Mine to Market May-June 2012 - Mount Isa Mines

Mine to Market May-June 2012 - Mount Isa Mines

Mine to Market May-June 2012 - Mount Isa Mines

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

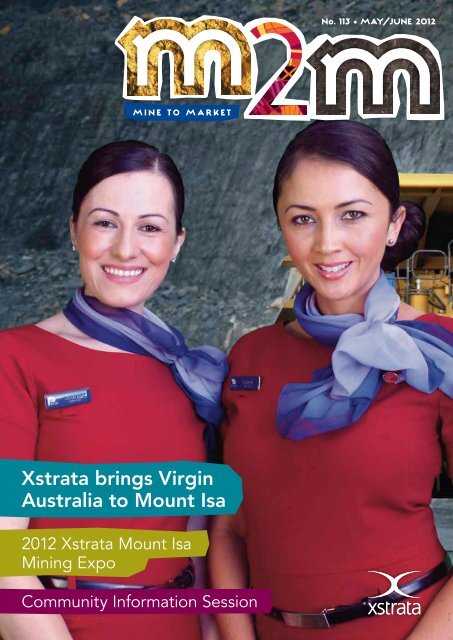

No. 113 • MAY/JUNE <strong>2012</strong>Xstrata brings VirginAustralia <strong>to</strong> <strong>Mount</strong> <strong>Isa</strong><strong>2012</strong> Xstrata <strong>Mount</strong> <strong>Isa</strong>Mining ExpoCommunity Information Session

No. 113 • MAY/JUNE <strong>2012</strong>24 25OperationsXstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s bringsVirgin Australia <strong>to</strong> <strong>Isa</strong> . . . . . . . . . . . . . . . . . . 1Xstrata Zinc continues <strong>to</strong> thrive . . . . . . . . . . 4Enhancements <strong>to</strong> Altiris Transact . . . . . . . . 12Raising our profile locally and abroad . . . . 15Paving the way at <strong>Mount</strong> Margaret . . . . . . 15Sink underway for new hoisting shaft . . . . . 17Skilling our bright sparks . . . . . . . . . . . . . . . 23Sharing our knowledge . . . . . . . . . . . . . . . . 24Community<strong>2012</strong> Xstrata <strong>Mount</strong> <strong>Isa</strong> Mining Expo . . . . . . 2Policelink . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Celebrating our communitypartnership achievements . . . . . . . . . . . . . . 10Cloncurry’s two new community projects . . 11Community Helicopter receivesofficial christening . . . . . . . . . . . . . . . . . . . . 11Workplace Giving . . . . . . . . . . . . . . . . . . . . 20Keeping our community informed . . . . . . . 25Bravehearts Mow-a-thon gets a$5,000 kick start . . . . . . . . . . . . . . . . . . . . . 20EnvironmentRehabilitation showinggood growth rates . . . . . . . . . . . . . . . . . . . 16Change <strong>to</strong> environmentallyfriendly degreasers . . . . . . . . . . . . . . . . . . . 16Our PeopleAn<strong>to</strong>nia Briant’s s<strong>to</strong>ry . . . . . . . . . . . . . . . . . . 6Des Marriott’s s<strong>to</strong>ry . . . . . . . . . . . . . . . . . . . 13Tony Ruddell’s s<strong>to</strong>ry . . . . . . . . . . . . . . . . . . 21Alf Cianetti retires after 57 years. . . . . . . . . 22Nathan Bullock’s s<strong>to</strong>ry . . . . . . . . . . . . . . . . . 27Up CloseJoe Golling . . . . . . . . . . . . . . . . . . . . . . . . . 14HealthCopper: Winning the war ondrug-resistant superbugs . . . . . . . . . . . . . . . 7Zinc in society . . . . . . . . . . . . . . . . . . . . . . . . 9Xstrata drives rollout of new antidote . . . . . 26Be smart with your heart . . . . . . . . . . . . . . . 28SafetyImproving safety at EHM lab . . . . . . . . . . . 12The CO 2 RE Project . . . . . . . . . . . . . . . . . . . 18MICO Continuous Improvementideas continue <strong>to</strong> roll in. . . . . . . . . . . . . . . . 18Manual Task Risk Assessment made easy. . 19NoticesXstrata North QueenslandSponsored Apprenticeships 2013 . . . . . . . . 9Announcements, Calendar,For sale, In memoriam . . . . . . . . . . . . . . . . 29From the COOsAfter 15 months of negotiations, we werehappy <strong>to</strong> announce on 11 <strong>May</strong> <strong>2012</strong>Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s and VirginAustralia signed a Heads of Agreement,which will see the airline servicing the <strong>Mount</strong> <strong>Isa</strong> <strong>to</strong>Brisbane route from August.Since Xstrata acquired <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s in 2003,the issue of not having a competitive airline servicebetween <strong>Mount</strong> <strong>Isa</strong> and Brisbane has been a keyconcern raised by our employees and their families ina number of our surveys and studies as well as by ourbroader community through the local media.As a result of this issue being of significantimportance <strong>to</strong> all of you, we have been working hardsince February 2011 <strong>to</strong> sign the agreement betweenus and Virgin that will benefit not only our business butall the people of <strong>Mount</strong> <strong>Isa</strong>.While we are excited <strong>to</strong> bring a second airlineservice <strong>to</strong> <strong>Mount</strong> <strong>Isa</strong>, we will also continue <strong>to</strong> useQantas <strong>to</strong> service our business needs and are gratefulof the excellent service Qantas has, and will continue<strong>to</strong> provide, <strong>to</strong> the <strong>Mount</strong> <strong>Isa</strong> region.It is a sign of the growth of the mining industry inthe north-west region that there is demand <strong>to</strong> supportSteve de KruijffChief Operating OfficerXstrata CopperNorth Queenslandtwo major airlines in <strong>Mount</strong> <strong>Isa</strong>. It is also an exampleof how the whole community may benefit from thecontinued development of our operations.We look forward <strong>to</strong> welcoming Virgin <strong>to</strong> ourcommunity and thank Virgin Australia’s Manager NewBusiness, Ashley Rae, who attended our first XstrataCommunity Information Session for <strong>2012</strong> on 30 <strong>May</strong>and so generously offered a prize of return airfare <strong>to</strong>Brisbane for two people for one of our communitymembers at the information session.We encourage everyone <strong>to</strong> provide their support inorder <strong>to</strong> ensure we continue <strong>to</strong> service both airlines in<strong>Mount</strong> <strong>Isa</strong>.Finally, we would also like <strong>to</strong> thank the <strong>Mount</strong><strong>Isa</strong> Chamber of Commerce and all of our Xstrataemployees for contributing <strong>to</strong> such a successful andentertaining <strong>2012</strong> Xstrata <strong>Mount</strong> <strong>Isa</strong> Mining Expo.Without all of our volunteers and dedicated work putin by all involved, we would not be able <strong>to</strong> hold suchgreat community events that promote the miningindustry. This year more than 7,500 communitymembers, including school groups, attended themining expo.Brian HearneChief Operating OfficerXstrata Zinc AustraliaOn the coverVirgin Australia crew membersJoanne and Lauren get a tasteof ‘the <strong>Isa</strong>’ at the <strong>2012</strong> Xstrata<strong>Mount</strong> <strong>Isa</strong> Mining Expo.Xstrata s<strong>to</strong>ck priceXstrata is listed on the Londonand Zurich s<strong>to</strong>ck exchanges.£9.57As at 30 <strong>May</strong> <strong>2012</strong>. Xstratashare price on the LondonS<strong>to</strong>ck Exchange (XTA.L)Contact the edi<strong>to</strong>rInput from all Xstrata NorthQueensland operationsis invited. Any articles,innovations, achievements,ideas or suggestions arevery welcome. Pleasecontact Lara Lavers, XstrataCommunity Relations on email:llavers@xstrata.com.auor phone: (07) 4744 2955.The Xstrata ReportingLineThe Xstrata Reporting Line is anindependently run, confidentialfacility providing employeesand stakeholders with a meansfor reporting breaches ofXstrata’s Business Principles,policies or prevailing legislation.To access this line please visitwww.xstrataethics.com orfreecall: 1800 121 889

Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sbrings Virgin Australia <strong>to</strong> <strong>Isa</strong>At Xstrata we work hard <strong>to</strong> makea difference, which is whyover the past 16 months, wehave been working closely withVirgin Australia <strong>to</strong> secure a second airline<strong>to</strong> service the <strong>Mount</strong> <strong>Isa</strong> <strong>to</strong> Brisbane route.And on the 11 <strong>May</strong> <strong>2012</strong>, we signeda Heads of Agreement between Xstrata<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s and Virgin Australia whichwill see the airline fly between <strong>Mount</strong> <strong>Isa</strong>and Brisbane five days a week, Monday <strong>to</strong>Friday commencing in August.Steve de Kruijff, Chief Operating OfficerXstrata Copper North Queensland saysthe heads of agreement between thetwo companies comes after passengernumbers flying through <strong>Mount</strong> <strong>Isa</strong> Airportincreased by 10 per cent betweenMarch 2011 and March <strong>2012</strong> <strong>to</strong> almost22,000 people.“More competition in the skies is abenefit <strong>to</strong> the communities in the northwestregion,” Steve says.“This announcement is also greatnews for employees and their familiesin <strong>Mount</strong> <strong>Isa</strong>.“Research conducted with our peopleover the past few years found the cos<strong>to</strong>f airfares was one of the most criticalobstacles <strong>to</strong> their staying in <strong>Mount</strong> <strong>Isa</strong>.“Now our people will be better able<strong>to</strong> plan for their holidays and events ontheir terms.”Justin Montgomery, General ManagerSales, Virgin Australia says the new serviceswould benefit <strong>Mount</strong> <strong>Isa</strong> and regionalcommunities greatly by providing choiceon the route.“Virgin Australia is proud <strong>to</strong> servicethe community of <strong>Mount</strong> <strong>Isa</strong>. These newservices will bring a range of benefitsincluding more competitive pricing,enhanced flight connections and ahigher quality overall travel experience,”Justin says.“The <strong>Mount</strong> <strong>Isa</strong> community will beable <strong>to</strong> connect with our growing networkfrom Brisbane that includes more than33 domestic cities and more than400 international destinations.”Steve thanks the other industry groupsand bodies in the <strong>Mount</strong> <strong>Isa</strong> region thathave joined us in voicing a need for asecond airline <strong>to</strong> service <strong>Mount</strong> <strong>Isa</strong>.“Organisations such as the <strong>Mount</strong><strong>Isa</strong> Chamber of Commerce, our localrepresentatives and the State Governmentshould also be recognised for their tirelessefforts in pursuing a second airline <strong>to</strong> come<strong>to</strong> <strong>Mount</strong> <strong>Isa</strong>,” Steve says.Xstrata will continue <strong>to</strong> use Qantas andVirgin services <strong>to</strong> help ensure <strong>Mount</strong> <strong>Isa</strong>has two reliable and competitive airlines.For flight information between <strong>Mount</strong> <strong>Isa</strong><strong>to</strong> Brisbane on Virgin Australia visitwww.virginaustralia.commine <strong>to</strong> market1

Our very own BSafe Bee buzzed around our expo display, delighting kids andreinforcing the importance of staying safe at work, home and in the community.Students from St Joseph’s Catholic PrimarySchool, Cloncurry, rescue ‘Bob’ from <strong>Mine</strong>Rescue’s smoke tunnel.Cloncurry State School students make authenticconcentrate froth using the Copper Concentra<strong>to</strong>r’smini Float Cell.Students from Barkly State School practicetruck driving using <strong>Mine</strong>s Processing’sremote control loaders and haul trucks.After its resounding popularity in 2011, Xstrata’sGreen Screen pho<strong>to</strong> booth was back, providingschool children and community members theopportunity <strong>to</strong> have their pho<strong>to</strong>graph taken andsuperimposed against a variety of backdropsshowcasing our north Queensland operations.Barkly Highway students ‘Try a Trade’ with ourSkills Centre apprentices and instruc<strong>to</strong>rs.St Joseph’s students have fun learningabout our mining process.2 mine <strong>to</strong> market

<strong>2012</strong> Xstrata<strong>Mount</strong> <strong>Isa</strong> Mining ExpoCommunityInspired by Xstrata’s award winning 2011 display, the <strong>2012</strong> Xstrata <strong>Mount</strong> <strong>Isa</strong>Mining Expo committee vowed <strong>to</strong> make this year’s exhibit bigger and betterthan ever. With our <strong>2012</strong> display winning Best Outdoor Display and wowingschool children, industry professionals and community members throughoutthe three-day event, it was a promise they definitely fulfilled.This year many of our operation’sdepartments and project areasparticipated in the interactivedisplay, ensuring there was a hugerange of activities that catered for all ages.School children from Cloncurry, <strong>Mount</strong><strong>Isa</strong> and the <strong>Mount</strong> <strong>Isa</strong> School of the Airenjoyed the display with 10 primary andhigh schools coming along <strong>to</strong> learn moreabout our north Queensland operations.<strong>Mine</strong>s Rescue boasted a new andimproved tunnel where participants wererequired <strong>to</strong> carry out a rescue mission in asimulated underground environment. Forthe first time, the <strong>Mine</strong>s Rescue displayalso featured an Emergency Refuge Bay(ERB), increasing the authenticity of theunderground experience.This year the Environmental team,supported by Southern Gulf Catchments,blew specta<strong>to</strong>rs away with their replicaof the Copper Smelter and AcidPlant complete with dry ice ‘plume’,their massive fish tank with numerousamphibious creatures and their brand new,mobile sulphur dioxide moni<strong>to</strong>r.Another favourite exhibit amongst theschool children was Safety and Health’s Iam Awesome Fit challenge which saw twolucky participants win brand new lap<strong>to</strong>psbased on their grip strength and push-upability. Our new Shape Up Online programalso featured at the display and Kineticnurses offered community members freemini health checks at our mobile healthmoni<strong>to</strong>ring van. Switch on Safety wasanother safety theme highlighted at thisyear’s expo with a short, educationalfilm shown in our pop-up cinema and aninteractive game show which taught kidsthe importance of ‘switching on’ <strong>to</strong> staysafe. Queensland Health and <strong>Mount</strong> <strong>Isa</strong>Physiotherapy were also on hand, makingour Safety and Health display one not <strong>to</strong>be missed.Our Skills Centre apprentices andleaders were well represented, showcasinga fully interactive display and allowingvisi<strong>to</strong>rs <strong>to</strong> ‘try a trade’ <strong>to</strong> learn moreabout the skills acquired on the path <strong>to</strong>becoming a qualified tradesperson.A number of our Geologists, MiningEngineers and Metallurgists were onhand <strong>to</strong> explain how our operations work,covering everything from exploration rightthrough <strong>to</strong> processing. Visi<strong>to</strong>rs were able<strong>to</strong> hold rock specimens and fossils and hada go at moving ‘ore’ (pumice rock) usingmodel remote control loaders and haultrucks. Creating real mineral concentratefroth with the Copper Concentra<strong>to</strong>r’s miniFloat Cell was also a hit with visi<strong>to</strong>rs ofall ages.A new feature at this year’s miningexpo was the <strong>Mount</strong> <strong>Isa</strong> Open Pitteam‘s colourful and informative booth.Factsheets were available and CommunityRelations and operational staff were onhand <strong>to</strong> answer questions aboutthe proposed project, currentlyin the pre-feasibility study stage.Representatives from ErnestHenry Mining (EHM) were alsopresent with employees fromour Cloncurry based operationsavailable for enquiries aboutEHM’s underground mining andmagnetite projects.This year, we were luckyenough <strong>to</strong> have three of ourcommunity partners join usat Expo. North West WildlifeCarers Group, <strong>Mount</strong> <strong>Isa</strong>Fish S<strong>to</strong>cking Group and theStride Foundation all camearmed with exciting activitieswhich kept school children and adultsthoroughly entertained.Maryann Wipaki, SustainableDevelopment Manager, Xstrata Copper,praises the expo committee and volunteersfor their commitment in the lead up <strong>to</strong> andduring the three day event.“Employees from a range ofdepartments came <strong>to</strong>gether <strong>to</strong> ensurethis year’s expo was one <strong>to</strong> remember,”she says.“Without the hard work and dedicationof the expo committee and the numerousemployees who volunteered their time ourdisplay wouldn’t have been so interactive,fun or educational.“Thank you <strong>to</strong> everyone who helpedmake our display at year’s Mining Exposo dynamic.”Zinc and Copper Human Resources employeesman the Xstrata Careers booth armed with usefulmaterial for students and community membersinterested in pursuing a career in the miningindustry. The younger school students alsoenjoyed this display and had a great time playinga career matching game.mine <strong>to</strong> market3

