- Page 5: IndexIndex (cont.)Weather-compensat

- Page 11 and 12: Installation sequenceInstalling the

- Page 13 and 14: Installation sequenceInstalling the

- Page 15 and 16: Installation sequenceOpening the co

- Page 17 and 18: Installation sequenceElectrical con

- Page 19 and 20: Installation sequenceClosing the co

- Page 21 and 22: Commissioning, inspection, maintena

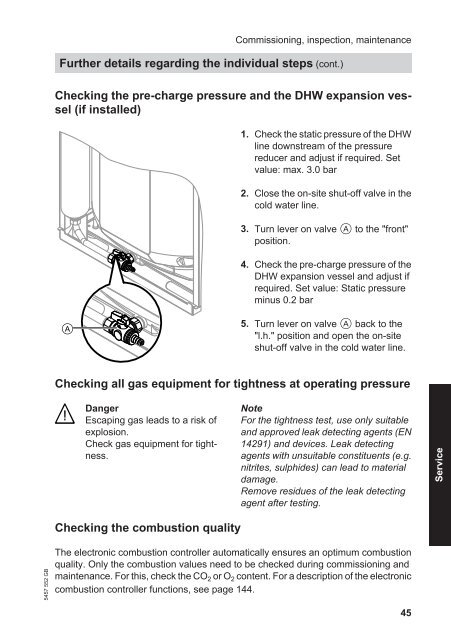

- Page 23: Further details regarding the indiv

- Page 28 and 29: Commissioning, inspection, maintena

- Page 30: Commissioning, inspection, maintena

- Page 33 and 34: Commissioning, inspection, maintena

- Page 35 and 36: Commissioning, inspection, maintena

- Page 37 and 38: Commissioning, inspection, maintena

- Page 39 and 40: Commissioning, inspection, maintena

- Page 41 and 42: Draining the boiler on the DHW side

- Page 43: Checking and replacing the magnesiu

- Page 47 and 48: Commissioning, inspection, maintena

- Page 49 and 50: Commissioning, inspection, maintena

- Page 51 and 52: Commissioning, inspection, maintena

- Page 53 and 54: Commissioning, inspection, maintena

- Page 55 and 56: Commissioning, inspection, maintena

- Page 57 and 58: Commissioning, inspection, maintena

- Page 59 and 60: Commissioning, inspection, maintena

- Page 61 and 62: Code 1Calling up coding level 1Note

- Page 63 and 64: Code 1General/Group "1" (cont.)Codi

- Page 65 and 66: Code 1DHW/Group "3"Select "DHW" for

- Page 67 and 68: 5457 552 GBCode 1Heating circuit 1,

- Page 69 and 70: Code 1Heating circuit 1, heating ci

- Page 71 and 72: Code 1Heating circuit 1, heating ci

- Page 73 and 74: Code 2Calling up coding level 2 (co

- Page 75 and 76: Code 2General/Group "1" (cont.)Codi

- Page 77 and 78: Code 2General/Group "1" (cont.)Codi

- Page 79 and 80: Code 2General/Group "1" (cont.)Codi

- Page 81 and 82: Code 2General/Group "1" (cont.)Codi

- Page 83 and 84: Code 2DHW/Group "3" (cont.)CodingCo

- Page 85 and 86: Code 2Heating circuit 1, heating ci

- Page 87 and 88: Code 2Heating circuit 1, heating ci

- Page 89 and 90: Code 2Heating circuit 1, heating ci

- Page 91 and 92: Code 2Heating circuit 1, heating ci

- Page 93 and 94: Code 2Heating circuit 1, heating ci

- Page 95 and 96:

Diagnosis and service scansDiagnosi

- Page 97 and 98:

Diagnosis and service scansDiagnosi

- Page 99 and 100:

Diagnosis and service scansDiagnosi

- Page 101 and 102:

Diagnosis and service scansChecking

- Page 103 and 104:

TroubleshootingFault display (cont.

- Page 105 and 106:

TroubleshootingFault codes (cont.)D

- Page 107 and 108:

TroubleshootingFault codes (cont.)D

- Page 109 and 110:

TroubleshootingFault codes (cont.)D

- Page 111 and 112:

TroubleshootingFault codes (cont.)D

- Page 113 and 114:

TroubleshootingFault codes (cont.)D

- Page 115 and 116:

TroubleshootingRepairsPutting contr

- Page 117 and 118:

TroubleshootingRepairs (cont.)2. Te

- Page 119 and 120:

TroubleshootingRepairs (cont.)1.

- Page 121 and 122:

TroubleshootingRepairs (cont.)Check

- Page 123 and 124:

TroubleshootingRepairs (cont.)6. Ch

- Page 125 and 126:

TroubleshootingRepairs (cont.)Check

- Page 127 and 128:

Function descriptionConstant temper

- Page 129 and 130:

Function descriptionWeather-compens

- Page 131 and 132:

Function descriptionInternal extens

- Page 133 and 134:

Function descriptionExternal extens

- Page 135 and 136:

Function descriptionExternal extens

- Page 137 and 138:

Function descriptionControl functio

- Page 139 and 140:

Function descriptionControl functio

- Page 141 and 142:

Function descriptionControl functio

- Page 143 and 144:

Function descriptionControl functio

- Page 145 and 146:

Function descriptionElectronic comb

- Page 147 and 148:

DesignsExternal connection diagram5

- Page 149 and 150:

Parts listsParts lists5457 552 GBSp

- Page 151 and 152:

Parts listsParts lists (cont.)20520

- Page 153 and 154:

Parts listsParts lists (cont.)02909

- Page 155 and 156:

Parts listsParts lists (cont.)10608

- Page 157 and 158:

Commissioning/service reportsCommis

- Page 159 and 160:

CertificatesDeclaration of conformi

- Page 161 and 162:

Keyword indexKeyword indexAAcknowle

- Page 163 and 164:

5457 552 GB163