THANET OFFSHORE WIND LIMITED - Vattenfall

THANET OFFSHORE WIND LIMITED - Vattenfall

THANET OFFSHORE WIND LIMITED - Vattenfall

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> <strong>LIMITED</strong><strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> FARM <strong>OFFSHORE</strong> DECOMMISSIONING PLAN MAY 2008

CONTENTSPage NoCONTENTS 11. INTRODUCTION 1.12. EXECUTIVE SUMMARY 2.13. BACKGROUND INFORMATION 3.13.1 <strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> <strong>LIMITED</strong> 3.13.2 <strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> FARM - PROJECT DETAILS 3.13.3 AS-BUILT INFORMATION 3.23.4 ADDITIONAL INFORMATION 3.24. DESCRIPTION OF ITEMS TO BE DECOMMISSIONED 4.14.1 <strong>OFFSHORE</strong> SUBSTATION 4.14.2 <strong>OFFSHORE</strong> WTG STRUCTURES 4.24.3 SUBSEA CABLES 4.44.3.1 Export Cables 4.44.3.2 Interarray Cables 4.44.3.3 External Cable Protection .4.45. DESCRIPTION OF PROPOSED DECOMMISSIONING MEASURES.. ...... 5.1 5.1 PLAN OF WORKS AND INTEGRATION5.15.2 PROPOSED METHOD OF REMOVAL5.2.1 Offshore Substation5.2.2 Offshore WTG Structures5.2.3 Offshore Cables5.15.25.25.35.3 PROPOSED WASTE MANAGEMENT SOLUTIONS5.35.4 DETAILS OF ANY ITEMS WHICH MAY BE LEFT IN SITU<strong>OFFSHORE</strong> FOLLOWING DECOMMISSIONING5.36. ENVIRONMENTAL IMPACT ASSESSMENT. 6.17. CONSULTANTS WITH INTERESTED PARTIES 7.18. COSTS 8.19. FINANCIAL SECURITY 9.110. SCHEDULE 10.111. PROJECT MANAGEMENT AND VERIFICATION 11.1MAY 2008 Page 0.1 of 0.2

12. SEABED CLEARANCE 12.113. RESTORATION OF THE SITE 13.114. POST DECOMMISSIONING MONITORING, MAINTENANCE ANDMANAGEMENT OF THE SITE 14.115. SUPPORTING STUDIES 15.116. APPENDIX 1 - ENVIRONMENTAL STATEMENT SUMMARY 16.117. APPENDIX 2 -- CASHFLOW SUMMARY 17.1MAY 2008 Page 0.1 of 0.2

1. INTRODUCTIONThanet Offshore Wind Limited (TOW), as the owner of the Thanet Offshore Wind Farm (Thanet)project, has prepared this Decommissioning Plan in accordance with the requirements of theEnergy Act 2004. Construction of the project is currently planned to commence shortly and becompleted during 2009. This Decommissioning Plan covers the elements of the project that areplanned to be built offshore and is based on the known parameters at the Thanet site and oninformation received from the main contractors who have been appointed as PreferredContractors to the project. The Decommissioning Plan will be reviewed as the project progressesand detailed design, construction and installation works are undertaken and completed. It willthen be reviewed at least every five years to ensure that it is compliant with the legislation inplace at that time.There will be a requirement to decommission at the end of the operational life of the Thanetproject. The scope of the decommissioning works described here is determined by the legislationand guidance in place at this point in time and involves those accessible installed components ofthe wind farm. This includes the Offshore Substation (Topsides and Jacket Structure); all of theWind Turbine Generator (WTG) components; part of the WTG Foundations and approximately10m sections of the Export Cables and Interarray Cables close to the offshore structures. Thecable sections to be removed will be the sections of cable exiting from the J/1-tubes on thestructures to the grade-in point of cable burial protection for the subsea cables.This Decommissioning Plan only covers the offshore elements of the Thanet project. Thedecommissioning of the onshore elements will be covered under general planning regulation.Following an Environmental Impact Assessment (EIA), this decommissioning programme scopewas outlined in the project Environment Statement (ES) dated November 2005, and was widelyconsulted on as part of that process. No objections were raised in respect of thesedecommissioning proposals or the associated ES.This programme has been produced in accordance with the Department for Business Enterpriseand Regulatory Reform ("BERR") decommissioning guidance - "Decommissioning of OffshoreRenewable Energy Installations under the Energy Act 2004 Guidance Notes for Industry".The BERR guidance notes have the following eight programme process stages:STAGE 1STAGE 2TOW initiates discussions with BERR and outlines a planned timetable for theproject.The Secretary of State issues notice requiring a decommissioning programmeonce satisfied with the statutory consents.MAY 2008 Page 1.1 of 1.2