Xstrata Zinccontinues<strong>to</strong> thrive4 mine <strong>to</strong> market

Investing an additional$87 million in<strong>to</strong> two ofits key operations inthe <strong>Mount</strong> <strong>Isa</strong> regionhas seen Xstrata Zinccontinue <strong>to</strong> rampup its activities inthe north west.In <strong>May</strong>, we announced Xstrata Zinc hadaccelerated production from the LadyLoretta underground mine and furtherextended the life of the Handlebar Hillopen cut operation.As a result of the continued increasein production at Xstrata Zinc’s operations,we have experienced a net increase inannual zinc production of 5 per cent (or25,000 <strong>to</strong>nnes).Construction of the Lady Loretta projectcommenced in July 2011 <strong>to</strong> developa greenfield underground zinc-leadsilvermine 140 km north-west of <strong>Mount</strong><strong>Isa</strong>, originally expected <strong>to</strong> commenceproduction by the end of 2013 at a rateof 1 million <strong>to</strong>nnes per annum (Mtpa).Work on the decline development, surfaceinfrastructure and services are progressingwell ahead of schedule.With further investment committed <strong>to</strong>accelerate the development of the mine,we will increase the annual ore productionrate from 1.0 Mt <strong>to</strong> 1.2 Mt and bringforward the start of production by oneyear <strong>to</strong> late <strong>2012</strong>. Work has commencedimmediately <strong>to</strong> secure key equipment andredesign the development infrastructure,mining plan and associated road upgrades<strong>to</strong> accommodate the increased annualore volume.The accelerated development of LadyLoretta has been supported by an increasein <strong>to</strong>tal resources from 12.6 million <strong>to</strong>nnesin <strong>June</strong> 2010 <strong>to</strong> 13.3 million <strong>to</strong>nnes inDecember 2011. This assessment increasesthe amount of zinc metal contained by12 per cent <strong>to</strong> 1,406 kt and lead metalcontained by 10 per cent <strong>to</strong> 448 kt over a12 year mine life.Brian Hearne, Chief Operating OfficerXstrata Zinc Australia says expansions ofboth mines would realise significant valuefrom our Australian zinc business, includingan estimated 30 new direct jobs.“We are accelerating the deliveryof ore from Lady Loretta <strong>to</strong> <strong>Mount</strong> <strong>Isa</strong>by developing the upper ore bodiesindependently <strong>to</strong> the deeper undergroundresources,” Brian says.“At the same time, we are investingin a further expansion of the HandlebarHill operation following improvementsin mining methods and metallurgicalperformance since the mine was designedin 2007.The improvements have allowed us <strong>to</strong>look at mining previously marginal ore.”The $30 million Handlebar Hill OpenCut South project supports the third stageof expansion of this operation, 20 km northof <strong>Mount</strong> <strong>Isa</strong>, and extends the life of mineby a year <strong>to</strong> 2014.Developing a narrow cutback <strong>to</strong> thesouth of the pit and targeting deeperore from under the first two stagesof development adds approximately1 million <strong>to</strong>nnes of ore at 8.7 per cent zinc,2.7 per cent lead and 44 g/t silver <strong>to</strong> theexisting Handlebar Hill open pit reserves.mine <strong>to</strong> market5

An<strong>to</strong>nia Briant’ss<strong>to</strong>ryPersonal Assistant <strong>to</strong> the GeneralManager of Processing, An<strong>to</strong>niaBriant is Xstrata Zinc’s organisationaficionadowith an infectious laughthat warms the halls of the Mill Officeand a lightning-fast wit that keeps herworkmates on their <strong>to</strong>es.At 17, this born-and-bred <strong>Mount</strong><strong>Isa</strong>n packed her bags and headed <strong>to</strong>Queensland’s south east corner for ataste of life in the big smoke of Brisbane.Little did she know, a few years downthe track after establishing a successfulcareer in Brisbane, a job opportunity inher home<strong>to</strong>wn would prove <strong>to</strong> be thechallenge she had been waiting for.“After finishing Year 12, I headed <strong>to</strong>Brisbane where I began my career as anassistant in the Financial Services industry.“After a few years, I was ready <strong>to</strong> takethe next step in my career, and I guess youcould say I had a niggling feeling my heartwas pulling me back <strong>to</strong> “<strong>Isa</strong>”. So, in 2010 I<strong>to</strong>ok on the position of Personal Assistant<strong>to</strong> the General Manager of Processing.Eighteen months later, each day continues<strong>to</strong> present me with a new opportunity <strong>to</strong>do what I do best.“It might not seem like it from theoutside, but it takes a whole lot of thoughtand juggling <strong>to</strong> make sure my boss’s daysrun smoothly. But that’s what I love aboutmy work; maintaining my GM’s schedulewith military-like precision so he can get onwith his job. It’s a balancing act, but it feelsawesome <strong>to</strong> see your work playing a rolein ensuring our operations go off withouta hitch.“I also get <strong>to</strong> throw myself in<strong>to</strong>organising some of Xstrata Zinc’s events,like office parties, conferences, as well asrecruiting volunteers for the LeukaemiaFoundation’s ‘World’s Greatest Shave’ –I’m always able <strong>to</strong> rope in a few helpers<strong>to</strong> bump up our fundraising <strong>to</strong>tal.“At the moment I’m working on theZinc Christmas party. It’s a big undertaking– securing a date that suits the entire Zinc“It’s a balancing act,but it feels awesome<strong>to</strong> see your workplaying a rolein ensuring ouroperations go offwithout a hitch.”operation, sourcing catering and findinga venue that can accommodate all of ourstaff is tricky. But all that hard work has ahuge payoff – an event where our peoplecan let their hair down and reflect on agreat year – and I get a kick out of my rolein that.”6 mine <strong>to</strong> market

Winning the war ondrug-resistant superbugsFrom the cables that feed electricityin<strong>to</strong> our homes <strong>to</strong> the tinyconnections in our mobile phonesand computers, copper’s uniqueconductive qualities ensure it plays a keyrole in powering 20th century life.Now, thanks <strong>to</strong> its phenomenalanti-bacterial capabilities, copperis coming out on <strong>to</strong>p in the war ondrug-resistant superbugs.<strong>Market</strong>ed as Cu+, AntimicrobialCopper is the latest weapon in the fightagainst rising infection rates in medicalcare facilities around the world. According<strong>to</strong> the International Copper Association,7 million people suffer or die from healthcareassociated infections globally everyyear, and 80 per cent of these infectionsare spread by <strong>to</strong>uch. Cleaning agents likechlorine work, but don’t provide long termsolutions <strong>to</strong> the contamination issue. Whenused in high-frequency contact areas liketaps, light switches, soap dispensers, nursecall but<strong>to</strong>ns, bed rails and intravenousdrip racks, copper stems the spreadof potentially deadly drug-resistantbacteria often present in hospitals, likeStaphylococcus aureus or “Golden Staph”.This development comes after a fiveyearJapanese study – presented at theFirst Annual World Congress of Microbesin 2011 – recorded major reductions inbacterial load on <strong>to</strong>uch and non-<strong>to</strong>uchsurfaces made from copper, as opposed <strong>to</strong>plastic or stainless steel.A further study conducted by theUnited States Department of Defenseacross three major American hospitalsfound that the introduction of copperfittings slashed the risk of potentiallydeadly super-bug infection by a whopping40 per cent. In a simple experimentconducted and presented by researchersat the University of Southamp<strong>to</strong>n in theUnited Kingdom, 10 million multi drugresistantStaphylococcus aureus (MRSA)bacteria were completely annihilated inless than 10 minutes after making contactwith a 1cm 2 copper plate. The samenumber of MRSA bacteria survived forweeks on the stainless steel control plate.The scientific theory is that coppershort-circuits the stable electricalmicro-current of the bacterium’s outermembrane. This creates holes throughwhich an unopposed stream of copperions can bombard the inner workingsof the cell, obstructing the criticalbiochemical reactions the bacteriumneeds <strong>to</strong> survive. It’s a fast, but deathlyeffective microscopic attack.And it’s not just the medical industryincluding copper in their proactive riskprevention policies. The Chilean transportsystem is replacing subway handrails withnew, copper coated fixtures; copper taps,door push-plates and meal preparationbenches were recently installed in aJapanese kindergarten, and just thisyear a Ronald McDonald House in theUnited States added copper fittings <strong>to</strong>high-<strong>to</strong>uch areas in bathrooms, kitchensand dining areas.The grab for Antimicrobial Copper isexpected <strong>to</strong> add 500 thousand metric<strong>to</strong>nnes per year <strong>to</strong> global copper demand.The Australian branch of the InternationalCopper Association is working with keyindustry partners <strong>to</strong> market AntimicrobialCopper products <strong>to</strong> the healthcare andpublic transport sec<strong>to</strong>rs across the country.Add <strong>to</strong> that copper’s extensive usein green technologies – like solar cellsand electric cars – and it’s clear copper ismore than just an essential element forpowering our houses and technologicalgadgets. Copper has an enduring role inguaranteeing the health of modern society,and a vital part <strong>to</strong> play in the future of asustainable world.Did you know?Copper surfacesdestroy 99.9 per cen<strong>to</strong>f bacteria withinminutes of contact.No longer simply ahumble conduc<strong>to</strong>rof electricity, copperis stepping in<strong>to</strong> thespotlight as a coldbloodedgerm-killer.mine <strong>to</strong> market7

