REINFORCED EARTH - Freyssinet Thailand

REINFORCED EARTH - Freyssinet Thailand

REINFORCED EARTH - Freyssinet Thailand

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

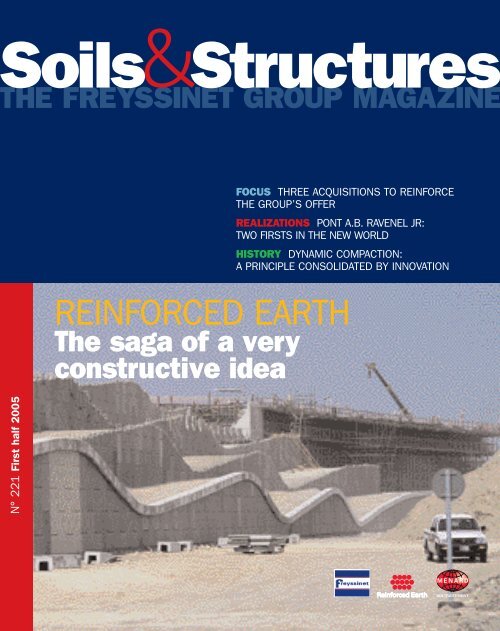

oils&StructuresHE FREYSSINET GROUP MAGAZINEFOCUS THREE ACQUISITIONS TO REINFORCETHE GROUP’S OFFERREALIZATIONS PONT A.B. RAVENEL JR:TWO FIRSTS IN THE NEW WORLDHISTORY DYNAMIC COMPACTION:A PRINCIPLE CONSOLIDATED BY INNOVATION<strong>REINFORCED</strong> <strong>EARTH</strong>The saga of a veryconstructive ideaN° 221 First half 2005

PANORAMAA wall on the lineAt Telegraph Bay, in the southof Hong Kong island, considerable workhas been carried out in order to builda road that leads to Cyberport, a new ITand new technology business park.After designing the road, Reco HK has justcompleted building a 25.5 m hightwo-tier Reinforced Earth with 13 mbackfill surcharge.“The eight months that it took to completethis project were very challenging”,confides Norman Lee, project managerat Reco HK, “because we had to workunder trying environmental conditions(proximity to the road restricted usto using short reinforcements, andcreated difficulties in implementinglogistic resources) without compromisingarchitectural aesthetics.”The pathwayin the sky<strong>Freyssinet</strong> has just finished buildinga 34 m long suspended footbridgein the Mafate natural amphitheatreon Reunion island. To build thisstructure on a section of the islandthat is isolated, with no roadinfrastructures, all the site materialshad to be brought in by helicopter.New methods across the PyreneesIn north-east Spain, the Cantabrian highway goesalong a viaduct 848 m long between Vegarrozadas andSoto del Barco. Built by Necso, this structure is madeup of ten 74 m spans and two 50 m end spans.Its deck is made up of a box girder that was cast in situ andis 11 m wide with a constant height of 3.75 m, post-tensioned(582 t of steel). Two precast 8 m abutments were fixedon both sides with 736 Freyssibar prestressing bars,40 mm in diameter, with an average length of 10 m.Supplied and installed by <strong>Freyssinet</strong> SA, this new method(see s&s no. 219) was used for the first time in Spain.Strong foundationfor wastewatertreatment plantAfter three months of work, Ménard Soltraitementhas completed the soil improvement workfor the future San Martin de la Vega wastewatertreatment plant, one of the largest inthe region of Madrid (Spain). The loamy-sandsoil was not dense enough for the foundationof the structure, and consequentlyMénard Soltraitement’s teams had to treat130,000 m 2 of soil by dynamic compaction.To complete the site within the deadlines,three dynamic compaction teams were required,using masses of 15 to 20 tonnes.HomageJean Muller diedon 17 March atthe age of 80.A graduate of theprestigious EcoleCentrale, he joinedStup (Technicalcompany for using prestressingtechniques, which later became<strong>Freyssinet</strong> International in 1976)in 1947. After heading the NewYork branch of <strong>Freyssinet</strong>Company Inc. from 1951 to 1955,he went on to become thetechnical director and thenresearch director of CampenonBernard. At the same time, hefounded the offices of Figg andMuller in 1978 and Jean MullerInternational (JMI) in 1986.As of 1988, Jean Muller continuedhis career with Scetauroute(today Egis). <strong>Freyssinet</strong> offersits most sincere condolencesto his family and loved ones.10 800squaremetresof Reinforced Earthon the Westlink M7Currently the largest motorway project in Australia,the Westlink M7, to be opened at the end of 2006,will link the outskirts west of Sydney to existingmotorway networks. Launched as a BOT project andassigned to the AbiGroup-Leighton (ALJV) joint-venture,this project aims at building 40 km of roadway,17 interchanges, 38 overhead crossings and underpassesand 146 bridges. The Australian subsidiaryof the Group, Reinforced Earth, has obtained a contractto design and build 10,800 m 2 of ReinforcedEarth wall on more than 18 structures.Ronel Suthers, marketing co-ordinator of ReinforcedEarth comments: “Our challenge has been to masterthe co-ordination of the design of each structure inour design offices at Hornsby, the manufacture ofelements at Lithgow or in other factories, and thentheir delivery on site.”Strengtheningin JamaicaIn Kingston, Jamaica, Ménard Soltraitementis strengthening the land carved outof the mangrove to build a dual three-lanesuperhighway. Called Highway 2000,this new 6-kilometre stretch will doublethe size of the existing road in 2006 to easethe traffic in the harbour area. To consolidatethe highly compressible land in theshort time available, Ménard Soltraitementis installing 1.5 million metres of verticaldrains and more than 130,000 metresof controlled-modulus columns (CMC).First half 2005 Soils & Structures 3

P A N O R A M ARenovation at the topIn January this year, <strong>Freyssinet</strong> took partin renovating the upper platform of theLa Gacholle lighthouse, a 19.56 m highstructure on land that was built in 1882in what is today the national park ofCamargue (France). Once the damagedareas were repaired with limestone toresemble the original state, a coating offlexible epoxy was applied to the platformto improve its watertightness.South AfricaResa wins bid forrecord contractThe South African Reinforced Earth subsidiaryrecently signed a contract (the biggest concludedsince it’s inception in 1975) for the design andsupply of retaining walls for the MbabaneBypass, a 12 km section of freeway bypassingMbabane, the capital of Swaziland. Constructionof the freeway began in October 2004 and isplanned for completion in March 2006. Theproject comprises the construction of 14retaining walls (5,500 m 2 ); 12 true abutmentsand 4 mixed abutments (5,000 m 2 ) and; thecreation of 4 massive tiered fills, each more than30 m high. All structures will be clad with a plainTerraClass facing. The total face area is 36,000 m 2and the total length of 45 * 5mm highWaterprotectionbarrierIn Australia, near the Sydneyairport, Austress <strong>Freyssinet</strong> hasbuilt a wall on the banks of theTempe public landfill. This wallis 18 m deep, 1,360 metreslong and is made of bentonite.It was built to prevent leachatesfrom the landfills fromcontaminating the water in theadjoining canal. The excavationwas done using a special craneimported from the United States.Austress <strong>Freyssinet</strong> has alsoinstalled a control device and asystem for draining leachatesinto a purification station.A testimonial bridgein Hong KongIn China, <strong>Freyssinet</strong> has been awardeda contract for the operations of heavy lifting,supply and installation of stay cables,and spherical and pot bearings for theShenzhen Western Corridor bridge, currentlyunder construction. This new 3.8-kilometrelong cable-stayed road-bridge which isa dual three-lane, will be the fourth linkbetween Hong Kong and China. Erectedon the Hong Kong side, the inclinedasymmetrical pylon of the structure will besupporting two sets of 13 stay cables(300 t). While construction on thisproject has just started, <strong>Freyssinet</strong> Asia hasfinished installing the 113 spans of theDeep Bay double viaduct not far away.Responsible for precasting and installingthese elements, <strong>Freyssinet</strong> Asia is also incharge of designing the 2 launching trusses(photo above) as well as implementing thepreload, bearings and expansion joints.<strong>Freyssinet</strong> gives a helping handin tsunami disaster-stricken areasIn India, as everywhere in South Asia, work has begun to rebuild the areas devastatedby the December 26th tidal wave. <strong>Freyssinet</strong> International is working on the siteof the nuclear power station plant of Kudankulam in the south of the country(see s&s no. 217), and has made a donation to the neighbouring communities.This donation was handed over at the plant in early January by S. K. Agrawal,Director of Construction, and will be used to purchase land and build houses.European first in FinlandA member of the consortium responsible for building the first EPR (EuropeanPressure Reactor) nuclear reactor on the Olkiluoto site in Finland togetherwith Siemens, the Areva Group has entrusted the supply and implementationof the prestressing of the protective shield to <strong>Freyssinet</strong>’s Structures division.After the Tianwan nuclear power plant (China), this will be the third protectiveshield that uses <strong>Freyssinet</strong> 55C15 prestressing anchors.4 Soils & Structures First half 2005

