PRESTRESSED CONCRETE FLOORS : A Far ... - Freyssinet

PRESTRESSED CONCRETE FLOORS : A Far ... - Freyssinet

PRESTRESSED CONCRETE FLOORS : A Far ... - Freyssinet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

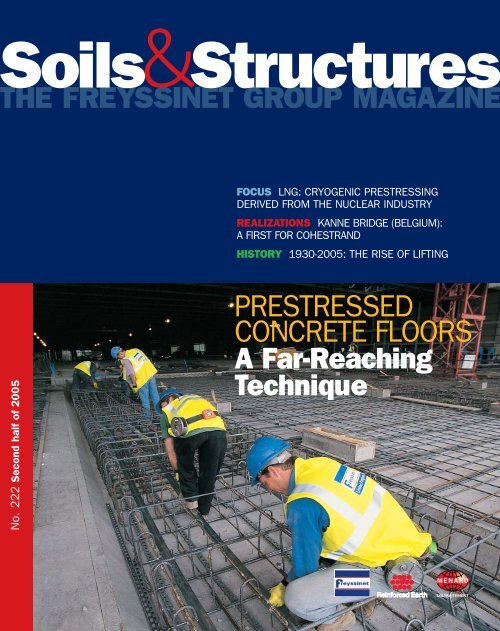

oils&StructuresHE FREYSSINET GROUP MAGAZINEFOCUS LNG: CRYOGENIC PRESTRESSINGDERIVED FROM THE NUCLEAR INDUSTRYREALIZATIONS KANNE BRIDGE (BELGIUM):A FIRST FOR COHESTRANDHISTORY 1930-2005: THE RISE OF LIFTINGNo. 222 Second half of 2005<strong>PRESTRESSED</strong><strong>CONCRETE</strong> <strong>FLOORS</strong>A <strong>Far</strong>-ReachingTechnique

P A N O R A M ACONTENTSPANORAMAACTIVITY AND LIFE IN THE GROUPTHE WORLD IN BRIEF 2CLOSE UPSUNGAI PRAI, READY FOR SERVICE 6FOCUSLNG: CRYOGENIC PRESTRESSING DERIVEDFROM THE NUCLEAR INDUSTRY 8REPORT<strong>PRESTRESSED</strong> <strong>CONCRETE</strong> <strong>FLOORS</strong>A <strong>Far</strong>-ReachingTechnique 10REALIZATIONSKANNE BRIDGE(BELGIUM) 16MBABANE BY-PASS(SWAZILAND) 18MONDRAGON PLATFORM(FRANCE) 19MIRAGE TOWERS(MEXICO) 19NUCLEAR CONTAINMENT VAULTS(INDIA, CHINA, FINLAND) 20CALARASI PLATFORM(ROMANIA) 21KWANG YANG PLATFORM(SOUTH KOREA) 22THE LA SIOULE VIADUCT(FRANCE) 23SAINT-CHÉRON RAIL BRIDGE(FRANCE) 24KONIN BRIDGE(POLAND) 25GAEGOK BRIDGE(SOUTH KOREA) 25BAI CHAY BRIDGE(VIETNAM) 26OUR PROFESSIONCMC OPERATOR: CONSTANTVIGILANCE 27COMPANYA COMPREHENSIVE OFFERINGIN SOUTH KOREA 28HISTORYTHE RISE OF LIFTING 30Prestressing Bars andCables on the TrackBelgium. The Belgian high speed rail network is beingextended and four new viaducts crossing severaldeep valleys on the line between Liège and theGerman border have just been completed.Between December 2004 and May 2005,<strong>Freyssinet</strong> Belgium contributed to theconstruction of these structures bysupplying and installing 650 prestressingbars to connectsupports and beams and1,200 t of cable (13C15,19C15) in the supports,beams and sub-ballastslabs.Know-howon the AgendaTurkey. On 31 May and 1 June last,under the respective chairmanship ofProfessor Erhan Karaesman and EmreAykar, Managing Director of Yapi Merkesi,<strong>Freyssinet</strong> International and C o . andFreysas, the Group’s Turkish subsidiary,organized two conferences in Ankaraand Istanbul on long span bridge designand associated construction methods.Around 200 people attended presentationsby Michel Virlogeux, Benoît Lecinq andJérôme Stubler at the conferences.Natural Panelsat the ZooSpain. The architects of the new Valencia Zoochose Reinforced Earth for the structures markingthe boundaries of the park’s different areas.Tierra Armada SA is currently building13,600 m 2 of separating walls for the project.These will be clad with imitation stone panelsdecorated with themes inspired by the jungle.2 Soils & Structures Second half of 2005

PANORAMAThird TechSpan ArchStructureUnited Arab Emirates. 150 km west of Doha on the UmmBab-Salwa road, Reinforced Earth is working on the third site touse TechSpan prefabricated arches in Qatar. They are buildinga structure using 8 elements, each with an opening of 13 metresand a length of 34 metres. At each outlet the tunnel walls willbe given a Freyssisol facing.Successfor CMCsUnited-States. Withits proposal for a controlledmodulus column (CMC)soil treatment solution,DGI-Menard (<strong>Freyssinet</strong>)was awarded the contractfor works prior to theconstruction of a servicestation at Monongahelain Pennsylvania, whichit carried out during thesummer. Followingcompletion of the work,during which 135 CMCswere installed, thecompany won a newcontract of the same typein the Washington area.LandscapeIntegrationSpain. On the island of Tenerife inthe Canaries, two 5,580 m 2 and 1,312 m 2tiered retaining walls, designed by TierraArmada (<strong>Freyssinet</strong>), were built duringwidening works on the Tf-142 coastal roadbetween El Guincho and Icod. Particulararchitectural care was taken over the facingpanels for the two structures in order toensure perfect integration into theenvironment.ExternalPrestressingRussia. Since the beginningof June, <strong>Freyssinet</strong> has beensupplying and installingexternal prestressing for thesteel roof of a new ice rinkin Kolomna, near Moscow.The saddle roof is 250 m longand 150 m wide.3,600 tonnesof PrestressingUnited Arab Emirates. <strong>Freyssinet</strong> Gulf hasjust won the contract to supply and installthe prestressing (3,600 t) for the Ras AlKhor Bridge.Connecting the mainland part of Dubai to an11-kilometre long peninsula separated fromit by a sea inlet, the structure comprises twodecks providing six new traffic lanes andis made up of 8 spans, each with a lengthof 60 m.Supplyand SupportMorocco. Since February 2005, <strong>Freyssinet</strong>has been providing technical supporton the new Casablanca to El-Jadidamotorway to Moroccan company SGTM,which is building the bridge over theOum er-Rebia. Comprising two parallel500 m long decks made up of segmentscast in situ, this cantilevered structurewill carry four lanes of traffic. <strong>Freyssinet</strong>is supervising the construction workand has supplied two pairs of mobile rigsas well as the prestressing and worksequipment.Second half of 2005 Soils & Structures 3

P A N O R A M AReinforced Earthon the Rome Ring RoadItaly. Having carried out the design work, Terra Armata issupplying the materials for several retaining walls for Rome’snew ring road.Measuring up to 14 m in height and 350 m in length, theseMSE structures use two types of facing, namely conventionalTerraClass cruciform concrete panels and TerraTrel welded mesh.Prestressing forFour Gas Storage TanksIran. With an area of over 1,300 km 2 , the South Pars fieldin the Persian Gulf is one of the world’s largest natural gasdeposits and its development means that ground installationsneed to be constructed regularly. Four storage tanks arecurrently being built, two with a volume of 55,000 m 3for propane storage and two with a volume of 45,000 m 3 forbutane. <strong>Freyssinet</strong> has supplied and installed all of theprestressing for these four structures (900 t) and more than1,100 anchors.FIB Symposium 2005Hungary. <strong>Freyssinet</strong> and Pannon <strong>Freyssinet</strong>, the Group’sHungarian subsidiary, took part together in the FIB(federation internationale du béton - international federationfor structural concrete) symposium held between 23 and25 May in Budapest on the theme “Keep concrete attractive”.As well as presenting its most recent worldwide achievementswith special emphasis on those in Eastern Europe, theGroup also took part in the conference with a noteworthypresentation by Benoît Lecinq on the Kanne SuspensionBridge in Belgium and the use of the Cohestrand strand.50m-LongSpanSouth Korea. Equippedwith an MSS (movablescaffolding system) typeself-launching truss,<strong>Freyssinet</strong> Korea is buildingboth parallel decks of theHwaebuk 1 (520 x 12.15 m) and Hwaebuk 2 (300 x 12.15 m)motorway bridges between the localities of Chungwon-gun andChungcheongbuk-do in the east of the country. The 60 m-longtruss, which weighs 200 t, allows for each 50 m-long prestressedspan to be completed in just 35 days.High LinkMexico. The construction of a 365 m long bridge has just beencompleted near Texcapa on the Mexico City to Tuxpan motorway.The bridge deck is more than 100 m high at its highest point.Present at the site since December 2003, <strong>Freyssinet</strong> Mexicohandled the design and supply of the mobile rigs, expansion jointsand installed the prestressing.4 Soils & Structures Second half of 2005

