Treater Valves - Home | Kimray Mobile

Treater Valves - Home | Kimray Mobile

Treater Valves - Home | Kimray Mobile

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

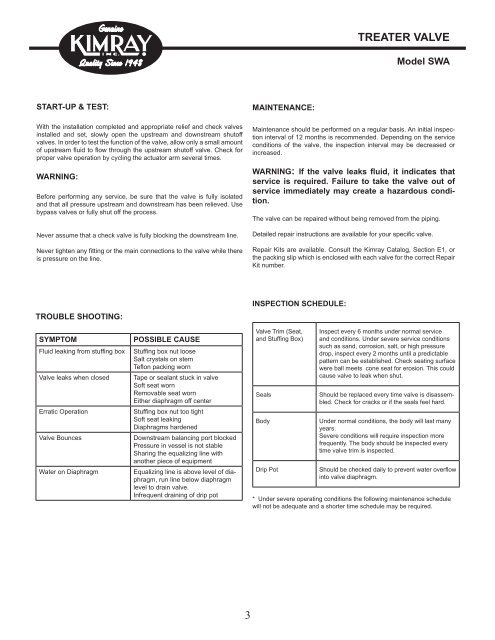

TREATER VALVEModel SWASTART-UP & TEST:With the installation completed and appropriate relief and check valvesinstalled and set, slowly open the upstream and downstream shutoffvalves. In order to test the function of the valve, allow only a small amountof upstream fluid to flow through the upstream shutoff valve. Check forproper valve operation by cycling the actuator arm several times.WARNING:Before performing any service, be sure that the valve is fully isolatedand that all pressure upstream and downstream has been relieved. Usebypass valves or fully shut off the process.Never assume that a check valve is fully blocking the downstream line.Never tighten any fitting or the main connections to the valve while thereis pressure on the line.MAINTENANCE:Maintenance should be performed on a regular basis. An initial inspectioninterval of 12 months is recommended. Depending on the serviceconditions of the valve, the inspection interval may be decreased orincreased.WARNING: If the valve leaks fluid, it indicates thatservice is required. Failure to take the valve out ofservice immediately may create a hazardous condition.The valve can be repaired without being removed from the piping.Detailed repair instructions are available for your specific valve.Repair Kits are available. Consult the <strong>Kimray</strong> Catalog, Section E1, orthe packing slip which is enclosed with each valve for the correct RepairKit number.TROUBLE SHOOTING:INSPECTION SCHEDULE:SYMPTOMFluid leaking from stuffing boxValve leaks when closedErratic OperationValve BouncesWater on DiaphragmPOSSIBLE CAUSEStuffing box nut looseSalt crystals on stemTeflon packing wornTape or sealant stuck in valveSoft seat wornRemovable seat wornEither diaphragm off centerStuffing box nut too tightSoft seat leakingDiaphragms hardenedDownstream balancing port blockedPressure in vessel is not stableSharing the equalizing line withanother piece of equipmentEqualizing line is above level of diaphragm,run line below diaphragmlevel to drain valve.Infrequent draining of drip potValve Trim (Seat,and Stuffing Box)SealsBodyDrip PotInspect every 6 months under normal serviceand conditions. Under severe service conditionssuch as sand, corrosion, salt, or high pressuredrop, inspect every 2 months until a predictablepattern can be established. Check seating surfacewere ball meets cone seat for erosion. This couldcause valve to leak when shut.Should be replaced every time valve is disassembled.Check for cracks or if the seals feel hard.Under normal conditions, the body will last manyyears.Severe conditions will require inspection morefrequently. The body should be inspected everytime valve trim is inspected.Should be checked daily to prevent water overflowinto valve diaphragm.* Under severe operating conditions the following maintenance schedulewill not be adequate and a shorter time schedule may be required.3