windows are providing a golden glowto the skaters who methodically cruisearound the big ice with that unique blend<strong>of</strong> controlled precision and deceptive speed.Despite the fact that it’s a race weekend,there’s a feeling <strong>of</strong> calm. Well, almost. Onthe short track ice the Korean team is goingthrough their paces, and they seem to be ahair away from crashing on every turn. Tothe uninitiated, short-track speed skating isan exciting mix <strong>of</strong> speed, strategy and skillwith what appears to be a little bit <strong>of</strong> rollerderbythrown in for good measure. <strong>The</strong> closeproximity <strong>of</strong> skaters jostling for position ona small ice surface <strong>of</strong>ten leads to falls and, inthis sport, falls can be very dangerous.If a skater hits a hockey board feet first, chancesare pretty good that he or she could break an ankleor worse because the body (as a spring) can’tabsorb enough energy without breaking first.To prevent injury the Oval short-track rinkis lined with a series <strong>of</strong> blue pads, but todescribe them that way is to say the walls<strong>of</strong> the Louvre are covered with a ‘bunch <strong>of</strong>paintings.’ <strong>The</strong> foam pads that line the Ovalin Calgary, and more recently the Olympicspeed skating venue in Richmond, BritishColumbia, are the result <strong>of</strong> years <strong>of</strong> testing,revision and more testing to create theperfect pad.Clifton Johnston and Sean Maw literallysnort aloud when I ask if the blue wondersthat line the Calgary short track are infact perfect pads. Johnston is a seniorinstructor in mechanical engineering atthe <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong> andhis compatriot Sean Maw is an associatepr<strong>of</strong>essor with Mount Royal <strong>University</strong>and serves on the board <strong>of</strong> Speed SkatingCanada – however their identity for the lastfew years has simply been “the pad guys.”“<strong>The</strong>re’s really no such thing as a perfectpad,” says Johnston. “We just want to makethe best pad for the given budget, for thespecific rink in question.” We’re standingin the pad guys’ natural habitat – a dingy,half-lit storage bay located beneath theOval spectator stands – or as they call it,‘the dungeon.’ <strong>The</strong> dungeon is stuffed withfoam sheets <strong>of</strong> all sizes, thicknesses andshapes in various states <strong>of</strong> undress or cover.Against one wall is a single blue pad, whichis being pounded by a big, 120-pound redbarrel attached to a swinging arm. A devicethe researchers have dubbed ‘the Impactor.’“Speed skating blades are razor sharp,”explains Johnston, “so what you don’t wantto have is a pad that will bounce a skater<strong>of</strong>f the padding and into the path <strong>of</strong> theother skaters. On the other hand, you don’twant a solid board, or a pad that’s too hard,otherwise there is a risk that skaters couldsuffer a concussion or other serious injury.”So how do you design a pad that bouncesjust the right amount? <strong>The</strong> answer is bytesting a lot <strong>of</strong> foam, in a lot <strong>of</strong> differentways. “We conceptually think <strong>of</strong> the skaters,foam and pad covers as a series <strong>of</strong> springsthat, if designed correctly, absorb the energy<strong>of</strong> an impact and prevent injuries withoutbouncing a skater back into traffic,” saysMaw. “If a skater hits a hockey board feetfirst, chances are pretty good that he orshe could break an ankle or worse becausethe body (as a spring) can’t absorb enoughenergy without breaking first. With theright padding system, the skater’s body willhave time to reorient itself before breaking,so that the force <strong>of</strong> the impact can bedistributed over a larger part <strong>of</strong> the body,allowing both the pads and the skater’s bodyto absorb more energy before injuries occur.That can reduce both the likelihood andseverity <strong>of</strong> injuries.”After years <strong>of</strong> testing the researchers havecreated pads that feature a series <strong>of</strong> foamlayers that strategically place springier foamwith more give on the outside and layerincreasingly dense foams underneath.<strong>The</strong> pads are placed inside a speciallydesigned cover and linked with a complicatedseries <strong>of</strong> Velcro snaps, belts and fixed poststhat are painstakingly placed according tothe researchers’ analysis <strong>of</strong> where falls aremost likely to occur.“<strong>The</strong> bottom line,” says Johnston, “is thatevery detail matters and we’re learningmore every day. We’re learning that thenumber and placement <strong>of</strong> the Velcrosnaps is important, we’re learning that theenvironmental conditions are importantbecause the foam’s characteristics willchange over time. So it’s a work in progress,but I think skaters are safer today thanthey were before we began our work.” >>SCHULICH14 ENGINEERSCHULICH 15 ENGINEER