PANORAMAInspired FacingUnited States. Thetown of Castle Rock(Colorado) has justseen the completionof a road bridgecrossing a railwaytrack and a roadintersection.Designed by the municipal authorities andconsulting engineers in consultation withthe inhabitants, the structure includes facinginspired by the rock pattern typical of theregion so that it blends into its environment.Reinforced Earth was given the job ofdesigning and supplying materials for theretaining walls. The company reproduced thepattern on the facing panels in six differentvariations. These were then arranged atrandom over the entire structure in order toreproduce the irregular appearance of therock as closely as possible.750 t of Prestressingfor a ViaductHungary. In March 2006, Pannon <strong>Freyssinet</strong>,the Group’s Hungarian subsidiary, will beginthe installation of 750 t of internalprestressing for the Köröshegy viaduct.Located between Zamardi and Balatonszaszo,120 km south west of Budapest, this newstructure, which will carry the M7 motorway,is 1,800 m long and has 17 spans, the highestof which are 88 m at their highest points.On the MoracaRiverMontenegro. After commencing inMay 2005, the installation of the staycables on the Millennium Bridge,near Podgorica, was completed atthe beginning of the summer and thestructure was inaugurated on 13 Julylast. <strong>Freyssinet</strong> supplied the staycables (300 t) for the structure, whichcrosses the Moraca River with a spanof 173 m and supervised theirinstallation by the general contractoras part of its role as technical supportprovider.Mecatiss joins <strong>Freyssinet</strong>France. Following the integration of Salvarem at the beginning of 2005,the takeover of Mecatiss on 6 September 2005 strengthens the Group’scapabilities in the nuclear field.Headed by Bernard Marquez and attached to the <strong>Freyssinet</strong> StructuresDivision, Mecatiss designs, manufactures and implements fire barrier,leakage protection and radiation protection systems meeting the requirementsof the nuclear, petrochemical and shipbuilding industries and airports andpublic buildings. Equipped with an integrated test laboratory, the companypursues an active R&D programme and studies all new techniques andapplications relating to textiles, silicon elastomers, resins and mineral fibresto meet the specific needs of its customers.A Ready-to-Assemble QuaySouth Korea. The Pusan portauthorities have chosen a designfavouring protection for the installationof a new quay in an area of the portbattered by the swell. The structure(350 x 50 m) has been entrusted togeneral contractor Posco E&C Corp.,and makes heavy use of prefabricatedelements, which have beensubcontracted to <strong>Freyssinet</strong> Korea.To produce the structure’s 100 prestressedconcrete caissons, 800 slabs (8 x 4 m)and 500 vertical panels (22 x 1.6 m),the company will pour a total of15,000 m 3 of high-performance concreteand install 729 t of prestressed steel.Cable-stayedroofingEgypt. To accommodatethe finals of the next AfricanFootball Cup of Nations,which will take place in Egyptin January and February 2006,Alexandria has started workon an 80,000 seat stadium.The suspension for theroof that will partly topthe structure consists of18 horizontal and 19 verticalstay cables supplied andinstalled by <strong>Freyssinet</strong>.Second half of 2005 Soils & Structures 5

W I D E A N G L ESungai Prai,Ready for ServiceThe Prai river has now been crossed: the last stay cables supporting the485 m long deck of the main bridge, at Butterworth in the west of the MalayPeninsula, were installed by <strong>Freyssinet</strong> on 25 July 2005. The company hasinstalled 112 stay cables to a demanding schedule on this structure since9 October 2004. The bridge is expected to open in January 2006.6 Soils & Structures Second half of 2005

Second half of 2005 Soils & Structures 7

F O C U SJÉRÔME STUBLER, DEPUTY GENERAL MANAGERLNG: Cryogenic PrestressingDerived from the Nuclear IndustryHaving played a role in equipping the containment vaultsof nuclear power stations all over the world for morethan 30 years, <strong>Freyssinet</strong> has worked tirelessly to perfectits prestressing system. Today, its quality andperformance make it the solution of excellence for theconstruction of liquefied natural gas (LNG) storage tanks.Jérôme Stubler, Deputy General Manager and StructureDivision Director, explains.Sols & Structures. - As apreferred player in thedevelopment of France’snuclear power stations,for which it suppliedand installed all theprestressing, <strong>Freyssinet</strong>is now positioning thistechnology on the marketfor liquefied natural gas(LNG) storage tanks.What exactly does thatinvolve?Jérôme Stubler. –Justlike the structure thathouses a nuclear reactor,the concrete shell ofa liquefied natural gasstorage tank is acontainment vessel. Theyare both circular vesselsdesigned to contain theinternal pressure thatcould be caused by anaccident, as well as fornormal operation forcertain storage tanks withinternal metal liners thatrest on the concrete shell.In both cases, the qualityof the prestressing is thedecisive element in thestructure’s performanceand durability. This quality,which has established<strong>Freyssinet</strong> in the field ofnuclear power stations,is also the mark of ourcapabilities in the LNGmarket. Over the last threeyears it has been illustratedon numerous storage tankconstruction sites all overthe world (see p. 9).What makes <strong>Freyssinet</strong>’snuclear prestressingdifferent?Over the last 30 yearsthe company has beenassociated with theconstruction of all of thecontainment vaults forpower stations in Franceand a very large numberof those built inprestressed concrete allover the world. Today,the Company is presentin India and China atconventional powerstation sites as well as inFinland, where the firstEPR (European PressureReactor), due to take overfrom the plants currentlyin operation, is being builtCosta Azul, a Project in Mexicowith VINCI Construction Grands ProjetsOn 4 July 2005, as a subcontractor of VINCI ConstructionGrands Projets, <strong>Freyssinet</strong> was awarded the contractfor the supply and implementation of the prestressingfor two liquid natural gas storage tanks inCosta Azul, south of Tijuana (Lower California), Mexico,a region with high levels of seismic activity. Thesestructures will be built by VINCI Construction MajorProjects for Sempra, an American gas sales company.at Olkiluoto (see alsop. 20). This success,originally linked toEDF’s requirements,which were decisivein the development ofhigh-performancemodels, is also a result ofinternal requirementsand has been illustratedover time by continuousprogress in the fields ofproducts, research andimplementation.Regarding productsspecially developed fornuclear power stations,one has to mention the55C15 anchor, the mostpowerful unit inexistence, the ductingsystems under ductileEach with a capacity of 160,000 m 3 , these two storagetanks will require the installation of 920 t of prestressingin the form of horizontal prestressing comprising19T15 cables and U-shaped vertical prestressingusing 13T15 cables. The site was supplied with thefirst prestressing elements and materials in September2005 for implementation lasting from the end of2006 to spring 2007.rigid tubes, which providean additional guaranteeof the impermeabilityof structures, and specialthixotropic grouts(“Thixogel”) that allow fortotally bleed-free injection,thus giving optimal andlonger-lasting corrosionprotection. In parallel,new implementationprocedures have beendeveloped.These include equaltension jacks,which make it possibleto obtain the sametension in every strandand reduce creep, whichis another additionalguarantee of longevity.But <strong>Freyssinet</strong>’s nuclearprestressing service ismore than just a productsupply: the companydevelops detailedexecution methodsand provides site ownerswith dedicated teamshaving experience ofimplementation andthe very rigorousquality assuranceprocedures peculiar tostructures of this type.8 Soils & Structures Second half of 2005

FOCUSIdku (Egypt).Sakhalin (Russia).South Pars (Iran).Altamira (Mexico).So it’s a tried and testedmodel that <strong>Freyssinet</strong>is now using as a basisfor developing its positionin the LNG market?The similarity of thestructures and theimportance of the safetyand durability of thesestructures form the basisof the approach, whichaims above all to providethe appropriate technicalresponse, guaranteeingquality. LNG storagetanks have a specialfeature which is the verylow temperature, - 160°C,at which the gas mustbe kept in order for it toremain in a liquid state.As this temperature alsoaffects the structure,<strong>Freyssinet</strong> has workedon a "cryogenic"prestressing, i.e. onethat retains its ductilityand does not becomeembrittled despite thetemperature conditions.The solutions proposedfor the two storage tankscurrently being built atChengdu in China havesuccessfully met thechallenge of cryogenicresistance tests.In parallel with this typeof technical response, andon the nuclear model,<strong>Freyssinet</strong> offers itscustomers anorganization that givesthem access to all of theexperience of <strong>Freyssinet</strong>’snetwork in both researchand operations.So all in all, the offeringis customized to meet thespecialized requirementsof our customers?Faced with rising oil pricesand the prospect ofresources running out,gas, which also has thebenefit of a cleaner image,is becoming an attractiveenergy source and thenumber of developmentprojects is increasing. In2003, there were over100 exporting andreceiving terminals dueto be built worldwideby 2020, representingan investment ofapproximately 3 billioneuros. More recently, theChinese authorities haveannounced their desireto diversify their energysupply sources andincrease the proportionof natural gas to 7 or 8%.Clients, sites, projectsIn 2004, <strong>Freyssinet</strong> supplied and installed 700 tof prestressing on the two 140,000 m 3 storagetanks at Idku in Egypt, implemented withVINCI Construction Grands Projets.Eleven storage tanks are also under construction:•Sakhalin (Russia): Two 130,000 m 3 storagetanks (750 t of prestressing);• Fos-Cavaou (France): Three 103,300 m 3 storagetanks (1,400 t of prestressing);• South Pars (Iran): Two 55,000 m 3 LPG (liquefiedpetroleum gas) storage tanks and two 40,000m 3LBG (liquefied butane gas) storage tanks (1,000 tof prestressing);•Chengdu (China): Two 160,000 m 3 storage tanks(1,230 t of prestressing).Several others are being planned in Mexico (seebox) as well as UK, Spain, Belgium and Nigeria.In parallel, the last fewyears have seen a hugeincrease in the price ofsteel, making all-metalstorage tanks lesscompetitive.In this very buoyantcontext, <strong>Freyssinet</strong>’sLNG prestressingservice thus has bothtechnical and economicadvantages.■Second half of 2005 Soils & Structures 9