PANORAMA23,711m 2 of post-tensionedconcrete slabsStamped on deliveryOn January 3 rd this year, a few weeks after the viaduct of Millauwas opened to the public, the French Post Office (La Poste)confirmed the structure’s vocation as a vehicle of exchangeand communication by printing a stamp with its picture on it.The stamp costs €0.50 and was designed by Sarah Lazarevic.<strong>Freyssinet</strong> Singapore has taken part in designing and laying 23,711 m 2of post-tensioned concrete floors for the headquarters of the computerservices company Infineon Asia Pacific. The structure is made up oftwo oval-shaped buildings slightly out of line with each other, linkedtogether by footbridges on the third, fifth, seventh and ninth floors.Tunnels on the runwayIn order to widen the runway at Melilla airport, a Spanishcoastal town to the north-east of Morocco, Tierra ArmadaSpain manufactured and supplied 4,000 square metresof retaining wall facing as well as arches needed for building thetwo tunnels. The first structure (179 m) will be assembled abovea spring of water and the second (202 m) abovea road. All the arches as well as the cladding were made byTierra Armada then stored in a precast yard next to the airport.Strengthenedto the top<strong>Freyssinet</strong> carried out repairs andstrengthening works on a 70 mhigh reinforced concrete towerin the cement factory of Jbel Oustin Tunisia.During the 10 months of the project,350 m 2 of Carbon Fibre Fabric (TFC)and 80 metal saddles were installed,with 35 m 2 of shotcrete alsosprayed at a height of over 50 mhigh without ever disrupting factoryproduction.HistoricalanchorsBetween December 2004 andJanuary 2005, <strong>Freyssinet</strong>carried out the generalreplacement of the anchors ofthe retaining cables on thedeck of the Matrou transporterbridge. Listed as an historicalmonument since 1976 andtoday reserved for pedestrians,this structure which crossesthe Charente River was built byFerdinand Arnodin in 1900.It has a suspended deck175 m long with its pylonsextending 50 m above thehighest water level.Resisting the coldSelected by the STTS group (Saipem-Technigaz-Tecnimont-Sofregaz), <strong>Freyssinet</strong> will supply and install the horizontaland vertical prestressings for two liquefied naturalgas (LNG) tanks built in Chengdu (China).Before it won this outsourcing contract, <strong>Freyssinet</strong>’sprestressing system had successfully passed cryogenicresistance tests. 1,230 t of strands will be laid betweennow and December 2005.First half 2005 Soils & Structures 5

C L O S E - U P6 Soils & Structures First half 2005

The great wall ofSeydhisfjördhurDuring the second half of 2004 in Iceland, the land of the midnight sun,Reinforced Earth - <strong>Freyssinet</strong>’s British subsidiary, built two TerraTrel retainingwalls of 6,600 m 2 . Erected for the communities of Seydhisfjördhur (photo)in the west of the country and Isafjördhur in the north-east, these two structuresdo not foreshadow future road building projects but rather revivethe age-old function of walls in this region: protecting men from avalanches.First half 2005 Soils & Structures 7

F O C U SThree acquisitionsto reinforcethe Group’s offerBy taking over Hebetec, JMBMéthodes and Salvarem at thebeginning of 2005, <strong>Freyssinet</strong>is completing and enhancing itsmarket proposal. Presentationand explanations by BrunoDupety, Group Chairman and CEO.Soils & Structures. - The year2005 began for<strong>Freyssinet</strong> in the spirit ofexternal growth with theintegration of three companies.Can you tell usabout them?Bruno Dupety. – Thefirst of the three to joinus was Hebetec on25 th October 2004. It isa company with 23employees, based inHindelbank near Berne,in the German-speakingpart of Switzerland.It specialises in lifting,lowering and displacingof heavy loads. Whenit was created in 1995,it worked exclusively oncables. In ten years,it has grown in by leapsand bounds: its turnoverhas jumped from€700,000 to €4 million.Today it is a companythat has operationsworldwide. We actuallycame into contact witheach other through oneof our Asian subsidiaries.Focusing on its corebusiness, Hebetec hasdeveloped other skillsrelated to the buildingof temporary steelframes, which aresometimes requiredin lifting operations.It has developed arevolutionary slidingprocess called the AirPad Sliding System (APS)for the naval industry.Based on the use of jacksand the air pad principle,this system was recentlyused in South Koreato launch giant methanetankers that had beenbuilt on-shore. Thisprocess which noweliminates the need fordry docks, is set for apromising future!Lastly, to create a firstlink between civilengineering and<strong>Freyssinet</strong>, I must pointout that it was a teamfrom Hebetec thatlowered the temporaryportals for the bridgecap of the Millau viaduct250 m (170 tonnes)in September andOctober 2004.In a field closer to us, wetook over JMB Méthodesand its patents for“deck shifting underrailways” during thesame period. Thisprocess makes it possibleto erect bridges overrailway tracks overnight!We didn’t have to travelall around the world tofind out about Salvarem:until December 31 st ,it was part of VINCIConstruction GrandsProjets. Created in 1979under the nameRadiacontrôle andspecialising in thesanitisation of ionisedenvironments, it wasacquired by EMCCin 1990 and then byCampenon Bernardin 1993. It has beenintegrated into theStructures Division of<strong>Freyssinet</strong>, and is today awholly-owned subsidiaryof the Group. It has aworkforce of about150 people, spread overthe three sites inBeaumont-Hague(Normandy), Saclay(Paris region) andPierrelatte (south-eastFrance) working for thefour major companiesof the French nuclearindustry, CEA, Cogema,Andra and Framatome,specialising in threeareas – radioprotection,sanitisation anddismantling in ionisingenvironments.In 2004, it posted aturnover of €10 million.It has a very strongtechnical culture andis solidly establishedin a specialised field,which is the dominantcharacteristic of the8 Soils & Structures First half 2005

FOCUScompanies in our group.Salvarem has createdinnovative tools andmethods for sanitisationand decontamination,and has won renown forthe dismantling of theMonts d’Arrée andBrennilis (Finistère)power plants as well asthe CEA’s Triton nuclearreactor in Fontenay-aux-Roses (Paris region).What are yourobjectives in taking overthese companies?Our civil engineeringoperations often involvethe lifting of heavy loads,either to positionpermanent structures orstructural componentsor for temporarydisplacements duringrepair or maintenanceoperations. Thisexpertise, which usedto be provided by<strong>Freyssinet</strong>, was lackingin our structure. Insteadof redeveloping it,which would havemeant training peopleand purchasingequipment, we preferredto seize the opportunityof this acquisition whichtakes us immediatelyto the forefront of thismarket. Furthermore,Hebetec has providedus with openings intocountries like Germany,Switzerland andAustria, wheretraditionally we are notgreatly represented.Our activities will beorganized in 3 ways:Hebetec will continueits activities with its ownclients; it will workeither as a partneror as a subcontractor of<strong>Freyssinet</strong>’s entitiesand subsidiaries; it willlease out equipmentto companies of theGroup that havemaintained their liftingexpertise, I’m thinkingnaturally of <strong>Freyssinet</strong>France. The takeoverof JMB Méthodes willreinforce the advantagegained by theacquisition of HebetecWith its three businesses, radioprotection,sanitisation and dismantling in ionisingenvironments, Salvarem rounds up <strong>Freyssinet</strong>’snuclear offering.The Air Pad Sliding system (APS) developed by Hebetec uses jacks and airpads to launch boats that are built on dry docks.and should positionus on a niche market.The integration ofSalvarem, just like thatof Hebetec, is aimedat extending andenhancing what wecurrently offer. However,in this case,it is a question ofcompleting expertisethat the Group has hadfor over twenty yearsthrough the NTS(Nuclear Special Works)Division located inMarseilles. For manyyears <strong>Freyssinet</strong> wasactive in the nuclearsector through thesupply and installationof prestressing formany nuclear reactorcontainments. It laterdeveloped a structuremaintenance offer andhas recently takenon the sanitisation anddecontamination ofthe gutters of theauxiliary buildings ofpower plants, inparticular for EDF. In amarket where thereare no majordismantling operationsas yet, it is only bypooling together ourforces and workingin synergy that wecan optimise ourcommercial penetrationand position ourselvesmore effectively onmedium-sized projects,where our objectiveis to gradually step upour operations."External growth" isanother way of saying"growth" pure andsimple. So how is 2005shaping up for <strong>Freyssinet</strong>in this respect?In the first quarter of2005, <strong>Freyssinet</strong>recorded an 11%increase in consolidatedturnover comparedto 2004. Most of thecountries in which weoperate experiencedgrowth, confirmingour subsidiaries’ strongmarket positioning.Our objective remainsfocused on "doing betterand more everywhereinstead of doingeverything everywhere".As a result, ourperformance continuesto improve, allowing usto consider furtheracquisitionsin our specialised linesof business. ■First half 2005 Soils & Structures 9