Johnston and Maw’s pads have alreadybeen adopted by the world’s top speedskating (short and long track) rinksincluding Salt Lake City, Beijing, Vancouverand <strong>of</strong> course U <strong>of</strong> C’s Olympic Oval. So far,as they say, ‘no news is good news.’“We’re very encouraged,” says Maw.“For example a couple <strong>of</strong> years ago at theshort track World Cup in Salt Lake theyhad several bad crashes and several fairlysevere injuries. At the last World Cup, afterinstalling our pad system, they didn’t havea single injury from crashes, so anecdotallyat least the system seems to be working.”<strong>The</strong> big question, <strong>of</strong> course is how the twowill feel if nobody is injured in Vancouverthis February? “Relief!” <strong>The</strong>y say in unison,“We’ll be very, very relieved.”Darren Stefanyshyn is one <strong>of</strong> those guyswho doesn’t have a lot <strong>of</strong> stuff in hisspartan <strong>of</strong>fice, so you tend to pay attentionto what he does have. Shoes. Many shoes.By his own admission Stefanyshyn is agear-freak who you never want to take toSport Chek, since he says he can spendhours in a sporting goods store. “I like tosee how things work,” he says, “and I like tothink <strong>of</strong> ways to make them better.”Stefanyshyn is cross-appointed withthe <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong> andthe Faculty <strong>of</strong> Kinesiology where he cancombine his passions on a seeminglyendless variety <strong>of</strong> sports-related researchprojects including hockey sticks, golf clubs,bike seats, work boots, clap skates, shoes –lots and lots <strong>of</strong> shoes – and most recentlythe Adidas Powerweb suit.If you watched the last winter and summerOlympic games on television, then youlikely saw the Powerweb suit in action.Cross country skiers wore them, sprinterswore them, track athletes wore them … infact it seemed the only people who weren’twearing them were the swimmers whohad their own ‘suit’ controversy goingon. <strong>The</strong> Powerweb suit kind <strong>of</strong> resemblesa superhero outfit, and according toStefanyshyn, testing at Kinesiology’sHuman Performance Lab suggest that thePowerweb suit could indeed make athletesa little more ‘super’ in competition.“<strong>The</strong> tests indicate that athletes wearingthe suit had an average 5.3 percentimprovement in power output and were1.1 percent faster over a 30 metre sprint,”says Stefanyshyn. “For you or me that’sobviously not a big deal, but for manysports, where world records hang onfractions <strong>of</strong> a second, that one percentadvantage could be huge.”Perhaps the most interesting thing aboutthe suit is that no one is completely sureabout exactly why it works. As he explainsit, “We have several theories and we believeit’s likely a combination <strong>of</strong> several factors.”A biomechanical theory is that the suit actskind <strong>of</strong> like a sausage skin, compressing theathlete’s muscles. This compression keepsthe athlete’s body properly aligned andensures that they are moving in an optimalpath to maximize <strong>performance</strong>. It alsomakes them more aware and focused onmuscle movement. Another theory is thatthe springy special material that makesup the silver Powerweb bands, recoils and‘returns’ energy to the athlete. A thirdtheory that Benno Nigg, director <strong>of</strong> theHuman Performance Lab, is testing is thatthe suit helps to dampen muscle vibration.Nigg believes that the body tries to <strong>of</strong>fsetmuscle vibration by tensing muscles. Hebelieves this constant low grade musclecontraction can lead to fatigue so if youreduce vibration you theoretically couldimprove <strong>performance</strong>.Regardless <strong>of</strong> exactly how the suit works,it’s clear that many athletes who have triedthe suit like it. “I really do get a kick out<strong>of</strong> watching the games and seeing athletesperform in something that I’ve been a part<strong>of</strong> designing,” says Stefanyshyn. “In someways you kind <strong>of</strong> feel like a parent, andwhen you see an athlete excelling, and youknow that you’ve had a small part in theirsuccess you can’t help but feel excited.”Stefanyshyn says that while the Powerwebsuit can help athletes to do their best, itcertainly doesn’t provide the same artificialadvantage <strong>of</strong> a suit like Speedo’s LZRswimsuit. <strong>The</strong> LZR suit featured buoyantpolyurethane material that has helpedswimmers make a mockery <strong>of</strong> swimmingworld-records. “I don’t really think the suitgives an athlete an artificial <strong>performance</strong>boost, and I certainly don’t think it’sunethical,” says Stefanyshyn. “<strong>The</strong> suitdoes help an athlete to optimize their<strong>performance</strong>, but since any serious athletewho wants to wear the suit can wear it, youcan’t really argue that it provides an unfairadvantage for anyone, it’s just another toolto help athletes optimize <strong>performance</strong>.”In the end that’s what the <strong>Schulich</strong> teamhopes they can provide Canadian athletesthis February in Vancouver – the very bestchance <strong>of</strong> performing to the limits <strong>of</strong> theirability, on the world’s biggest stage. If theycan do that, <strong>Schulich</strong> engineers can take alittle satisfaction in knowing that they tooplayed their part.Don McSwiney is the director <strong>of</strong>communications for the Faculty <strong>of</strong> Kinesiologyat the <strong>University</strong> <strong>of</strong> Calgary.Sean Maw, left, and Clifton Johnstondesigned the crash pads for the 2010 Olympicsto help prevent speed skating injuries.Photo by David MollSCHULICH16 ENGINEERSCHULICH 17 ENGINEER

AN IRREVERENT LOOKAT OLYMPIC INNOVATIONNearly every Olympics features a flurry <strong>of</strong> technological innovation. Most innovation is powered by the world’sgiant sporting goods manufacturers including Adidas, Mizuno, Speedo and, <strong>of</strong> course Nike. Nike, in fact, created68 event-specific shoes for all 28 sports. Adidas created a special shoe for 400-metre gold medalist JeremyWariner, built on ultralight carbon plates made <strong>of</strong> microscopic nanotubes (20 times stronger than steel)that they claimed help a runner accelerate to the left – because, <strong>of</strong> course, track athletes never go to the right.FIBREGLASS POLE VAULTFibreglass poles totally changed the sport <strong>of</strong>pole-vaulting when they replaced bamboo.When first used, it moved the Olympicstandard by 3 inches up to 15 feet and 10inches. At the next games, in 1972, theserecords where smashed when the perfectedfibreglass “cata-pole” allowed a US jumper tovault 18 and a half feet. Moreoever, it alsochanged the technique <strong>of</strong> the sport, withathletes developing the “catapult” techniquedue to the flexibility <strong>of</strong> the new poles.THE SPEEDO LZR RACERDuring the 2008 swimming world championships in Manchester, England,a curious spectacle emerged. Nearly every race resulted in a new worldrecord. <strong>The</strong> swimmers however seemed more embarrassed than jubilant.At issue was Speedo’s LZR (pronounced ‘laser’) Racer swimsuit. <strong>The</strong> suitsquashes, flattens and compresses swimmers into aerodynamic shapes thatstrategically reduce drag. Critics say that the special polymer panels resistwater, making the swimmer more buoyant. So far 93 world records havebeen broken – or smashed – by swimmers wearing the LZR Racer. It is nowillegal in Canada and will be banned internationally in 2010.TRAININGToo much or too vigorous training was, formany years, ridiculed as being ungentlemanly,unsportsmanlike, against the “spirit <strong>of</strong> theOlympic Games” or worse, cheating. Thingsbegan to change in the 1920s.Here are a few innovations and technologies that pr<strong>of</strong>oundly changedthe face <strong>of</strong> Olympic competition overnight.ACETYLSALICYLIC ACIDYep, good old aspirin, made availablewithout prescription in 1915. Once youhave started training, logically anythingthat gives you the ability to do more couldbe a real advantage. Aspirin, in layman’sterms, acts as an anti-inflammatory for thewhole body, which is one reason why it’s alsorecommended as heart attack protection.COMPUTERSIn the 1972 Munich Summer Olympics, data processingnetworks linked to all the Olympic sporting locations inGermany. This meant that for the first time, broadcastersaround the world could begin to provide results to audiencesjust moments after a race or event was decided.THE CLAP SKATESporting equipment tends to improve slowly sothat you don’t see a huge gain in <strong>performance</strong>.One decided exception was the introduction <strong>of</strong>the clap skate to the sport <strong>of</strong> speed skating, whichunhinges the blade and allows the skater’s foot tocome up while the blade stays in contact with theice. In 1992 when the clap skate was introduced,records started to be broken.FIBREGLASS SKIS<strong>The</strong> first successful plasticfibreglassski was inventedin 1959 in Montreal.By 1968, fiberglass hadsupplanted both woodand aluminum for use inslalom racing skis and inmost recreational skis.BACK AWAY FROM THE BUFFETIn some sports a simple rule change has made all the difference. In bobsled(named after the fact that, as the driver tried to gain speed and direct the sled, thepassengers were obliged to “bob” up and down), simply changing the maximumallowed weight <strong>of</strong> the bobsled completely changed the type <strong>of</strong> athlete who wasrecruited to race. Since heavier is better in bobsled – a sport ruled by gravity –the Germans cleaned up in the 1952 Olympics, winning both gold medals witha combined crew weight <strong>of</strong> over 472.5 kilograms in the four-man and 236.6kilograms in the two-man! Following the games, the bobsled federation slappeda weight limit on sleds and overnight, chubby buffet champs were replaced byskilled athletes, with an explosive mix <strong>of</strong> speed, strength and dexterity.A MINI WAR?It has been said that nothing drives technological innovationlike war – however the Olympics may not be far behind. InBeijing, for example, companies such as General Electricused the games to showcase a number <strong>of</strong> startling newtechnologies such as the portable MRI that can give tracksideviews <strong>of</strong> an athlete’s knees. <strong>The</strong> National Aquatics Centerthere was covered in an iridescent blue plastic coating thattraps 90 percent <strong>of</strong> the solar energy, meaning the facilityuses less energy to heat its five pools. Even the tickets soldto events came with embedded microchip technology thatincluded the purchaser’s personal information, meaning thatscalping became, for the first time, nearly impossible.TIMEKEEPINGIf you’re going to go faster, <strong>high</strong>er and strongerit’s important to know exactly by how much.• In Los Angeles, 1932, most races were timedwith one <strong>of</strong> 30 synchronized stop watches.• In Mexico, 1968, all events were timedelectronically for the first time. <strong>The</strong> ‘touch pad’was also introduced to the pool, for a moreaccurate finishing time.• Seoul 1988 were the first games withcomputerized timekeeping.HONOURABLE MENTIONLights! Action! TV! Since audience interest drives theOlympic machine, television may well be the mostimportant Olympic innovation. <strong>The</strong> first televisedgames were in 1936 in Berlin, which sent a closed circuitbroadcast to locations in Germany. In 1948 the gameswere transmitted out <strong>of</strong> the host country for the first time.Full CBS network television coverage started in 1960.Written and compiled by Don McSwiney with help fromDoug Brown, the resident Olympic historian in the Faculty<strong>of</strong> Kinesiology at the <strong>University</strong> <strong>of</strong> Calgary.SCHULICH18 ENGINEERSCHULICH 19 ENGINEER