R E P O R T <strong>PRESTRESSED</strong> <strong>CONCRETE</strong> <strong>FLOORS</strong>A FAR-REACHING TECHNMarket necessities, force of habitand the culture of the sectorhave favoured the growth of floorprestressing in many countries,but have not allowed it to developin France. This situation couldchange with the introduction ofnew regulations in 2006 and thanksto concerted efforts at <strong>Freyssinet</strong>.BONDED PRESTRESSING is made up of strands enclosed ina sheath injected with a rigid product (such as cement grout).THE MALAYSIA TELECOMTOWER in Kuala Lumpur(Malaysia): 76 floors,230,000 m 2 (1997).MORE THAN HALF A CENTURYLATER the opposition encounteredto prestressed floors inFrance is a reminder at <strong>Freyssinet</strong> ofthe opposition Eugène <strong>Freyssinet</strong>had to overcome at the time of hisinvention. Of course, this time it isnot a question of bringing aboutacceptance of an idea or a newmaterial, but of changing designand implementation habits inorder to allow the technique toextend its field of applicationbeyond the few cases where it isabsolutely necessary. "Luckilythere’s no shortage of references",comments Fernand De Melo,<strong>Freyssinet</strong>’s Technical Director inFrance who, having worked abroadfor a long time naturally mentionsAustralia, South East Asia, Singaporeand Hong Kong, regionswhere the combination of rapidurban growth and a lack of spacehave favoured the technique."But," he emphasizes, "muchcloser to home, Great Britain is akey example, if not a model." (seepage 13). "On the one hand, theadvantages of the technique areglaringly obvious," continues theTechnical Director, inviting us tocompare two photos of car parks,one conventional, with a forest ofpillars, the other astonishingly spaciousand clearly better able tofacilitate traffic movements andparking. "In fact," explains FernandDe Melo, "the advantage ofprestressing, which is found in civilengineering and the building tradewith this type of floor, can besummed up in two terms: increaseof span, which in this case can beup to 15 m as opposed to 7 to 8 m,and the weight reduction of structures(floor thicknesses can bereduced from 40 to 20 or 25 cm)".This brings a whole range of advantagessuch as the reduction ofexpansion joints and the cost ofUN-BONDED PRESTRESSING is made up of sheathed greasedstrands directly installed within the floor slab or inserted intosheaths injected with a flexible product (wax, grease, etc.).10 Soils & Structures Second half of 2005

DOSSIERIQUEA Full Range of SolutionsTWO TECHNIQUES...There are two types of technique for prestressed floors: prestressingby bonded post-tensioning, in which the bare strands ina smooth or ribbed sheath are injected with cement grout afterbeing tensioned and un-bonded prestressing, which uses strandsremaining free inside a sheath, where they are protected fromcorrosion by a grease.Un-bonded prestressing is often more economical for floors notsubjected to excessive loads. It is less advantageous if a highlevel of prestressing is needed (premises subjected to significantloads such as archive buildings) or if there is a risk that flooropenings will be made after pouring, since un-bonded prestressingrequires the recreation of anchors after the tendons are cut.In certain cases, the two techniques are combined: bonded prestressingin beams and un-bonded prestressing in slabs.…TWO SORTS OF STRAND, SEVERAL TYPES OF ANCHORThe two diameters of strand used are 15.70 mm (T15 strand)and 13 mm (T13). Depending on the diameter and the number ofstrands they receive (1, 3, 4, 5), the anchors are given codenames that are easy to decipher: 1E15 (1 strand of 15), 3E13,3E15, 4E13, 4E15, etc.IMPLEMENTATIONSUnlike subcontract packages that do not interfere with the ’criticalpath’ of the project, floor prestressing involves cooperationbetween the main structure contractor, who frequently carries outthe main work (formwork, passive reinforcement and concreteplacement), with the <strong>Freyssinet</strong> teams responsible for installing,inspecting and stressing the post-tensioning materials. Complyingwith the positioning tolerances within the slab thickness iscritical to the execution phase. It has led Austress <strong>Freyssinet</strong> todevelop a range of "chairs" making it possible to guarantee thepositioning of the sheaths to a close tolerance. These are nowalso used in Great Britain.maintaining them, etc. The benefitsof the technique in terms ofapplications follow on very logicallyfrom this basic data.Vast PlatformsFor architects and project managers,this makes it possible to“save space” with vast column freeplatforms, which are veryfavourable for creating openspaces that are easy to fit out andare highly suitable for office buildings,as well as facilities such asshopping centres, airports and carparks. For building owners, thisspace saving also translates veryfirmly into extra square metres ofspace, particularly in the case ofvery tall buildings, where one levelcan be gained every 20 to 25 floors.Finally, structural simplificationequals savings on materials and areduction in overall cost – advantagesthat companies can’t ignorewhen preparing their responses toinvitations to tender. <strong>Freyssinet</strong>estimates that savings of the orderof 15 to 20% can be made. Paradoxically,since its appearance in the1980’s as an adaptation of the techniqueused for civil engineeringstructures, floor prestressing hasnever really taken off in France.“Prestressing is not part of thebuilding construction culture inFrance,” Fernand De Melo believes.“On the one hand, this is becauseconstruction design offices are notused to designing using the technique,and on the other hand itsbecause general contractors thatcould turn to specialist designfirms are reluctant to do so for fearof losing control.” “It also suffersfrom a special technical status thatlimits it to such cases where thereare large spans, unusually heavylive loads and to what are known as’transfer floors’, where it representsthe necessary alternative to reinforcedconcrete,” explains▼▼Second half of 2005 Soils & Structures 11

R E P O R T <strong>PRESTRESSED</strong> <strong>CONCRETE</strong> <strong>FLOORS</strong>1 253 46 7▼▼Christian Lacroix, <strong>Freyssinet</strong>Regional Director for Île-de-France. Regulations have also beena hindrance. The BPEL (béton précontraintaux états limites / prestressedconcrete at limit states)calculation method used as a referenceby the technical inspectionservices is applicable to civil engineeringstructures but has beenshown to be unfavourable for prestressedconcrete floors, where itleads to an increase in passive steelquantities and consequently thecost price.In this apparently static context animportant change will neverthelessoccur as from 2006 with the introductionof the Eurocode. Morefavourable to the technique, thisregulation drafted within the Europeanframework could restart aprocess by allowing companies touse the services of design firmsapplying the new calculationmethod, enabling them to maketheir designed structures moreinnovative and competitive.“The <strong>Freyssinet</strong> technical departmentdedicated to prestressedfloors consists of a manager at eachof <strong>Freyssinet</strong> France’s regionaloffices and is responsible for ensuringthat expertise is pooled andthat we function as a network,”says Fernand De Melo, “and we12 Soils & Structures Second half of 2005

DOSSIERFor bonded prestressing, thestrands are delivered to site onreels (weighing around 3 tonnes).They are unwound, cut to lengthand threaded into the sheathsbefore concreting (2).For un-bonded prestressing, thecables (1) are usually deliveredprefabricated (fitted with anchorsat the ends). They are installeddirectly in the reinforcements (3),on the chairs placed on theformwork.The cables can be tensionedusing a light monostrand jack,generally three days afterconcreting, thus allowing for theremoval of the formwork (4-7).hope to be able to rely on Belgium,where Edouard Henrard has beenworking with a design firm for sometime.” Before the new regulationscome into force, this departmentwill also benefit from the calculationexpertise of two specialistengineers. In this field, supportfor the French team will comefrom across the Channel, wherethe British work according to aregulation (the British Standard)similar to the Eurocode and haveagreed to provide advice and supportin the selection and use of calculationsoftware.The Technique Saves Space andReduces the Overall Cost of Projects.“Belgium: a 25-year lead, but the same obstacles”Great Britain: regulationschange everythingOver the last 20 years, the annual production volume ofprestressed floors in Britain is estimated to have increasedfrom less than 50,000 m 2 to 1.3 million m 2 . At the endof a 2005 business year with a particularly large number ofprojects completed in Britain and Ireland, Patrick Nagle,Managing Director of British subsidiary <strong>Freyssinet</strong> Ltd.,and Paul Bottomley, Technical and Sales Director, answeredthree questions for Soils & Structures.How do you explain the success ofprestressed floors in Great Britain?Is it a recent phenomenon?PATRICK NAGLE. – 10 years ago we hadto canvass architects and consultingengineers, as it seems you have to doin France with your partners, inorder to convince them of theadvantages of floor prestressing.Those days are all but gone andsince the end of the 1990s, the trendhas changed and so have mentalities.Today, people approach us tocost solutions that incorporate prestressingright from the design stage.Cases come to us in the form of preliminarydesigns (slab configuration,thickness, loads) to be finalized,which is what our design office does.This success is the fruit of the longtermwork undertaken by <strong>Freyssinet</strong>Ltd. and other companies to changementalities and culture in the UnitedKingdom - and it took some time.Another explanation, linked to amore recent phenomenon, is thatthe increase in labour costs and steelprices has also increased the attractionof prestressing. I would also addthe time saved on the site comparedwith a reinforced concrete solution,which accordingly represents afinancial saving for the general contractorand the space saving offeredby prestressed floors. In fact, withinthe same “shell”, the designer canplan for additional floors. Finally, Iwould say that the success has beenOver the last ten years, <strong>Freyssinet</strong> Belgium’s achievementsin Belgium and Luxembourg must representan average of 30,000 m 2 of prestressed floors peryear," estimates Edouard Henrard, Sales Director of<strong>Freyssinet</strong> Belgium. This figure simply reflects theadaptation of companies to their markets: in France,the development of the motorways generated a gooddeal of activity until 1985; this was not the case inBelgium, which is a small country where work of thistype was completed in 1970. Necessity knowing nolaw, it is now over 25 years since we turned to prestressedfloors and established contacts with veryactive design firms. Our first projects were officebuildings in Belgium and Luxembourg (offices for FortisBanque, Brussels National Airport, the Social andEducational Institute and hospitals, car parks andshopping centres, open space offices, etc.). For allthat, we encountered the same obstacles as inFrance at all levels of the process. In France there isan additional handicap due to the considerable developmentof prefabrication and the market share ofthat technique in car parks and short-span buildings.”boosted by the increase in the averageheight of buildings. In 2004 inManchester, <strong>Freyssinet</strong> Ltd made31,350 m 2 of prestressed floors for a47-storey building, which is morethan 170 m high and will house theDeansgate Hilton Hotel.Are British regulations favourableto this technique?PAUL BOTTOMLEY. – The obligationyou have in France to use a minimumamount of passive steel indefined locations does not exist tothe same extent in the UK. Here,the rules for the design of prestressedfloors are defined byBritish Standard BS8110, supplementedby technical report no. 43published by the Concrete Society.These recommendations are in factvery favourable to the technique,since they make it possible toreduce the conventional reinforcementto a minimum. In practice wecan often remove all the passivesteel in the bottom mat and most ofit in the top. This is completely▼▼Second half of 2005 Soils & Structures 13