PolicelinkWhat is Policelink?Policelink 131 444 is the number inQueensland <strong>to</strong> report non-urgent incidentsincluding:• wilful property damage• stealing offences• break and enters• s<strong>to</strong>len vehicles• lost property.Policelink 131 444 aligns with the nationalnumber for non-urgent police assistanceand is open 24/7.Policelink enhances the client servicewe can provide <strong>to</strong> you by giving policeofficers more time <strong>to</strong> perform operationalduties and improving front line policeresponse times.When should you call Policelink?Anytime you would like <strong>to</strong> report a nonurgentcrime or incident.If the crime is not happening now,is not life threatening or there is littlelikelihood of the suspected offendersbeing in the area, call Policelink 131 444for non-urgent assistance.You can also contact Policelink forgeneral enquiries.What happens when you call131 444?When you contact Policelink, ourspecifically trained Client Service Officersand Police Technical Advisors will receiveand process your non-urgent reports andanswer your general enquiries.Where appropriate, Policelink staff mayissue you with a crime report number forinsurance purposes.In many cases your report will befinalised on the first phone call.Why contact Policelink?Contacting Policelink 131 444 providesyou with an efficient way <strong>to</strong> reportnon-urgent incidents saving travellingtime and transport costs <strong>to</strong> your nearestpolice station.Your call <strong>to</strong> Policelink also providesthe Queensland Police Service withmore time <strong>to</strong> reinvest in<strong>to</strong> proactivepolicing initiatives.For example, if you choose <strong>to</strong>report your s<strong>to</strong>len wheelie bin or gardenhose via Policelink instead of having anofficer attending the scene, this willdirectly enhance community safetythrough time being reinvested in<strong>to</strong>other operational priorities.Benefits of PolicelinkWhen you phone Policelink you helpreduce the number of calls <strong>to</strong> existingpolice stations. Your choice of actionincreases the ability for frontline police <strong>to</strong>attend more urgent requests for assistance.Policelink will allow Queensland PoliceService resource hours <strong>to</strong> be re-investedin<strong>to</strong> other priorities and proactive functions<strong>to</strong> greater benefit the community.Policelink will reduce call volumes <strong>to</strong>Triple Zero (000) at Police CommunicationCentres leaving emergency lines open forthose people who really need it.Policelink 131 444is the number inQueensland <strong>to</strong> reportnon-urgent incidents.Think Policelink, call 131 444 <strong>to</strong> report non-urgent police matters 24 hours a day. Save Triple Zero (000) for emergencies. Currently,95% of calls <strong>to</strong> Triple Zero (000) are non-genuine emergency calls. For more information please visit www.policelink.qld.gov.au8 mine <strong>to</strong> market

Zinc in societyNot many people realise thatzinc goes in<strong>to</strong> many thingsthat we take for grantedeveryday including:• the bodies of the cars we drive,• roofs, gutters, down-pipes and fences on houses,• batteries for <strong>to</strong>ys, calcula<strong>to</strong>rs, watches as well as electricpowered vehicles,• fertilisers <strong>to</strong> help our gardens grow, and• vitamin supplements for better health.Through our day-<strong>to</strong>-day operations we support theproduction of a versatile material that is essential <strong>to</strong> human,animal and crop health and well-being and industry.As a member of the International Zinc Association, we aretaking part in activities <strong>to</strong> raise the awareness about the usesof zinc and zinc-containing products.Did you know?• About 50 per cent of the11 million <strong>to</strong>nnes of zincproduced annually is usedfor galvanising <strong>to</strong> protectsteel from corrosion.• Zinc can be recycled infinitelywithout loss of propertiesor quality.• Over 450,000 children die eachyear due <strong>to</strong> zinc deficiency.For further information on our zinc operations visitwww.mountisamines.com.auXstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sSponsored Apprenticeships 2013Xstrata is offering apprenticeshipopportunities for 2013 in the followingtrade areas:• Electrical• Diesel Fitting• Radio Technician• Boilermaking• Fitter Turning• Au<strong>to</strong> ElectricalThe purpose of sponsored apprenticeshipsAt Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s our focus is on transportable skills,employability and personal development of the individual.The purpose of Sponsored Apprenticeships is <strong>to</strong> provide anopportunity for high-performing existing employees <strong>to</strong> obtain atrade qualification.There are six Sponsored Apprenticeships offered in 2013.Numbers accepted in each trade will be dependent onbusiness needs.mine <strong>to</strong> market9

Celebrating our communitypartnership achievementsCommunityThis April, Ernest Henry Mining (EHM) hosteda dinner <strong>to</strong> celebrate the continued success of ourXstrata Community Program North Queensland.Around 60 guests, includingrepresentatives from ourpartner organisations gatheredat the Cloncurry Bowls Clubwhere we reflected on the significantachievements of our 2011–<strong>2012</strong> partnersand introduced our new <strong>2012</strong>–2013 XstrataCommunity Program North Queensland(XCPNQ) partnerships.Myles Johns<strong>to</strong>n, General ManagerErnest Henry Mining presented a speech<strong>to</strong> highlight the achievements of ourcurrent partnerships and outline ourfuture targets.“Since our partnership program beganin 2005 we’ve contributed more than$4.8 million <strong>to</strong> the Cloncurry communitywith many achievements <strong>to</strong> date that we’reproud <strong>to</strong> be associated with,” Myles said.“Some of our special achievements in2011 include providing more than athousand books <strong>to</strong> primary school studentsat Cloncurry State School and St Joseph’sCatholic Primary School, and the additionof 144 new books for each school’s librarythrough the Books in Homes program.“Our partnership with Cloncurry JusticeAssociation supported the Cloncurry NightPatrol project which assisted close <strong>to</strong>3,000 at risk people in 2011. This projecthelps reduce the number of young peoplepassing through the Criminal JusticeSystem,” Myles said.Two significant miles<strong>to</strong>nes fromprevious partnerships with Cloncurry Shire“Since our partnershipprogram began in 2005we’ve contributed morethan $4.8 million <strong>to</strong> theCloncurry community ...”Council were also highlighted includingthe installation of new shade structuresat Cloncurry Skate Park, the opening ofRobertson Park and our beautificationproject on Cloncurry’s main strip.We are proud <strong>to</strong> introduce our new<strong>2012</strong>–2013 partnership with CloncurryShire Council for the CloncurryCycleways Project. The project involvesthe construction and refurbishment ofpathways in Cloncurry and is expected<strong>to</strong> be completed in 2013.We look forward <strong>to</strong> working with ourpartner organisations in <strong>2012</strong> <strong>to</strong> improvelocal services and facilities and providesupport <strong>to</strong> capacity building initiativesin Cloncurry.Pictured above:Left: Representatives from our local Cloncurryschools accept a sign <strong>to</strong> promote our partnershipunder the Xstrata Community Program NorthQueensland from Myles Johns<strong>to</strong>n, GeneralManager, Ernest Henry Mining.Right: Representatives from Cloncurry State Schoolenjoyed the celebration of our Xstrata CommunityProgram North Queensland.10 mine <strong>to</strong> market

CommunityHelicopterreceives officialchristeningTop: Local community members were excited <strong>to</strong> see the designs on the newCloncurry Community Bus which features local places, people and events.Above: Community members walk through what will be the Art Gallery duringa <strong>to</strong>ur of the Cloncurry Community Precinct’s construction progress.Cloncurry’s two newcommunity projectsOn 30 March, 160 Cloncurry residents attended an eventcelebrating two Cloncurry Shire Council projects, bothsupported by Ernest Henry Mining (EHM).A new community bus was unveiled and a public viewingof construction progress for the Cloncurry Community Precinct <strong>to</strong>okplace at the event, which included a free barbeque.Community members were excited <strong>to</strong> see the new CloncurryCommunity Bus for the first time, which will provide local communitygroups with access <strong>to</strong> transport at a reasonable cost. The 22-seaterbus was purchased with money donated by six locally-basedmining companies including EHM, in addition <strong>to</strong> Cloncurry ShireCouncil funding.Following the bus launch, a guided <strong>to</strong>ur of construction progressfor the Community Precinct <strong>to</strong>ok place where the community couldwalk through each room <strong>to</strong> get a feel for space.The Cloncurry Community Precinct project involves theredevelopment of the library and supper rooms previously locatednext <strong>to</strong> the his<strong>to</strong>ric Shire Hall in the main CBD of Cloncurry. It willalso incorporate a new, modern library, meeting and function rooms,kitchen, amenities and community open space for events as well as anart gallery.Construction is scheduled for completion in <strong>June</strong> this year withan opening expected <strong>to</strong> take place in July. Xstrata has contributed a<strong>to</strong>tal of $2.75 million <strong>to</strong>wards the Precinct, making it our biggest socialinfrastructure project in Cloncurry <strong>to</strong> date and we can’t wait for thecompleted facility <strong>to</strong> be unveiled <strong>to</strong> the public.on April 14, the <strong>Mount</strong> <strong>Isa</strong> communityturned out in droves for the RACQNorth Queensland Rescue HelicopterOpen Day at the Overlander Hotelwhere the state-of-the-art ‘flying hospital’ wasofficially christened.Visi<strong>to</strong>rs enjoyed the community stalls and weregiven the rare opportunity <strong>to</strong> sit in the choppercockpit. Xstrata’s Community Relations team wason site <strong>to</strong> provide the public with information on ourCommunity Program and <strong>to</strong> give away hundreds offree gift bags <strong>to</strong> some very excited local children.The RACQ North Queensland Rescue Helicopterbrings an invaluable service <strong>to</strong> people in need living inremote north Queensland. Additionally the helicopterwill provide our north Queensland operations withvital emergency retrieval capabilities, particularlyimportant for our more remote operations at ErnestHenry Mining and Lady Loretta <strong>Mine</strong>.Early this year, we proudly announced a threeyear,$300,000 partnership with the RACQ NorthQueensland Helicopter Service. Our partnershipwill help <strong>to</strong> ensure this special service stays flying,providing value <strong>to</strong> the <strong>Mount</strong> <strong>Isa</strong> and the north westin<strong>to</strong> the future.Father Mick Lowcock christens the RACQ NorthQueensland Rescue Helicopter.mine <strong>to</strong> market11