R E P O R T <strong>REINFORCED</strong> <strong>EARTH</strong>THE SAGA OF A VERYForty years after itwas invented,the ReinforcedEarth technologyis used on the fivecontinents andis an exampleof the benefitsthat can be reapedby authenticinnovations.These benefitsstill hold a lot ofpromise, sincethe technology ishighly appreciatedby architectsand has manyconvincingenvironmentaladvantages.IT ALL BEGAN LIKE A GAME,when he built a sandcastle on thebeach in Saint-Tropez, as wasexplaining generally Henri Vidal, ahighway engineer and architect.But the sand kept on falling off andthis led to the idea of reinforcing theconstruction with pine needles.That is how the general principle ofReinforced Earth came about. Haslegend been mixed up with reality?Maybe not exactly, but the hypothesisof the brain wave is not at all surprisingin a group like <strong>Freyssinet</strong>,whose three businesses werefounded by famous and prolificinventors. “To sum up”, explainsPhilippe Héry, Director of the Soilsdivision of the <strong>Freyssinet</strong> group,“Reinforced Earth consists in reinforcinga backfill with reinforcementsstrips that were originallymade of metal. The reinforcedstructure then becomes its ownsupport and its outer facing is coveredwith a surface made of precastelements. This technique does not15 6have the disadvantages of concretewalls that are traditionally cast insitu (limited height, unsuitabilityfor average soil conditions, highcost), but also has many advantages.It is flexible, able to supportdifferential settlements, can beadapted to urban areas, where thereis a limited covered surface, and isearthquake tolerant. In addition tothese technical advantages, ReinforcedEarth has demonstrated itsarchitectural resources by givingrise to a very diverse range of surfaces(see p. 12) and its environmentalintegration potential. Today,it is also very much in phase withthe principles of sustainability. “Ayear after he filed a patent in 1963,Henri Vidal received an order foran initial structure, the wall inPragnères near Luz-Saint-Sauveur(Hautes-Pyrénées, France) andthen produced many structuresfor the railway company, SNCF. In1968, he created a company calledLa Terre Armée that dealt with thedevelopment of road and motorwayprojects and the business rapidlytook off and rapidly withbranches springing up abroad. Itsoon created subsidiaries in the“The Reinforced Earth technology is flexible. It can beardifferential settlements and is adapted to urban areas.”10 Soils & Structures First half 2005

DOSSIERCONSTRUCTIVE IDEA2 3 4United States (1977) and Spain(1972). In 1974, licenses wereacquired by Sumitomo andKawasho, that merged with NKKTrading in 2004 to become JFEShoji, in Japan, which is a highearthquake prone country. At thesame time, the company, whichhad become a group under thename Terre Armée Internationale(TAI), continued to carry outresearch and developed reinforcementswith a very high adherenceand consolidated its positions byfiling a large number of patents.1976 was a first symbolic milestonebecause it was the year that100,000 square metres of ReinforcedEarth were produced andcruted worldwide. Three yearslater, in 1979, the company establishedits reputation with the pub-7 8Prefabricated facing scales (1,3), metal or syntheticreinforcements (4,7), backfill material(4,6,7,8): the components of the technology placeReinforced Earth halfway between geotechnics andstructures. After they have been laid, they form acomposite material that is durable, effective and ableto adapt to the most complex configurations.«“Our package is engineering,supply of componentsand aid in set-up.”»PHILIPPE HÉRY, SOILS DIVISION MANAGERlication, by the roads and roadtraffic division, of Ouvrages en Terrearmée, recommandations et règlesde l’art (Reinforced earth structures,recommendations and good practices).At that time, Reinforced Earthwas hailed as one of the mostimportant innovations of the civilengineering industry. A quarter of acentury later, the page was turnedas the first patents entered the publicdomain. However, the processhas found its place: it reached themillion square metre mark ofannual production in 1993, and, in2004, only five years after TAI wastaken over by <strong>Freyssinet</strong>, it reachedthe two million square metre mark.Philippe Héry continues his review:“In terms of the number of squaremetres built, it is North America(and mainly Florida and Texas) thatcome first with 33%, followed byAsia with 32% (20% of which comesfrom Japan), Europe (18%), LatinAmerica (8%), and the rest splitbetween Australia, Africa and theMiddle East. In fact, he underlines,the fact that owing to its ability tooffer steel reinforcement stripsdesigned by Reinforced Earth aswell as the synthetic reinforcementstrip system (Freyssisol system)promoted by <strong>Freyssinet</strong> in the1990s, <strong>Freyssinet</strong> can meet allrequirements, even on soil with avery high chloride concentration asis the case of port structures or MiddleEastern countries.” All over theworld, Reinforced Earth is thus recommendedand used in applicationsthat range from roads andmotorways, railways, bridge abutments,hydraulic installations, trainplatform walls and industrial sites.“However, the perfect illustration ofthe success of the technique, is theway in which each country adopts itto suit its needs. This is what we’reseeing for example today with theimpressive infrastructure programmebeing carried out in Indiawhere the use of Reinforced Earth isbeing increasingly used, as well asin Europe and the United Stateswhere projects have to comply withvery stringent architectural andenvironmental standards.”Driven by the entities of five divisionsout of the seven divisions createdto enhance <strong>Freyssinet</strong>’s expertiseworldwide, Reinforced Earth,nevertheless stands out in the Groupby its relative absence in its constructionsites. This important▼▼First half 2005 Soils & Structures 11

R E P O R T <strong>REINFORCED</strong> <strong>EARTH</strong>1 2354867910specificity is explained by thefact that in France, for example, thecompany has less than fifteenemployees based at the <strong>Freyssinet</strong>site in Vélizy. “We are selling a system,not a product, stressesPhilippe Héry. Our “package” consistsin the engineering, the supply▼▼of components – cladding panelsand reinforcements – and technicalsupport during assembly, which is aservice aspect that is very importantfor us.” This characteristic is naturallyexpressed in the large proportionof engineers among ouremployees. The Technical Divisionthat works on the Reinforced Earthsegment, is known as SoilTech, andis based in Nozay. It is a relativelylight structure with four engineers,one of which is a consultant. Theteam draws on the global ReinforcedEarth network, whichenables it to multiply its action.SoilTech,a technical guarantee“All the companies are technicallyand commercially accountable,explains Nicolas Freitag, an engineerat SoilTech. This means thatmost of them have a design andengineering department dedicated12 Soils & Structures First half 2005

DOSSIERWhether it is the scaleshape, its composition,surface appearance,“graphic treatment or plantdecoration, the techniqueoffers a particularly richpalette of “renderings”.1 TerraPlus Retaining wallon the State Highway 4in Maryland (United States).2 Architectural Freyssisolsurfaces near Raon-l'Étape(France).3 Details of a patternadorning the ReinforcedEarth wall on StateHighway 114 in Texas(United States).4 Architectural pattern ofthe Childress wall in Texas,with TerraPlus surfaces(United States).5 5 de Mayo Interchange,Lower California (Mexico).6 TerraTrel Access rampnear Faulquemont (France).7 TerraBlock Retainingwall in Dubai (United ArabEmirates).8 Architectural facingsof a retaining wall onState Highway 45 in Texas(United States).9 Retaining wall withspecific panels onmotorway A29 in Vallon-de-Rogerville between the LeHavre and Saint- Saens(France).10 Architectural TerraClasswall in the port ofBoulogne-sur-Mer (France).to their operational activities (actionplans) and to meet requests for specificapplications received fromarchitects. SoilTech is the heart ofReinforced Earth’s research anddevelopment system. It focuses onthe technical aspect to “bring qualityto the business”, which is a major“At the heart of Reinforced Earth’sresearch and development, SoilTech worksto bring quality to the business.”Roger Bloomfield :« Sharing global expertise »criterion for our clients. Its tasks alsoinclude assisting the other companies.In everyday terms, this function,which represents more thanhalf of its business, is proof of thedynamism and diversity of technicalcommunications between entities,whether it is a matter of finding a setof references for sea walls in thearchives to finalise a call for tenderby the subsidiary in the United ArabEmirates, of looking for the solutionto a design problem in South Koreain the network, which has aboutthirty experts worldwide, or deliveringa solution to a young company.Research and development is amore highly strategic activity that isjust as linked to communications.SoilTech therefore carries out continuousintelligence, analyses lostcontracts with a fine-tooth comb,observes the competition, takes partin the work of the InternationalGeosynthetic Society (IGS), to “get afeel of needs and identify any shortcomings”.When you listen to NicolasFreitag, the SoilTech attitude for“The main asset of the ReinforcedEarth technology is itsability to change and adapt,which enables it to meet theneeds of new markets, reckonsRoger Bloomfield, CEO of RECoin the United States. As themain Reinforced Earth company,we put a lot into this strategyand work very closely withSoilTech. We hope in this waythat we will be helping the Group to cope with thefuture requirements. We apply the same approachwhen we take part in in-house meetings such as therecent ones in Dubai or in Boston last year. Actually,we should probably revamp our slogan “globalexpertise, local experience”, because today, ourpractices are more along the lines of “global sharingof local expertise”. All the major Reinforced Earthentities are today pursuing an active R&D policy;and the challenge is to share these areas of expertiseamong all the companies.”this mission can be summed up in asingle word that is in line with theoriginal idea: innovation. “In spite of40 years of history, we can do a lot toimprove the original ingenious ideausing new materials and numericaldigital analyses that will enable us tooptimise the performance andsafety of structures and inventionsthat may not have generated applicationsbut are the source of newideas!” Among the research focusesthat have recently given rise to thefiling of patents, we must point outthe development by SoilTech, in collaborationwith Terre Armée BV(Netherlands) and Terre Armée SNC(France), of the Omega connection,a system for anchoring the syntheticreinforcements stripsDeveloped by the Reinforced Earth research and developmentdivision, the Omega connexion is an anchoring systemfor synthetic reinforcements that is cast directly into the panelduring the prefabrication stage.▼▼First half 2005 Soils & Structures 13