R E P O R T<strong>PRESTRESSED</strong> <strong>CONCRETE</strong> <strong>FLOORS</strong>1. 72,000m 2 of prestressed slabs were producedfor the Neder-over-Heembeek water treatment plantin Vilvoorde (Belgium).2. National Bank Tower in Abu Dhabi (United ArabEmirates).3. In the heart of London (United Kingdom), theprestigious Esso Glen office complex has a total of50,000m 2 of prestressed floors.4. A car park without prestressed floors, with its forestof columns and cramped parking spaces.5. The car park at Atatürk airport in Istanbul (Turkey),designed with prestressed slabs, has large openspaces.6. Prestressing was used for the hemicycle at theEuropean Parliament in Strasbourg (1998) to reducethe height of the structure (thinner floors), providestability and earthquake-resistant monolithicbehaviour, and optimise the spans between shells.7. The prestressed slabs used for the new ExCelexhibition centre in London give the building a highload-bearing capacity.3145“The Strength of <strong>Freyssinet</strong> Ltd. is its ConsiderableExpertise and its Design Office.”14 Soils & Structures Second half of 2005

6 7different from what is customaryand permitted in France. As wellas that, the strength of <strong>Freyssinet</strong>Ltd. in this field is its considerableexpertise and its design office,which enable it to design and calculateprestressed floor solutions.▼▼In practice, how is your work onsites organized, in particular withthe contractor in charge of themain structure?P. N. – Sometimes, particularly inIreland, we are involved with thegeneral contractor, but more oftenthan not our customer is in fact the”frame” contractor who is responsiblefor the formwork, reinforcingand placing the concrete. We workwith them to produce the slabs.Unlike in France, where small areasare worked on with daily rotations,we work on larger pour areas,sometimes greater than 1000 m 2with a cycle time of 4 to 6 days. Ourrole consists of installing the prestressingelements, tensioning thestrands and injecting the ductswith the cement grout. The techniquehas not disrupted the organizationof sites as we are relativelyindependent in relation to theother operations. We are the oneswho adapt, and that’s why the mainstructure contractors use ourservices.Emirates: a techniquethat meets a needIn the United Arab Emirates, floor prestressing hasbeen in regular use since the 1990s. Khalil Doghri,Managing Director of <strong>Freyssinet</strong> Middle East in Dubai,and Khalid Rabadi, Building Prestressing DivisionManager, explain why.What are the most important factsabout <strong>Freyssinet</strong> Middle East’sfloor prestressing business?KHALIL DOGHRI. – The technique,which is limited to bonded prestressing,began in the region inthe 1990s after being introducedby the Australians. Today it iswidely used in the Emirates, especiallyin Dubai which is goingthrough a building boom – theworld’s tallest tower is being builtthere. Floor prestressing is part ofthe offering of many companies,some of which are from Asia, Australia,India, etc., including one ortwo general contractors that haveacquired the know-how forsmaller projects.How do you explain this success?K. D. – Buildings with spans ofmore than 7 m are being suggestedincreasingly often by architects fortheir greater convenience in termsof the use of space and layout. Thisis exactly the type of span permittedby our technique, which alsobrings many other advantages,such as reduced floor thickness,elimination of beams, reduction inbuilding height, ease of installationfor air conditioning equipment,etc. The technique is alsoattractive for main structure contractorsas it allows them to buildmore quickly using less steel andat a lower cost. As far as the spreadof the technique is concerned, weare in the opposite situation to theone in France, but for the samereason; force of habit, the cultureof engineers and the way companiesbuild have ensured the developmentof prestressing in thebuilding floors.How is your cooperation with thegeneral contractors organized?KHALID RABADI. – Upstream of projects,our design office studies thesolutions to offer for the contractorsand quantifies the savings thatcan be made. These optimizedsolutions represent 50 to 60% ofthe contracts we handle. Once thecontractor is awarded the contract,we provide assistance withimplementation and materials,such as cables, sheaths, anchors,etc. Our site superintendentssupervise the general contractor’sworkers, who install the prestressing,but we are responsible for thework and are present at the time ofpouring. Beyond the technicalaspects we emphasize quality ofservice, which is an integral part oftechnical quality and the warrantygiven for the work. In practice, thisassumes faultless organization sothat the materials are suppliedexactly when they are required.We also have to coordinate ourinvolvement with the work on themain structure, which not all supplierscan do. We could doubtlessimprove our command of thisservice and our competitivenessby sharing our experiences moreat a Group level.■Second half of 2005 Soils & Structures 15

REALIZATIONSapparatus, the cables, fitted withtheir collars, were put into place onthe pylons in two stages, using acrane for the first end, and by hoistingfor the second.■Why choose Cohestrand?“The need for the main cables to be durablenaturally led to Cohestrand being chosen,”explains Benoît Lecinq, <strong>Freyssinet</strong>’s TechnicalDirector, “as this cable was specifically developedby <strong>Freyssinet</strong> at the end of the 1990s to resisttransverse flanging forces and longitudinal slidingforces and thus preserve the continuity of protectionagainst corrosion at the level of the hangercollars on suspension bridges or deviation saddleson cable-stayed bridges.Like the strands of a stay cable, with the petroleumwax replaced by a special resin in this case, theCohestrand strands have a triple protection barrier– galvanization, interwire voids and voids betweenwire and sheath filled with an adhesive polymer,and HDPE sheath extruded and adhered to thestrand – the quality, homogeneity and reliability ofwhich are the fruit of industrial methods. And, likeparallel strand stay cables, the Cohestrand strandshave a potential service life of 100 years by design.A full scale test was also carried out on a section ofthe main cable to test the sliding resistance of thecollar. Conducted in August 2004 at the <strong>Freyssinet</strong>laboratory, it proved that the collar was capable ofresisting a longitudinal force in excess of 1,200 kNbefore any sliding occurred.”PARTICIPANTSOwner: Ministerie van deVlaamse GemeenschapDepartement Leefmilieu enInfrastructuur Afdeling Maasen Albertkanaal.General Contractor: THVHerbosch Kiere AntwerpseBouwwerken - Louis Duchêne.Design Firm: IV-INFRA.Technical Inspection Service:Seco.Metal Construction: VictorBuyck Steel Construction.Specialist Contractor:<strong>Freyssinet</strong> Belgium and<strong>Freyssinet</strong>.▼ ▼ ▼ ▼ ▼ ▼VINCI Innovation Awards 2005:Grand Prize for <strong>Freyssinet</strong>On 5 December 2005, Antoine Zacharias,Chairman and CEO of VINCI, presentedthe grand prize in the VINCI InnovationAwards 2005 to Benoît Lecinq (technicaldirector of <strong>Freyssinet</strong>), Sébastien Petit (engineerwithin the "Cabled structures" division)and Ivica Zivanovic (product developmentmanager) for the "Cohestrand suspensionbridge cable system" used on the Kannebridge. In addition to technical innovation,the panel highlighted "the level of technologicalexcellence achieved by the <strong>Freyssinet</strong>teams with this product."Second half of 2005 Soils & Structures 17