SafetyImproving safetyat EHM labThe new au<strong>to</strong>matic furnace atErnest Henry Mining’s Labora<strong>to</strong>ry hasquite literally taken the heat off ourLabora<strong>to</strong>ry Technicians.Kellie Walduck – Labora<strong>to</strong>ry Technician, watches on as thenew au<strong>to</strong>matic furnace breaks down magnetite concentratesamples for analysis at Ernest Henry Mining.Affectionately dubbed ‘Felicia’,the au<strong>to</strong>matic furnace is used<strong>to</strong> break down magnetiteconcentrate samples at a hightemperature so technicians can determinethe trace metal content.Before using the new au<strong>to</strong>maticfurnace, Labora<strong>to</strong>ry Technicians wererequired <strong>to</strong> use <strong>to</strong>ngs <strong>to</strong> manually placemagnetite concentrate samples in and ou<strong>to</strong>f a muffle furnace set at 1,030 degreesCelsius, all while wearing heat proofjackets and gloves. This process exposedLabora<strong>to</strong>ry Technicians <strong>to</strong> extreme heat,acid hazards and created manualhandling issues.Cameron Edinger-Reeve, Labora<strong>to</strong>rySupervisor, Ernest Henry Mining, saysthe au<strong>to</strong>matic furnace has dramaticallyimproved safety and made the process ofanalysing magnetite concentrate simpleand fast.“The machine au<strong>to</strong>matically opensand closes the oven door behind a safetyshield so that Labora<strong>to</strong>ry Techniciansaren’t exposed <strong>to</strong> heat. The samples arecooked and mixed, then poured in moltenform in<strong>to</strong> the waiting solution <strong>to</strong> cool. ”Cameron says.“Use of the au<strong>to</strong>matic furnaceprovides a testing environment thatis easy <strong>to</strong> reproduce, results in higherthroughput and saves time forLabora<strong>to</strong>ry Technicians.”Enhancements <strong>to</strong> Altiris TransactIT & Business Systems will be upgrading<strong>to</strong> a new Altiris help desk system in thethird quarter of <strong>2012</strong>.To complement this upgrade, IT &Business systems have also deployed newAltiris Transact forms.The new Transact forms will includea variety of improvements suggestedby Xstrata personnel <strong>to</strong> increase theefficiency of the teams that processrequests and strengthen compliancewith Xstrata policies.Key features of the new Transact formsand associated processes include:• Requests are not able <strong>to</strong> be submittedunless all prerequisite informationis provided, including a copy of thecompleted Acceptable User Agreement• No processing of a request by theservice desk until the request isapproved online by the managerspecified by Ellipse.It is the reques<strong>to</strong>r’s responsibility <strong>to</strong> ensurethat the request is approved.The new Transact forms and associatedprocesses will also include advising thereques<strong>to</strong>r of all necessary requirementsincluding approvals before the requestcan be submitted <strong>to</strong> the service deskfor processing.• Not allow a request <strong>to</strong> be submittedfor approval unless all data entered inthe Transact form has been validatedwithout errors• Au<strong>to</strong>matically determine theappropriate approving manager basedon the rules described in the DAM andinformation s<strong>to</strong>red in Ellipse• Provide a SharePoint page <strong>to</strong> allowreques<strong>to</strong>rs <strong>to</strong> view all requests that havebeen previously submitted for approval• Au<strong>to</strong>matically notify the approvingmanager by email when a requestrequires approval• Provide a SharePoint page forapproving managers <strong>to</strong> view andapprove or reject requests• Provide a reminder email every threedays <strong>to</strong> reques<strong>to</strong>rs and approvingmanagers of any requests waitingfor approval• Provide advice <strong>to</strong> reques<strong>to</strong>rs on how <strong>to</strong>deal with some of the common issuesthat cause delays such as an approvingmanager going on leave withoutsubmitting an Employee Action Form• Au<strong>to</strong>matically submit a request <strong>to</strong>the service desk after approval by theapproving manager• Provide details of the expected numberof days <strong>to</strong> process a request afterbeing <strong>to</strong> the service desk• Remind the reques<strong>to</strong>r and approvingmanager that any approved requestssubmitted without the necessaryrequirements will be rejected bythe service desk, if this happens thereques<strong>to</strong>r should contact the XQLService Delivery on 07 4744 3932 forassistance in resolving any issues, theReques<strong>to</strong>r has 3 working days beforethe form will be closed.Users will find many helpfuldocuments like FAQ’s and‘What form should I use’?The Altiris Form user guide in the AltirisSelf Help section by going <strong>to</strong> the followinglink <strong>to</strong> the ICT Support page, http://mountisa.copper.xstratanet/isafinance/itbsd/itbssupport/default.aspx12 mine <strong>to</strong> market

Des Marriott’ss<strong>to</strong>ryWhen Ernest Henry Mining’s(EHM’s) open pit mine wascompleted in December2011, around 80 of ouremployees transitioned in<strong>to</strong> new roleswithin our operations. Among those isDes Marriott, one of our newest ProductionDrillers in our underground mine. For Des,setting off on a career adventure has neverbeen more interesting.“I began working in the mining industry13 years ago as a Drilling Contrac<strong>to</strong>rtravelling around Australia <strong>to</strong> variousexploration sites. This is when I first setfoot on the EHM lease. I started workingpermanently in the EHM pit ten years ago.During that time I worked as a Blast HoleDriller, Drill and Blast Coordina<strong>to</strong>r andActing Drill and Blast Supervisor.“As the end of our open pit mine lifeapproached I submitted an expression ofinterest <strong>to</strong> transition in<strong>to</strong> a similar role inour underground mine. I had experiencedunderground mining before, and I waskeen <strong>to</strong> get a permanent feel for theunderground world. I saw the transition <strong>to</strong>an underground Production Drilling role asa valuable opportunity for me <strong>to</strong> use myskills in an exciting and new environment.“I’ve been in my new, underground rolenow for over five months and I’m gettinga feel for the place. Right now, as wellas training <strong>to</strong> operate the long hole rigs,I’m working on the development of themine’s ventilation system and training as aProduction Shot Firer. I’m proud <strong>to</strong> work inan area that plays such a huge part in theongoing development of our new mine,which is so important <strong>to</strong> the sustainabilityof EHM’s operations.“It’s unreal being able <strong>to</strong> work alongsideexperienced underground miners and soakup their on-the-job know-how. Initially itcan take time <strong>to</strong> get your bearings downthere – it’s like a labyrinth, but that’s whatmakes working underground so exciting.There aren’t many people in the world whocan say they work in a maze of tunnels,hundreds of metres beneath the surfaceof the earth. Five months since I started,underground feels like home <strong>to</strong> me andI’m enjoying every minute of it.”“I began working inthe mining industry13 years ago as aDrilling Contrac<strong>to</strong>rtravelling aroundAustralia <strong>to</strong> variousexploration sites.This is when Ifirst set foot onthe EHM lease. Istarted workingpermanently inthe EHM pit tenyears ago. “mine <strong>to</strong> market13

Joe GollingGeneral Manager George Fisher <strong>Mine</strong>Where did you grow up?AIn the “Ruhr Valley” area ofWestern Germany. During myyounger years, this was a bigEuropean coal mining and steel makingcentre – my home <strong>to</strong>wn had five mines,three steel mills and eight breweries. Overthe years, due <strong>to</strong> economic circumstancesthese have disappeared and the areahas had a hard time making the change<strong>to</strong> other industries. My home <strong>to</strong>wn ofDortmund may be better known <strong>to</strong> soccerfans, because BVB 09 Dortmund hasbeaten Bayern Munich five times in a rowover the last two years and is GermanChampion, again!Have you always had an interest in themining industry?Having grown up among all those coalmines, it always attracted my interest. Assoon as I left high school, I did my firstpractice run underground – and neverlooked back. I have been involved inunderground mining ever since. However, Ifound my true calling five years later, whenI made the switch from coal <strong>to</strong> base metalmining – much more interesting!What attracted you <strong>to</strong> work at Xstrata?This is my first job with Xstrata, but I hadfollowed the public float and progressof the company for years. The verticalintegration of the business and its focuson continuously improving its operationsimpressed me. Xstrata’s flat hierarchyenables all levels of management <strong>to</strong>be directly involved in decision makingand taking on responsibility, which I findvery motivating.Prior <strong>to</strong> becoming General Manager atGeorge Fisher <strong>Mine</strong>, what did you do?I went through the ranks of miningoperations from <strong>Mine</strong>r <strong>to</strong> UndergroundManager in Germany, North Africa andAsia. In 1987 I transferred <strong>to</strong> Australia <strong>to</strong>head up a new gold mining operationnorth of Kalgoorlie, Western Australia, untilthe mid nineties. Later, I was ManagingDirec<strong>to</strong>r of a major contracting companyfor many years before I <strong>to</strong>ok the job of<strong>Mine</strong> Manager <strong>to</strong> develop and run theNifty Copper <strong>Mine</strong> in the Great SandyDesert, Western Australia.14 mine <strong>to</strong> market“Being GeneralManager of a bigmine like GeorgeFisher, producing3.5 million <strong>to</strong>nnesper year withabout 1,000Xstrata employeesand contrac<strong>to</strong>rsis a verychallenging job. “How long have you beenworking at Xstrata?In <strong>June</strong> this year I will have workedat Xstrata for two years.What does your current role involve?Being General Manager of a big minelike George Fisher, producing 3.5 million<strong>to</strong>nnes per year with about 1,000 Xstrataemployees and contrac<strong>to</strong>rs is a verychallenging job. There are so many aspects<strong>to</strong> the operation, including technical andpersonnel issues, so you need a verydedicated and skilled team supportingyou <strong>to</strong> be successful in your role. Gettingaround <strong>to</strong> meet people and staying on <strong>to</strong>pof things is keeping me very busy – therenever seem <strong>to</strong> be enough hours in a day!What is the most rewarding part ofbeing General Manager of GeorgeFisher <strong>Mine</strong>?Dealing with people, solving thegeotechnical and mining problems of thisover 30 years old mine and setting GeorgeFisher <strong>Mine</strong> up as a world-class operation.Given the excellent mining reservesavailable, I’m proud <strong>to</strong> be part of the teamthat’s ensuring a great future for the minefor at least another 20 years <strong>to</strong> come.Your title is Dr Joe Golling – what is thebasis of your doc<strong>to</strong>rate?Besides a Master degree in MiningEngineering, I hold a PhD in <strong>Mine</strong>ralEconomics, which relates <strong>to</strong> the evaluation,financing and corporate structuring ofmining projects.Are you a member of, or associatedwith, any industry organisation?I am a member of the AusIMM – AustralianInstitute of Mining and Metallurgy.What is the best thing about living in<strong>Mount</strong> <strong>Isa</strong>?Being home every night with my lovelywife (not often on time, however) andenjoying the (mostly) pleasant weather ofnorth Queensland from our back veranda.Going bush and enjoying the peace andtranquillity of nature is what we like <strong>to</strong> domost in our free time – the area around<strong>Mount</strong> <strong>Isa</strong> is so versatile and interesting,there is always another place <strong>to</strong> explore.The good weather also allows us <strong>to</strong>get out and about in our little Cabriolet,driving <strong>to</strong>p-down and letting the windblow the worries from our minds.In each edition of<strong>Mine</strong> <strong>to</strong> <strong>Market</strong>,we will bring you anup close and personalchat with one of theGeneral Manager’sfrom our business.