R E P O R T <strong>REINFORCED</strong> <strong>EARTH</strong>1 The reduced implementationtime of the technique makesit a favourite in road,motorway and railwaystructures (photo 1: SouthKorea).2 Because it meets industrialsite layout requirements,Reinforced Earth has beenused to erect over onehundred dump wallsworldwide (photo 2: Australia).Its flexibility also makesit ideal for circular retainingstructures like the Muskegfoam tanks in Canada(photo 3).4 The qualities of ReinforcedEarth in land applicationsare repeated in sea orriver constructions, with astrong resistance to the stressof floods or swells. In DenBosch (The Netherlands),for example, mixed TerraClassand TerraTrel wallsretain houses in this way.13into the panel during the prefabrication.It is a fine example ofhow SoilTech is able to combine itsexpertise with the research carriedout in the network. SoilTech hasvalidated a similar connection,called C, also began designed in theUnited States and completed in theUnited Arab Emirates, using its profoundknowledge of standards, itsmastery of test procedures and statisticinterpretation.“This way of operating has provedto be right, Martin Van Den Berg,▼▼Provide solutions and anticipateneeds: this sums up the entire philosophyof the sales team of theFrench subsidiary, based in Vélizy,under the motto “global expertise,local experience”. It has dividedFrance into three operating areas:the South-West, under Pierre Sery,the director of Terre Armée SNC, theNorth with David Brancaz, and theSouth-East plus the export regions,under Alain Tigoulet. “Project manmanagerof Terre Armée BV assuresus. This is because, for over thirtyyears, it has enabled us to share allthe questions handled by SoilTechwith about forty Reinforced Earthsubsidiaries worldwide and to solvetheir clients’ problems.” SoilTechwill be focusing on a new subject inthe near future. It is directly connectedwith the emergence of sustainabledevelopment and concernsthe increasing use of excavatedmaterial on sites and nodoubt material obtained from dem-olition (recycled concrete, roaddrillingmaterial) as backfill. “Ourservices include material specifications,explains Nicolas Freitag, andwhen one of the companies can nolonger obtain supplies of conformingnew material that meets specifications,we have to provide themwith information on how to use ortreat (chalk treated with cement,loam treated with lime) to ensurethat mechanical or chemical problemsdo not deteriorate the reinforcementsstrips.”Togetherwith the design teamThe philosophy of Reinforced Earth’s sales teams focuseson delivering solutions and anticipating needs.14 Soils & Structures First half 2005

DOSSIERagers and the design firms Egis,Setec, Ingerop and Arcadis, who arein charge of the research and designon the capital investment projectsof public bodies (local councils,regional authorities, Government)are our privileged contacts, heexplains, because when a retainingstructure is planned, we gettogether to define a solution, eitheron our own initiative or because wehave been consulted. We’re also intouch with a large number of consultancies,including architecturalfirms specialiszed in civil engineeringstructures, and design offices(between 30 and 50) with whom wedevote nearly half our time.” Thisupstream work normally providesbetween 10 and 12 months of workbefore the project, most of the time24represented by flagship projectssuch as the recent bearing andretaining structures of the viaductof the RN 202 bis trunk road atSaint-Laurent-du-Var, the Soumontwall near Lodève, on the A75, in theHérault region (over 30 m high andcovering an area of 10,000 m 2 ), thefive structures of the Mussidan-Périgueux section of the A89 motorway(12,000 m 2 ), or the 30,000 m 2project being executed on the A51motorway at Monestier de Clermont,in the Isère region. The salesmanagers spend the rest of theirtime between preparing answers toinvitations to tender and projectfollow-up. On one hand, they workwith the design department headedby Eric Lucas, who provides themwith the survey statements theyneed to cost evaluate their projectcosts and assists them in resolvinggeotechnical problems, and AlainGorce, the construction manager, inrelation with the two panel prefabricationcompanies; and on theother hand they work with the beneficiariesof the construction works– earthwork contractors and structuralworks contractors to put thefinal touches to the geometry of thestructures, which may havechanged significantly since the initialstudies, and to define the actualimplementation conditions (natureand granulometry of backfills, soilcontent, etc.).For Alain Tigoulet, the list of tasksshould include contacts with the<strong>Freyssinet</strong> network, which supportsthe development of exports. “Anincreasing number of projects arebeing executed outside France, heconcludes. We have sites in the formerFrench territories and we’realso answering tenders in theBalkans, Romania, Russia, Greece,North Africa, Senegal, and even asfar as Swaziland, an area managedby Reinforced Earth Pty Ltd (SouthAfrica).”■INTERVIEWCharles Lavigne:“Sculpting nature”A specialist of civil engineering structures,architect Charles Lavigne has not onlylinked his name to the Normandy bridge,but also designed many Reinforced Earthstructures, in particular on the RN 202 bis trunk road, the Mussidan-Périgueuxsection of the A89 motorway and the A75 withthe Soumont wall.Reinforced Earth is considered a major innovation of thepublic works sector of the 1970s. Do you agree with this?Indeed I do, and for two reasons. From a technical viewpoint,Reinforced Earth opened up new horizons by making it possibleto erect very high walls with vertical faces that are very easy toinstall even in places that are difficult to access. From an architecturalviewpoint, its large surface scales, which conjure upthe cyclopean walls of Central America or Egypt, have given anew dimension to retaining walls. We can sum up by saying thatReinforced Earth makes it possible to remodel landscapes andsculpt nature.What was the first structure on which you used ReinforcedEarth for the first time?It was in the late 1970s on the A40 Nantua-Bellegarde motorway(Ain), at a spot where roads were on a mountain slope andwere separated. The creation of a Reinforced Earth wall usingthe excavated material of the higher road made it possible tosupport the downhill road, which was not supported by anything.For this structure, we designed an exclusive model withscales that came in four varieties. This obliged us to make apattern layout of 150,000 m 2 of Reinforced Earth, but in winterthe walls are adorned with stalactites and this gives a superbeffect.What are the architectural resources used in the process?How do you use them?To create light and shadow effects that emphasise or diminishthe presence of structures in the landscape, we can work withan entire range of surface skins (stony appearance, smoothappearance, etc.) and their organisation. On the Soumont wall,the creation of a staggered effect recalls the presence of astream. On the Brest ring road, I used tile-covered facings.Some architects use coloured concrete. TerraTrel is a solutionthat is very popular at the moment, because you can see thematerial. And because it can be used on slopes, we can plantvegetation on it, which rapidly gives a very natural facing in notime at all.What is your vision of the creative potential of Reinforced Earth ?The technique has already demonstrated what it can do. It canfind new applications in all the places where we want to createlarge movements of earth, give a landscape a facelift or requalifya site. I’m thinking of the use that could be made of ReinforcedEarth cords for landfills, the possible reclaiming of disusedquarries to return them to the environment. I think that iswhat we managed to do on the A40, and even more recently inthe La Maurienne valley, where we used Reinforced Earth torequalify the mountain bedrock that had been disfigured bymany brown fields.First half 2005 Soils & Structures 15

R E A L I Z A T I O N SSTRUCTURES/ARTHUR RAVENEL JR BRIDGETwo firsts inthe New WorldWith the record of thelongest central spanin North America, the bridgeon the Cooper river is alsothe first contract to supply andinstall stay cables that the companyhas signed in the United States.BETWEEN CHARLESTON ANDMOUNT PLEASANT in SouthCarolina, two steel bridges on thecoast form the crossing of Highway17 over the mouth of the CooperRiver. These two bridges, one ofwhich was built in 1928 and theother in 1968 have long ceased tomeet traffic needs or comply withsafety standards. They will soon bereplaced by the Arthur Ravenel Jrbridge that is nearly completed.This new bridge is remarkable formany reasons: with a length of4,023 m, 900 of which are cablestayed,and with a central span of472 m, it will beat the record of thelongest cable-stayed span in NorthAmerica (which had been held bythe Alex Fraser bridge in Vancouver).The Ravenel bridge is supportedby 128 stays that have beenentirely supplied, installed andtensioned by <strong>Freyssinet</strong>. That is theother remarkable new feature ofthis bridge. “It is the first time thatwe have won a contract to buildstay cables in the United States,explains Olivier Forget, projectmanager for <strong>Freyssinet</strong>. We onlyprovided technical support on theLeonard P. Zakim Bunker Hillbridge in Boston and the Bill Emersonbridge in Cape Girardeau.”With its vast experience, the veryinternational <strong>Freyssinet</strong> teamerected a pair of stay cables perpylon and per week, despite thefive hurricanes that hit the regionin September” notes Olivier Forgetwith pride. In addition to the supplyand installation of the staycables, the special climatic conditionsof the region led the StateDepartment of Transportation toask <strong>Freyssinet</strong> to carry out a seriesof studies and analyses of the staycable vibrations and provide adamping system. During the con-Olivier Forget, project managerfor <strong>Freyssinet</strong> , and José Lopes,<strong>Freyssinet</strong> field manager.struction works, we had to erect“high-wind” stability cables to stabilisethe structure when the averagewind speed exceeded 75 km/hfor an hour. Thanks to a systemmade up nails and a counterweight,the deck swung like a pendulumduring the hurricanes.Special dampers<strong>Freyssinet</strong>’s international team,made up of ten different nationalities,arrived on the site in early January2004. It finished laying thecable stays on 11 February 2005and is currently installing the 112internal hydraulic dampers, whichincludes 28 double dampers (speciallydesigned for the structure)and 16 external dampers that willbe installed on cables in excess of250 metres. At the same time, it iscarrying out the geometricaladjustments to the bridge. “We willcomplete our participation at theend of May with damping tests onthe cable stays in collaborationwith Advitam, our sister companyspecialised in the maintenanceand surveillance of structures”,concludes Olivier Forget. ■PARTICIPANTS▼ ▼ ▼ ▼ ▼Owner: South CarolinaDepartment of TransportationConsulting Engineer: TY Lin.Design engineer: ParsonsBrinkeroff – Buckland Taylor.Main Contractor:JV Skanska-Tide Water-HBGFlatiron.Specialised Contractor:<strong>Freyssinet</strong>.16 Soils & Structures First half 2005