R E A L I Z A T I O N SSOILS/MBABANE BY-PASSA Record Contract for36,000 m 2 of Reinforced EarthIn Swaziland, a relativelysmall Southern Africancountry, Reinforced Earthhas designed and is supplyingmaterials for several massive tieredfills, numerous bridge abutmentsand retaining walls for the capital’sby-pass link road.MBABANE, THE CAPITAL OFSWAZILAND, a kingdom landlockedbetween South Africa to thewest and Mozambique to the eastand barely 17,300 km 2 in area, iscurrently served by two motorways,one from Manzini in the the southeast, and the other , from the bordertown of Ngwenya in the north west.Whilst the first of these goes all theway to the city limit, the second currentlyends about ten kilometresshort of Mbabane, where it joins anold motorway (called the MR3 Corridor),which is 5 km long and wasplanned to be modernized. In orderto create a link between these twoaxes without splitting the city intotwo, the country’s authorities haveopted for a by-pass solution, forwhich construction work began in2004. “We got involved with theMbabane by-pass and MR3 roadmodernization projects very earlyon, in September 2002,” saysAndrew Smith, Director of theSouthern African Reinforced Earthsubsidiary. The company’s technicalresponses appear to have beenpersuasive and convincing. Twoyears later, Reinforced Earth signedone of its biggest contracts fordesigning and supplying 36,000 m 2of Reinforced Earth structures withWBHO, the general contractorresponsible for the construction.789 km of reinforcing stripsThe Reinforced Earth structures onthe Mbabane Bypass comprise14 retaining walls (totalling5,500 m 2 ) 12 true abutments and4 mixed abutments for eightbridges (5,000 m 2 ) and 4 tieredstructures – Mangwaneni (9,500 m 2 ),Qabalembadada (8,500 m 2 ), Esitebeni(4,500 m 2 ) as well as a wall used asan access slip road at Mangwaneni(3,000 m 2 ) – all to be constructedby 2007. “The tiered walls supportingthe line of the motorway werean alternative solution to the incrementally-launched bridges originallyplanned. These would havehad 30 to 40 m long spans on piersbetween 50 and 60 m high, saysAndrew Smith. The ReinforcedEarth tiered fills were proved to beeconomically, technically and environmentallyacceptable solutionsfor containing the 35-metre highembankments. A 3m high 2m widetier pattern was adopted for thetiers except for the Esitebeni structurewhich had to accommodate aservice road and the Qabalembadadastructure where the geometrydictated much higher tier wallsThe constituent materials for theReinforced Earth comprise weatheredgranite backfill TerraClass cruciformpanels and HAR reinforcingstrips (Reinforced Earth highadherence steel strips) 45 mmwide, 5 mm thick, with lengthsvarying from 4 to 22 m. “All thematerials –a total of 1,735 t of steel,the equivalent of 789 km of reinforcingstrip – are planned to bedelivered before the end of 2005,”concludes Andrew Smith. ■PARTICIPANTS▼ ▼ ▼ ▼Owner: Swaziland Ministry ofPublic Works and Transport.Consulting Engineers:BCEOM/Otieno Odongo& Partners JV.General Contractor:WBHO South Africa.Specialist Sub-Contractor:Reinforced Earth (Pty) Ltd.18 Soils & Structures Second half of 2005

REALIZATIONSSOILS/MONDRAGON PLATFORMNew Generation BallastedColumnsThe new high-performance Ménard Soltraitementcrane makes it possible to increase the size of ballastedcolumns. Demonstration at Mondragon.MORE POWERFUL, FASTER,MORE EFFICIENT... the newballasted column machine jointlydeveloped by Ménard Soltraite-ment and Enteco under the codename E600 has many advantages.It has just been used for the secondtime in the field to consolidatea 5,700 m 2 area of land at Mondragon(Vaucluse, France), wherea plant specializing in the transformationof livestock slurry intocompost is due to be built. “It is acomplex process system thatrequired complete control ofabsolute and differential settlements,particularly in the 2,500 m 2area where a raft that will have tobear loads of 6 t/m 2 is going to bebuilt,” says Ménard Soltraitementengineer Rémi Chatte. To treat thesoil, which is made up of silt andclay to a depth of 6 m, 980 ballastedcolumns (5,500 m) were putin place according to a squaremesh with side varying from 2 to2.50 m. With a record productionrate of 500 m per day (comparedwith 250 m with a conventionalmachine), the work, carried out bya single shift of four people, lastedonly four weeks. The advantages ofthis new machine do not stopthere as they make it possible toestablish the ballasted columns ata depth of up to 16 m. It can alsodeliver a pressure of up to 35 twhen resting on its rear legs (25 tfor conventional models), thusimproving the quality of the ballastedcolumns (their peak resistance,tested using a static penetrometer,varies between 20 and30 MPa). “We even set a record validatedby a bailiff at the previoustest site, recording a pressure of38 t”, adds Rémi Chatte. ■PARTICIPANTS▼ ▼ ▼ ▼Owner: Société de distributiond’eau intercommunale.Project Manager: Safegeenvironnement.General Contractor:groupement Spie-BatignollesSud-Est - Mathis -ScregSud-Est.Specialist Contractor:Ménard Soltraitement.STRUCTURES/MIRAGE TOWERS57,300 m 2 of prestressedfloors in MexicoIN THE HEART OF LA LOMA, a residential district of the Santa Fe quarter inMexico City, a complex with a total of 235 apartments has recently beenbuilt over an area of 15,000 m 2 . In order to optimize the habitable area andlighten the structure of the Mirage Towers, three 17-storey buildings constructedabove three underground carPARTICIPANTSpark levels, architect José Luis CambaCastañeda opted for the prestressedconcrete slab solution. A total of57,300 m 2 of prestressed floor surfacewas produced, using 160 t of extrudedmonostrands supplied and installedby <strong>Freyssinet</strong> de Mexico. ■▼ ▼ ▼Owner: Celta Bienes Raices,SA de CV.Project Manager: José LuisCamba Castañeda.Specialist Contractor:<strong>Freyssinet</strong> de Mexico.Second half of 2005 Soils & Structures 19

R E A L I Z A T I O N SSTRUCTURES/NUCLEAR CONTAINMENT VAULTSWorld-renowned expertiseAs a prestressing specialist fornuclear power station containmentvaults, <strong>Freyssinet</strong> has handled theinstallation of over one hundredprojects in 13 countries over morethan 30 years.2IN THE STATE OF TAMIL NADU,in southern India, two VVER 1000type reactors of Russian design arecurrently being installed near thetown of Trivandrum on theKudankulam site. For each of thetwo containment vaults, comprisinga prestressed concrete shell1,200 mm thick reinforced with a6 mm metal interior impermeabilityliner, <strong>Freyssinet</strong> has installed60 vertical inverted U-shaped prestressingcables, 53 horizontalcables looped on two ribs and15 horizontal cables looped on thedome, all made up of 55-strandsheathed and greased bundlesinjected with cement grout beforetensioning. “2,713 t of steel and514 type 55 C 15 anchors havebeen installed,” says Jean-LucienMongauze, Business Engineer at<strong>Freyssinet</strong>. The strands arethreaded one at time into a flexiblesheath in the case of horizontalcables, and into rigid tubes for verticalprestressing. As un-bondedprestressing is used, load-check,re-tensioning or replacementoperations can be carried out laterif necessary.In China, <strong>Freyssinet</strong> has just finishedinstalling the prestressing fortwo containment vaults at theTian-wan power station near thecity of Lianyungang in Jiangsuprovince. <strong>Freyssinet</strong> is also providingassistance for the construction11. Construction of the foundations of the containment vault forthe new EPR European reactor in Olkiluoto. 2. Anchor point forthe vertical prestressing for a containment vault in China.of two nuclear power stationsnamed Ling-Ao phase II and QinshanExtension phase II by supplyingand installing the prestressingfor the containment vaults (37 m indiameter and 56.70 m high). Thefirst is an extension of the Ling-Aophase I power station (itself anextension of the Daya Bay powerstation), constructed in theprovince of Guandong south ofShenzhen between 1997 and 2002and equipped with two 900 MWPWR reactors. The prestressing systemused is made up of 176 19 T 16dome cables, 224 horizontal cablesof the same type and 145 37 T 16vertical cables. This amounts to2,506 t of strands, 1,600 19 K 16anchors and 580 37 K 16 anchorags.The second project, Qinshan phaseII, relates to the enlargement of theQinshan II power station, whichwas built between 1996 and 2002.Less powerful than Ling-Ao with apower production capacity of 600MW, this power station was largelydesigned by Chinese engineers. Forthe containment vaults, 174 19 T 6dome cables, 199 19 T 16 horizontalcables and 144 37 T 16 verticalcables were put in place by the generalcontractor with the technicalassistance of <strong>Freyssinet</strong>.In Europe, <strong>Freyssinet</strong> is working inFinland on the new EPR (EuropeanPressure Reactor) constructionproject on the Olkiluoto site. This is20 Soils & Structures Second half of 2005