STAGE 3STAGE 4STAGE 5STAGE 6STAGE 7Detailed discussions between TOW and BERR, leading to submission of draftof programme.Consultations by TOW. Consideration of the draft programme by GovernmentDepartments and the Crown Estate. BERR prepares decommissioningAppropriate Assessment (where required under EU Habitats and BirdsDirectives).Formal submission of programme by TOW.Reviews of decommissioning programme.Responsible person ensures decommissioning is carried out in accordancewith the programme.STAGE 8 Responsible person carries out post decommissioning monitoring,maintenance and management of the site as specified in the programme.Stage 1 was completed as part of the November 2005 consent applications. Stage 2 has takenplace (the notice from the Secretary of State was received on 19th December 2006) and Stages 3and 4 have taken place between January 2008 and May 2008. This document represents Stage 5of the process and is the formal submission of the programme.It is anticipated that, following signature of contracts, construction of the Thanet project willcommence offshore in 2008 for completion in 2009. Full decommissioning of the project istherefore not expected before 2049, assuming that replanting of the WTGs takes place, asexpected, after approximately 20 years.MAY 2008 Page 1.2 of 1.2

2. EXECUTIVE SUMMARYThis Decommissioning Plan describes how the structures comprising the Thanet Offshore WindFarm (Thanet) project can be decommissioned in accordance with Annex E of the BERR'sdecommissioning guidance (Contents of a Decommissioning Programme). ThisDecommissioning Plan has followed the model framework headings below listed in the guidance:1. Introduction;2. Executive Summary (this section);3. Background Information;4. Description of Items to be Decommissioned;5. Description of Proposed Decommissioning Measures;6. Environmental Impact Assessment;7. Consultations with Interested Parties;8. Costs;9. Financial Security;10. Schedule;11. Project Management and Verification;12. Seabed Clearance;13. Restoration of the Site;14. Post Decommissioning Monitoring, Maintenance and Site Management; and15. Supporting Studies.16. Appendix 1 - Environmental Statement.17. Appendix 2 - Cash Flow Summary.Appendix 1 and 2 have been added to assist in explaining relevant aspects of the report and havebeen referred to in appropriate sections.This Decommissioning Plan concludes that all the components of the wind farm that the currentlegislation requires to be removed could be successfully decommissioned by Jack-up barges andsent to onshore recycling facilities.The decommissioning programme scope in this document is consistent with that outlined in theproject Environment Statement (ES) dated November 2005. Appendix 1 summarises the ESconclusions in respect of the current proposed Decommissioning Plan. These will be reviewedover time and a full new Environmental Impact Assessment (EIA) will be conducted beforedecommissioning actually takes place.MAY 2008 Page 2.1 of 2.2

The initial draft Decommissioning Plan and associated ES was widely consulted on as part of theproject consenting process, including with all of the bodies mentioned in Annex 2 of theDecommissioning Notice. The draft plan included all of the material elements of this proposedplan. No objections were raised in respect of the draft decommissioning proposals or theassociated sections of the ES.This Decommissioning Plan will be review at least every five yearsMAY 2008 Page 2.2 of 2.2