STRUCTURESTHAT OUTPERFORMBY J E N N I F E R S O W ABENDING, SQUEEZING, STRETCHING, FREEZING: PUSHINGMATERIALS TO THEIR LIMITS IS NOW REQUIRED TO DEVELOPMODERN STRUCTURES AND PRESERVE OLD ONES.Australia’s southernmost state ishome to a 50-metre sandstonebridge nearly two centuries old that is abit <strong>of</strong> an engineering marvel in this littlecorner <strong>of</strong> the world.<strong>The</strong> Ross Bridge was constructed overthe Macquarie River in the 1830s whenthe island state <strong>of</strong> Tasmania was a penalcolony for British criminals. Convictswere put to work building the bridge andsome <strong>of</strong> them happened to be talentedartists and stonemasons. <strong>The</strong> result was astructurally impressive bridge decoratedwith dozens <strong>of</strong> intricate carvings <strong>of</strong>symbols, flowers and human faces.Two prisoners actually received pardonsbecause <strong>of</strong> their extraordinary work.<strong>The</strong> Ross Bridge supports vehicular trafficto this day and has become known as“the finest masonry bridge <strong>of</strong> its time,”according to the Australian HeritageDatabase.“We are very proud <strong>of</strong> the Ross Bridgeas an outstanding and unique example<strong>of</strong> early colonial infrastructure thatcontinues to be used to the presentday,” says Pete Smith, director <strong>of</strong>Heritage Tasmania.It was a bridge built to last. But while itshistory makes it unique, the Ross Bridgehas one trait in common with countlessother structures: it’s at the mercy <strong>of</strong>the elements. Weathering is erasing thetreasured carvings like drawings on achalkboard. Many experts fear all the finedetail will be gone in 25 years.It won’t be lost forever, though, because<strong>of</strong> modern engineering technology.Four years ago, specialists in threedimensionallaser scanning mappedthe Ross Bridge. Derek Lichti, a formerpr<strong>of</strong>essor at Curtin <strong>University</strong> <strong>of</strong>Technology in Perth, Australia, andhis graduate student developed newcomputer algorithms to take informationfrom the digital scans to form acomplete, detailed image <strong>of</strong> the bridge.One day, that data will provide crucialguidance for the experts who restoreand preserve the bridge and its artwork.“<strong>The</strong> scans give you the precise geometry<strong>of</strong> the bridge,” explains Lichti, who is nowbased in the geomatics department at the<strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>. “Whenyou consider additional informationsuch as the material, in this case it’ssandstone, you can figure out thestructure’s strength properties.” >>Photo by David MollSCHULICH21ENGINEER