REALIZATIONSWith its diamond-shaped towers, the profile of the new bridgewill strike all passers-by. “The structure must have a light longitudinalprofile for aesthetic reasons and to withstand earthquakes, butit must at the same time be heavy enough for the hurricanesthat are common in the region“, explains Olivier Forget. In additionto its visible and modern design, the bridge was built usingother <strong>Freyssinet</strong> expertise: to control stay cable vibrationsto the bridge construction the structure was stabilised with112 internal hydraulic dampers and 16 external dampers.First half 2005 Soils & Structures 17

R E A L I Z A T I O N SSTRUCTURES/BONO BRIDGERebirth of a hundredand fifty year-old structureClosed for two years becauseof its bad state, the Bonosuspension bridge (Morbihan,France) has been given a newlease on life thanks to <strong>Freyssinet</strong>’sbridge renovation expertise.NESTLED AT THE BOTTOM OFTHE MORBIHAN GULF NEARAURAY, the small Breton village ofLe Bono (2,000 inhabitants) islocated on the banks of the Le SalRiver. The only link between thetwo banks was an “old” suspensionbridge, 100 m long, built in 1840.The structure had two trusses madeup of 3 load-bearing cables onwhich 62 hangers were attached.On each bank, loop-shaped retainingcables were supported by thewalls of the U-shaped tunnels duginto the granite bedrock. Thebridge deck was composed of roadbearers and metal pieces. It held aplatform made of hardwood organisedinto a Hungarian point andlaid on ledger strips. The bridge,which was designed at the periodwhen carts were in use, wasEvacuation by flotationThe team came to the site in October2004 and immediately set towork to dismantle the suspendedspan. “We “oxy-cut” the bridgedeck into 6 m sections, which wetook down using linear winchesand transported away by flotation”,explains Ronan Bohéas, an engistrengthenedin 1870 and again in1925 to enable it to bear the weightof vehicles of up to 12 tonnes. Lateralstiffening girders forminghand-rails were added to thebridge deck at this time.Whipped by sprayLocated in a sea environment andfully exposed to the vagaries of theweather and sea spray, the metalstructure had deteriorated over theyears, leading the local authoritiesto close the bridge to vehicles in1995 and to pedestrians at thebeginning of 2003. Although it nolonger held strategic interest forthe local inhabitants, since theconstruction of another bridgefurther upstream that enabledmotorists to cross the Sal, the oldbridge remained entrenched in thelocal memory and inhabitantsremained very attached to it.After the Bono mayor’s office managedto have the bridge listed onthe supplementary inventory ofhistorical monuments in 1997, itdecided to save the structure fromcollapse and mobilised to collectthe funds needed to restore thebridge and reopen it to strollers. Acall for tender was launched inJune 2004 for sand blasting andgeneral painting, the replacementor repair of certain metal parts andthe complete replacement of thehardwood platform. <strong>Freyssinet</strong>,who won the contract, proposedanother solution consisting ofcomplete reconstruction of thebridge deck using a galvanisedstructure, and changing of thetwelve suspension cables.18 Soils & Structures First half 2005

REALIZATIONSneer at <strong>Freyssinet</strong>. In early December,we removed the old suspensioncables. We collected the metal socketsand gave them to the cable supplierfor socketing. <strong>Freyssinet</strong> alsocarried out additional works, suchas rehabilitation of the access spansand anchor chambers. After thenew suspension cables were delivered,reconstruction of the bridgedeck began at the beginning of February.“The process was the oppositeof the dismantling process, i.e.,the sections were brought by sea”,continues Ronan Bohéas. After thebridge was completely rebuilt,at the end of April 2005, and the suspensionadjusted by equipressure,the old bridge was inauguratedand reopened with the pomp andfestivities worthy of this land of the“forban”, a two-mast rowboat. ■PARTICIPANTS▼ ▼ ▼ ▼Owner: town of Bono.Consulting Engineer:Morbihan public worksdepartment.Engineering ConsultingCompany: Sogreah Best(Pontivy – 56).Main Contractor: <strong>Freyssinet</strong>.SOILS/M7 MOTORWAYConsolidatingthe lakefrontIn Hungary, where workis underway to extendthe M7 motorway, MénardSoltraitement has mobiliseda team to carry out soil consolidationover 400,000 square metresalongside Lake Balaton.SINCE IT JOINED THE EURO-PEAN UNION, Hungary haslaunched a massive programme tomodernise its infrastructure, in particularto bring its motorways inline with the European network andto relieve the isolation of some of itsregions. For example the extensionworks on the M7 motorway, whichconnects Budapest to Sófiok, to thenorth-east of Lake Balaton, will,provide a link with Croatia, which isonly 120 km away. The contract forthe work on the section runningalongside the lake was awarded tothe Hungarian company Vegyepszer.Part of the works is on a tenkilometrestretch where there isthick marshy land (up to 5 m thickin some places) that requiresground improvement . Of the varioussolutions proposed, the maincontractor chose the one offered byMénard Soltraitement consisting ofdynamic replacement. This wasjudged to be the most efficient, themost competitive and the fastest toimplement.Dynamic replacement andcontrolled-modulus columns“We have to make sure that thebackfill is stable and reduce differentialsettlements to a minimum onthe motorway segment”, explainsGilles Costa, in charge of the workbeing carried out by Ménard Soltraitement.To cut down on pedestriantraffic on bridges under construction,we have created an originalsolution that combines dynamicreplacement sections and controlled-moduluscolumns (CMC).“At each end of the structures, thefirst 15 m of motorway were treatedwith CMC and the next 15 m withdynamic replacement with preloading.The current section of themotorway had been traditionallytreated with dynamic replacement.”To implement the projectand realize about 400,000 m 2 ofdynamic replacement within thetight deadline (the works were completedat the end of April), MénardSoltraitement mobilised five cranesdoing double shifts. At the sametime, a team of sounders and apressure meter team carried outpreliminary tests, work inspectionand installation of monitoringinstruments that were mainly interstitialpressure sensors. “Of thethirty odd people who took part inthis project, nearly a third wererecruited and trained locally” GillesCosta adds.■PARTICIPANTS▼ ▼ ▼Owner: Hungary MotorwayMain Contractor: Vegyepszer.Specialised Contractor:Ménard SoltraitementFirst half 2005 Soils & Structures 19

R E A L I Z A T I O N SSTRUCTURES/JEBEL ALI SILOSStrengtheningat the top and bottomIn Dubai (UnitedArab Emirates),additionalprestressingmade it possibleto increasethe capacity of asugar silo andenabled MénardSoltraitementto enhance itssoil consolidationexpertise.THE SHARP GROWTH OF THESUGAR refining industry in theJebel Ali free port franc in Dubai,has led the port authorities todevelop their storage facilities. In2004, it launched the constructionof a new 900,000-tonne silo. However,this capacity turned out to beinsufficient even before the projectwas completed. The only solutionthat could be envisaged withoutdemolishing and rebuilding the silowas to raise the concrete skin roofby 20 to 25 m.“To prevent any excess structuraloverall weight, the project consultingengineer recommended that anexternal additional prestressing beadded”, explains Khalil Doghri, managerof the <strong>Freyssinet</strong> Gulf agency.“That is how we managed to win thecontract in mid-May 2004 after abidding process.” To strengthen thestructure, the <strong>Freyssinet</strong> teamsinstalled 117 cables with a height of16 m around the sailor silo (this represented80 t of steel). Each ring wasmade up of 4 strands each 138 mlong connected by 468 X anchors,enclosed in single HDPE ductsinjected with cement grout.55 m high of sugar“When we were informed that newsilos were to be built during ourwork, we immediately presentedMénard Soltraitement to the ownerfor a foundation soil improvementsolution for the new structures”,continues Khalil Doghri.Changing the initial solution byThe silo’s capacity hasbeen increased with the117 additional prestressingthat strengthen it over aheight of 16 m.sinking piles sunk into the sandyand silt-laden soil, which is a verycommon technique in the UnitedArab Emirates, Ménard Soltraitementproposed the installation ofdynamic replacement that willenable the soil to bear the weight ofGroup synergythe silo at full load, which is theequivalent of a height of 55mof sugar… and carried off the contract.“The calculations were complicated”,confides DominiqueJullienne, in charge of MénardSoltraitement’s business in theEmirates, “and we had to take intoaccount all the loading and reloadingof heavy loads on time”.There were some other parameterssuch as the dynamic loads causedby the rubbing of sugar on the wallsof the silo. Finally, the solution proposedby Ménard Soltraitementconsisted in the combination ofthe company’s technical expertise:dynamic replacement, partialreplacement (piling of aggregateinto soils of weak consistency) andthe dynamic compaction of soils.This treatment was applied underthe silo skin roof, which resulted inthe uniform sagging of the siloslabs. “All the studies were validatedby modelling the behaviour of theslab laid on consolidated land andusing a Ménard pressuremeter”,concludes Cyril Plomteux, an engineerat Ménard Soltraitement. ■Located in the same premises in Dubai, <strong>Freyssinet</strong> Gulf, MénardSoltraitement and Reinforced Earth offer very complementaryservices to their clients. Employees of the three companies areconstantly in touch and propose comprehensive and responsivesolutions, thanks to a very diverse range of services. In additionto the construction of the new silos of the Jebel Ali free port, thesynergies developed over the last five years have resulted in othercommon projects such as the Townsville sugar terminal in Australia(see S&S no.° 217).20 Soils & Structures First half 2005