REALIZATIONSan exceptional programme which,for the protection of the reactor,requires a non-standard doubleshell comprising a 1,800 mm thickshell to protect against planecrashes covering the entire nuclearisland and an internal vault1,300 mm thick, with a 6 mm-thickmetal liner on the inside to guaranteeimpermeability. Acting onbehalf of Framatome, <strong>Freyssinet</strong>is supplying a turnkey service forthe provision and the installationof prestressing for the internalcontainment vault. Thus 104 54 T 16gamma cables, 119 54 T 16 horizontalcables and 47 54 T 16 verticalcables have been installed, witha total of 2,050 t of strands and540 55 C 15 anchors.Installation and inspection“The containment vault is the ultimatebarrier in the event of anaccident,” points out Jean-LucienMongauze. This means that itsconstruction and the installationof prestressing are matters for specialiststhat must comply withstringent quality requirements andthat require very strong cables.Since its first involvement in theFrench nuclear programme withEDF during the 1970s, <strong>Freyssinet</strong>has continued to improve its prestressingsystem. In particular ithas developed new injected groutsand improved the impermeabilityand rigidity of ducts by using rigidtubes for the vertical parts or partswith large curves, as well as thermoshrinkablesleeves and injectionconnections.<strong>Freyssinet</strong>’s current offering comprisesseveral types of prestressingchosen to take account of the technicalspecifications, the maintenance,the replacement and the lifetime of nuclear plants.In addition to these installationservices, <strong>Freyssinet</strong> offers its customersinspection and monitoringof the prestressing during andafter the works. “We have variousmeasurement systems available tous,” says Jean-Lucien Mongauze.In some cases, as well as extensometerswith vibrating cords thatgive information regarding the statusof the stresses within the concrete,we also equip a few cablesof each type with dynamometers.In the other cases, we also havethe possibility of load-checking allthe cables using the lift-offmethod and checking for the presenceof any corrosion by de-tensioningand examining someof the strands during power stationmaintenance shutdowns.<strong>Freyssinet</strong> will also design andsupply gondolas and service towersto provide access to the cablesand to install and inspect themduring the lifetime of the powerstation.■256 prestressing cables were installed in the two containmentvaults in Kudankulam (India).SOILS/CALARASI PLATFORMRecord OutputDURING THE SUMMER, MénardSoltraitement put a great deal ofeffort into successfully completingthe improvement of a 21,500 m 2platform in Romania. For the constructionof its new flat glass manufacturingplant, a project involvingin particular a 21,500m 2 storagewarehouse that will have to bear alive load due to use and occupancyof 8 t/m 2 , Saint-Gobain chose thetown of Calarasi, approximately100 kilometres east of Bucharest, asite where the soil conditions(compressible collapsible loess andsoft clay) and the seismic risk madestrengthening necessary. TheMénard Soltraitement solution wasfinally chosen in preference to theinitial plan for a floor supported onpiles. It consisted in installing conventionalpaving with a thicknessof 25 cm resting on soil strengthenedby a network of CMCs (controlledmodulus columns) via asand-gravel mixture distributioncushion with a thickness of 60 cm.“With this solution we were able toguarantee absolute settlement ofaround 3 cm and differential settlementof less than 1/500°,” saysPhilippe Liausu, Managing Directorof Ménard Soltraitement. In orderto carry out the work within the veryIn July and August, the twoCMC rigs enlisted consolidatedthe platform that will holdthe new Saint-Gobain plantin Romania.tight deadlines without risking prohibitivepenalties for delay, in Julyand August last, the companyenlisted two CMC rigs and installed3,900 CMCs with a 360 mm diameter(equivalent to 65,000 linearmetres) according to a 2.25 msquare mesh at a mean depth of17 m. The sustained rate allowed usto achieve a production record of1,740 linear metres of columns for aone workshop working one 12-hourshift, equivalent to approximately200 m 3 of mortar. “We also had touse three concreting plants so thatwe could produce the 8,000 m 3 ofmortar we needed,” adds PhilippeLiausu. The mobilization paid off:the company delivered the workthree days ahead of schedule. ■PARTICIPANTS▼ ▼ ▼ ▼Owner: Saint-Gobain.General Contractor: Hervé.Technical Inspection Service:Socotec.Specialist Contractor:Ménard Soltraitement.Second half of 2005 Soils & Structures 21

R E A L I Z A T I O N SSOILS/KWANG YANG PLATFORMAtmosphericConsolidationover 350,000 m 2At Kwang Yang (SouthKorea), the Menard Vacuumprocess makes possibleto consolidate land claimed fromthe sea.SOUTH KOREAN AUTHORITIEShave decided to make the portof Kwang Yang, located in thesouth of the country near Yosu,one of the most dynamic portareas in Asia. This implies anincrease in container storagecapacity and the number ofunloading docks at the site. Titanicsea filling works have thereforebeen underway at the port for severalyears. The operation consistsof filling immense racks formed bydykes of rocky ballast withdredged clay on the soft marineclay sea bed; the quay edge ismade up of concrete caissons submergedin the sea. As the resistanceof land obtained in this way isvery poor, consolidation was necessary.“The treatment by atmosphericconsolidation (Menard Vacuumprocess) we suggested waschosen in 2003 for treating an initialplatform of 295,000 m 2 (lot 3-1)which has just been delivered,”says Daniel Berthier, vice chairmanof Sangjee Menard. “Thecompany has just begun work on asecond area of 55,000 m 2 (lot 3-2).”The implementation of theprocess involves several stages. Inthe case of lot 3-2, the clayey submarinedeposits are approximately15 m thick and are topped by thehydraulic dredging backfill to+ 8.50. There is therefore a total of25 m of very soft, waterlogged clay,onto which a geotextile is unrolled.This is then covered with a sandydraining cushionand a layer ofungraded aggregate.A Network of Drains“This is the point where SangjeeMenard comes into action to installcylindrical vertical drains in thesoil in a 1-metre square mesh,”explains Daniel Berthier.From June 2005, 55,000 drains(1,300,000 lm) sunk to a depth of26 m underground were installed injust under one and a half monthswith to the mobilization of twoinstallation teams turning out12,000 m per machine per day. Subjectedto the pressure of the backfill(and, later, to the pressure drop createdby pumping), the watertrapped in the clay flows up towardthe upper layer of sand where it iscollected by a system of horizontaldrains, which are connected topumps. In order to increase theimperviousness of the system andin particular to counteract theharmful effect of sand lenses in thedredged clay, a slurry wall made ofsecant piles was constructed on theentire circumference by mixing thein situ soil with a bentonite/cementgrout. In addition, interconnectedsteel sheets were put onto theupper part of the slurry wall inorder to improve its effectiveness.An HDPE membrane with a thicknessof 1.50 mm, sealed into theclay in the trenches dug out abovethe slurry wall and covering all ofthe backfill, completes the installation.Then, after meticulous checkingof the system for leaks, pumpingwas activated. As the pumpscreate a vacuum under the membraneand remove the water fromthe soil, the ground is restructuredby settlement. This undergroundwork is supplemented at the surfaceby the excess load effect ofbackfill placed above the membrane.On the lot on which workhas just started, a global settlementof 7 m is expected in a 12 monthsperiod, with residual settlementguaranteed for 10 years, of 10 cm inprimary consolidation under anoperating load of 5 t/m 2 . ■The underground network of 1,300 km of drains connected topumps will allow for the soil to be restructured within 12 months.22 Soils & Structures Second half of 2005

REALIZATIONSSTRUCTURES/THE LA SIOULE VIADUCT1,200 t of Multiple PrestressingStrandsIn the Puy-de-Dôme, workhas just been completed onthe largest concrete viaductin France, a structure in whichprestressing is present throughout.IN THE AUVERGNE VOLCANOESNATIONAL PARK, between thevillages of Bromont-Lamothe andSaint-Ours-les-Roches, constructionof the la Sioule viaduct on theA89 (Clermont-Ferrand – Bordeaux)was completed last September.Designed by the Sociétéd’études et de calculs en ouvragesd’art (Secoa) and architect BerdjMikaelian, the structure comprisesa single concrete box-girder, theheight of which varies from 5.50 mat the midspan stitch to 10 m atthe the piers. Its eight spans, thetwo central ones stretching 192 meach, rest on hollow reinforcedconcrete piers, the highest ofwhich rises to 135 m.1,200 Tonnes of SteelFor the deck, the CampenonBernard-Dodin group of companies(VINCI Construction) chosethe balanced cantilever constructionmethod with segments cast insitu and entrusted the prestressingto <strong>Freyssinet</strong>. “It would be moreaccurate to say the “prestressings,”says Alain Ghenassia, <strong>Freyssinet</strong>’sRhône-Alpes regional director.“They all use our C system and representa total of 1,200 t of steel."Chronologically, a transversal prestressinginjected with cementgrout was first applied to the lowerhollow block of the segments onpiers (themselves “tacked” to thepier heads using two or four 19T15cables according to the piers). Onthe upper part of the segments, inthe upper block, monostrands werethen installed transversally every250 mm. “We suggested usingsheathed and greased strands as analternative to a solution that wouldhave required larger units andwould therefore have been moredifficult to install,” explains AlainGhenassia. During the constructionof the spans, initial interior prestressingwas installed to tie the segmentstogether and take the inherentweight of the structure.Anchored per pair of segments oneither side of the piers, these cablesare formed of bundles of 19 bare15.70 mm strands inserted into ametal sheath injected with cementgrout, the longest of which is 200 min length.Finally, external continuity prestressingby cables (31C15) measuringup to 250 m was installed in thecaisson between December 2004and July 2005 to carry the structure’soperational loads. Inserted into aThe deck houses two setsof prestressing: one tyingthe segments together oneither side of the piers, theother bearing the structure’soperational loads.black HDPE sheath injected withpetroleum wax in accordance withCIP (Commission inter-ministériellede la précontrainte/interministerialprestressing commission) recommendations,these can be re-tensionedor even individually replacedif necessary.After 36 months of civil engineeringworks, the viaduct will open totraffic at the beginning of 2006. ■PARTICIPANTS▼ ▼ ▼ ▼ ▼Owner: Autoroutes du Sudde la France.Project Manager: Setec TPI.Designer: Secoa.Architect: Berdj Mikaelian.General Contractor:Campenon Bernard TP-DodinJV.Specialist Contractor:<strong>Freyssinet</strong>.Second half of 2005 Soils & Structures 23