Data from three-dimensional laser scans are the key to saving the 186 carvingson Australia’s historic Ross Bridge.Photo courtesy Debra Spohn“<strong>The</strong> way we design new structures mustaccount for future climate change,” saysDavid Lapp, Manager <strong>of</strong> Pr<strong>of</strong>essionalPractice with Engineers Canada. “Ourexisting infrastructure has been designedand built using historical climate data.With the climate changing withinthe service life <strong>of</strong> the infrastructure,those data become less valid, puttingthe infrastructure at increased risk tonegative impacts from climate change.”Laser scanning is used in a range <strong>of</strong>applications including medical imagingand monitoring the deterioration <strong>of</strong>infrastructure such as bridges, dams,even industrial machinery.Lichti co-founded Scanalyse, an Australiancompany that developed the world’s firstsystem to use 3-D laser scanning to detectthe amount <strong>of</strong> wear on the internal liners<strong>of</strong> grinding mills at mine sites. One <strong>of</strong> thecompany’s processes, MillMapper, providesa way to check the condition <strong>of</strong> the linerswhile reducing shutdown time. Scanalysewon the title <strong>of</strong> Western Australia’s Inventor<strong>of</strong> the Year in 2007 and its technology isnow used around the world.Since the beginning <strong>of</strong> time, structures<strong>of</strong> all sorts have been created with theintention that they would do a decent job<strong>of</strong> withstanding everyday wear and tear andlast long into the future. New methods arecontinuously being developed to maintainthe integrity <strong>of</strong> existing structures andimprove the <strong>performance</strong> <strong>of</strong> new ones.“Engineers and companies are alwaystrying to push the envelope and improveon materials and solutions,” says Vic Perry,Vice-President and General Manager <strong>of</strong>Ductal at Lafarge North America, aninternational supplier <strong>of</strong> constructionmaterials like cement, concrete and asphalt.Lafarge recently developed Ductal, a fibrereinforcedconcrete that is much strongerthan conventional concrete. Ductal has easedmore than a few headaches, particularly forroad engineers who are taunted by the forces<strong>of</strong> Mother Nature and the deterioration thatgoes hand-in-hand with heavy traffic.“Typical bridge decks are notorious forhaving maintenance issues,” explains Perry.“Trucks are constantly passing over them,there’s de-icing salt in the winter, freezingand thawing. Over time, cracks developand the salt starts to corrode the steelrebar and it expands.” Ductal is Lafarge’ssolution to minimize those problems.Because <strong>of</strong> its dense composition, Ductalcan be used in smaller amounts thanconventional concrete. That means abeam in a bridge, for example, would bethinner and lighter. Ductal can also reduceor eliminate the need for reinforcing systemsthat use steel rebar or <strong>high</strong>-strength cablesin the same bridge design.“We end up with better durability, longerlifespans and structures that require lessmaintenance.”Perhaps at no time in history have durabilityand longevity been more <strong>of</strong> a priority thanthey are now. Governments and the privatesector have been pouring billions into aseemingly endless pit <strong>of</strong> aging infrastructure.Engineers andcompanies are alwaystrying to push theenvelope and improveon materials andsolutions.This issue is top-<strong>of</strong>-mind at EngineersCanada, which has a national committeecalled the Public Infrastructure<strong>Engineering</strong> Vulnerability Committee.<strong>The</strong> committee studies the impactsand estimates the risks <strong>of</strong> the changingclimate on infrastructure in Canada.<strong>The</strong> aim is to identify potentialvulnerabilities and make engineeringrecommendations for remedial actionssuch as adjustments to engineeringpractices as well as infrastructure designcodes, standards, and procedures relatingto operations and maintenance.It all boils down to building moreresilient structures to withstand thebrutality <strong>of</strong> both blizzards and the hotsummer sun, wind and rain, and endlessfreeze-thaw cycles. >>Raafat El-Hacha examines the damage to a masonryblock caused by a month’s worth <strong>of</strong> experiments in theenvironmental testing chamber.Photo by David MollSCHULICH22 ENGINEERSCHULICH 23 ENGINEER

Ductal was used in the construction <strong>of</strong> theShawnessy C-train station in Calgary, including 24ultra-thin canopies supported on single columns.Photo courtesy Lafarge North AmericaWhat better way to develop stronger materials thanby putting them to the test under rigorous, real-lifeconditions. Blowing rain, load fluctuations, salt waterspray, freezing, thawing and everything in between canbe programmed to happen inside a massive stainlesssteel environmental testing chamber at the <strong>Schulich</strong><strong>School</strong> <strong>of</strong> <strong>Engineering</strong>. At 10 metres long, it is thelargest facility <strong>of</strong> its kind in North America. <strong>The</strong> airinside can go from room temperature down to minus68°C all the way up to 85°C in just four hours. It weighsmore than 11 tonnes, and that’s without all the tanks,pumps and electronics. Researchers can simulatepractically any weather condition and humidity level.“<strong>The</strong> chamber allows us to test different types and sizes<strong>of</strong> large-scale structural members and materials suchas concrete, masonry, steel, timber and composites,”explains Raafat El-Hacha, project leader and structuralengineering pr<strong>of</strong>essor. “We can evaluate the effects<strong>of</strong> the environment and loading factors on thedeterioration <strong>of</strong> civil infrastructure by simulatingsevere environmental exposure conditions.”Before and after: steel rebar is badly corroded after twoweeks in the environmental testing chamber.Photo by David Moll<strong>The</strong> harsh Canadian climate regularly pummelsbridges, roads and buildings but the damage may notbe apparent for years. El-Hacha can see first-handwhat happens to materials when they are subjectedto extreme conditions over and over again. A length<strong>of</strong> steel rebar emerged badly corroded after twoweeks in the chamber; the bottom half <strong>of</strong> a masonryblock crumbled to dust within a month. This is whatmakes the environmental testing chamber so exciting:researchers can essentially speed up time. >>