3. BACKGROUND INFORMATIONThis section of the Decommissioning Plan contains the background information and detailsrelating to the Thanet project.3.1 <strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> <strong>LIMITED</strong>Thanet Offshore Wind Limited (TOW) was created to develop opportunities for energy generationfrom renewable resources in the Thanet area. TOW was awarded the right to develop an offshorewind farm in the Thames Estuary Strategic Environmental Assessment (SEA) area by the CrownEstate under Round 2 of the offshore wind licensing arrangements. All necessary consents forthe construction and operation of the wind farm have been gained following TOW's submission ofthe consents application and associated Environmental Statement (ES) for the Thanet project tothe (BERR) in November 2005. The ES contained details of the proposed Decommissioning Planand those proposals are consistent with the proposals set out in this document.3.2 <strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> FARM - PROJECT DETAILSThe Thanet project is located 11.3km offshore from Foreness Point, which is on the eastern mostpart of the Kent coastline. The development rights for the Thanet project are based on a 300MWmaximum generation limit. This is sufficient to provide electricity for 240,000 average homes,which will account for a significant proportion of the energy needs for east Kent.The maximum height of the Wind Turbine Generators (WTGs) being considered will be 115mfrom mean sea level (MSL) to the blade tip in the vertically up position. The minimum clearancebetween the blade tip in the vertically down position to mean high water springs (MHWS) level is22m. The spacing between WTGs will be a minimum of 450m within rows and 675m betweenrows.The WTGs will be interconnected by an offshore 33kV Interarray Cable network and connected toan Offshore Substation platform where the voltage is stepped up to 132kV. Electricity will betransferred to shore by two Export Cables, which will be routed to a landfall point in Pegwell Bay.The subsea cables will be buried to between 1 and 3m (depending on soil type in the area) toprovide adequate protection from all forms of hostile seabed intervention. Grid connection will bemade by cables buried under the A256 Sandwich Road to the existing substation at the disusedRichborough Power Station, from where power will be distributed by the existing local electricitynetwork.MAY 2008 Page 3.1 of 3.5

It is likely that changes to the licensing of Offshore Transmission assets (132kV and above) willcome into effect in the next few years and may entail a change in ownership of some of theseassets. TOW will ensure that any and all decommissioning obligations entered into under thisDecommissioning Plan for such assets will be transferred to any new owner, should thesechanges come into force, and that this plan is modified to reflect such changes.The Thanet project will have a design operational life of 40 years (with an expected replanting ofthe WTGs after 20 years) after which time it will be decommissioned.Figure 3.1 shows the location of the Thanet site together with details of the proposed electricalconnection (including the positions of the cable crossing points). Figure 3.2 shows the proposedcable landfall and onshore cable route to the electrical connection point at Richborough. Theproposed layout of the development, showing the turbine locations and substation location is alsoattached to this plan.3.3 AS-BUILT INFORMATIONThe Construction Design and Management (CDM) Regulations require TOW, in its role as Clientfor the works, to appoint a CDM Co-ordinator and Principal Contractor for the construction of theproject. All of the contractors and consultants involved with the project will be contracted to supplycomprehensive as-built data for the wind farm, which will be used by the Principal Contractor andthe CDM Co-ordinator to prepare the final Health and Safety file. This will include as a minimumthe following:• As-built positions for all structures;• Details of the construction of all structures; and• Positions, depths of burial and other forms of cable protection for all subsea cables(both Export Cables and Interarray Cables).If at any time during the lifetime of the wind farm the as-built details vary, for example, a repair toa subsea cable, amended details will be prepared for the ongoing live status of as-built data.3.4 ADDITIONAL INFORMATIONTOW has assimilated considerable data and information in relation to the Thanet site. This hasincluded the following, which have all previously been provided to the BERR as part of theconsenting process:• Environmental conditions - wind and wave data, currents, seabed conditions, waterdepth etc;MAY 2008 Page 3.2 of 3.5

• Details of fishing activity and fishing vessels operating in the vicinity of the Thanet site;• Details of navigational shipping (both types of vessels and routes used); and otherspecial information on areas of Sabellaria Spinulosa and bird surreys etc.All of this information will be retained and made available during the decommissioning works.Where additional information is assimilated during the lifetime of the wind farm, including anydeclared Archaeological Exclusion Zones, this will also be made available as required underTOW's Lease Agreement with the Crown Estate.MAY 2008 Page 3.3 of 3.5

FIGURE 3.1 LOCATION OF THE <strong>THANET</strong> <strong>OFFSHORE</strong> <strong>WIND</strong> FARM SITE SHOWING DETAILS OF THE PROPOSED ELECTRICAL CONNECTIONMAY 2008Page 3.4 of 3.5