REALIZATIONSSOILS/NORTH KIAMA BYPASS ROADBuilding a TunnelThe Reinforced EarthCompany in Australiacombined retaining wallswith precast concrete TechSpanarches to make it possible for a newaccess highway in North Kiama(Australia) to cross a railway.Located two hours by car to thesouth of Sydney, North Kiama(New South Wales), with itsbeaches, mountains with lush vegetationand picturesque blow hole(cavity in the rocks on the seashorefrom which water spurts to heightsof 60 m under pressure fromwaves), is a choice destination forAustralians. For many years, carscould only take one road to getthere: a single-lane, winding roadcalled the Princes Highway. Constructionof a new road was proposedin 1990, but it was not until1997 that construction of thiscompletely new, double-lanehighway commenced.The second phase of construction,that began in November 2003,involved the Australian ReinforcedEarth subsidiary designing andsupplying a a covered railroad span(64 m long and 12 m wide) composedof TechSpan elements andReinforced Earth supported accessramps to replace the previousPrinces Highway grade crossing.“The plans for the tunnel weredrawn up using 3D-design software.This made it possible to optimizethe design allowing for thecomplex geometry created by thehorizontally and vertically curvedrail track and the acute-angledretaining walls supporting thehighly skewed bypass road. Thiswas probably the main challengeof the project,” states Michiel Knol,Reinforced Earth engineer andproject manager. These 3D simulationsmade it possible to validatetunnel height and, especially, toadjust the ends of the coveredspan that were turned towards theinterior. It was necessary to build86 TechSpan® arch elements: 70with classic width, 7 with reducedwidth and 9 specially tapered elements.In the final configuration, the roadwill cross over the covered span.For this, 2400 m 2 of retaining wallsare under construction and will beused for the access ramps on eachside. “We were forced to find atechnical solution to allow thegeneral contractor to build thewalls without interrupting trafficon the Princes Highway runningalongside the structure on theocean side,” explains Michiel Knol.The construction timeline calledfor the retaining walls on the landside to be built first. On the otherside, temporary TerraTrel meshwalls (1270 m 2 ) have been built tostabilize the backfill and avoid runover into the road. “Once trafficcan be moved to the land side,we'll be able to complete constructionof the covered span andretaining walls on the ocean side,”specifies Michiel Knol.“Technically and architecturallyspeaking, this is an interestingproject that uses three of our constructionsystems to achieveglobal aesthetic harmony,” concludesGraham Linn, ReinforcedEarth warehouse manager. He alsohighlights the attention brought tothe facing panels, in particular,that were specially precast toblend harmoniously with the landscape.■PARTICIPANTS▼ ▼ ▼Owner: Roads & TrafficAuthority of NSW.General Contractor: JohnHolland Pty Ltd.Design and Supply: ReinforcedEarth Company AustraliaFirst half 2005 Soils & Structures 21

R E A L I Z A T I O N SSTRUCTURES/SUNGAI PRAI BRIDGEA lessonof know-howIn Butterworth (Malaysia),the construction ofthe Sungai Prai Bridge hasmobilised the <strong>Freyssinet</strong> teams,who are working on constructionmethods as well as the supply anderecting of stay cables.Melo in charge of the methods unitat the <strong>Freyssinet</strong> Technical Division.This will enable us to install“triple-box” spans that are 14 mwide and weighing 1,500 t, composedof precast segments suppliedfrom the bridge deck that hasalready been laid. These are thecentral cores of the deck, and theywill receive the precast lateral cantilevers,lowered by cranes andthen held in place with prestressedcables.Multiple cantilevers“The laying method used for themain span of the cable-stayedbridge is not very different”, continuesFernand de Melo. The precastsegments (also three-box girders)are brought from the deck, whichhas already been built and installedby cantilever construction method,from each pylon by a portal framefixed to the deck. The stay cablesare installed and tensioned at twosegmentintervals. As on the rest ofbridge, the lateral cantilevers arefixed with prestressing bars to themain structure. The segment of twoof the access ramps are laid using asecond self-launching truss thaterects the 29 spans, two sections ofwhich will span the railway tracks.The third spiral access ramp is builton a falsework.The Prai river crossing will be on a485 m cable-stayed bridge with acentral span of 185 m. The deck issupported by 112 twin stay cables,protected by white HDPE ductsand supported at the two pylons(39m high) by single-tube deviationsaddles. “The first stay cablewas launched on 9 th October 2004,and we have 9 months to finish layingthe cables”, explains PascalMartin-Daguet the <strong>Freyssinet</strong> engineerin charge of the site. Beforethe structure is opened to traffic inJanuary 2006, to ease Butterworth’straffic woes, <strong>Freyssinet</strong> will alsohave supplied and laid bearingsand expansion joints.PARTICIPANTS▼ ▼ ▼ ▼Owner: Lingkaran LuarButterworth Sdn Bhd(concession company).Main Contractor and designoffice: Perunding Jurutera DAHSdn Bhd (Dar Al-Handasah).Main Contractor: IJM-ZüblinJoint-Venture.Specialised Contractor:<strong>Freyssinet</strong> PSC – <strong>Freyssinet</strong>APTO Joint-Venture.■ON THE WEST COAST OF THEMALAYSIAN peninsula, lessthan 100 km from the Thai border,the town of Butterworth oppositethe island of Penang, is one of thecountry’s largest port complexes. Itis also the heart of a region undergoingfast industrial and urbangrowth, where the 12.1 km ButterworthOuter Ring Road project waslaunched as a concession in 1997 toconnect the Jalan Baru interchangein the south of the town and theSungai Dua interchange in thenorth, running alongside the portand the ferry terminal. In additionto the many road improvementworks, the project also includes theconstruction of a dual three-lane2.85 km bridge (28.8 m wide) thatwill cross the Prai River, as well as a"trumpet" interchange that willcome back to the port.The structure is made up of twoapproach bridges each comprisingten and eleven 50 m spans, a 185 mcable-stayed span and three accessramps. “We began by developinga 120 m overhead self-launchingtruss weighing 850 tonnes (see pictureabove), that enabled us to laythe segments composed of 21spans on each side of the cablestayedbridge”, explains Fernand deSupported by 112 twin cable stays, the bridge that will crossthe Prai river is 485 m long.22 Soils & Structures First half 2005

REALIZATIONSSTRUCTURES/ESSO GLEN COMPLEX IN LONDONPost-tensioned concrete slabsgain popularity in Great Britain50,000 m 2 of post-tensionedconcrete slabs have been laidin the heart of the City.IN VICTORIA, CENTRAL LON-DON, a group of prestigious officebuildings with avant-garde architectureare under construction. Theprogram, known as Esso Glen, ismade up of two structures: one 10-storey glass building graced withcurves and the other a more classical6-storey building. “These twobuildings represent a total of50,000 m 2 of post-tensioned concreteslabs. We supplied and installed320 t of 5S13 and 12K15 strandsfor this project, as well as temporaryprestressing cables (1S15) for thetransfer beams,” notes Paul Bottomley,<strong>Freyssinet</strong> Ltd TechnicalDirector. This site, located in theheart of the City district, is a sign ofthe current growth in the use of prestressingin Great Britain and Ireland.Architects, contractors and clientshave compared the architecturaladvantages and profitability of theprocess for all types of residential orprofessional real estate projects,”explains Patrick Nagle, ManagingDirector of <strong>Freyssinet</strong> Ltd.The company has seen a sharpincrease in its projects: <strong>Freyssinet</strong> iscurrently working on the BeethamHilton, a 47-storey building underconsturction in Manchester; theBridgewater Place, a 33-storey realestate complex in Leeds; the AMSHouse, a smaller project near London;and the Ballincollig Var Parksin Cork in Ireland.■STRUCTURES/THE GUIPÚZCOA GREEN BELTCarbon strengthening on the waterwayTHE SPANISH BASQUE COUN-TRY has an unequalled supply ofhydraulic resources and experiencesa drought each year. To find asolution to this problem, theGuipúzcoa authorities have adopteda special plan based mainly onthe interconnection of the dams ofthe towns of Ibai-Eder and Barrendiola,in the Urola valley.To connect the two structures, separatedby a distance of 16 km, therouting that was chosen was that ofa mining railway track that was nolonger in use. The project couldtherefore use existing infrastructures(11 bridges and 19 tunnels),which nevertheless had to bestrengthen and renovated. Theauthorities decided to kill two birdswith one stone by creating a “greenbelt” for cyclists and strollers allalong the route. “We won the contractto rehabilitate 8 concretebridges, made up of between 1 and3 isostatic spans, making a total of17 spans since each structure had adouble-T deck that was 3.6 mwide”, explains Pedro Sancho, headof <strong>Freyssinet</strong>’s Basque countryoffice branch.The solution recommended by thedesign team was based on strengtheningthe bending resistance, soeach bridge girder could withstanda tension stress of 380 kN in its centre,and on strengthening the shearforce. The technical solution developedby the technical departmentof <strong>Freyssinet</strong>’s Iberian-Americandivision in Madrid, is based on theuse of composite materials. The<strong>Freyssinet</strong> teams strengthened allthe structures with 2,864 m of carbonfibre laminates (LFC) and122.70 m of carbon fibre fabric(TFC) of a width of 300 mm. In theplaces where the concrete wasdamaged, the steels were first passivatedusing epoxy resin agents.After that, we applied high-performancethixotropic mortar andacrylic paint to protect against carbonation.■PARTICIPANTS▼ ▼ ▼Owner:Diputación Foral de Gipuzkoa.Main Contractor:Mariezcurrena.Specialised Contractor:<strong>Freyssinet</strong> S.A.First half 2005 Soils & Structures 23