Artist’s conception <strong>of</strong> the Bow in downtownCalgary, scheduled for completion in 2012.Image courtesy EnCana Corporation<strong>The</strong> giant steel triangles that make up the Bow’s structuralbackbone are put into place in the summer <strong>of</strong> 2009.Photo by David MollSukhothai, a World Heritage Site in Thailand, is being digitallyreconstructed using Derek Lichti’s three-dimensional laser scans.Photo courtesy Derek Lichti“It’s one thing to take a beam into the lab andstart loading and flexing it and say, ‘We’ve justrun ten thousand cycles and it works fine,’”says Vic Perry <strong>of</strong> Lafarge. “But in the realworld, as the vehicles go over a bridge everyday, there are huge temperature fluctuationsand de-icing salt on the road. What wecan do in the testing chamber is spray thesalt in there and keep loading and flexingthe material and monitor its <strong>performance</strong>in a variety <strong>of</strong> temperatures. We can runthousands <strong>of</strong> cycles in a short period <strong>of</strong> time.”In fact, it’s possible to get the equivalent<strong>of</strong> 20 years <strong>of</strong> field work in just one weekin the chamber.Working with the potential <strong>of</strong> materials is atthe heart <strong>of</strong> creative engineering design.“It’s exciting to see the steel structure goingup,” says Adrian Todeila <strong>of</strong> the most complexstructure he’s ever worked on. Todeila is anassociate with the firm Halcrow Yolles, thestructural consultant for the task <strong>of</strong> erectingone <strong>of</strong> the tallest skyscrapers in Canada.<strong>The</strong> Bow, a 58-storey building in downtownCalgary, will house the new headquarters <strong>of</strong>EnCana Corporation.As the name suggests, the Bow will havea curved shape. Unlike many other tallbuildings, the Bow does not draw itsstrength from a concrete core. Instead,125 triangles made <strong>of</strong> structural steel spanthe outside surface <strong>of</strong> the building. Eachtriangle is six storeys <strong>high</strong> and invertedagainst the next to form a design called adiagrid. <strong>The</strong> steel ranges in thickness from45 to 100 mm. Just welding it in placerequires meticulous work under makeshiftshelters so environmental conditions suchas temperature are just right.<strong>The</strong> design team chose a perimeter diagridinstead <strong>of</strong> a traditional central concrete corebecause it allows elements such as cornercolumns to be placed outside the building,which frees up more floor space. <strong>The</strong>re’saesthetic value as well: the triangles will bevisible in the finished building.A diagrid is also preferable in this casebecause <strong>of</strong> the way it handles certain forcesto which the building is subjected. Whenthe finished Bow <strong>of</strong>fice tower juts out <strong>of</strong> theCalgary skyline sometime in 2012, it willcontain 43,000 tonnes <strong>of</strong> steel and be ableto withstand a windy city like Calgary.SCHULICH“As is generally the case with tallbuildings, wind loads become thepredominant lateral loads imposedon the structure. <strong>The</strong> diagrid <strong>of</strong>fers a<strong>high</strong>er redundancy in terms <strong>of</strong> load pathredistribution,” explains Todeila. Whenthe brisk chinook winds whip <strong>of</strong>f theRocky Mountains, it’s common for peopleto feel a tall building such as the CalgaryTower sway beneath them. <strong>The</strong> design<strong>of</strong> the Bow will reduce that effect.Steel versus concrete also reducesthe overall weight <strong>of</strong> the structure,an important consideration for sucha tall building.“<strong>The</strong> diagrid has always been considereda very efficient system from a structuralpoint <strong>of</strong> view. With recent improvementsin technology and manufacturingtechniques, fabricators can now doprecision cuts and it’s easier to perfectthe complex geometry <strong>of</strong> the diagridstructure.”It’s one thing to design creative buildingsusing new knowledge and techniques.Preserving old ones requires a differentexpertise.“<strong>The</strong> scans <strong>of</strong> the Ross Bridge are soimportant because they provide accuratecopies <strong>of</strong> the carvings,” says Debra Spohn,manager <strong>of</strong> the Tasmanian Wool Centrein Australia. <strong>The</strong> tourist spot has a RossBridge exhibit that includes plaster casts<strong>of</strong> the carvings on the bridge. Those castswere generated from the data providedby the 3-D laser scans.“Along with detailed photographs takenin the 1960s, the scans help us assessthe amount <strong>of</strong> erosion that has occurred.At a future date, the carvings couldpossibly be replaced with reproductionsand the originals housed somewhereto preserve them,” Spohn explains,remarking that history buffs like herare grateful for the accomplishments<strong>of</strong> modern technology.Besides analyzing the data from the RossBridge scans, Derek Lichti has taken part inother projects involving historic sites suchas the ancient cities <strong>of</strong> Ayuthaya andSukhothai in Thailand. <strong>The</strong> structural integrityand intricate detail <strong>of</strong> these World HeritageSites are under threat from the effects <strong>of</strong>weathering and heavy tourist traffic.It’s one thing to designcreative buildings using newknowledge and techniques.Preserving old ones requiresa different expertise.In 2003, Lichti arrived with his laser scannerand mapped the magnificent temples, carvingsand statues to provide a way to monitordeterioration and create a permanent recordfor future preservation efforts. Historiansare also using the images to create digitalreconstructions for educational purposes.26 ENGINEERSCHULICH 27 ENGINEER“When I was standing on the sites inThailand, it was amazing to think thosebuildings are 800 to 1,000 years old,”Lichti recalls. “It was awesome to bestanding in front <strong>of</strong> built structures thatold, and to do a little bit to help preservethem is really rewarding.”It was a case <strong>of</strong> 13th-century architecturemeeting 21st-century technology,an example <strong>of</strong> how advancements inengineering are playing a role in savingthe gems <strong>of</strong> the past while helping tocreate the <strong>high</strong>-<strong>performance</strong>, sustainablestructures <strong>of</strong> the future.Jennifer Sowa is the managing editor <strong>of</strong><strong>Schulich</strong> Engineer magazine and the mediarelations <strong>of</strong>ficer for the <strong>Schulich</strong> <strong>School</strong><strong>of</strong> <strong>Engineering</strong>. She is a former print andbroadcast journalist.

IN CONVERSATIONWITH HANY MICHAELQ: How did you shape the work cultureat Wardrop?A: Our management team set the goal tocreate an environment in which peoplefeel appreciated, in which they have theopportunity to make a difference. Wepay a lot <strong>of</strong> attention to making surewe hire the right people and makingsure we retain them for the long term.We constantly survey our employeesand there are usually two or threetop concerns that emerge. We makeit a priority to address those issueswithin the year before the next surveycomes out. We treat our employees likecustomers because they’re our assets.<strong>The</strong>y walk out the door every day andyou have to make sure they come back.People are very passionate aboutmaking a difference and having a sayin what goes on. We try to engage ouremployees and get their feedback asmuch as we can. We have a mentoringprogram and several fun eventsthroughout the year such as go-cartracing and paintball. It’s a way tointeract with people in an informalmanner and it’s more effective than astructured approach.Hany Michael is Senior Vice-President, Energy atWardrop <strong>Engineering</strong>, a consulting firm that servesthe energy, mining, infrastructure and manufacturingsectors around the world. Michael’s leadership hashelped the company become one <strong>of</strong> the top 100 designengineering firms in North America. He was also part<strong>of</strong> the management initiative that shaped Wardrop’sworkplace culture, resulting in the company making thelist <strong>of</strong> Canada’s Top 100 Employers for eight years ina row. Hany Michael graduated from the <strong>University</strong> <strong>of</strong>Calgary in 1987 with a degree in chemical engineering.(Photo courtesy Hany Michael)Q: Why does that make goodbusiness sense?A: It’s great to have people who arepassionate about their workplaceand want to improve it. It improvesour efficiency and our productivity.It gives people the sense thatthey’re contributing and making adifference. We have to constantlybe at the top <strong>of</strong> our game becausewe’re competing with companiesaround the world. We’re no longerjust competing against Canadianfirms. We have to bring energy andinnovation to everything we do.Q: What did it take for you tolearn that?A: I’ve been exposed to a number<strong>of</strong> different work environmentsthrough summer jobs and my firstfew jobs after graduation. You seethings you like and things you don’t.I promised myself that if I ever gotinto a position where I could havesome influence that I would takesome <strong>of</strong> those lessons and use them.Q: What was the best experience?A: I was working for a company inCalgary as a summer student. Duringmy first week there, a gentlemanknocked on my <strong>of</strong>fice door. He askedme how I liked the job and invited meto come see him if I ever wanted todiscuss anything. I found out later hewas the vice-president <strong>of</strong> our group.That really stuck with me. He actuallytook time from a very busy scheduleto come down and say hello and talkto me. I never forgot that. To this day,I always get a group <strong>of</strong> new employeestogether and spend some time talkingabout the history <strong>of</strong> the company,our philosophy, and I give them theopportunity to ask questions.Q: How do you know when you’reworking in a great workplace?A: When people you work with start tobecome your friends and you findyourself socializing with them outside<strong>of</strong> work. When you’re working onprojects and you don’t want to letanyone down because they’re yourcolleagues and your friends and youfeel like part <strong>of</strong> a team. That’s a greatworkplace.Q: What’s the best job you ever had?A: My current job. <strong>The</strong> part that reallyexcites me is being able to workwith people and help them in theircareers and get them to where theywant to be. I enjoy the technical workand managing large projects, butmaking an impact on someone’s lifeis very gratifying.HIGHPERFORMANCEHEALTHBY PETER CALAMAIBIOMEDICAL ENGINEERS SHARE A COMMON PASSION – THEY LOVE TO SOLVE THEPROBLEMS OF THE HUMAN BODY BY APPLYING ENGINEERING PRINCIPLES.<strong>The</strong> problems are as complex andmultifaceted as the body itself. At the<strong>University</strong> <strong>of</strong> Toronto, Molly Shoichetis collaborating on research to deliverbiological “factors” or compoundsthat would stimulate stem cells tobegin repairs after spinal columninjuries or strokes. At the ÉcolePolytechnique in Montreal, MichaelBuschmann invented a cartilagerepair technology. BioSyntechCanada is winding up successfultrials <strong>of</strong> Buschmann’s processwhich involves a therapeuticbiomaterial that improves theregeneration <strong>of</strong> knee cartilage,thereby reducing knee pain andpossibly preventing the onset <strong>of</strong>osteoarthritis and the need for jointreplacement surgery.At the <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>,Carolyn Anglin and colleagues are puttingthe finishing touches on a computer-assistedsurgery technique that aims to greatly reducethe post-operative pain <strong>of</strong>ten experiencedafter knee replacement operations.Such imaginative passion combined withincreased funding and rapid advances insome foundational sciences has madebiomedical engineering a hot researcharea across North America. In Canadaspecifically, the federal governmentin September 2008 endorsedbiomedical engineering and medicaltechnologies as one <strong>of</strong> four healthpriorities in the national science andtechnology strategy. In response,the current five-year strategic plan<strong>of</strong> the Canadian Institutes <strong>of</strong> HealthResearch, the main federal fundingagency in the health sciences,pledges to “support research at theinterface between the biological andthe physical and applied sciences.”Biomedical engineering is a disciplinewith ancient roots (a leather and woodartificial toe was found on an Egyptianmummy dating from between 1069 and 664BC) but associated largely in the public mindwith similar prostheses and medical deviceslike heart pacemakers. So what’s lately made itso exciting? >>SCHULICH28 ENGINEERSCHULICH 29 ENGINEER

