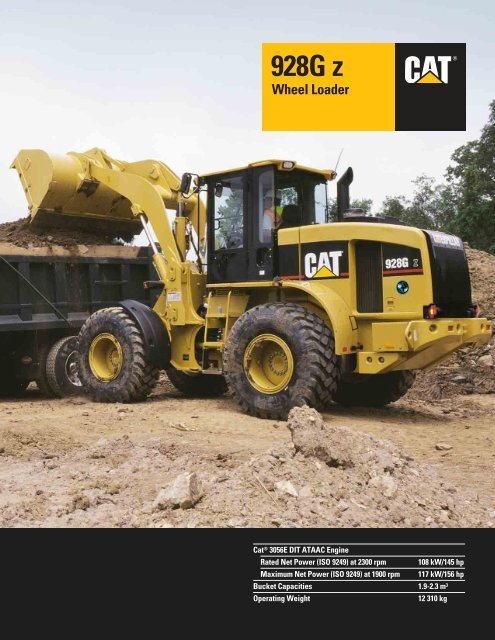

928G Z – Zeppelin-Cat

928G Z – Zeppelin-Cat

928G Z – Zeppelin-Cat

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Operator StationErgonomic design emphasizes comfort, visibility and easy operation.Cab. The ergonomic cab provides acomfortable work environment withlarge windows, spacious interior room,generous storage areas and low interiorsound levels.Access/Egress. The two-door designmakes access and egress easy.Both doors open fully and lock flushagainst the cab for efficiency and safety.Steps leading up to the cab are wide,serrated and angled out for securefooting.Windows. Large windows improvevisibility in all directions. The rearwindow features a standard electricdefroster. Sliding glass is availableas an option on the doors.Visibility. Visibility to critical areassuch as the bucket have been optimized.Lift arm spacing is wide and linkagegeometry maximizes visibilitythroughout the production cycle.6

<strong>Cat</strong>erpillar Buckets<strong>Cat</strong>erpillar buckets are an integral part of a machine designed to optimize performance.Choice of Buckets. <strong>Cat</strong>erpillar offers a varietyof buckets to meet your specific job requirements.Careful match of the bucket design andmachine operating characteristics provide thebest digging, loading and carrying performance.General Purpose Buckets. <strong>Cat</strong>erpillar generalpurpose buckets, available in 1.9 m 3 and 2.3 m 3capacities with bolt-on cutting edge, andare suitable for most general applications.Features include: Improved bucket design with longer floorand a larger radius for easier flow of materialinto the bucket Patented Two-Bolt Corner Guard CuttingEdge System for superior wear resistance,better stability and a simple bolt-on system Built-in, replaceable heel wear plates forextended bucket lifePenetration Bucket. The <strong>Cat</strong>erpillarpenetration bucket has a 2.1 m 3 capacity.It provides best results in materials that requiremoderate impact and breakout forces.Features include: Sharpened cutting edges and curved sidebars for maximum penetration. Flush-mount weld-on teeth. Flat floor for easier loading. Full-width edge for backdragging. Fore/aft wear strips extend bucket life.Ground Engaging Tools. Ground engagingtools include hardened steel cutting edges,choice of short or long teeth and a varietyof tooth adapters. These tools optimizeperformance, improve load retention andextend the useful life of <strong>Cat</strong>erpillar buckets.Versatility. For expanded machine versatility,factory installed quick couplers and otherspecial purpose buckets are also available.Contact your <strong>Cat</strong>erpillar dealer for details.8

Owning and Operating CostsCost saving features help improve your bottom line.Low Fuel Consumption. The 3056E DITATAAC engine features low fuelconsumption for more economicaloperation and meets all worldwideemissions standards.Heavy-Duty Power, Fast Cycle Times.High horsepower provides rugged,dependable power and faster cycletimes, allowing the operator to getmore work done in a day.Extended Service Intervals.Service intervals have been extendedto reduce machine service time andincrease machine availability: 4000 hour hydraulic oil change(S•O•S sampling required) 1000 hour hydraulic filter change 500 hour engine oil changeSmoother Transmissionfor Increased Productivity.A smoother shifting transmissionprovides a more comfortable workenvironment, allowing the operator tobe more productive throughout theentire work shift.Demand Fan. Demand fan changesspeed to meet cooling requirementsand save fuel.Engine Derate Feature. Auto Deratemonitors vital engine systems and willreduce the engine horsepower up to50% to protect the engine.Optional Axle Cooler. Protection forsevere applications.Equipment Management Option.<strong>Cat</strong>erpillar’s asset management orequipment management system calledProduct Link-World View, enablesdealers and their customers to trackequipment for hours and location, andin some cases monitor machine health.This easy-to-use system providesinformation flow between a machineand the user through the internet basedDealer Storefront. This informationhelps lower operating costs throughtimely service/repairs and optimizedmachine use.Machine Security System Option.The Machine Security System (MSS)inhibits unauthorized machine use byimmobilizing vital electrical circuits.Critical machine circuits are inhibitedunless a valid key is used to startthe machine.10

