Parker Non-Lube Heavy Duty Air Cylinders ... - Wainbee Limited

Parker Non-Lube Heavy Duty Air Cylinders ... - Wainbee Limited

Parker Non-Lube Heavy Duty Air Cylinders ... - Wainbee Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

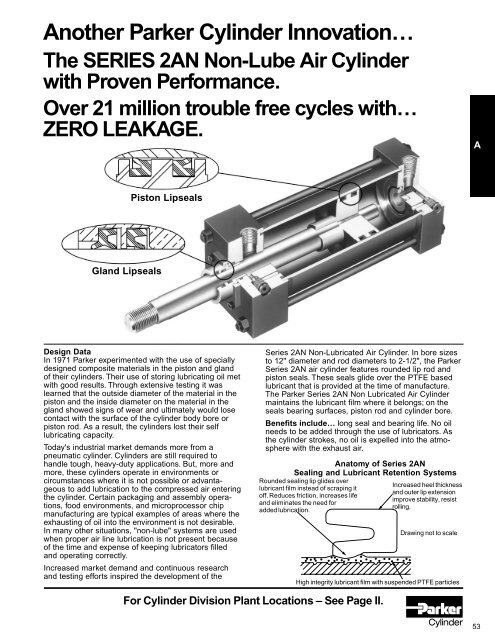

Another <strong>Parker</strong> Cylinder Innovation…The SERIES 2AN <strong>Non</strong>-<strong>Lube</strong> <strong>Air</strong> Cylinderwith Proven Performance.Over 21 million trouble free cycles with…ZERO LEAKAGE.APiston LipsealsGland LipsealsDesign DataIn 1971 <strong>Parker</strong> experimented with the use of speciallydesigned composite materials in the piston and glandof their cylinders. Their use of storing lubricating oil metwith good results. Through extensive testing it waslearned that the outside diameter of the material in thepiston and the inside diameter on the material in thegland showed signs of wear and ultimately would losecontact with the surface of the cylinder body bore orpiston rod. As a result, the cylinders lost their selflubricating capacity.Today's industrial market demands more from apneumatic cylinder. <strong>Cylinders</strong> are still required tohandle tough, heavy-duty applications. But, more andmore, these cylinders operate in environments orcircumstances where it is not possible or advantageousto add lubrication to the compressed air enteringthe cylinder. Certain packaging and assembly operations,food environments, and microprocessor chipmanufacturing are typical examples of areas where theexhausting of oil into the environment is not desirable.In many other situations, "non-lube" systems are usedwhen proper air line lubrication is not present becauseof the time and expense of keeping lubricators filledand operating correctly.Increased market demand and continuous researchand testing efforts inspired the development of theSeries 2AN <strong>Non</strong>-Lubricated <strong>Air</strong> Cylinder. In bore sizesto 12" diameter and rod diameters to 2-1/2", the <strong>Parker</strong>Series 2AN air cylinder features rounded lip rod andpiston seals. These seals glide over the PTFE basedlubricant that is provided at the time of manufacture.The <strong>Parker</strong> Series 2AN <strong>Non</strong> Lubricated <strong>Air</strong> Cylindermaintains the lubricant film where it belongs; on theseals bearing surfaces, piston rod and cylinder bore.Benefits include… long seal and bearing life. No oilneeds to be added through the use of lubricators. Asthe cylinder strokes, no oil is expelled into the atmospherewith the exhaust air.Anatomy of Series 2ANSealing and Lubricant Retention SystemsRounded sealing lip glides overlubricant film instead of scraping itoff. Reduces friction, increases lifeand eliminates the need foradded lubrication.Increased heel thicknessand outer lip extensionimprove stability, resistrolling.Drawing not to scaleHigh integrity lubricant film with suspended PTFE particlesFor Cylinder Division Plant Locations – See Page II.53