In the opinion <strong>of</strong> several leading biomedicalengineering researchers, the currentemphasis on <strong>high</strong> <strong>performance</strong> in the fieldcan be linked to some defining characteristicsthat set engineers apart from scientists andmedical practitioners.Janet Ronsky, a <strong>Schulich</strong> <strong>School</strong> <strong>of</strong><strong>Engineering</strong> pr<strong>of</strong>essor <strong>of</strong> mechanical andmanufacturing engineering and CanadaResearch Chair in Biomedical <strong>Engineering</strong>,specifically contrasts the approach <strong>of</strong> medicaldoctors with that <strong>of</strong> engineers.Doctors are trained to look for patternsthat fit a diagnosis. “<strong>The</strong>ir creativity isin detecting what you’ve got. After that,the solution is pretty well prescribed.For engineers, however, there are a wholebunch <strong>of</strong> possible solutions to any problem,”Ronsky says.A complementary view is expressed byMichael Buschmann, a pr<strong>of</strong>essor in theÉcole Polytechnique’s department <strong>of</strong>chemical engineering and Canada ResearchChair in Cartilage Tissue <strong>Engineering</strong>.Molly Shoichet is looking for ways tostimulate stem cells to begin repairs afterspinal column injuries or strokes.Photo by Darryl Augustine“Engineers love to use numbers. <strong>The</strong>yfavour a quantitative approach,” he says.And while engineers embrace the scientificpoint <strong>of</strong> view known as a priori knowledgethey “typically want to solve problems,not just understand something.”U <strong>of</strong> T researcher Molly Shoichet, apr<strong>of</strong>essor in the department <strong>of</strong> chemicalengineering and applied chemistryand Canada Research Chair in Tissue<strong>Engineering</strong>, notes that a decade ag<strong>of</strong>ew engineering students were eventaught biology.“Yet today we can think about not simplyimplanting a device for every specificfunction but about actually overcomingthe very disease itself through biomedicalengineering,” she says.In addition, a special kind <strong>of</strong> engineer isattracted to biomedical engineering, saysRonsky. “<strong>The</strong> field tends to capture peoplewhose imagination is turned on by theadditional layer <strong>of</strong> complexity when youadd a biological system to the standardengineering areas.”Ronsky’s long-term research provides anexample <strong>of</strong> just such complexity. Since1998 she’s been leading a project toimprove the diagnosis and treatment <strong>of</strong>S-shaped curvature <strong>of</strong> the spine (scoliosis)in youth. <strong>The</strong> research has produceda 3-D reconstruction <strong>of</strong> the torsoderived primarily from two-dimensionalphotographs captured with four cameras.This technique lets doctors track theprogression <strong>of</strong> the affliction withoutrelying on twice-yearly heavy doses <strong>of</strong>X-rays, with their heightened potential forharm during puberty.As well, Ronsky’s team has marriedgeomatics with the photographic techniqueso the technicians who fashion braces forspinal scoliosis can now work from a detailedmathematical model <strong>of</strong> an individual’storso on a computer monitor. Once theyhave designed a brace that best matchesthe 300,000 points defining that specifictorso, fabrication instructions are sent toa computer numerical controlled (CNC)milling machine which produces a full-scaleversion, exact in every detail.“We can now start applying some science towhat’s working in the design <strong>of</strong> the bracesand what’s not working,” says Ronsky.She estimates that the customized bracemakingis three to four years away fromcommercial application. That’s smack-dabin the middle <strong>of</strong> the two-to-seven year timeframe that is the mantra for the newestCanadian initiative in this burgeoningfield – a national biomedical engineeringinnovation centre announced in 2008 byU <strong>of</strong> C President Harvey Weingarten in hisannual Report to the Community.<strong>The</strong> Biovantage Alberta Ingenuity Centreat the <strong>University</strong> <strong>of</strong> Calgary will provide anational focus on moving the promisingproducts <strong>of</strong> biomedical engineeringto market – a priority <strong>of</strong> the federalS&T strategy – by bringing togethercommercialization experts with researchersfrom the university, government andprivate sectors. It will be “very much runlike a business,” says Ronsky, who is theinaugural director.A technological showpiece <strong>of</strong> the centreis a unique suite <strong>of</strong> test instruments forbiomaterials and tissue engineering thatare being custom built by the ElectroForceSystems Group <strong>of</strong> the Bose Corporation,better known to consumers for <strong>high</strong>-endaudio components. <strong>The</strong> instruments aredriven by a Bose-designed linear motorthat provides leading-edge fidelity.<strong>The</strong> centre at the <strong>University</strong><strong>of</strong> Calgary will provide anational focus on movingthe promising products<strong>of</strong> biomedical engineeringto market – a priority <strong>of</strong>the federal S&T strategy– by bringing togethercommercialization expertswith researchers from theuniversity, governmentand private sectors. It willbe “very much run like abusiness,” says Ronsky, whois the inaugural director.Ronsky says the test instruments willallow centre researchers to preciselymeasure how much deformation iscaused when any given force is appliedto everything from a stretch <strong>of</strong> skin rightup to ligaments attached to bones. <strong>The</strong>instruments can be run through repetitivecycles which would simulate the effectson ligaments <strong>of</strong> walking, for example.That’s not all that sets the new centreapart from more conventional researchfacilities, even those incorporating socalledbusiness “incubators.” While thecentre will not hire new faculty, it willfund “innovators in residence” who arepursuing projects with commercializationprospects within that two-to-seven yeartime frame. <strong>The</strong>se could be people fromthe <strong>University</strong> <strong>of</strong> Calgary, other academicinstitutions, industry or “anywhere inthe world” says Ronsky.“<strong>The</strong>re’s a world-wide shortage <strong>of</strong> peopletrained in biomedical engineering andwith entrepreneurial skills.”Moving the bright ideas <strong>of</strong> universityresearch to market has long been seen asa problem by policy-makers. In the early1970s, the Science Council <strong>of</strong> Canadadefined the issue in a landmark studyentitled “Innovation in a Cold Climate.”An innovation report earlier this year fromthe Council <strong>of</strong> Canadian Academies foundthat little had changed in three decades.Ronsky says there are three reasons thenew centre should make a difference.It will:• provide a venue and a capacity specificallydesigned to make commercializationhappen;• allow researchers to take part at their“comfort” level, from handing their ideaover to others for commercialization totaking it all the way to market themselves;• give industry a mechanism for partneringwith academic research and gaining accessto specific problem-solving expertise oreven clinical trials.With more than 100 researchers alreadyworking in biomedical engineeringresearch at <strong>Schulich</strong> and across thecampus, Biovantage already has its eyeon some projects that could even becalled “shovel-ready,” such as the imagingtechnology developed in Ronsky’s spinalscoliosis project.Also close to marketability, accordingto <strong>Schulich</strong>’s Carolyn Anglin, is acomputer-assisted system to help surgeonshorizontally slice the patella or kneecapmore accurately, an essential step in kneereplacement operations.Patellar cuts that are tilted rather thanflat are thought to be an important factorin the post-operative pain experiencedby as many as one in four knee surgerypatients. >>SCHULICH30 ENGINEERSCHULICH 31 ENGINEER