R E A L I Z A T I O N SSTRUCTURES/SAINT-CHÉRON RAIL BRIDGEExpress Method fora Railway BridgeAcquired by<strong>Freyssinet</strong> atthe beginningof the year, theAutoripage ®technique makesit possible toput a structurein place on arailway line withrail trafficinterrupted foronly a few hours.Illustration inSaint-Chéron(France).13IN THE TOWN OF SAINT-CHÉRON (ESSONNE), the levelcrossing on the Brétigny-Toursline is now just a memory formotorists. They can now cross therailway line with the greatest ofease thanks to the restructuring ofthe RD 116 road and the constructionof a rail bridge, which wasinstalled within a few hours thanksto Autoripage ® , a technique thatwas added to the <strong>Freyssinet</strong> constructionoffering with the acquisitionof the company JMB Méthodeslast January.50 metres in 5 hours“We allowed a window of 12 hoursfor safety, but in the end we onlyneeded 5 hours to carry out themanoeuvre and slide the structurefrom its prefabrication area to itsfinal location,” says Jean-LucAs it only requires smallteams to work on thelower part of the structure,the technique is alsobeneficial in terms of riskprevention.Bringer, Director of the SCCM(Service centralisé câbles et manutention/CentralizedCables andHandling Service) unit at<strong>Freyssinet</strong>. This time saving of severalhours was in fact part of amuch greater time saving if youconsider the project as a whole.“The conventional solution wouldhave been to build a bridgedirectly on the route and move railtraffic onto a temporary structure,which would have led to a significantreduction in average trainspeed, or sometimes trains evenhaving to be stopped,” explainsJean-Marie Beauthier, inventor of24the process. With Autoripage ® , thebridge is entirely prefabricated inan area adjacent to the railwayembankment before being put inplace. Apart from for the very limitedtime needed for this operation,which means stopping trafficfor between 10 and 48 hours, traintraffic is not disrupted at all whilethe structure is being built.Placed on its raft 50 m away fromits final location, the Saint-Chéronrail bridge was a 2,400 t structurewith a length of 35 m and a skew of74 degrees with two central spans,one for road traffic (12 metreswide), the other for cyclists (4mwide), flanked by two approachspans. The bridge was put in placeby sliding using a system of cablesand three jacks used as linearwinches with a unit capacity of1,000 t and a stroke of 350 mm,specially designed for this type ofactivity by Hebetec, the <strong>Freyssinet</strong>subsidiary specializing in heavyload handling. “Using this systemwe can reach a maximum pushingspeed of 12 to 13 metres per hour,”says Martin Duroyon, SectionEngineer at <strong>Freyssinet</strong>. At Saint-Chéron, this pace was reduced byhalf to allow the excavators to clearthe embankment ahead. This teamoperation also received a contributionfrom Advitam, a companyassociated with the VINCI Group,which developed a monitoringsystem to ensure centralized controlof the jacks and monitoring ofthe structure’s movement (measurementof displacements andloads, altimetric and lateral movements).Autoripage ® : the principleInvented by Jean-Marie Beauthierin 1992, the Autoripage ® technique24 Soils & Structures Second half of 2005

REALIZATIONSconsists of moving an entire structuresuch as a rail bridge from itsprefabrication area to its finallocation within a very short time,thus limiting interruptions to railtraffic to between 10 and 48 hours.The structures to which it isapplied are assembled on a raftand comprise two approach spanssupported by struts inclined at 45°,which replace the traditionalripraps (this configuration makesit possible to avoid filling operationsaround the structure at alater stage and the construction ofa transition slab or wing walls).The actual Autoripage ® operationinvolves sliding the structure to itsfinal location on the soil on a bedof lubricating bentonite-basedgrout using a system of cables andhydraulic jacks. As the structureonly exerts very low pressure onthe soil (0.3 to 0.7 bar), Autoripage ®can be used on any type of ground.Since the takeover of JMB Méthodesby <strong>Freyssinet</strong>, several structureshave been constructed usingthis technique in Thonon-les-Bains, Thaon-les-Vosges, Saint-Rémy-lès-Chevreuse, Chalon-sur-Saône, in Luxembourg, etc. ■PARTICIPANTS▼ ▼ ▼ ▼ ▼ ▼ ▼Railway Works Owner: RFF.Road Works Owner: ConseilGénéral de l’EssonneAssistant Project Manager:SNCF Rive GaucheProject Manager: SNCF-EVENVal d’orgeGeneral Contractor: GuintoliAutoripage: <strong>Freyssinet</strong> France,Service centralisé câbles etmanutention (SCCM)Design and Methods: JMBMéthodesSTRUCTURES/KONIN BRIDGEIncremental launchingon the River WartaIN KONIN (POLAND), on theWarsaw to Poznan motorway,<strong>Freyssinet</strong> Polska, the Group’s Polishsubsidiary, has assisted withthe construction of a new steelbridge by handling the incrementallaunching operations above theRiver Warta. Generally curved inshape, the structure measures440 m and comprises five rectilinearspans. The deck was put inplace in 220 m (780 t) sections intwo phases, in July and August, inonly five days. “The main difficultywe encountered,” explains AnnaOldziejewska, Marketing Managerat <strong>Freyssinet</strong> Polska, “was in thearc-shaped geometry of the structure,and its lower wings, neitherthe width nor the height of whichwere constant.” To compensate forthese differences and to allow thestructure to rest axially on thesupports, mobile ’auto-centred’devices (specially designed by<strong>Freyssinet</strong> for this structure) combinedwith five jacks with a unitcapacity of 30 t were used.The actual incremental launchingrequired the use of four jacks witha stroke of 60 mm using a force of892 kN. Once the incrementallaunching operations were finished,<strong>Freyssinet</strong> Polska installed60 pot bearings. ■STRUCTURES/GAEGOK BRIDGEA 100% <strong>Freyssinet</strong> ProjectIn South Korea a new motorwaysection passes through a particularlyhilly area close to Geagok andcrosses a structure that is 280 mlong (and 20 m wide), which<strong>Freyssinet</strong> Korea will be building inits entirety, including the civil engineering.Resting on piers of up to 50 m inheight, the deck comprises fivecantilevered spans (70, 50, 55, 35and 70 m) and has interior prestressingmade up of un-bonded19C13 cables (220 t). “Our team onsite, made up of 35 people, buildone segment on each side of thepiers every 18 days,” says Jong TaeHan, Works Director at <strong>Freyssinet</strong>Korea. The abutments are built onscaffolding. When the structure iscompleted in June 2006, the<strong>Freyssinet</strong> Korea teams will remainin the region and will begin workon another structure on the sameroute, the Beobgy I Bridge, with a20 m wide, 180 m long deck. ■PARTICIPANTS▼ ▼ ▼Owner: Gyeongsangnam-do.General Contractor: DaewooE&C Corporation.Specialist Contractor:<strong>Freyssinet</strong> Korea.Second half of 2005 Soils & Structures 25

R E A L I Z A T I O N SSTRUCTURES/BAI CHAY BRIDGELandscapedStay Cables onHalong BayIn the Gulf of Tonkin(Vietnam) on the edgeof Halong Bay, constructionof the Bai Chay Bridge is in progress.The structure is fitted with the latestgeneration of <strong>Freyssinet</strong> stay cablesand pipes.LOCATED ON THE ROUTE OFTHE FUTURE MOTORWAYNo. 18, which will connect Noi BaiInternational Airport to the northof Hanoi to Bac Luan on the Chineseborder, in 2006 the Bai ChayBridge will cross a sea inlet overlookingHalong Bay and will be theA central layer of stay cables,narrower protective pipesin special colours: threesolutions to help the structureblend into the panorama.key to the economic developmentof a high-potential region, which isstimulated by both the location ofthe industrial city of Haiphongalongside the motorway and theBay’s significant tourist and portactivity.With a central span of 435 m and atotal length of 903 m, the Bai Chaybridge is larger than the Elorn(France), Sunshine Skyway (UnitedStates) or Coatzacoalcos (Mexico)bridges and breaks the lengthrecord for prestressed concretebridges supported by a centrallayer of stay cables. “The arrangementof the stay cables does notreflect a desire to break a record,”explains Roger Raymond, <strong>Freyssinet</strong>Area Manager, “but rather an effortto enhance a UNESCO world heritagesite.” With two lanes of trafficin each direction as well as twofootpaths, the deck, comprisingsegments cast in situ, is 25.30 mwide. The cantilevered structurewill be supported by 112 stay cablesanchored into two pylons reachinga height of more than 137 m.A Special PipeDepending on their location, thebundles of cables are made up of37 to 75 strands and their lengthvaries from 50 to 230 m. All of themare fed into a ’low drag stay pipe’,which is fitted with a specificdevice to prevent vibrations linkedto the combined action of the windand rain. The originality of the BaiChay pipes goes further, as theowner wanted to use three shadesof yellow on them to create shadedtones in trompe l’oeil reminiscentof a sunset from the centre of thepylons outwards. “Thanks to itsmastery of stay cable technology,<strong>Freyssinet</strong> was able to respondfavourably to this request,” saysBenoît Lecinq, <strong>Freyssinet</strong>’s TechnicalDirector. “Our R&D work hasenabled us to find formulations forthe sheaths to allow the designersto give their architectural expressionfree rein. <strong>Freyssinet</strong> offers itscustomers pipes in various coloursthat preserve their mechanicalproperties and their resistance toultraviolet rays.” To absorb vibrations,the bridge will also beequipped with three types of internaldamper depending on thelength of the stay cables. 20 internalradial dampers (IRD) per pylonwill be installed on the longestcables, 20 internal hydraulicdampers (IHD) for intermediatelengths and 16 internal elastomericdampers (HDR) for the shortestones.■PARTICIPANTS▼ ▼ ▼ ▼Owner: Socialist Republic ofVietnam – Transport Ministry –Project no. 18.Finance: Japan Bank forInternational Cooperation.Project Manager: Japan Bridge& Structure Institute Inc. ;Pacific ConsultantsInternational; TransportEngineering DesignIncorporation; Hyder Consulting-CDC Ltd.Specialist Contractor:<strong>Freyssinet</strong>.26 Soils & Structures Second half of 2005