Environmentally Responsible Design<strong>Cat</strong>erpillar machines help you build a better world and help preservethe fragile environment.Low Fuel Consumption. The <strong>928G</strong> z isthe top performer in its size class.The result is more work done in a day,less fuel consumed and minimal impacton the environment.Low Exhaust Emissions. The <strong>Cat</strong> 3056EDIT ATAAC is a low emission enginedesigned to meet current worldwideemission regulations and is Stage IIcompliant.Quiet Operation. The engine coolingsystem allows the engine to be fullyenclosed, allowing less engine noiseto escape. With the optional soundsuppression package, the <strong>928G</strong> z iseven quieter.Ozone Protection. To help protectthe earth’s ozone layer, the airconditioning unit uses only R-134arefrigerant which does not containharmful chlorofluorocarbons (CFC’s).Fewer Leaks and Spills. Engine oil, transmissionand hydraulic filters are positionedvertically and are easily removed withoutspillage. The <strong>Cat</strong> 3056E is fitted with aClosed Circuit Breather to eliminate valvecover drips. <strong>Cat</strong> O-ring face seals, XT hoseand hydraulic cylinders are all designed tohelp prevent fluid leaks that can weakenthe machine’s performance and cause harmto the environment.Rebuildable Components. All major componentsare designed for rebuildability.Biodegradable Hydraulic Oil.<strong>Cat</strong>erpillar biodegradable hydraulic oilcan be used in the <strong>928G</strong> z, providingan environmentally-sound alternativeto mineral-based oils.Complete Customer Support<strong>Cat</strong>erpillar dealer services ensure a longer machine operating life with lower costs.Selection. Make detailed comparisonsof machines before purchasing.What are the job requirements?What production is needed?What is the true cost of lost production?Your <strong>Cat</strong> dealer can give you preciseanswers to these questions.Purchase. Look at the value the <strong>928G</strong> zoffers. Consider the financing optionsyour <strong>Cat</strong> dealer offers as well as daytodayoperating costs. Dealer supportservices can be included in the cost ofthe machine to yield lower equipmentowning and operating costs over the lifeof the machine.Operation. For the best operatingtechniques to increase productivityand your profit, turn to your <strong>Cat</strong> dealerfor the latest training literature andknowledgeable staff.Maintenance. Choose from a widerange of maintenance services at thetime of machine purchase. Repairoption programs guarantee the cost ofrepairs up front. Diagnostic programssuch as S•O•S Oil Analysis andTechnical Analysis help avoidunscheduled repairs that can costunnecessary time and money.Replacement. Repair, rebuild orreplace? Your <strong>Cat</strong> dealer can help youevaluate the cost involved to makethe right choice.Product Support. You will find nearlyall parts at our dealer parts counter.<strong>Cat</strong> dealers utilize a worldwidecomputer network to find in-stock partsto minimize machine downtime.Additionally, <strong>Cat</strong>erpillar offers a lineof genuine remanufactured componentswhich can help lower repair costs.11

