MCR 702 TwinDrive Rheometer - MEP Instruments

MCR 702 TwinDrive Rheometer - MEP Instruments

MCR 702 TwinDrive Rheometer - MEP Instruments

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

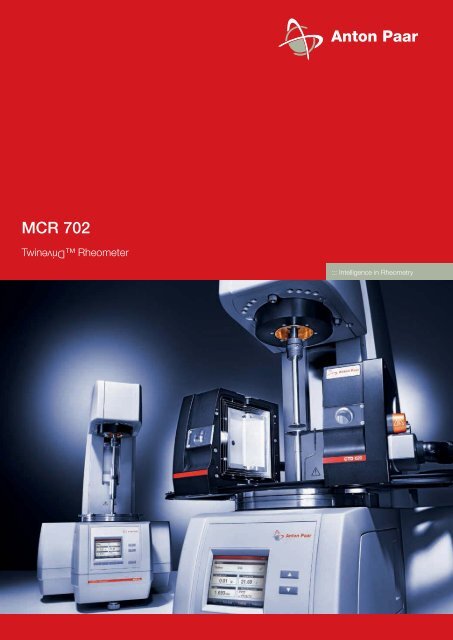

<strong>MCR</strong> <strong>702</strong>T <strong>Rheometer</strong>::: Intelligence in Rheometry

One <strong>Rheometer</strong>. All Possibilities.TM<strong>MCR</strong> <strong>702</strong> with Twin TechnologyDrive

The rheometry revolution:TAnton Paar introduces a groundbreakinghigh-end rheometer in a classof its own: <strong>MCR</strong> <strong>702</strong> with Ttechnology.For the first time ever in the history of rheometry,you can perform rheological tests with twotorque transducers and drive units at once, in asingle instrument: Two powerful EC motor units in acombined modular setup – flexible and precise enoughto deliver any result you are looking for.In short, <strong>MCR</strong> <strong>702</strong> with T is the firstsingle system to cover all possible rheologicalapplications – past, present and future.

T Test ModesEC ModeNow the choice is yours: The EC test modeprovides you with the vast range of applicationoptions that <strong>MCR</strong> rheometers are known for.In this mode, the lower EC (Electrically Commutated)motor is simply removed and <strong>MCR</strong> <strong>702</strong> is operated as aCMT (Combined Motor Transducer) rheometer.By using a single air-bearing-supported EC motor unit,you can make the most of the motor’s TruStraincapability and perform ‘classic’ stress-controlled tests.The option to either control the shear rate or the shearstress opens up countless applications specific to singlemotorrheometers. measuring drivingWith the lower motor unit removed, <strong>MCR</strong> <strong>702</strong> is readyto be equipped with any temperature device and/orapplication-specific accessory you may require. Thereare over 35 options to choose from, all of them readilyrecognized and configured by Toolmaster, <strong>MCR</strong> <strong>702</strong>’sautomatic tool recognition and configuration system.

TComplete Gap ControlIsolign: Nano-scale precision<strong>MCR</strong> <strong>702</strong> T is the first rheometer to offernano-scale precision on several counts – such aslow-torque measurements down to a minimum of1 nNm and the control of angular deflections downto 100 nrad.Now this peak precision also extends to the system’smeasuring gap control: The new Isolign Piezo flangeperforms gap size changes as small as 10 nm. Basedon a system of 3 Piezo elements in the flange of themeasuring chamber reception, Isolign is reliablyemployed in all T test modes.Common step-motor-based systems employ a longkinematic chain to translate single motor steps into gapsize changes in the micrometer range. Capable of stepsizes down to 10 nanometers, Isolign is decadesmore precise than any other comparable solution forgap size adjustments in rheological tests.In high-sensitivity tests over long periods of time(e.g. creep, step strain or step shear rate tests oncomplex fluids) and tests across vast temperatureranges, the measuring gap is kept constant withinlower tolerances than ever before.TruGap: Consistent gap controlThe patented TruGap system (US Patent 6,499,336)consistently measures and precisely adjusts <strong>MCR</strong> <strong>702</strong>’smeasuring gap to the desired position independently oftemperature and thermal expansion. Permanent control,documentation and traceability of the actual measuringgap are guaranteed, eliminating the need for regularzero-gap settings.

TA world of optionsTemperature devicesChoose from a wide range of modulartemperature devices tailored to specific rheologicalrequirements – from -150 °C to 1000 °C, fromlow-viscosity liquids to highly elastic solids, fromtraditional rotational tests to DMTA measurements.All systems are easily exchanged, ensuringvirtually gradient-free temperature control for allapplications.Measuring systemsAnton Paar offers a wide range of <strong>MCR</strong> measuringsystems and continuously develops new customtailoredsolutions. These systems can be used withall temperature devices and are interchangeablewithin their category of accessories. Made fromdiverse materials and featuring different surfacesand dimensions, all systems are optimizedregarding compliance, thermal expansion andthermal conductivity.Toolmaster:Effortless exchangeToolmaster (US Patent 7,275,419) recognizes allmeasuring and environmental systems connectedto the rheometer and accordingly configuresthe entire system accordingly. In the 2EC mode,Toolmaster recognizes any system attached toeither side of <strong>MCR</strong> <strong>702</strong> via a transponder chipcontaining all relevant data.New paths for your applications:The RheoCompass software<strong>MCR</strong> <strong>702</strong> T calls for a navigation toolthat gives you the complete overview as well asthe exact insights you require: Anton Paar’s newRheoCompass software, the most innovativeand up-to-date rheometer software available onthe market.Designed for intuitive use, RheoCompassenables application-oriented template filtering,customized test and analysis definitions, highlysimplified data retrieval and much more.