Paving the way for<strong>Mount</strong> MargaretRaisingour profilelocally andabroadIn March <strong>2012</strong> members of ourSenior Management Team gavetwo key presentations <strong>to</strong> a broadsec<strong>to</strong>r of mining inves<strong>to</strong>rs acrossAustralia and the Asia Pacific.On 27 March Steve de Kruijff,Chief Operating Officer XstrataCopper North Queensland,presented at one of Asia’smost influential mining industryinvestment conferences <strong>to</strong> over1,700 senior level executives atthe Asia Pacific Mining Congressin Singapore.Steve focused on how we’rechanging our operations <strong>to</strong> securethe business’s future in northQueensland, including excitingprojects such as the <strong>Mount</strong> <strong>Isa</strong>Open Pit pre-feasibility studyand transformation of ErnestHenry Mining <strong>to</strong> an undergroundmining operation.At around the same time, over6,000 kilometres away, MylesJohns<strong>to</strong>n, General ManagerErnest Henry Mining, presentedat this year’s Australian CopperConference, held in Brisbane on the27 and 28 March.Myles shared the s<strong>to</strong>ry of theoperation’s journey since productioncommenced in March 1998, rightthrough <strong>to</strong> its recent transformationfrom an open cut mine <strong>to</strong> anunderground mining operation.The Australian CopperConference brings <strong>to</strong>getherAustralia’s leading players in thecopper mining sec<strong>to</strong>r, highlightingone of the oldest metals usedby man, with arguably thegreatest utility in terms of socialdevelopment.Full-scale works have commenced<strong>to</strong> construct the haul road thatwill connect the <strong>Mount</strong> MargaretMining (MMM) project’s E1 coppertenement <strong>to</strong> Ernest Henry Mining (EHM).Constructed over the next threemonths, the haul road will allow us <strong>to</strong>truck ore mined at E1 eight kilometreseast <strong>to</strong> EHM for processing in our existingconcentra<strong>to</strong>r facility.John Twomey, Project Direc<strong>to</strong>r, says thecommencement of haul road constructionis an important miles<strong>to</strong>ne that bringsMMM one step closer <strong>to</strong> production, whichis scheduled <strong>to</strong> begin in the second halfof <strong>2012</strong>.“We have already completed about2.5 kilometres of road developmen<strong>to</strong>n our existing mining lease. With therequired environmental approvals finalised,we’re now constructing the remaining5.5 kilometres,” John says.“Preparations are also underway for theinstallation of office buildings, workshops,amenities and other facilities at E1 over thecoming months.”“Our project team has workedtirelessly throughout the initialplanning and approval stagesand can feel proud that themore major and visible outputsare coming <strong>to</strong> fruition as aresult of their efforts.”“We expect <strong>to</strong> commence pre-stripworks for the E1 North open pit minein the next few months and are lookingforward <strong>to</strong> commencing production soonafter that.”A haul truck tips waste material <strong>to</strong> be used as sub-base for the neweast-west haul road being constructed between Ernest Henry Miningand the E1 tenement. You can see <strong>Mount</strong> Margaret in the distance.mine <strong>to</strong> market15

Graduate Environmental Advisor Ryan Francisand EHM Environmental Advisor Alinta Orrinspect rehabilitation works on our southernwaste rock dump earlier this year.Rehabilitationshowing goodgrowth ratesErnest Henry Mining’senvironmentalteam is proud of thehealthy progress ofthe most recentlycompleted stage ofour ongoing landrehabilitation program.Between November 2011 andJanuary <strong>2012</strong>, Ernest Henry Mining(EHM) successfully completedrevegetation works across our vast2011 target area. Last year, 50 hectares ofland within the footprint of the EHM leasewas planted with local grass species.The area encompassed the southern wasterock dump, with sections of our northernwaste rock dump and a black soil s<strong>to</strong>ckpilealso completed.Six months on, Ryan Francis, GraduateEnvironmental Advisor, Ernest HenryMining, is pleased with the renewed healthof the rehabilitated areas.“We planted bull, curly and barleymitchell grasses, red flinders grass, aswell as native cooch and golden beardgrass in line with the requirements of ourEnvironmental Authority,” Ryan says.“All of the species are native <strong>to</strong> ourlocal area and the rehabilitation is comingalong well, with the grasses reaching up <strong>to</strong>a metre in height.”Consultants from the University ofQueensland’s Centre for <strong>Mine</strong>d LandRehabilitation (CMLR) visit our site annually<strong>to</strong> conduct our Rehabilitation Moni<strong>to</strong>ringProgram. Their next visit is scheduled for<strong>June</strong> this year.“The CMLR consultants use sitesundisturbed by mining as a reference point<strong>to</strong> study the progress and health of ourrehabilitated areas,” Ryan says.“Our last report showed the vegetationplanted over the past eight years is wellestablished with soil quality supportinglong-term growth.”To date, EHM has completed morethan 240 hectares of rehabilitation works,demonstrating our commitment <strong>to</strong>sustainable mining and maintaining theenvironmental health of the region in<strong>to</strong>the future.Change <strong>to</strong>environmentallyfriendly degreasersFollowing the successful trial ofBowers’ Citrus Extreme and BlackMagic degreasers at the George Fisherworkshops in late 2011, we have madethese available across our <strong>Mount</strong> <strong>Isa</strong>mining operations.These new degreasers providesignificant benefits, including improvementsin the demulsification of our oil/watersepara<strong>to</strong>rs, superior environmentalperformance and lower pH levels.Citrus Extreme and Black Magic areheavy duty, biodegradable, quick-breakdegreasers for removal of grease, oils andother industrial soiling from machineryparts, engines and workshop floors.16 mine <strong>to</strong> market

Sink underwayfor new hoisting shaftThe anticipation was palpable at Ernest Henry Mining on10 <strong>May</strong> as sinking works commenced for our new ore hoistingshaft. The shaft will allow an increase in underground miningproduction at three times the current rate.Ernest Henry Mining (EHM)transitioned from open pit mining <strong>to</strong>underground mining in December2011. Following the successful shaftpre-sink last year, this final stage of sinkingworks marks a significant miles<strong>to</strong>ne in our$589 million project which will extend thelife of our operations <strong>to</strong> at least 2024.Myles Johns<strong>to</strong>n, General ManagerErnest Henry Mining, says the sevenmetre wide shaft will be sunk <strong>to</strong> adepth of around 1,000 metres overthe next 12 months, with fit-out andcommissioning works <strong>to</strong> follow.“We are currently trucking ore fromour underground mine via a decline at arate of about two million <strong>to</strong>nnes per year,increasing <strong>to</strong> three million <strong>to</strong>nnes per yearby the end of <strong>2012</strong>,” Myles says.“At this point in our operation, wewill be producing around 25,000 <strong>to</strong>nnesof copper and 35,000 ounces of gold inconcentrate per year.“Following the commissioning ofthe shaft in 2013, production will rampup <strong>to</strong> six million <strong>to</strong>nnes of ore per year,producing 50,000 <strong>to</strong>nnes of copper and70,000 ounces of gold in concentrate,”he says.“I would like <strong>to</strong> congratulate the teamfor their tireless work <strong>to</strong> date <strong>to</strong> advancethe project <strong>to</strong> this stage and encourage allinvolved <strong>to</strong> maintain your focus so we cancomplete the shaft sink safely and <strong>to</strong> plan,”he says.Over the last year we have installed andcommissioned key pieces of infrastructure,including six winders and a 28 metre tallsky-shaft. This equipment will allow sinking<strong>to</strong> progress at rates of up <strong>to</strong> three metresper day.Steve de Kruijff, Chief Operating OfficerXstrata Copper North Queensland saysour shaft underground project is playingan important role in sustaining our northQueensland operations which providesignificant economic benefits for theregion and the state of Queensland.“Our $589 million investment in thisproject extends the life of our ErnestHenry operations by at least 12 years,creating 330 jobs during the constructionphase and 400 full-time jobs from 2013,providing ongoing economic security forCloncurry,” Steve says.Pictured aboveLeft: Contrac<strong>to</strong>rs work <strong>to</strong> install a winder inpreparation for shaft sinking.Right: Over the past year key pieces ofinfrastructure, including a 28 metre tallsky-shaft and six winders, have been installedand commissioned alongside the completedopen pit mine at Ernest Henry Mining inpreparation for shaft sinking.mine <strong>to</strong> market17