Engine<strong>Cat</strong>erpillar four-stroke cycle, six cylinder3056E DIT ATAAC diesel engine.Rated Net Power2300 rpmISO 9249108 kW/145 hpEEC 80/1269 108 kW/145 hpMaximum Net Power 1900 rpmISO 9249117 kW/156 hpEEC 80/1269 117 kW/156 hpBore100 mmStroke127 mmDisplacement6 liters Net Power ratings are testedat the reference conditions forthe specified standard. Net power advertised is the poweravailable at the flywheel when theengine is equipped with alternator,air cleaner, muffler and fan atminimum speed. No derating required up to 3000 maltitude. Auto derate protects hydraulicand transmission systems. When the fan is at maximum speedrated net power is 97 kW (130 hp)and Maximum Net Power is 109 kW(146 hp) at the flywheel per the SAEreference conditions. The <strong>Cat</strong>erpillar 3056E DIT ATAACengine meets Stage II off highwayemission regulations.Features Electronically controlled rotaryfuel pump Three-ring, controlled-expansion,lubricated pistons Gear-driven water and oil pumps One-piece cast iron cylinder headswith two valves per cylinder Fuel priming pump and fuel/waterseparator S•O•S sampling port for engine oil Replaceable dry liners Cast aluminum valve cover Radiator can be easily accessedfor cleaningEngine TorqueTransmissionMaximum travel speeds with20.5-25 R25 tires.km/hForward1 82 133 264 38Reverse1 82 133 26Electronically-controlled <strong>Cat</strong>erpillarcountershaft transmission with fullon-the-go directional and speedchange capability.High-energy friction materials andthick reaction plates for bettertolerance of heat.High-contact ratio spur gears areprecision ground and heat treated forquiet, reliable operation.Electronic autoshift is standard.Button on implement control leverallows downshifting on demand.Computer controlled modulationprovides smoother transitions.NmEngine TorqueNetEngine PowerNet600 120500 100400 80300 60200 40Loader Hydraulic SystemOutput at 2300 engine rpmand 69 bar withSAE 10W oil at 65°C 152 L/minMaximum working pressure 248 barHydraulic cycle timeRaise6.1 SecondsDump1.2 SecondsLower, empty,float down2.8 SecondsTotal10.1 SecondsLift cylinders, double actingBore120.6 mmStroke685 mmTilt cylinders, double actingBore127 mmStroke550 mmOpen-centered system.Fixed displacement vane-typeimplement pump.Low effort, hydraulic joystickcontrols.Electronic pilot shut-off switchdisables implement functions foradded safety.Hydraulic couplings with O-ring faceseals.Optional heavy-duty oil cooler.Ride Control System available toprovide smoother ride with lessspillage from bucket during load &carry operations and better hard bankcapability.kWEngine Power100201000 1200 1400 1600 1800 2000 2200Engine Speedrpm12

Tires 17.5-25 Other tire choices are available, 20.5-25 In certain applications, the loader’s 20.5 R25productive capabilities may exceed■ 600/65 R25the tire’s tonnes-km/h capabilities. 17.5 R25contact your <strong>Cat</strong> Dealer for details.<strong>Cat</strong>erpillar recommends that you consulta tire supplier to evaluate all conditionsbefore selecting a tire model.WeightsOperating Weight12 308 kgSpecifications are for <strong>928G</strong> z with optionalcounterweight, standard lubricants, full fuel tank,cab with A/C, sliding glass, <strong>Cat</strong> contour seat,limited slip axles with dual disc rear, 4L 4Vhydraulics, heavy duty cooler, supplementalsteering, roading fenders, reversing fan, back-upalarm, guards, ride control, radio, 2.0 m 3 bucketwith bolt-on cutting edge, 80 kg operator and20.5 R25 radial (L-3) XHA tires.SteeringAxlesBrakesMinimum turning radius(over tire)5233 mmSteering angle, each direction 40°Steering cylinders, two, bore 70 mmHydraulic output at2300 engine rpm and69 bar 104 L/minMaximum workingpressure207 barFully hydraulic power steering.Center-point frame articulation.Front and rear wheels track.Separate variable displacement pistonpump provides steering power at allengine and ground speeds.Tilt steering console.High-impact rubber steering stops.Secondary steering system meetsISO 5010 and roading regulationsin various countries.Fixed front, oscillating rear(±11° with 20.5 R25 tires).<strong>Cat</strong>erpillar axle with fully-enclosedbrakes and final drives.Patented Duo-Cone Seals betweenaxle shaft and housing with built-inprotection from debris.Rear wheel can raise or drop a totalof 384 mm with 20.5 tires.Limited Slip differentials are optionalon front, rear or both axles.Rear axle trunnion has remotelubrication fitting.Planetary final drives are lubricatedfrom the main oil sump.High contact gearset reduces noiselevels during meshing.Service brake Inboard oil-immersed disc brakeson front and rear axles are standard. Completely enclosed and sealed. Adjustment-free. Separate circuits for front and rear. Dual pedal braking system. Fully integrated with hydraulicsystem, no air system required.Secondary brake Indicator light alerts operator if brakepressure drops. Continually-charged nitrogenaccumulators provide stopping powerafter loss of engine power.Parking brake Mechanical, shoe-type brake. Mounted on drive line for positivemanual operation. Application of parking brakeneutralizes the transmission.Heavy-duty brake Optional heavy-duty brakes withintegrated oil cooler.<strong>928G</strong> z Wheel Loader specifications 13