For more details and specifications, referto the brochures on <strong>MCR</strong> temperaturedevices and the three individual brochureson <strong>MCR</strong> application-specific accessories:Structure Analysis, Additional Parameter Settingand Extended Material Characterization.<strong>MCR</strong>Application-specific Accessoriesfor Structure Analysis::: Intelligence in RheometryApplication-specific accessories<strong>MCR</strong>Application-specific Accessoriesfor Additional Parameter Setting::: Intelligence in RheometryObtain additional structure information, set additionalparameters or employ your rheometer’s functionality forfurther material characterization...Structure AnalysisGather sample structure information by combiningthese optical and dielectric methods with rheology:4 Rheo-Microscope4 Rheo-SALS4 Dynamic Optical Rheo-Analyzer (DORA)4 Rheo-SAXS4 Rheo-SANS4 Particle Image Velocimetry (PIV)4 Dielectric SpectroscopyExtended MaterialCharacterization::: Intelligence in RheometryAdditional Parameter SettingUse these accessories to set additional parameterstogether with the temperature for rheological tests:4 Pressure Cell4 UV Curing System4 Immobilization Cell4 Magneto-Rheological Device4 Electro-Rheological DeviceExtended Material CharacterizationTransfer the <strong>MCR</strong> rheometer’s measuring capabilitiesinto further material characterization applications:<strong>MCR</strong>Temperature Devices::: Intelligence in Rheometry4 Dynamic-Mechanical Thermal Analysis (DMTA)4 Extensional Rheology4 Interfacial Rheology4 Ball Measuring System4 Building Material Cell4 Tribology Cell

Specifications<strong>MCR</strong> <strong>702</strong> TUnit EC mode 2EC modeEC motor (brushless DC) with high resolution optical encoder and air bearing -Permanent torque (60 min), no signal drift -Controlled shear rate and shear stress -Isolign Piezo flange - Gap size change nm 10 10Maximum torque mNm 230 230Minimum torque, rotation nNm 10 5Minimum torque, oscillation nNm 2 1Torque resolution nNm 0.1 0.1Angular deflection, set value µrad 0.1 to ∞ 0.1 to ∞Angular deflection, resolution nrad 10 10Step rate, time constant ms 5 5Step strain, time constant ms 10 10Step rate, time to reach 99 % of set value (independent of sample) ms 30 30Minimum angular velocity, controlled (1) rad/s 10 -9 10 -9Maximum angular velocity, controlled rad/s 314 2 x 314Minimum angular frequency (2) rad/s 10 -7 (3) 10 -7 (3)Maximum angular frequency rad/s 628 628Normal force range N 0.005 to 50 0.001 to 50Normal force resolution mN 0.5 0.5Toolmaster TM , measuring system and measuring cell (wireless detection and transmissionof measuring system and calibration parameters)-QuickConnect for measuring systems, screwless -Electronic trim lock for the measuring system -TruRate TM -TruStrain TM -Normal force and velocity profiles, tack, squeeze -Automatic gap control/setting, AGC/AGS -Dimensions mm 753 x 444 x 586 753 x 444 x 586Weight kg 47 56Depending on your application and test mode, <strong>MCR</strong> <strong>702</strong> T can be operated with ...Direct strain, amplitude controller -Direct stress, amplitude controller -Raw data (LAOS, waveform, ...) -Digital Eye video option and camera - Maximum temperature range °C -150 to +1000Pressure range bar up to 1000Structure Analysis (Microscope, SALS, SANS, Birefrigence, PIV, ...)Additional Parameter Setting (UV, Magneto- and Electro-Rheological Device, ...)Extended Material Characterization (DMTA, Tribology, …)ConnectionsUSB, Ethernet, 4 analog interfaces, 3 auxiliaryinputs, Pt 100 and thermocouple interfaces1) Depending on measuring point duration and sampling time practically any value is achieved2) Set frequencies below 1.0E-04 rad/s are of no practical relevance due to the measuring point duration > 1 day3) Theoretical value (duration per cycle = 2 years)Legend:optional

Photos: Croce & WirAnton Paar ® GmbHAnton-Paar-Str. 20A-8054 GrazAustria - EuropeTel: +43 (0)316 257-0Fax: +43 (0)316 257-257E-mail: info@anton-paar.comWeb: www.anton-paar.com<strong>Instruments</strong> for:Density and concentrationmeasurementRheometryViscometrySample preparationMicrowave synthesisColloid scienceX-ray structure analysisRefractometryPolarimetryPetroleum testingHigh-precision temperaturemeasurementSpecificationssubject to changewithout notice01/13 C92IP002EN-C

![Rice, size measurement of broken grains [pdf] - MEP Instruments](https://img.yumpu.com/46724497/1/184x260/rice-size-measurement-of-broken-grains-pdf-mep-instruments.jpg?quality=85)