<strong>The</strong> field tends to capturepeople whose imagination isturned on by the additionallayer <strong>of</strong> complexity when youadd a biological system to thestandard engineering areas.In computer-assisted surgery, marker arrays attachedto the bones and to the surgeon’s tools help improvethe accuracy <strong>of</strong> the cuts.Photo by David MollSCHULICH32 ENGINEERSCHULICH 33 ENGINEER

“<strong>The</strong> surgeons are basically eyeballing it now.With our system, there is a line on the monitorwhich effectively says, along with input fromthe surgeon, cut here. It’s very much like avideo game where you’re trying to match up thedesired line with the actual line,” says Anglin, anassistant pr<strong>of</strong>essor in the departments <strong>of</strong> civilengineering and mechanical and manufacturingengineering. Anglin, along with Janet Ronsky,is a member <strong>of</strong> the McCaig Institute for Boneand Joint Health at the <strong>University</strong> <strong>of</strong> Calgary.Anglin’s team, including students Jack Fu,Jeff Wai and Estee Lee, have been developingthe technology for two years, working withsurgeon Dr. Carol Hutchison and orthopaedicresidents Dr. Curtis Myden and Dr. EldridgeBatuyon at Calgary’s Foothills Hospital.<strong>The</strong>ir goal is to further simplify the hardwareand reduce the number <strong>of</strong> steps so thecomputer-assisted surgery doesn’t takesubstantially longer than the current eyeballmethod. She says that commercial firms, whichalready have s<strong>of</strong>tware for computer-assistedsurgery on larger bones like the tibia and femur,could conceivably have the patella system readyfor use within the “next couple <strong>of</strong> years.”Another promising application <strong>of</strong> the computerassistedsystems like the cut-here patella isin surgical training, now largely geared to atraditional apprenticeship model. Anglin saysusing the systems for surgery simulationsshould result in surgeons doing morepreplanning and thinking differently aboutaccuracy because they will be able to view thesimulated consequences <strong>of</strong> followinga particular course <strong>of</strong> action.“We want to change their brains,” she says.Also showing nascent commercializationpromise at the <strong>University</strong> <strong>of</strong> Calgary, accordingto Ronsky, are minimally invasive imagingand sensing technologies which might becalled digital biopsies and whose potentialapplications span cardiac, neurological, cancerand joints. As one example, a probe thatuses wavelengths in the near infrared couldconceivably let paramedics confirm strokesand their location during the ambulance rideto emergency. <strong>The</strong> probe allows measurement<strong>of</strong> blood volume and blood oxygen levelswithout puncturing the patient’s skin.Another imaging technology that couldsoon be ready for prime time would greatlyreduce the need to poke holes in the flesharound joints to keep tabs on the state<strong>of</strong> osteoarthritis, a procedure known asarthroscopy. Instead, by using biologicalmarkers to monitor a binding component <strong>of</strong>cartilage called proteoglycans, researcherswould have a handle on the physicalintegrity <strong>of</strong> the cartilage and on the effect <strong>of</strong>various treatments.If there is a cloud on the horizon amidstall this optimism, it’s whether the CanadianInstitutes <strong>of</strong> Health Research will getthe funding increases in the currenteconomic climate to follow through onthe government’s stated intention <strong>of</strong>making biomedical engineering a priorityarea. Researchers in Canada can only lookwistfully south to the U.S. where the privateWhitaker Foundation provided more than$500 million over three decades to establishbiomedical engineering programs at 30universities, deliberately spending itself out<strong>of</strong> existence by 2006.Yet, as Janet Ronsky says: “Engineersare problem-solvers.”Peter Calamai was the national science reporterfor <strong>The</strong> Toronto Star from 1998 to 2008. He isa contributing editor <strong>of</strong> Cosmos, an Australianscience magazine and an adjunct pr<strong>of</strong>essor atthe <strong>School</strong> <strong>of</strong> Journalism and Communicationat Carleton <strong>University</strong> in Ottawa. Calamai isalso a director <strong>of</strong> the new Science Media Centre<strong>of</strong> Canada (www.sciencemediacentre.ca).Carolyn Anglin developed a computer-assistedsurgery system with the goal <strong>of</strong> reducing painafter knee replacement surgery.Photo by David MollSCHULICH34 ENGINEERSCHULICH 35 ENGINEER

