NiCu 70/30

NiCu 70/30

NiCu 70/30

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

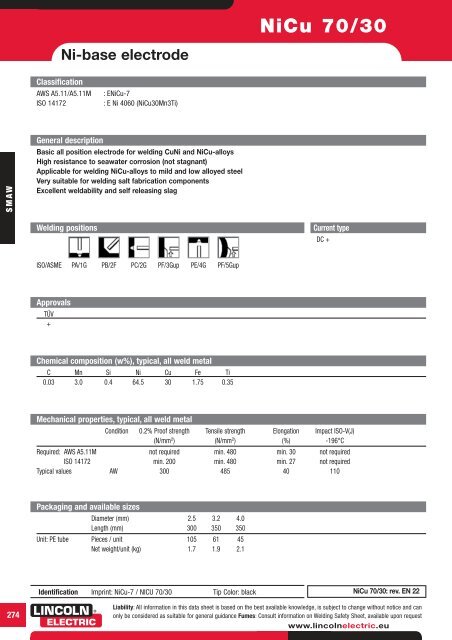

Ni-base electrode<strong>NiCu</strong> <strong>70</strong>/<strong>30</strong>ClassificationAWS A5.11/A5.11MISO 14172: E<strong>NiCu</strong>-7: E Ni 4060 (<strong>NiCu</strong><strong>30</strong>Mn3Ti)SMAWGeneral descriptionBasic all position electrode for welding CuNi and <strong>NiCu</strong>-alloysHigh resistance to seawater corrosion (not stagnant)Applicable for welding <strong>NiCu</strong>-alloys to mild and low alloyed steelVery suitable for welding salt fabrication componentsExcellent weldability and self releasing slagWelding positionsCurrent typeDC +ISO/ASME PA/1G PB/2F PC/2G PF/3Gup PE/4G PF/5GupApprovalsTÜV+Chemical composition (w%), typical, all weld metalC Mn Si Ni Cu Fe Ti0.03 3.0 0.4 64.5 <strong>30</strong> 1.75 0.35Mechanical properties, typical, all weld metalCondition 0.2% Proof strength Tensile strength Elongation Impact ISO-V(J)(N/mm 2 ) (N/mm 2 ) (%) -196°CRequired: AWS A5.11M not required min. 480 min. <strong>30</strong> not requiredISO 14172 min. 200 min. 480 min. 27 not requiredTypical values AW <strong>30</strong>0 485 40 110Packaging and available sizesDiameter (mm) 2.5 3.2 4.0Length (mm) <strong>30</strong>0 350 350Unit: PE tube Pieces / unit 105 61 45Net weight/unit (kg) 1.7 1.9 2.1Identification Imprint: <strong>NiCu</strong>-7 / NICU <strong>70</strong>/<strong>30</strong> Tip Color: black <strong>NiCu</strong> <strong>70</strong>/<strong>30</strong>: rev. EN 22274Liability: All information in this data sheet is based on the best available knowledge, is subject to change without notice and canonly be considered as suitable for general guidance Fumes: Consult information on Welding Safety Sheet, available upon requestwww.lincolnelectric.eu

<strong>NiCu</strong> <strong>70</strong>/<strong>30</strong>Materials to be weldedSteel grades BS<strong>30</strong>76 DIN 17743 Mat. Nr ASTM/ACI UNSNA 13 <strong>NiCu</strong><strong>30</strong>Fe 2.4360 Monel 400 N04400G-<strong>NiCu</strong><strong>30</strong>Nb 2.4365NA 18 <strong>NiCu</strong><strong>30</strong>Al 2.4375 Monel K500 N05500The <strong>NiCu</strong> <strong>70</strong>/<strong>30</strong> is also applicable for welding mild, low alloy, and stainless steels to CuNi and <strong>NiCu</strong> alloysSMAWCalculation dataSizes Current Current Arc time Energy Dep.rate Weight/ Electrodes/ kg Electrodes/Diam. x length range type - per electrode at max. current - 1000 pcs. kg weldmetal kg weldmetal(mm) (A) (s)* E(kJ) H(kg/h) (kg) B 1/N2.5 x <strong>30</strong>0 45 - <strong>70</strong> DC+ 50 72 0.80 20.7 90 1.853.2 x 350 <strong>70</strong> - 90 DC+ 65 129 1.2 32.5 46 1.494.0 x 350 90 - 1<strong>30</strong> DC+ 67 245 1.75 47.17 31 1.51* stub end 35 mmWelding parameters, optimum fill passesWelding positions PA/1G PB/2F PC/2G PF/3G up PE/4G PF/5G upDiameter (mm)2.5 65A 60A 65A 55A 55A 55A3.2 90A 85A 90A 75A 75A 75A4.0Remarks/ Application adviceWelding with Heat-Input max. 1.5 kJ/mmInterpass temperature max. 150°C275