FIGURE 3.2 THE PROPOSED CABLE LANDFALL AND ONSHORE CABLE ROUTEMAY 2008 Page 3.5 of 3.5

4. DESCRIPTION OF ITEMS TO BE DECOMMISSIONEDThis section of the Decommissioning Plan contains details of all items which TOW believes willform part of the scope of future offshore decommissioning works. The scope has been brokendown into three separate areas:1. Offshore Substation;2. Offshore WTG Structures; and3. Subsea Cables (Export and Interarray).These will be predominantly steel or metal items with the exception of the electrical componentson the Offshore Substation and WTG structures, the grouted connections between the piles andthe supporting structures and the WTG blades. The non steel items are chemically inert and willcomprise only a small proportion of the total weight of material to be decommissioned.4.1 <strong>OFFSHORE</strong> SUBSTATIONThe Offshore Substation for Thanet will consist of a jacket structure, which will be piled to theseabed and have a welded connection at the top of the piles to the jacket. The Jacket will supporta Topsides structure, which will house the main offshore transformers. The Offshore Substationwill be the 'hub' for the offshore wind farm and provide voltage step up to allow electricity from theThanet site to be exported back to shore via two 132kV Export Cables, which will terminate at theOffshore Substation. There will also be 10 separate arrays of offshore WTGs connected by 33kVInterarray Cables, which will deliver the generated electricity to the Offshore Substation. Voltagestep up occurs at two transformers on the Offshore Substation prior to the export of the generatedelectricity.The items which will be decommissioned will be as follows:• All of the Topsides equipment and transformers. As this equipment is likely to havebeen installed in modular components, it will be lifted away in a similar fashion;• The Topsides support structure;• The Jacket structure, including all of the appurtenances such as J-Tubes and boataccess systems;• The piles, which will be cut of at 2m below seabed level at the bottom of any scourhole; andMAY 2008 Page 4.1 of 4.4

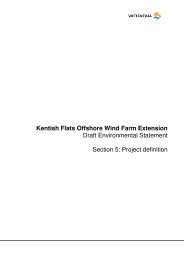

• The sections of cable (both Export and Interarray) which emanate away from theOffshore Substation from the exit point of the bellmouth on the J-tube to the touchdownpoint on the seabed and out further to the transition point where cable burial starts inthe seabed. This will typically be a section of cable 10-25m long. All cables left withinthe J-tubes will also be recovered.It should be noted that any scour holes that have formed at the base of the pile foundations will fillnaturally within a few days after the removal of the pile. The designs for the substation jacket andtopsides are attached.4.2 <strong>OFFSHORE</strong> WTG STRUCTURESThe offshore Wind Turbine Generators (WTGs) at Thanet will be installed in the followingsequence. The individual named components are illustrated in Figure 4.11. The foundations will consist of a monopile and a transition piece. The monopilefoundation will be driven into the seabed. The Transition Piece will then be installedover the pile and secured to the monopile with a grouted connection.2. The Interarray Cables will then laid, buried and pulled onto the foundation platform viathe l-tube.3. The WTG tower (in 2 sections) will be installed onto the Foundation.4. The WTG nacelle and hub with three blades will then be installed onto the tower.5. The cables will then be terminated at the WTG switch gear, tested and energised andthe WTG commissioned using grid power from onshore via the Export Cables.The items that will be decommissioned will be as follows:• The WTG including three blades;• The WTG tower in two sections;• The Transition Piece and all attachments, such as 1-tubes, boat fenders, accessladder systems and access platform;• The monopile foundation cut at 2m below seabed level at the bottom of any scour hole;and• The sections of Interarray Cable which emanate away from the WTG structures fromthe exit point of the bellmouth on the l-tube to the touchdown point on the seabed andout further to the transition point where cable burial starts in the seabed. This willMAY 2008 Page 4.2 of 4.4

• typically be a section of cable 10-25m long. All cables left within the l-tubes will also berecovered.It should be noted that any scour holes that have formed at the base of the pile foundations will fillnaturally within a few days after the removal of the pile.FIGURE 4.1GENERAL ARRANGEMENT OF WTG STRUCTUREMAY 2008 Page 4.3 of 4.4