Service Refill CapacitiesROPS/FOPSSoundLitersFuel tank 225Cooling system 42Crankcase 16Transmission 34.5Differentials and final drivesFront axle 26Rear axle 25Hydraulic system (including tank) 125Hydraulic tank 70 <strong>Cat</strong>erpillar cab with integratedRollover Protective Structure(ROPS/FOPS) are standard. ROPS meets ISO 3471:1994. FOPS meets ISO 3449:1992 Level II.Operator SoundThe operator sound level measuredaccording to the procedures specifiedin ISO 6394:1992 is 74 dB(A), for caboffered by <strong>Cat</strong>erpillar, with doors andwindows closed.Exterior SoundAs manufactured by <strong>Cat</strong>erpillar,this machine's exterior sound powerlevel meets the criteria spelled outin the European Directives, labeling.– standard version 104 dB(A)– low sound or Blue Angelversion 101 dB(A)Bucket ControlsSupplemental SpecificationsLift circuit Four positions: raise, hold, lowerand float. Adjustable automatic kickout fromhorizontal to full tilt.Tilt circuit Three positions: tilt back, holdand dump. Adjustable automatic bucketpositioner to desired loading angle. Does not require visual spotting.Controls Choice of two low effort controlsystems: a joystick or a two-levercontrol of lift and tilt circuits. Optional third function hydrauliccircuits available with individuallever controls for remote hydraulicfunctions. Controls can be disabled for roading.Change inOperating WeightChange in ArticulatedStatic Tipping Loadwith 2.0 m 3 Hook-On BucketkgkgAir conditioner -48 -44Canopy, ROPS (less cab) -198 -181Counterweight, 250 kg (removal) -290 -483Guard, crankcase -17 -22Guard, power train -58 -56Ride Control System -41 -28Secondary steering (removal) -42 -52Tires, 1 piece rims17.5-25, 12PR (L-2) -661 -41017.5-25, 12PR (L-3) -582 -36117.5-25, radial (L-2/L-3) -519 -32217.5-R25, radial (L-2) -614 -38117.5 R25, radial (L-3) -458 -284Tires, 3 piece rims17.5-25, 12PR (L-2) -529 -32817.5-25, 12PR (L-3) -457 -28317.5-25, radial (L-2) -413 -25617.5-25, radial (L-2/L-3) -489 -30317.5 R25, radial (L-3) -389 -241550/65 R25, radial (L-2) -196 -122550/65 R25, radial (L-3) -136 -8520.5-25, 12PR (L-2) -240 -14920.5-25, 12PR (L-3) -96 -6020.5-25, radial (L-2/L-3) -52 -3320.5-R25, radial (L-2) -172 -10720.5-R25, radial (L-3) 0 0600/65 R25, radial (L-3) Michelin +4 +2600/65 R25, radial (L-3) Goodyear +216 +13414 <strong>928G</strong> z Wheel Loader specifications

Typical Material Densities – Loosekg/m 3Basalt 1960Bauxite, Kaolin 1420Claynatural bed 1660dry 1480wet 1660Clay and graveldry 1420wet 1540Decomposed rock75% rock, 25% earth 196050% rock, 50% earth 172025% rock, 75% earth 1570Earthdry, packed 1510wet, excavated 1600Granitebroken 1660Gravelpitrun 1930dry 1510dry, 6-50 mm 1690wet, 6-50 mm 2020kg/m 3Gypsumbroken 1810crushed 1600Limestonebroken 1540crushed 1540Sanddry, loose 1420damp 1690wet 1840Sand and clayloose 1600Sand and graveldry 1720wet 2020Sandstone 1510Shale 1250Slagbroken 1750Stonecrushed 1600Bucket Size SelectorMaterial DensityBucket1.9 m 32.0 m 32.1 m 32.3 m 3 1400 1600 1800 2000 2200 kg/m 3% – Bucket Fill Factor115% 100% 95%<strong>928G</strong> z Wheel Loader specifications 15