R E A L I Z A T I O N SSTRUCTURES/PLOCK BRIDGEThree records over the vistulaConstruction of the PlockBridge (Poland), the biggestcable-stayed structure in thecountry, began in July 2002 and willbe completed in the middle of 2005.The structure will be 1,200 m longincluding 585 m of access spansand a 615 m main cable-stayedbridge with a 375 m central span.The dimensions of this bridge builtover the Vistula to the northwest ofWarsaw do not at all reflect theimportance of this project, combiningthe expertise of <strong>Freyssinet</strong>International and <strong>Freyssinet</strong> Polskawhich is breaking all sorts ofrecords in Poland.The main span of the bridge is thelongest ever built in the country andthe access spans, composed ofmetal, required the largest liftingoperations ever performed. Assembledon the ground in segments60 m-long and 27 m-wide, these600 t pieces were put into placeusing a lifting frame and hydraulicjacks and were then weldedtogether.In the second phase of construction,two 64 m-high I pylons wereinstalled and the deck of the centralspan was built by the successivecantilever construction method.The segments were brought to thesite by the river and were then liftedinto place using a SL 230 system ofcables and hydraulic jacks with atotal capacity of 4710 kN. While thesegments were being placed,<strong>Freyssinet</strong> teams installed the 56stay cables. The twin stay cables aredisposed on a central plane, “a configurationthat brought eleganceand grace to the structure,” saysKrzysztof Berger, General Manager.Depending on their length, whichvaried from 38 to 188 m, the cablesare composed of bundles of 47 to 84strands enclosed in Mediterraneanblue,HDPE (high density polyethylene)ducts.In association with supply andinstallation of the stay cables andheavy lifting, <strong>Freyssinet</strong> was alsoinvolved in a third part of theproject: installation of bearings anduse of out-of-specifications systems.In this respect, the structurealso broke a third record. Of the 56bearings installed on the piers, twospherical bearings, one placed oneach of the end piers, were ofextraordinary dimensions and hada nominal capacity of 110 mN.“The final stay cable was installed<strong>Freyssinet</strong> drew upon itsexpertise in heavy lifting,cable staying and structuralfitting to work on Poland’slargest cable-stayed structure.in January 2005 and the deck willbe closed when the temperaturereaches +5ºC. Construction thatnever interrupted river traffic, willnow continue until June 2005 witha reduced team responsible forfinal adjustments” concludesAndrzej Berger, the engineer.PARTICIPANTS▼ ▼ ▼ ▼ ▼Owner: town of Plock andGeneral Road and HighwayDepartment (GDDKiA).Engineering ConsultingCompany: Pontprojekt Gdansk.General Contractor: MostyLodz S.A. and Mosty Plock -consortiumConsulting Engineer: ZBMInwestor Zastepczy Sp z.o.o.Specialised Contractor:<strong>Freyssinet</strong> Polska,in association with <strong>Freyssinet</strong>International.■24 Soils & Structures First half 2005

REALIZATIONSSOILS & STRUCTURES/THE ORAN INTERCHANGEOpenings for the construction teamBy joining forces to proposea more competitive variantfor the Oran interchange inAlgeria, <strong>Freyssinet</strong> has providedReinforced Earth with theopportunity to carry out its firstretaining structure in ten years.IN 2001, A PERIOD DURINGWHICH ALGERIA massively renovatedits infrastructure, the publicworks department of the Wilaya ofOran, the country’s second largestcity, decided to build an interchangein the eastern part of thecity. The project included severalcivil engineering structures, one ofwhich was a curved bridge with aradius of 56 m. “In 2002, the Algerianpublic enterprise Seror-Tlemcen,who had won the contract,contacted us for assistance indesigning the bridge”, explainsHabib Merabet, head of <strong>Freyssinet</strong>’sNorth African operations. In thebeginning, the project consisted inbuilding a slab-bridge on trusseswith access ramps comprising ahollow abutment in reinforced concrete.“However, given the height ofthe bridge piers and the ruggedlandform, this technical solutionquickly proved to be expensive,continues Habib Merabet. It wouldalso have meant closing down trafficon a very busy stretch below thebridge.”An intrados on a spiralTo make up for these disadvantages,<strong>Freyssinet</strong> and Terre ArméeSNC proposed a variant to the solutionconsisting in launching theprecast slab-bridge and thereplacement of the hollow abutmentwith a 18 m high Freyssisolretaining wall. Structural studiesfor the bridge kicked off in 2003.“We redefined the geometry of thestructure with an intrados with aspiral to make it easy to shift”,explains Stéphane Faure, the engineerin charge of the works. Thefinal solution was a slab-bridgewith a constant thickness of 1 m,positioned in a circle with an averageradius of 56 m. The 123 mbridge has two 17 m end spans andfour 22 m central spans. “Thewhole structure represented morethan a quarter circle to shift.”remembers Stéphane Faure.As the superelevation of the bridgevaried between 0 to 7% with adownhill longitudinal slope thatcould be as steep as 7%, <strong>Freyssinet</strong>opted for a flexible launching systemthat also had retaining characteristics.On site, work began withthe erecting of the piers and creationof a precast area made up oftwo curved sleeper plates thatserve as a rack for the TP200 pushrams and bear the weight of thestructure. The equipment is completedwith a 25 m curved launching,side guides on the piers andslip saddles.The construction was carried outin four sections that were assembledby a centred prestressing,coupled at the end of each sectionand made up of sixteen 19C15cables. After the piers had beenerected, <strong>Freyssinet</strong> fitted the bridgewith Tetron and Neoprène potbearings and expansion joints. Itthen installed the final continuityprestressing, made up of twelve19C15 cables. At the same time,Reinforced Earth supplied morethan 20 moulds for making 800Freyssisol panels. This technology,used for the first time in the countryby Seror, was used to build theaccess ramp to the main abutment(2,500 m 2 ). The bridge was inauguratedon 24 December 2004. ■PARTICIPANTS▼ ▼ ▼ ▼Owner:Direction des travaux publics(DTP) de la wilaya d’Oran.Main contractor :Seror-Tlemcen.Design and methods :<strong>Freyssinet</strong>.Specialised Contractor:<strong>Freyssinet</strong> and Terre Armée SNC.First half 2005 Soils & Structures 25

R E A L I Z A T I O N SSTRUCTURES/GERRARDS CROSS PLATFORMA supermarket on the right trackIn Gerrards Cross (UnitedKingdom), there wasn’tenough space for asupermarket and a parking lot. Withthe use of TechSpan arches, bothwill soon be inaugurated on aplatform built over the railroad tracks.TAKING ADVANTAGE OF THEFOUR HOURS during whichrailroad traffic comes to a halt,PCE’s arch erection teams works onthe site in Gerrards Cross, a smalltown to the northeast of London.Every night, the team, working formain contractor Jackson Civil Engineering,installs 5 of the 343 piecesof the TechSpan arches that willsoon form a 320 m-long cut-andcovertunnel above two railroadtracks. On this structure will bebuilt a platform upon which will risea supermarket and car park. Is thisan original way to make the most ofpreviously-unusable spaces? Notreally, according to Jon Cross, thedirector of Reinforced Earth. Hetraces this idea back to the early1960s: “As early as 1962, NorwestHolst, a VINCI subsidiary, executedground investigation for thescheme.”Now, 35 years later, another VINCIgroup subsidiary, Reinforced Earth,became involved in the project. Infact, engineering consultant namedWhite Young Green approached thecompany in 1998 to assist developmentof a solution using a buriedprecast segmental arch system: thiswas the starting point for theGerrards Cross project. Originally,the preliminary design called for14 m span arch to cross the existingtwin tracks Chiltern Line. “Sincethen, Jon Cross explains, the finalscheme required a much larger20 m span to allow for any futurewidening of the railway line up tofour tracks.”Safety andenvironment firstFrom the outset, safety and theenvironment have always been thetwo key criteria guiding this highimpactproject. Those living nearthe site must not be disturbed bywork performed at night. “Whenwe won the bid for the contract in2003, we immediately sought tooptimize the arch sections forincreased width and to limit thenumber of pieces needed to beinstalled”, describes Jon Cross. Thismade it possible to limit the equipmentrequired on the site as muchas possible: a 160 t capacity cranewas sufficient for installation of thearch pieces that each weighed 23 t.”Installation began on October 10th,2004 towards the western end ofthe tunnel. At the western portal,the entrance is formed from aseries of truncated arch units tiedtogether with an in-situ concreteringbeam. The eastern portal comprisesfull-height precast concreteheadwalls flanked by ReinforcedEarth TerraClass wingwalls. Thespan must also pass through thecentral span of the Packhorse roadwaybridge. The continuity of thecovered span relies on 9 singlepiece precast arch units placed ontwo skew back beams. The entiretunnel structure is founded onauger bored piles.Construction is planned for completionin the second quarter of2005 following backfill of the archwith 100,000 m 3 of ground limestone.Then, all that remains is constructionof the supermarket that isplanned to open at the end of thethird quarter.■PARTICIPANTS▼ ▼ ▼ ▼ ▼ ▼Owner: Tesco SupermarketsProject Manager: GleedsConsulting Engineer: WhiteYoung GreenMain Contractor: Jackson CivilEngineeringArch Construction: PCE LtdSpecialised Contractor:Reinforced Earth Company Ltd26 Soils & Structures First half 2005