CANADA‘STOP 20UNDER 20BY CAROLINA ROMEOCERTAIN EXPERIENCES STICK WITH YOU FOREVER: YOUR FIRST YEAR OFUNIVERSITY, THE FIRST YEAR LIVING AWAY FROM HOME, THE FIRST TIME YOUREPRESENT YOUR COUNTRY INTERNATIONALLY. THESE EXPERIENCES TEACHYOU A LOT AND YOU CHERISH THEM FOR THE REST OF YOUR LIFE.<strong>The</strong> Top 20 Under 20 LeadershipSummit is one <strong>of</strong> those experiences.I was one <strong>of</strong> the recipients <strong>of</strong> Canada’sTop 20 Under 20 Award for 2009. WhenI met the others at the conference, theyseemed like ordinary people I might runinto on the streets <strong>of</strong> Calgary. <strong>The</strong>y wereoutgoing, easy-to-talk-to teenagers.But when I found out more about them,I realized how extraordinary they reallywere and how far determination, hardwork and persistence can take you nomatter what your passion is.Among this group <strong>of</strong> teenagers wereresearchers, public speakers, founders <strong>of</strong>charitable organizations, artists, coaches,mountain climbers and volunteers. <strong>The</strong>tasks they took on and the problems theychose to tackle were very broad – but theychose to help in areas that interest themor affect people they care about.Two projects involved helping people withdisabilities take part in everyday activitiesincluding sports. Another challengedpeople to climb Mount Kilimanjaro inAfrica to raise money for HIV and AIDSclinics. A young artist painted a pictureabout his experience swimming in subzeroArctic sea water and formed a studentactivist group to raise awareness aboutclimate change. Others raised significantfunds to spread knowledge about cancer,malaria and homelessness.When you look at this group <strong>of</strong> youngachievers, you see diversity: we comefrom different regions <strong>of</strong> Canada, wehave different backgrounds and differentpassions. But we all have something withinus that drives us to accomplish what somepeople call “unbelievable” things at sucha young age. I believe that drive comesfrom not settling for mediocrity, from notbeing satisfied with what has been givento us. We want the best possible life forthose around us. We have chosen to strivefor perfection and look for solutions toproblems that affect us or our loved ones.When I found out moreabout them, I realizedhow extraordinary theyreally were and how fardetermination, hardwork and persistencecan take you no matterwhat your passion is.<strong>The</strong> most important thing I learned fromthis experience is this: if you have a goal,a vision <strong>of</strong> something that is meaningfulto you, work hard and don’t stop tryinguntil you achieve what you’re looking for.<strong>The</strong>re are people out there who will beglad to support you, but that drive – thedesire to achieve excellence – must comefrom within.Carolina Romeo is a second-yearstudent at the <strong>Schulich</strong> <strong>School</strong><strong>of</strong> <strong>Engineering</strong>. She skipped twogrades in junior <strong>high</strong> school andwas awarded a Chancellor’s Clubscholarship in 2008, entering the<strong>University</strong> <strong>of</strong> Calgary at the age <strong>of</strong>15. She joined the women’s fieldhockey team, becoming the youngestever athlete at the U <strong>of</strong> C and theyoungest ever female varsity-levelathlete in Canada.Romeo also plays ringette at thenational and international levelsand coaches girls in ringette andfield hockey. She enjoys cooking andhas volunteered at charitable eventsincluding the Easter Seals Ball, adinner and dance to raise money forchildren with disabilities.In May 2009, Romeo was namedone <strong>of</strong> Canada’s Top 20 Under 20.This annual list is compiled by Youthin Motion, a non-pr<strong>of</strong>it organizationthat recognizes Canadians under theage <strong>of</strong> 20 who have demonstrateda significant level <strong>of</strong> innovation,leadership and achievement.Photo by Jason Stang. Illustration by Dave GouldenSCHULICH37ENGINEER

2009INTERNSHIPPHOTOCONTESTTHE SELECTIONS WERE MADE BYA PANEL OF JUDGES INCLUDING:MARJAN EGGERMONTSenior Instructor and Artist-in-Residence<strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>WINNERS OF THE 2009 INTERNSHIPPHOTO CONTEST AT THE SCHULICHSCHOOL OF ENGINEERING WERE CHOSENIN FOUR CATEGORIES:At Work on InternshipEWAN NICHOLSONEwan Nicholson Photography Inc.Member and Past President,Canadian Association <strong>of</strong> Photographersand Illustrators in CommunicationsPEGGY SIMONSChemical engineer and former executivewith Petro-CanadaLife on InternshipCheck This OutAdventures AbroadFor more information about the winningphotographs and to view other entries,please visit www.schulich.ucalgary.ca.AT WORK ON INTERNSHIP1 st Place (left)MATTHEW STARKTurbine - when technology creates artLIFE ON INTERNSHIP1 st Place (above)SHANNON PAYNE<strong>The</strong> aftermath <strong>of</strong> Tomatina,a giant tomato fight held everyyear in Bunol, SpainFormer Associate Dean (Student Affairs)at the <strong>Schulich</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>SCHULICH39ENGINEER

CHECK THIS OUT1 st Place (left)CHRISTOPHER MOOREVespa in the rain in SwitzerlandADVENTURES ABROAD1 st Place (above)CARL DYCKSeaweed harvesting on the shores<strong>of</strong> Lombok, IndonesiaSCHULICH40 ENGINEERSCHULICH 41 ENGINEER

CHECK THIS OUT2 nd Place (left)BRUCE DUONGShedding some light on a sculpturein the Municipal Museum <strong>of</strong>Contemporary Art in Ghent, BelgiumAT WORK ON INTERNSHIP2 nd Place (above)JESS MACARTHURWind power east <strong>of</strong> Waterton, AlbertaSCHULICH43ENGINEER

LIFE ON INTERNSHIP2 nd Place (above)STEVE LAHODATrying to get my bearings straightamong the awesome remains <strong>of</strong> theGreat Wall <strong>of</strong> China near BeijingADVENTURES ABROAD2 nd Place (left)ANDREW RUSHWORTHDescending Mt. Sinai in EgyptSCHULICH44 ENGINEERSCHULICH 45 ENGINEER