➤➤➤➤➤➤➤➤➤➤➤➤Dimensions with BucketAll dimensions are approximate. Dimensions may vary with bucket.➤15➤➤1➤2➤316181710111213➤➤➤➤➤➤14➤➤➤➤➤➤➤➤2523244➤5➤19➤➤7➤➤9➤68➤➤➤20➤➤➤2122➤➤1 Height to top of ROPS/FOPS2 Height to top of exhaust stack3 Height to top of hood4 Height to centre of axle5 Ground clearance6 Overall length7 Length - rear axle to bumper8 Centre line of front axle to hitch9 Wheel base length10 Dump clearance at maximum lift and 45˚ dump11 Bucket clearance at maximum lift and carry12 Bucket pin height at maximum lift13 Overall height - bucket raised14 Reach at maximum lift and 45˚ dump15 Rack back angle at maximum lift and level16 Dump angle at maximum lift17 Rack back angle at ground18 Rack back angle at carry19 Carry height20 Digging depth21 Width over tread center22 Overall width over tires23 Minimum turning radius over tires3269 mm3189 mm2197 mm685 mm408 mm7252 mm1920 mm1450 mm2900 mm2879 mm3752 mm3872 mm4971 mm927 mm60°45°44°47.8°449 mm86 mm17.5-25 12PR L-2 20.5-25 12PR L-3 600/65 R25 GP-3D1950 mm 1950 mm 1950 mm2407 mm 2504 mm 2544 mm5186 mm 5236 mm 5256 mm24 Loader clearance radius with bucket in carry position See Operating Specifications on pg. 1725 Steering angle - left/right40° 40° 40°Change in vertical dimension-65 mm 0 mm -11Dimensions listed are for <strong>928G</strong> z with optional counterweight, standard lubricants, full fuel tank, cab with A/C, sliding glass, <strong>Cat</strong> contour seat, limited slip axleswith dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-up alarm, guards, ride control, radio,2.0 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires. Refer to Operating Specifications for bucket variations.16 <strong>928G</strong> z Wheel Loader specifications

Z-bar Linkage and BucketAll dimensions are approximate. Dimensions may vary with bucket.Pin-on BucketsGeneral Purpose BucketsPenetrationBolt-OnCutting EdgeBolt-OnTeeth and Segments*Bolt-OnTeeth*Flush-MountedTeeth*Rated bucket capacitym 32.0 2.3 2.0 2.3 1.9 2.2 2.1Struck capacitym 31.7 1.9 1.7 1.9 1.6 1.8 1.81014Bucket widthDump clearance at full liftand 45° dischargeReach at full liftand 45° dischargeReach at 45° dischargeand 2130 mm clearanceReach with lift arms horizontaland bucket levelmmmmmmmmmm2549 2549 2549 2549 2549 2549 25492879 2842 2766 2730 2766 2729 2729927 964 1021 1058 1021 1058 10581455 1474 1492 1509 1492 1509 15092253 2305 2399 2451 2399 2451 245120Digging depthmm86 86 99 99 99 99 996Overall lengthmm7252 7304 7398 7450 7378 7430 743013 Overall height with bucketat full raise24 Loader clearance radius withbucket in carry positionStatic tipping load, straightStatic tipping load,full 40° turnBreakout forcemmmmkgkgkN4971 5070 4971 5070 4971 5070 50575781 5796 5845 5860 5845 5860 58609859 9702 9690 9537 9778 9711 97028587 8444 8417 8276 8508 8444 8435117 111 116 110 126 119 119Operating weightkg12 308 12 358 12 442 12 492 12 357 12 407 12 431Specifications are for <strong>928G</strong> z with optional counterweight, standard lubricants, full fuel tank, cab with A/C, sliding glass, <strong>Cat</strong> contour seat,limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-up alarm,guards, ride control, radio, 2.0 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires.* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standards specifies the cutting edge.<strong>928G</strong> z Wheel Loader specifications 17