4.3 SUBSEA CABLESThe term 'subsea cables' refers to both the Export (132kV) Cables and the Interarray (33kV)Cables.4.3.1 Export CablesThere are two Export Cables which connect the Thanet project to the shore. Their positions areillustrated in Figure 3.2. They will be buried to 1-2m beneath the seabed depending on localisedseabed conditions.The Export Cables will for the most part be left buried in situ and will not form part of thedecommissioning works. The exceptions being the sections of cable close to the OffshoreSubstation and at the landfall (refer to Sections 4.1 and 4.2).The sections left in place will also include:• The sections of cable which cross the in-service PEC and Tangerinetelecommunication cables; and• The section of Export Cables through the intertidal zone.4.3.2 Interarray CablesThe only sections of Interarray Cables which will be removed are those 10 to 20m sections closeto each of the WTGs and those close to the Offshore Substation, as identified in Section 4.2.4.3.3 External Cable ProtectionIn addition to the removal of cable sections as identified in Sections 4.3.1 and 4.3.2 above, anyexternal cable protection will also be recovered. This is expected to be concrete mattresses usedto protect surface laid sections of cable which are found at the cable crossing locations andwhere cables exit J/l tubes before being buried into the seabed.An assessment will be made immediately prior to decommissioning to establish if the removal ofthis external cable protection would potentially cause more damage to the environment. It ispossible that these features may have formed artificial reefs and as such may be better left inplace and undisturbed. Absent of any such assessment result, this Decommissioning Planassumes that the external cable protection will be recovered.Only where the mattresses are removed will the cables underlying them also be removed.MAY 2008 Page 4.4 of 4.4

5. DESCRIPTION OF PROPOSED DECOMMISSIONING MEASURESThis section of the Decommissioning Plan describes the measures to be taken for thedecommissioning of the Thanet Offshore Wind Farm (Thanet) project.5.1 PLAN OF WORKS AND INTEGRATIONA detailed plan of work will be prepared for the decommissioning works at least one year aheadof the proposed decommissioning date and will incorporate the results of a detailed and recentEIA on the subject. The process supporting the EIA will include pre-decommissioning surveys tostandards set under MGN 275 (e.g. IHO Order 1 standard multi-beam bathymetry). The plan ofwork will include detailed Method Statements together with project specific hazard and riskassessments. TOW will also liaise with other developers in the Thames Estuary SEA area toensure that if potential synergies are available for decommissioning facilities at the same time,then such synergies are exploited.5.2 PROPOSED METHOD OF REMOVALThe detailed Method Statement for the Decommissioning Plan will cover:• Health and safety considerations;• Best Practicable Environmental Option (BPEO), the option which provides the mostbenefit or least damage to the environment as a whole in both the long and short term,at an acceptable cost; and• Safety of surface and subsurface navigation.For the decommissioning of the wind farm components which have to be removed, the installationmethodology is generally reversed. As in Section 4, the proposed methodology of removal hasbeen split for the three separate areas as follows:1. Offshore Substation;2. Offshore WTG Structures; and3. Subsea Cables.MAY 2008 Page 5.1 of 5.4

5.2.1 Offshore SubstationThe Offshore Substation will be removed using an offshore Heavy Lift Vessel (HLV). The HLVwill lift major components such as Topside modules and Topside structure onto an adjacenttransport barge. The various components will then be transported back to the decommissioningport, where a quayside crane will lift the components onto the quayside where they will beprocessed for recycling or disposal as appropriate. All decommissioning will have appropriatehazard and risk assessments completed to ensure risks to personnel were minimised andhandling of any hazardous materials carefully controlled.The Offshore Substation and piles will be removed in a similar fashion to that described above.The piles will be cut at 2m below seabed level at the bottom of any scour holes that have formed.If at all possible, remote cutting technologies will be utilised to minimise or exclude any diverintervention for health and safety reasons. The cutting process will probably be a combination ofhigh pressure water with entrained grit to assist cutting.An HLV will be required for the decommissioning of the Offshore Substation, as the weight of thevarious components will be higher than those encountered with the decommissioning of theoffshore WTGs.5.2.2 Offshore WTG StructuresThe sequence for the decommissioning of each of the WTG structures will generally be asfollows:1. A row or 'string' of WTGs will be de-energised via the Offshore Substation to facilitatethe first stage in decommissioning the WTGs.2. Each WTG will have its hub and blades locked in position in a 'Y' arrangement toenable safe removal.3. A jack-up crane barge will be mobilised to the wind farm, which will jack-up at eachWTG position in order to lift and remove all redundant components from each WTG.4. The Interarray Cables will be cut at the start of cable burial into the seabed and the cutlength will then be removed from the WTG switchgear, pulled through the I-tube andlifted onto the jack-up barge.5. The WTG blade at the base of the 'Y' will then be unbolted and lifted onto the jack-upbarge to assist in the subsequent removal of the WTG nacelle.6. The WTG nacelle with its locked hub and two blades will then be unbolted from thetower and lifted onto the jack-up barge.MAY 2008 Page 5.2 of 5.4