O U R P R O F E S S I O NA PROTECTIVE CURRENT TO STOP CORROSIONIn specialised civil engineering,some professions can be understoodat a glance while othersrequire greater insight. This seemsto be the case with the team of aBritish subsidiary of <strong>Freyssinet</strong>Group, the CCSL Company (CorrosionControl Services Ltd). “Thesame operations are always used incathodic protection (see box),declares Ian Spring, technicaldirector of CCSL. Our first task is toconnect cables to the concretereinforcement and to check it’selectrical continuity. We can theninstall an anode that can come indifferent forms depending on therequirement. We also install monitoringelectrodes and connect allthese elements to an electrical cabinet.”After the current (usuallywith a voltage of less than 12 V) hasbeen established, treatment followsimmediately and CCSL cantrack performance from its officesin Telford, using remote devices.Although it is increasingly appliedas a preventive treatment for newstructures, cathodic protectioncontinues to be used more forrepair works, where the deteriora-tion of concrete may come fromtwo main causes: chlorides (whenthe structure is exposed to a saltyatmosphere) or carbonation (developmentof calcium carbonate dueto the transformation of the atmosphericcarbon dioxide reducing thepH of the concrete). “Our first task,therefore, is to establish a diagnosis,explains Jim Preston, director ofCCSL. We do this either when weare asked to do so directly by aclient who has observed a deteriorationin a concrete structure, or asa subcontractor when a consultanthas already recommended thatcathodic protection be carried out.Whatever the operation scheduleand the nature of the corrosion,CCSL has a solution in the vastoffering that it has managed todevelop in less than ten years (thecompany was created in 1996) notonly for the treatment of existingstructures, but also for new construction:cathodic protection forreinforced concrete, buildings withsteel frames and submerged structuresin marine environments suchas pipelines, etc.. CCSL works inthe four corners of the world (it isOnce the titanium anode isinstalled, the installers makethe electric connections.currently in the United Kingdom,Ireland, Hong Kong, Croatia andSaudi Arabia) and has thus collectedvaluable data about structuresthat have received this type oftreatment. This enables it to offerits clients reliable and proven solutions.“Demand for this technique goes asfar back as the 1980s, continues JimPreston, and we can say that it literallyexploded at that time. The prin-ciple is, however, much olderbecause it began with the work ofHumphrey Davy in 1824. We thereforedid not invent anything newand only adapted a long-establishedengineering technique to the problemsof our modern materials.” ■12An electrolytic processThe environment for steel reinforcement that is provided by good qualityconcrete is of high alkalinity. Provided this environment is maintained, thesteel will remain passive and no corrosion will take place. Corrosion is aprocess of electrochemical deterioration. The infiltration of impurities intoconcrete (for example atmospheric carbon dioxide) disrupts the chemicalbalance and reduces the pH of the material. Chloride ingress to the steel willalso result in depassivation. Upon contact with water and oxygen, metalatoms are ripped from the surface, lose electrons and are ionised. The metalbecomes polarised, forming one or several macro-batteries on its surface.The resulting electrical field erodes the metal at the anode (pits). Such lossof elements results in what is known as corrosion. To neutralise and stop thisprocess, the metal is transformed into a cathode. This can be accomplishedeither by running a weak impressed continuous electric current through themetal or by connecting it to a galvanic anode, a different metal that will corrodemore readily than iron and create an electron flow that enables to fightthe charges to which the reinforcements are submitted: that is cathodic protectionusing sacrificial anode.THE PRINCIPLE OF CATHODIC PROTECTIONPowersupply(cabinet)Directionof electron flowElectrodesRemotesurveillancesystem(computer)ANODECl-Cl-ConcretePenetrationof ions fromthe anodeCl-Cl-Metalreinforcement(reinforced steel)First half 2005 Soils & Structures 27

C O M P A N YFREYSSINET POLSKACONFIRMS ITSBREAKTHROUGHFor six years now, <strong>Freyssinet</strong> Polskahas made a name for itself in Polandthanks to a dynamic and efficientteam and by marking each year withan important achievement.In May 1995, a year after Polandapplied for membership to theEuropean Union, <strong>Freyssinet</strong> Internationalopened a technical informationoffice in Warsaw, under themanagement of Krzysztof Berger,an engineer of public works. Fouryears on and after many successes(external prestressing of the GóraKalwaria bridge, strengthening ofthe silos in Werbkowice, Brzeg andBodaczów, etc.), they consolidatedtheir advantage with the creationof the limited liability company<strong>Freyssinet</strong> Polska SP. Z o.o.That was how the success story ofthe 33-employee subsidiary began.“We started off with <strong>Freyssinet</strong>’s traditionalareas of expertise, explainsKrzysztof Berger, General Managerof <strong>Freyssinet</strong> Polska since 1999, andwe gradually added ReinforcedEarth and soil treatment activitiesto our offering. Consequently, ourimage has changed considerablyand we are now recognisedthroughout the country as one ofTHE COMPANY IN BRIEF▼ ▼ ▼ ▼ ▼Name: <strong>Freyssinet</strong> Polska Sp.z.o.o.Address: Poland, 05-822Milanówek, ul. Mala 5,tél./fax: + 48 22 724 43 55/56.2004 Turnover:4,5 M€.Number of employees: 27.General manager:Krzysztof Berger.the unavoidable players in the specialisedcivil engineering business.”This small subsidiary’s reputationis concretely illustrated in prestigiousprojects that it has carried offin barely 6 years: construction offive cable-stayed bridges over theA4 motorway in 1999; incrementallaunching of the bridges of theCzerniakowski interchange in Warsawin 2002; the cable-stayedbridges of Wolin and Poznan in2003; the Plock bridge on the Visulatoday (see page 24). In 2003, thesesuccesses, and the efforts behindOne of the 5 cable-stayed bridges on the A4 motorway.Successive launching of bridges in the Czerniakowskiinterchange in Varsovia.them, were crowned with theGazela Biznesu prize (Businessprize) awarded by the magazinePuls Biznesu to investors, designoffices or civil engineering companiesfor their dynamism, resultsand commitment to sustainabledevelopment.An active support from<strong>Freyssinet</strong> BelgiumIn the Group and in terms of organisation,<strong>Freyssinet</strong> Polska isattached to the Northern Europedivision, which includes the UnitedKingdom, the Benelux and theScandinavian countries. “There area lot of synergies between the variouscompanies within the division,says Krzysztof Berger. In 1999,when the works sites of the A4motorway began just a few daysafter the company had been created,we received a lot of supportfrom <strong>Freyssinet</strong> Belgium, and particularlyClaude Mortier who sentseveral technicians to work withour teams. However, this culture ofexchange and support is not limitedto the regional level: it continues,for instance with <strong>Freyssinet</strong>France on the bridges in Plock,Wroclaw, Warszawa and is currentlybeing developed in soils.” ■1 2 3 4 5 6 7 8 9 10 11Headed by par Krzysztof Berger (on the left side) (3), the company is divided into five divisions: the Works division, directed by Andrzej Kandybowicz 3,which is made up of two engineers, Piotr Beczek and Andrzej Berger 2, and three team leaders, Sylwester Ostafinski, Grzegorz Hrynczyszyn and TomaszCieplucha; the logistics division with Zofia Krawczyc and Katarzyna Wlódarczyk (9) the Marketing department, with Lucjan Talma (10) and AnnaMarjanska (4); the Accounting Division with Pawe_ Skrzypczak and Karolina Wudarczyk (6); the soil improvement business headed by ArkadiuszFranków (5) and composed of an engineer Adam Syzdól (1) and a project designer, Marta Sierocinska (11) for Reinforced Earth activity, Jakub Saloni (7)for Ménard Soltraitement. The company also employs a warehouse manager Dariusz Kwiatkowski (8) and a maintenance mechanic, Krzysztof Szkop.28 Soils & Structures First half 2005