SafetyMICO ContinuousImprovementideas roll inBruce Shevelling, MaintenanceCoordina<strong>to</strong>r, Mobile FleetMaintenance has successfullydesigned a ContinuousImprovement (CI) initiative, improvingboth operational and financialperformance within his department.Bruce says the initiative, titled ‘InstallFilter <strong>to</strong> Hydraulic Oil Fill Line’, hasreduced the need <strong>to</strong> replace hydraulicoil filler pumps on undergroundequipment such as Toro Loaders andTamrock and Atlas drill rigs.“I identified that a number of Unitswere experiencing down time due <strong>to</strong>hydraulic oil filler pump failures as aresult of contamination of oil during<strong>to</strong>p ups,” Bruce says.“By installing filters at a cost of$350, the number of pump failures hasreduced significantly.“After installation, a filter onlyneeds <strong>to</strong> be changed once a yearwhich costs $150 as opposed <strong>to</strong>replacing an entire pump system at acost of $1,500,” he says.Bill Dearling, Reliability Engineer,recognises the positive effect Bruce’sCI idea has had on operations.“Since the installation of thesefilters there has been a noticeabledecrease in the number of pumpsrequiring replacement,” Bill says.Continuous ImprovementSuperintendent Bill Cook says Bruce’sidea is evidence that even simpleinitiatives can make a significantdifference in how we do our jobsor how we improve our job safety,processes and efficiencies.“In Continuous Improvement weare constantly looking for ideas <strong>to</strong>assist in life of mine sustainability,”Bill says.“We know there are many moreof these ideas out there and we aretrying <strong>to</strong> ensure we can capture themthrough the CI process.“Anyone who has an idea shouldask their Supervisor or contact aContinuous Improvement Advisorfor assistance in ensuring their ideais placed in their department’s CIregister,” he says.As recognition of his idea’simplementation Bruce receiveda $250 gift voucher.Bruce Shevelling’s Install Filter <strong>to</strong> Hydraulic Oil Fill Line Continuous Improvement initiative“Since the installation of these filtersthere has been a noticeable decreasein the number of pumps requiringreplacement,” Bill says.18 mine <strong>to</strong> marketThe CO 2 REProjectIn April this year, 46 Xstrata Copper employeesvolunteered <strong>to</strong> take part in a groundbreakingstudy that looks <strong>to</strong> shake-up theway Respira<strong>to</strong>ry Protective Devices (RPDs) aredesigned, tested and used.Conducted by the University of Wollongong,the aim of the CO 2 RE study was <strong>to</strong> betterunderstand the level of carbon dioxide (CO 2 ) rebreathingthat occurs naturally in respira<strong>to</strong>rs undera range of work conditions.CO 2 re-breathing occurs when expired airremains in the breathing space of the respira<strong>to</strong>rafter each breath. Inhalation of CO 2 causeschanges in the concentration of CO 2 in theblood which can affect an individual’s respira<strong>to</strong>ryprocesses, even in small amounts.There is evidence that increased exposure <strong>to</strong>CO 2 can cause RPD wearer discomfort, which isone of the primary reasons why people removerespira<strong>to</strong>rs during work. Removal increases theworker’s risk of exposure <strong>to</strong> potentially dangerousair-born particles, which is why finding a solution <strong>to</strong>wearer discomfort is important <strong>to</strong> us at Xstrata.Until now, no comprehensive scientific studyhas focused specifically on the effects of speakingtasks on CO 2 in respira<strong>to</strong>rs. In addition <strong>to</strong> this,many studies on CO 2 re-breathing are limited bysample sizes of less than ten participants.Participation in the CO 2 RE study was open <strong>to</strong>Xstrata Copper employees who were familiar withthe regular use of RPDs. The 46 volunteers <strong>to</strong>okpart in a graded exercise test on an stationary bikethat increased in resistance every five minutes. Atthe third minute of each stage participants reada passage of text out loud. Measures of expiredand inspired CO 2 , heart rate, breathing frequency,peak inspira<strong>to</strong>ry air flow and dyspnoea, orbreathing discomfort, were moni<strong>to</strong>red.Carmen Smith, Exercise Physiologist andPrincipal Investiga<strong>to</strong>r says data analysis for the 40Xstrata participants that completed all the testsequences is currently underway.“The preliminary results show that speech andparadoxically low exercise workloads compoundCO 2 accumulation in respira<strong>to</strong>rs,” Carmen says.The project was coordinated by Kristie Davies,Graduate Occupational Hygienist, Xstrata <strong>Mount</strong><strong>Isa</strong> <strong>Mine</strong>s. Kristie would like <strong>to</strong> thank the volunteersand management team of the Copper Smelter fortheir involvement in the study.“This was a real opportunity for our people <strong>to</strong>have an influence on the design and use of RPDs.The findings of this study will have significantramifications for RPD pro<strong>to</strong>cols in<strong>to</strong> the future,so thank-you <strong>to</strong> those who <strong>to</strong>ok the time <strong>to</strong> getinvolved,” Kristie says.

SafetyJoel Edson – Xstrata North QueenslandOccupational Therapist, conducting aManual Task Risk Assessment of ShayneDunbar – Anode Production Supervisor.Manual Task RiskAssessment made easyXstrata’s Sustainable Development Department has developed aninnovative manual task assessment <strong>to</strong>ol <strong>to</strong> help workers identify highrisk manual tasks in the workplace and implement appropriatecontrols <strong>to</strong> reduce these risks.Manual tasks are our numberone cause of work-relatedinjury. In an effort <strong>to</strong> reducethe risk of injury associatedwith performing manual tasks, we havedeveloped a <strong>to</strong>ol called the Manual TaskRisk Assessment (MTRA), which calculatesimmediately the injury risk based on thephysical requirements and exposure <strong>to</strong> amanual task.Three types of MTRA <strong>to</strong>ols are availablefor workers <strong>to</strong> use• An electronic version located onXstrata Copper’s Safety and HealthDepartment Intranet page, the XstrataZinc homepage and Ernest HenryMining’s homepage• Wall mounted MTRA <strong>to</strong>ols locatedin crib rooms, training areasand workshops• Desk-sized MTRA <strong>to</strong>olsTo use the MTRA the opera<strong>to</strong>r simplyidentifies the weight being handled or thespeed of movement, postural requirementsand repetition for performing a task. Theopera<strong>to</strong>r moves the appropriate dials onthe assessment <strong>to</strong>ol, and then the MTRAindicates a risk level associated withperforming that task. The opera<strong>to</strong>r canthen consider control options <strong>to</strong> decreasethe risk for this task based on the riskfac<strong>to</strong>rs identified.Joel Edson, Occupational Therapist,Xstrata North Queensland, says the MTRAhas received positive feedback from theworkers who trialled the <strong>to</strong>ol during 2011.“Following months of development andtrials we have now refined the <strong>to</strong>ol and itsdesign based on the feedback received,”Joel says.Our General Managers, Managersand Superintendents have endorsed theassessment <strong>to</strong>ol further demonstratingour organisational commitment <strong>to</strong> themanagement of Manual Task Risk.“Support received from all levels ofthe organisation demonstrates a clearacknowledgement of Manual Task Risk anda commitment <strong>to</strong> supporting initiativesaimed at risk mitigation and control. It hasbeen broadly acknowledged that this <strong>to</strong>olhas addressed a previously unmet needin a simple, innovative and effective way,”Joel says.Specific areas of Xstrata’s NorthQueensland Copper and Zinc Operationshave been involved in the initial roll out ofthe mechanical versions which commencedin <strong>May</strong> <strong>2012</strong>, with further development <strong>to</strong>occur based on evaluation and feedbackreceived over the coming months.For more information on the ManualTask Risk Assessment <strong>to</strong>ol contact yourSafety Advisor or Xstrata’s OccupationalTherapist Joel Edson.mine <strong>to</strong> market19