7. The WTG tower will then be unbolted and removed. The WTG tower will be removed inone piece for speed of dismantling.8. The piles will then be cut at 2m below seabed level. The cutting process is likely to bethe same as described for the Offshore Substation piles in Section 5.2.1 above. Thecut Monopile and Transition Piece will then be removed by the crane in a single piece.9. All of the cut components will be transported to the decommissioning port forprocessing. As many components as possible will be recycled, others will be safelydisposed of. Because the structures are mainly constructed from steel, there will be avery high percentage of recycled materials. The transportation process will be by eitherthe main jack-up barge completing the lifts or a support transport barge may beutilised.10. This sequence will be repeated for all WTGs.5.2.3 Offshore CablesThe Offshore Cables that are planned to be removed will be removed as part of the operationsdescribed in 5.2.1 and 5.2.2.5.3 PROPOSED WASTE MANAGEMENT SOLUTIONSWaste management will be carried out in accordance with all relevant legislation at the time. It isintended that the vast majority of all elements of the offshore wind farm will be taken back to landfor reuse and recycling.5.4 DETAILS OF ANY ITEMS WHICH MAY BE LEFT IN SITU <strong>OFFSHORE</strong>FOLLOWING DECOMMISSIONINGAs described in the previous sections, it is proposed to leave major sections of offshore cablesand the embedded piles in the seabed. The basis of this decision is that the item in questionmeets at least one of the four situations in which (based on the IMO standards) non-removal orpartial removal may be considered.The four situations are where:1. The installation or structure will serve a new use, whether for renewable energygeneration or for another purpose, such as enhancement of a living resource (providedit would not be detrimental to other aims, such as conservation);2. Entire removal would involve an unacceptable risk to personnel;MAY 2008 Page 5.3 of 5.4

3. Entire removal would involve an unacceptable risk to the marine environment; or Entireremoval would involve extreme costs.The primary reason for leaving cables buried and embedded piles in the seabed is that theirremoval is likely to cause a major impact to the environment and may require significant anddangerous diver involvement. However, all four of the above situations are expected to berelevant and influential in justifying that the proposed exclusions from recovery. For instance, thecomplete recovery of all of the pile structures would entail a major excavation of the seabed thatwould be very costly and hugely damaging to the environment in the area.MAY 2008 Page 5.4 of 5.4

6. ENVIRONMENTAL IMPACT ASSESSMENTThe original EIA for this project included an assessment of the decommissioning scopeenvisaged under this plan. Appendix 1 summarises the findings of this EIA.A further Environmental Impact Assessment (EIA) will be undertaken to assess the potentialeffects of the proposed decommissioning measures on the environment. This will involve a set ofpre-decommissioning surveys that will, amongst other things, fully determine the extent ofSabellaria Spinulosa in the area. An outline version of the Decommissioning EnvironmentalStatement (ES) will be prepared within one year of the completion of the construction of theThanet project. This outline version will then be developed into a more detailed document twoyears prior to the start of decommissioning works when more certainty exists on the scoperequired to match the legislation in place at that time.The EIA will use the analysis already undertaken for the wider EIA undertaken prior to consent ofthe installation of the wind farm. The Decommissioning ES will then be reviewed towards the endof the life of the installation, when a final review of the decommissioning programme isundertaken to finalise the decommissioning measures proposed.The final EIA will aim to:• Identify and assess potential impacts on the environment, including exposure tocontaminants associated with the installation other biological impacts arising fromphysical effects, conflicts with the conservation of specifies, with the protection of theirhabitats;• Identify and assess potential impacts on amenities, the activities of communities (suchas Sabellaria) and on future uses of the environment;• Describe the measures envisaged to avoid, reduce and, if possible, remedy anysignificant adverse effects indicated (such as leaving some buried items in situ); and• Identify and assess the effect on marine life caused by the removal of the WTGfoundation, which may now offer shelter or support to fishes or plant life by acting asartificial reefs (such as the concrete mattresses).MAY 2008 Page 6.1 of 6.1