O U R P R O F E S S I O NCMC OPERATOR:CONSTANT VIGILANCESemi-rigid cementedinclusionshen we arrive at a site,”«Wexplains Mathieu Prot, aControlled Modulus ColumnOperator (see below) for MénardSoltraitement, “the first thing wedo is check the equipment in itsentirety – that is, the crane, itsmast and the concrete pump supplyingit – and make sure everythingis working properly. InstallingCMCs leaves no room for improvisationand the type of concrete weuse means we have to work nonstop.”As soon as he has finished hischeck-up, the operator goes to hisworkstation, a cabin with controllevers arranged next to a computerscreen. He will only come out againonce the concrete supply to thepump has been used up (45 or 90 m 3depending on the model).On the ground, marking set out bythe Ménard Soltraitement engineersshows him the exact positionof the CMCs to be installed. Guidedby a manoeuvre that controls themovement of both the pump and atracked remote-controlled device,the operator places the auger accuratelyon the marks, ensuring thatthe mast is vertical and if necessaryadjusting it using an inclinometer.As soon the auger starts to penetratethe soil, all the drilling parametersare recorded by the computerin real time. The operator then hasto carry out a variety of tasks simultaneously– careful monitoring ofthe verticality of the mast and thework of the auger, its turningtorque and the depth it reaches. Allthis data is conveyed to the operatoras well as to the onboard computerby the rotation table fixed tothe mast, “a real concentration ofhigh technology,” covered withsensors.As well as being used for monitoringthe operation and calling forimmediate corrective decisions oractions, the data collected also pro-A soil reinforcing process, controlled modulus columns (CMC) aresemi-rigid cemented inclusions with distortion modules that are5 to 30 times lower than those of concrete. In practice, CMCs aremade using a special auger that pushes back the soil, and thistechnique, which does not require either vibration or driving, doesnot affect the environment. The tool is screwed into the soil to therequired depth and then brought back up with no spoil. A fluidgrout is then put into the soil by the core of the hollow auger (thespecial auger) to form a column of cemented material approximately25 to 60 cm in diameter, which withstands stresses of 10to 50 bar depending on the proportions of the mixture.For the operator, nothingis left to chance: the positionsof the CMCs are rigorouslymarked out by the engineersand all the performance datais recorded by the onboardcomputer.vides traceability of the work and isoften passed on to the customer ordesign firm by Ménard Soltraitement.Once the required depth hasbeen reached, the operator beginsthe second implementation phase,which requires just as much attention,as the mortar must now hasbe incorporated in the correct proportionsand its pressure checked.Linked to the nature of the soil, thenumber of CMCs completed dailyvaries, but is in fact measured inmetres. On average, Mathieu Protestimates that he does 500 to 600 mper day.With machines that are performingbetter all the time – in particularguaranteeing the vertical adjustmentof the automatic mast – theCMC operator’s job is changingand is becoming more specializedand demanding, which alsoexplains why mostly experiencedoperators are sent to the site underthe supervision of a SectionEngineer.■Second half of 2005 Soils & Structures 27

C O M P A N YA COMPREHENSIVEOFFERING IN SOUTHKOREAIn just over 10 years, <strong>Freyssinet</strong>Korea and Sangjee Menard havesuccessfully deployed all the knowhowof the Group in Korea by signinga number of prestigious contracts<strong>Freyssinet</strong> KoreaAlthough the presence of<strong>Freyssinet</strong> in South Korea goesback to September 1989, when theGroup opened a representativeoffice in Seoul, the company hasonly been formally registeredunder the name of <strong>Freyssinet</strong>Korea since 1993. Made up of fivepeople, the company was thendirected by WS Park and JY Kim,who has been Managing Directorsince 1999. Initially involved inprestressing works and structuralequipment, <strong>Freyssinet</strong> Korea cameto a significant turning point withthe Seohae bridge site in 1995. “Forthat structure,” said JY Kim, “wetook care of the prefabrication ofthe segments for the 52 spans ofthe two decks, heavy lifting, segmentlaying, prestressing, carriagewayjoints and stay cables.”This extensive service enabled thecompany to gain the status of aVITAL STATISTICS▼ ▼ ▼Employees: 66 executives,technicians andadministrators, 201 manualworkers.2004 Sales Figures:21,640 million wons(18 million euro).Managing Director: JY Kim.major public works player.Finding itself in a boom situationafter this success, the companyadded repairs to its portfolio ofservices and in 1997 signed up forits first project, the strengthening ofa cantilever bridge. The companythen worked on five major projectsover the next few years: the installationof the segments for a highspeed rail bridge using the MSS(movable scaffolding system); thelaunching of the Jang-An Bridgeand the installation of stay cableson the Samcheonpo, Yeong-Heungand Namdo bridges (bow-string).121 2 3 4 5 6 7 8 9PEOPLE AT FREYSSINET KOREASome of the <strong>Freyssinet</strong> Korea management team: Ji Yeong Kim (1), managing director; Byung Joo Huh (2), chief of the Reinforced Earthdepartment; Ki Chul Won (3), marketing manager; Jong Tae Han (4), construction manager; Yoon Ik Cha (5), procurement and equipmentmanager; Sung Woo Kim (6), finance and administration manager; Hyun Kwon Hong (7), chief of the technical department; Sang Jin Park (8),geotechnical division manager; Seung Ik Kim (9), Structures division and technical manager.28 Soils & Structures Second half of 2005

COMPANYSangjee MenardSupport fromReinforced Earth3In the meantime, the companyonce again expanded its offering byadding Reinforced Earth andTechSpan prefabricated arches. Assoon as they were recruited, thegeotechnical engineers saw a stringof Reinforced Earth projects, whichled to <strong>Freyssinet</strong> Korea approachingReinforced Earth, the Group’sAustralian subsidiary, in order tobenefit from its expertise and supportfor staff training for the firstdesigns. Australia also came to theaid of Korea when the first ordersfor TechSpan arches were taken in2005 for the construction of twocovered trenches on the Cheongwon-Sangjiuand Taebaek-Seohak1. Between 1998 and 2000,<strong>Freyssinet</strong> Korea assisted in thebuilding of the Seohae bridge,a 7,310 m structure acrossthe bay of Asan, by designinga self-launching truss for theconstruction of the spans andsupplying and installing theprestressing for the pylons andstay cables.3. Between 1999 and 2000,<strong>Freyssinet</strong> Korea carried outall of the superstructureconstruction, prestressing andlaunching work on the 525 mJang-An bridge, 100 km southwestof Seoul.2. In soils, <strong>Freyssinet</strong> Korea isto complete its first TechSpanarch project in 2006 on theCheongwon-Sangju motorway.The structure will require theinstallation of 524 half-arches.motorways. At the same time, thedeployment of structural skills continuedwith the introduction offloor prestressing (Samsung LeeumMuseum) in 2003, followed by theCohestrand strand and deviationsaddles, which will be implementedin 2006.■In the Land of the Morning Calm, soil improvement works are handledby Sangjee Menard, an equal shareholding joint venture set upin 1992 between the Korean company Sangjee Co. Ltd and MénardSoltraitement, which handled its first project at the Honam-Oilrefinery in Yeosu in 1993 (70,000 m 2 of dynamic compaction anddynamic replacement). In 1995, the work for a second phase atHonam-Oil, similar to the previous phase, and the use of theMenard Vacuum process on the platform of the Kimhae watertreatment plant (85,000 m 2 ) confirmed the company’s status as asoil treatment specialist. From 1997, the Jangyoo water treatmentplant was handled by Menard Vacuum (70,000 m 2 ).After restructuring the capital of the joint venture, Ménard Soltraitementincreased its shareholding to 80% in 2003. The group is currentlymanaged by Ki Hyun Song, who is also the Chairman of Sangjee,and by Daniel Berthier, vice chairman and Ménard Soltraitement’srepresentative in the country. In 2004 the companyachieved sales of 7 M€ ; it has 11 employees working on site andeight people at the head office. It is currently handling its largestproject yet at Kwang Yang in the south of the country (see page 22).1 2PEOPLE AT SANGJEE MENARDKi Hyun Song, chairman of Sangjee Menard;Daniel Berthier, vice chairman of Sangjee Menard andMénard Soltraitement representative for South Korea.Second half of 2005 Soils & Structures 29