CommunityBravehearts Mow-a-thongets a $5,000 kick startChief Operating Officer Steve de Kruijffdonates <strong>to</strong> Bravehearts IncOn April 16 Claude Harvey,Bravehearts Inc. representativeand committed fundraiser,commenced a 77 day, 2,260kilometre Mow-a-thon which <strong>to</strong>ok him fromoutback <strong>Mount</strong> <strong>Isa</strong> <strong>to</strong> the beaches of theGold Coast.For the past nine years, 66-year-oldClaude has devoted his time <strong>to</strong> theBravehearts cause, raising over $350,000for Australia’s leading child protectionadvocacy charity.We were pleased <strong>to</strong> kick off Claude’sfundraising efforts with a $5,000 cheque,presented by Steve de Kruijff, ChiefOperating Officer Xstrata CopperNorth Queensland, on day one of hisepic journey.“Pushing a lawn mower from <strong>Mount</strong> <strong>Isa</strong><strong>to</strong> the Gold Coast is an amazing feat andwe were more than happy <strong>to</strong> be able <strong>to</strong>assist in Claude’s fundraising journey with a$5,000 donation,” Steve says.“Our donation will be used in aidingchild abuse prevention, education andcounselling programs.“This is Claude’s ninth year raisingmoney for Bravehearts and we weredelighted he decided <strong>to</strong> start his biggestcampaign <strong>to</strong> date in <strong>Mount</strong> <strong>Isa</strong>,” he says.Bravehearts currently providescounselling services <strong>to</strong> hundreds ofchildren and families across Australiaat a cost of nearly half a million dollarsper year.“Pushing a lawn mowerfrom <strong>Mount</strong> <strong>Isa</strong> <strong>to</strong> theGold Coast is an amazing featand we were more thanhappy <strong>to</strong> be able <strong>to</strong> assist inClaude’s fund raising journey.”Workplace GivingXstrata’s Workplace Giving Program isa simple way for employees <strong>to</strong> makeregular donations <strong>to</strong> selected localcommunity organisations and charitiesvia au<strong>to</strong>mated deduction from yourfortnightly or monthly pay.Last year, our employees donated over $49,000 <strong>to</strong> the11 community groups participating in workplace giving.While this is a fantastic result, we think we could bedoing more.Over the next few months we will be revitalising ourWorkplace Giving program, and you will see features on eachpartner appearing regularly in <strong>Mine</strong> <strong>to</strong> <strong>Market</strong>, <strong>to</strong>gether with aform you can complete and send back <strong>to</strong> us if you would like <strong>to</strong>start supporting these local groups.This edition we have featured the North QueenslandHelicopter Rescue Service. Learn more about this group and thevital service they provide <strong>to</strong> north-west Queensland through ourarticle featured on page 11.If you would like <strong>to</strong> find out more about how <strong>to</strong> donatethrough our Workplace Giving Program, contact your HR Advisorand keep an eye on future editions of <strong>Mine</strong> <strong>to</strong> <strong>Market</strong> for furthernews on our program partners.20 mine <strong>to</strong> market

Tony Ruddell’s s<strong>to</strong>ryTony Ruddell, Project Manager for Xstrata Technologyin Townsville knows what it’s like <strong>to</strong> be confronted bya sudden and unexpected change <strong>to</strong> ‘the plan’.In 1994, then Maintenance–Boilermaker,Townsville Copper Refinery, Tony wasriding his mo<strong>to</strong>rbike home from workwhen a drunk driver, attempting <strong>to</strong>overtake another vehicle, collided head-onin<strong>to</strong> him. Suffering a compound fracture<strong>to</strong> his femur, shattering his fibula and tibiaand fracturing his ankle and heal, Tony had<strong>to</strong> have his legs pieced back <strong>to</strong>gether by ateam of surgeons before embarking on anexcruciating six-week recovery. But, in life’sever-unpredictable fashion, that terrifyingordeal would prove <strong>to</strong> be a pivotalmoment that would steer Tony’s careerdown a very different path.“During my six week recovery period– <strong>to</strong>tally over watching daytime televisionand getting more and more frustrated withmy incapacitation – I called the refineryhoping they’d let me come back <strong>to</strong> work.I would have done anything if it meant I’dbe out of the house.“With a ‘we will see what we can do’from my boss, light duties in the DrawingOffice were organised and, as theysay, the rest is his<strong>to</strong>ry. I had started mycareer at the refinery as an apprenticeboilermaker, and now I was kissing mytrade goodbye. Armed with little morethan my determination and on-the-jobknow-how, I went back <strong>to</strong> TAFE and thenJames Cook University <strong>to</strong> receive mydrafting qualifications.“Almost ten years later, I’m back in onepiece and busy confronting the challengesassociated with the expansion of XstrataTechnology’s ISA Process, which has anincreasingly global focus. This means Ispend a lot of time travelling the world <strong>to</strong>commission new plants. While it is difficultbeing away from my family – especiallymy kids – I get <strong>to</strong> see parts of the planetmany people would never even dream ofvisiting. I love immersing myself in newcultures and interacting with people whosee the world differently.“Everyone can start aproject; not everyone cancomplete it – that’s thechallenge. Who wouldhave thought I had it inme <strong>to</strong> become a draftsman?I am so grateful <strong>to</strong> mycolleagues for their supportduring my recovery andcareer transition – MikeMurphy, who drove me<strong>to</strong> and from work, thedraftsmen who let me invade their domain,Gordon Ellacott, my on the job men<strong>to</strong>rand Brian Young, my old maintenancedepartment foreman, who let me go so Icould take on this challenge. That’s the bestthing about Xstrata – the people.”“Everyone can start aproject; not everyonecan complete it –that’s the challenge.I am so grateful forthe support I havereceived from mycolleagues. That’sthe best thing aboutXstrata – the people.”mine <strong>to</strong> market21

<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s treasureAlf Cianetti retires after 57 yearsAlf Cianetti with his beloved wife, Carla.In 1953 Alf and his family boarded apassenger ship from Livorno, an iconic,16th century harbour city on the westcoast of Tuscany, Italy. Bound for atiny, north west Queensland mining <strong>to</strong>wnhundreds of kilometres from any ocean, thishard working immigrant from the shores ofthe Tyrrhenian Sea would soon become oneof <strong>Mount</strong> <strong>Isa</strong>’s most treasured characters.This year, Alf will retire after 57 yearsof service <strong>to</strong> Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s. Here,we pay tribute <strong>to</strong> one of the charactersthat make up the fabric of our his<strong>to</strong>ry,Alf Cianetti.Alf Cianetti has the proud stance of ageneration of immigrants who helped pullAustralia from its post-war depression. At76, and still as spritely as ever, Alf’s careerwith <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s began in 1956, where,with limited English and still adjusting <strong>to</strong> lifein the Australian outback, he commencedwork at the mine. After 36 years at theMobile Fleet Workshop, Alf joined themaintenance team at the copper smelter in1998, where he works <strong>to</strong> this day.Built on the site of the original workshopdepot, Alf nods in the direction of thecopper smelter and jokes how little he’stravelled since 1953.With a love of the outdoors, Alf spendsmuch of his downtime fishing. But ask himabout the best thing he’s ever caught, andbe met with a wry, charismatic smile. Hiswife Carla – who he met on a return trip<strong>to</strong> Europe in 1961 and married a mereeight weeks later – is the catch of his life,he says.“When you know what you want,well that’s it, you know?” Alf says.Married on 25 January, 1962, Carlaand Alf welcomed their son Emilio in<strong>to</strong>the world a year later. A civil engineerand department direc<strong>to</strong>r with the <strong>Mount</strong><strong>Isa</strong> City Council, Emilio is continuing hisfather’s legacy in the <strong>to</strong>wn Alf admits“has a hold on him”.In a career spanning almost60 years, Alf has witnessed <strong>Mount</strong> <strong>Isa</strong>’stransformation from little more than anetwork of miner’s camps <strong>to</strong> a thrivingand diverse community. He can tell youof times past when men would brawl inthe dust behind the <strong>Mount</strong> <strong>Isa</strong> Hotel, thenshake hands and head inside for a laughand drinks shouted by then <strong>Mount</strong> <strong>Isa</strong><strong>Mine</strong>s Chairman Sir George Fisher. Heremembers the union strikes of the ‘60sthat brought the mine and the state ofQueensland <strong>to</strong> its knees, and recalls thedays when depressed metal prices forceda diaspora of redundant mine workers andsaw the <strong>to</strong>wn’s population plummet <strong>to</strong> lessthan 17,000. Alf has experienced <strong>Mount</strong><strong>Isa</strong>’s cultural and economic evolution; as<strong>to</strong>ry not only of struggle and adversity bu<strong>to</strong>f spirit, camaraderie and success againstthe odds.Paul Telford, General Manager CopperSmelter, Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s, says Alf’scareer longevity is an inspiration.“Throughout his long career with us,Alf has made a marked contribution <strong>to</strong> ouroperations,” Paul says.“He played a key role in improving thecopper smelter equipment lubricationstrategy, resulting in improved reliabilitywith rotating equipment he maintains.“Alf’s dedication <strong>to</strong> his role isinspirational <strong>to</strong> all of us here at the CopperSmelter. He will be sorely missed by allwho had the pleasure of working alongsidehim, but we wish him and Carla all the bestfor a well-earned retirement.”Congratulations Alf, ona remarkable career.22 mine <strong>to</strong> market