7. CONSULTATIONS WITH INTERESTED PARTIESThe full project ES issued in November 2005 included a description of the decommissioningproposals outlined in this document. The ES also included a review of the proposedDecommissioning Plan. The document was consulted on widely, at both national and regionallevels, and included all the stakeholders that have been involved in assessing thisDecommissioning Plan. No objections were received by the BERR in respect of thedecommissioning proposals and the BERR licensing team already has full copies of allcorrespondence from the consultees involved.The final decommissioning programme will describe any additional consultation processproposed by TOW. When all consultations have been completed, a summary of the consultationsundertaken with interested parties will be prepared a year before the decommissioning activity isproposed to commence. This report will explain the extent to which such views have been takeninto account in the programme and scope of work (e.g. the mitigation of damage to Sabellariareefs from the jack-up barges needed to carry out the works). Relevant correspondence will beannexed to the programme and, if appropriate, information will be included within the ESdescribed in Section 6 above.MAY 2008 Page 7.1 of 7.1

8. COSTSIn developing a capital cost for the Thanet project, TOW has made an estimate for the futuredecommissioning for the offshore wind farm. More detailed information on this and other costs isset out in the Cashflow Forecast attached at Appendix 2. TOW will develop a more detailed costestimate for the decommissioning works once the construction activities are completed. This willcover the following subject areas:• Design of removal techniques;• Health, safety and environmental constraints• Optimum removal techniques for major items;• Logistics;• Transportation and off-loading;• Management and disposal of materials onshore;• Survey requirements to confirm decommissioning works complete; and• Potential post-decommissioning surveys and monitoring (if required).As no additional equipment will be deployed during the decommissioning activities the vastmajority of the costs involved consist of the hire cost for the vessels and equipment used toremove the structures. These costs will typically involve a mobilisation fee of around £1,000,000and then a charge for each day of operation of typically £50,000 to £75,000 per day at currentprices. The current indications on costs are broadly in line with the BERR estimates of netdecommissioning costs of around £40,000 per MW indicating a net decommissioning cost for theThanet project of £12m.MAY 2008 Page 8.1 of 8.1

9. FINANCIAL SECURITYThanet Offshore Wind Limited (TOW) is a Special Purpose Vehicle (SPV) designed solely for theoperation of the Thanet project. All consents, licences, loans, assets and revenues involved in theThanet project are owned by TOW. TOW will provide adequate Financial Security to cover itsobligations under this Decommissioning Plan without recourse to any of its shareholders, whomay themselves change from time to time over the project life.It is understood that an industry-wide Trust may be set up to cover all participating developersmonitoring obligations post-decommissioning plus any other obligations that may occur afterdecommissioning. Subject to a review of the details, TOW would intend to participate in such ascheme should it be established.It is fully recognised that TOW itself will have to provide funds to cover the main decommissioningactivity that is expected to occur at the end of the 40 year lease with The Crown Estate andacknowledged that, should the WTGs not be replanted, decommissioning may actually take placeafter approximately 20 years.TOW would prefer to secure its decommissioning obligations through a mid-life accrual fund, paidinto a dedicated and restricted Escrow account. If this was acceptable, TOW would commit onetenth of the expected net decommissioning costs to the escrow account following the tenth yearof operation tenth year of operation beginning 1 st January 2010, the first year of completeoperation following commissioning (currently expected to be approx £1.2m pa). In the event of areplanting of the WTGs at Year 20 TOW would request that these funds were released back toTOW and that a separate accrual is started again on the same principles at Year 30.This is a sensible and practical method for ensuring that the decommissioning obligations are metand does not involve excessive administrative burden. The financial strength of a renewableenergy project late in its operational life (compared to an Oil or Gas activity that depletes overtime) is such that decommissioning obligations can be met from operational cash flows asevidenced below.TOW is in the process of raising £500m of funds in order to construct the Thanet project. Thesefunding arrangements will be flexible enough to cope with the provision of secured funds fordecommissioning envisaged as £12m. Expected net annual revenues from the project, using thecurrent price for electricity and ROCs, range from £44,220,424 in 2009 part way through whichthe project will be commissioned, through to £187,120,556 in 2029, for the approx 1 TWh ofannual output expected (P50 case). The cash requirements to fund the decommissioningobligation are already modelled by the Lenders at £1.2m pa following the tenth complete year ofoperation (2020) and rank above any debt repayment. Sums reserved for decommissioning areprovided for in the 'Opex' Section of the Cashflow Forecast at Appendix 2. It can be clearly seenthat TOW will easily be able to fulfil its obligations under this Decommissioning Plan whicheverSecurity arrangement is preferred.MAY 2008 Page 9.1 of 9.2