Standard EquipmentStandard equipment may vary. Consult your <strong>Cat</strong>erpillar dealer for specifics.ElectricalAlternator, 80-ampBatteries, maintenance-free, 950 CCA, (2)Directional signals (front & rear)Halogen work lights (front & rear)Ignition key start/stop switchStarting aid, thermalStarting and charging system, 24VSwitch, battery disconnectOperator EnvironmentCab, ROPS (sound suppressedand pressurized)Gauges:Engine coolant temperatureHydraulic oil temperatureTorque converter oil temperatureFuel level gaugeSpeedometerDigital tachometerDigital hour meter/odometerTransmission oilWarning indicators:Primary steering malfunctionElectrical system voltage lowCoolant temperatureEngine oil pressure lowParking brake appliedBrake charge pressure lowTransmission oil temperatureTransmission oil filter bypassHydraulic oil filter bypassAdjustable tilt steering columnCoat hookGround level door releaseHeater/defrosterHorn, steering wheel mounted (electric)Hydraulic control lever lockoutInterior lightInterior and exterior auxiliarypower socketsLighterLunch box storage with cup holderPilot hydraulic implement controlsRear window defroster, electricRear view mirrors (2 inside)Seat, adjustable suspension, armrest(fabric or vinyl)Seat belt, 51 mm or 75 mm, retractableTinted safety glass, frontTool boxTwo door cab, fixed glassWet arm wiper/washer (front & rear),front intermittentPower TrainEngine, <strong>Cat</strong>erpillar 3056E DIT ATAACLow emission diesel engineTurbochargedAfter cooledElectronically controlled engineAir cleaner, dry typeAxle seal guardsBrakes, enclosed wet-disc full hydraulicDifferentials, conventional (front/rear)Driveshaft, lubed for lifeEngine fuel priming pumpEngine speed controlFuel/water separatorMufflerRadiator, unit serviceableS•O•S oil sampling portengine oiltransmission oilTorque converterTransmission, 4F/3R, autoshift,single lever control with F/N/Rand kickdown buttonTransmission neutralizer;operator programmableHydraulicsHydraulic diagnostic connectorsHydraulic oil coolerHydraulic control, 2-valve,1-lever with F/N/RS•O•S oil sampling port, hydraulic oilOther Standard EquipmentAntenna, for radioAntifreeze/coolant, extended-lifeprotects to -36°CBrakes, secondary and parkingBucket positioner, automaticCounterweightEngine enclosure, lockableFenders, frontHitch, recoveryLoader linkage, Z-bar with sealed pinsLift kickout, automaticMachine Security System readyProduct Link, World View readyRemote grease linesSteering stops, cushionedSwing-out, hydraulically drivendemand fanVandalism protection,lockable service pointsVisual indicators:Air cleaner serviceCoolant levelHydraulic oilTransmission oil18 <strong>928G</strong> z Wheel Loader specifications

Optional EquipmentOptional equipment may vary. Consult your <strong>Cat</strong>erpillar dealer for specifics.ElectricalAlternator, 95-ampAlarm, back-upBeacon light, rotating, magnetic-mountElectrical accessories package(12V or 24V converter,accessory plug outlet, wiring)Rear-view camera systemRoading lightsWorking lights, auxiliary, cab-mountedOperator EnvironmentAir conditioner (R-134a refrigerant)Canopy, ROPSClosed Circuit Breather (CCB)Mirrors, external (two, two sizesavailable)Radio prep packages:12V installation, includes speakers,cable, mounting bracket, hardware,converter and accessory plug,radio not included24V installation, same as above,but without converter oraccessory plugRadio, AM/FMRear view camera systemSeats:<strong>Cat</strong> Contour Seat, fabric,with adjustable backrest andlumbar support<strong>Cat</strong> Contour Seat, fabric, electricallyadjustable with air suspensionKAB seat, fabric, heated, with alarmand fully adjustable armrestsSliding door windows (left and right)Sun screen, rearSun visor, frontPower TrainBrakes, heavy duty, with rear axleoil coolerDifferential, limited slip, front axleand/or rear axleFan, reversingRide control systemStarting aid, engine coolant heater,120V or 240VHydraulicsHydraulic control, two lever(lift/tilt)Hydraulic control 3rd valveHydraulic oil cooler, heavy-dutyOther Optional EquipmentAntifreeze/coolant, extended-life,protects to -50°CBuckets/ground engaging toolsCounterweight, additional 250 kgDust bowl precleanerFendersroading, rearsteel, frontGuards:CrankcaseDriveshaftLightsPower trainRadiatorWindshieldMachine Security SystemMaterial handling armPallet forks, carriageProduct Link, World ViewQuick Coupler, <strong>Cat</strong>erpillarRadiator, wide fin spacing, 5.5 fpiSound suppression packageSteering:SecondaryTires:Bias ply,17.5-R25 and 20.5 R25Radial, 17.5-R25, 20.5 R25 and600/65 R25<strong>928G</strong> z Wheel Loader specifications19

<strong>928G</strong> z Wheel LoaderHEHL3227-1 (06/2006) hrFeatured photos of machines may not always include standard equipment.See your <strong>Cat</strong>erpillar Dealer for available options.Materials and specifications are subject to change without notice.www.CAT.com© 2004 <strong>Cat</strong>erpillarAll Rights Reserved®20