TOW has been advised however that the preferred mid-life accrual fund proposal may not meetthe BERR's requirements because TOW is a SPV If this proves to be the case then as analternative TOW would meet its obligations through either a Bond or Letter of Credit structurewhich would ramp up from 2020 by the amounts as described above.MAY 2008 Page 9.2 of 9.2

10. SCHEDULEA full EIA will be commissioned two years ahead of the proposed decommissioning period.A detailed schedule of the decommissioning works will then be prepared a year before the start ofthe works taking onboard the results of the EIA and its consultation process. Such schedules willbe forwarded for BERR review and approval.The schedules will clearly map out the sequence of decommissioning activities, providing detailfor the offshore removal works. It is expected that each WTG will take on average two (2) days todecommission, remove and load onto a barge for transport to a shore facility, after taking weatherdowntime into consideration. The Offshore Substation is expected to take up to three (3) weeks todecommission, remove and load onto a barge for transport to shore for recycling.TOW considers that the main offshore decommissioning work could be completed in an extendedsingle summer season of working of up to nine (9) months. This will probably required 24 hourworking and will also involve a significant element of pre-planning and advance preparation worksas described above.MAY 2008 Page 10.1 of 10.1

11. PROJECT MANAGEMENT AND VERIFICATIONThe final Decommissioning Plan will provide information on how TOW will manage theimplementation of the decommissioning works and also provide assurance to the BERRconcerning progress and compliance.The project management of the decommissioning works will be undertaken with the same rigor asthe original installation works. TOW envisages a single main contractor for the decommissioningwork and will also appoint an experienced and highly qualified project management team toensure the decommissioning work proceeds to schedule and in accordance with the requirementsof the Decommissioning Plan.MAY 2008 Page 11.1 of 11.1

12. SEABED CLEARANCETo demonstrate that the site has been cleared following the decommissioning works, a fullsubsea seabed survey will be undertaken with independent monitoring through onboardobservers, possibly drawn from the local fishing community. This survey will cover areas of atleast 500 metres around each and every structure and the results will be submitted to the BERR.The main purpose of this survey will be to confirm that the full scope of the decommissioningworks has been completed. However, the same survey will be used to enable identification andhaving regard to any declared Archaeological Exclusion Zones subsequent recovery of any roguedebris located on the seabed, which may have arisen from the activities and may pose a risk tonavigation, other users of the sea or the marine environment. Where rogue debris is identifiedand recovered the area affected will be resurveyed with the independent monitoring as proposedabove.MAY 2008 Page 12.1 of 12.1

13. RESTORATION OF THE SITEUsing the pre-construction survey data, the site will be restored as far as possible and desirableto the condition that it was prior to the original construction of the installation. However, as theoriginal method of installation for both the WTG foundations and subsea cables were designedwith due regard to cause minimum disturbance during their initial installation, TOW does notenvisage, or plan, to undertake any specific underwater intervention works to restore any seabedconditions.TOW does not intend to fill any scour holes that have formed around the base of the piledfoundations. TOW considers that the scour holes will fill naturally after the removal of the pileswithin a few days and that operations required to fill the holes would be disruptive to marine lifeand introduce significant foreign materials into the local seabed.MAY 2008 Page 13.1 of 13.1

14. POST DECOMMISSIONING MONITORING, MAINTENANCE ANDMANAGEMENT OF THE SITEA post-decommissioning monitoring and maintenance plan will be included as part of the EIAprocess that will take place ahead of the decommissioning of the facility. This will establish what(if any) future management of the Thanet site will be required and whether this can be carried outas part of an industry-wide programme. In the absence of these final proposals, TOW will assumethat an annual survey of the site will be required for up to three years following the end of theplanned decommissioning activity. Should any items that might be left in-situ become uncoveredduring this period then TOW will recover such items and recycle them onshore. The nature of thisannual survey will be the same as the Seabed Clearance survey (see Section 11) and the resultswill be provided to the BERR.MAY 2008 Page 14.1 of 14.1

15. SUPPORTING STUDIESAny supporting studies or investigations which are undertaken in support of futuredecommissioning plans will be included as annexes to the Decommissioning Plan. This planincludes as an Annex the results of the Environmental Impact Assessment conducted in 2005 inrelation to this plan.MAY 2008 Page 15.1 of 15.1

APPENDIX 1 Environmental Statement Summary [Attached under separate cover.]MAY 2008 Page 16.1 of 16.1

APPENDIX 2 Cashflow Summary [Attached under separate cover.]MAY 2008