Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

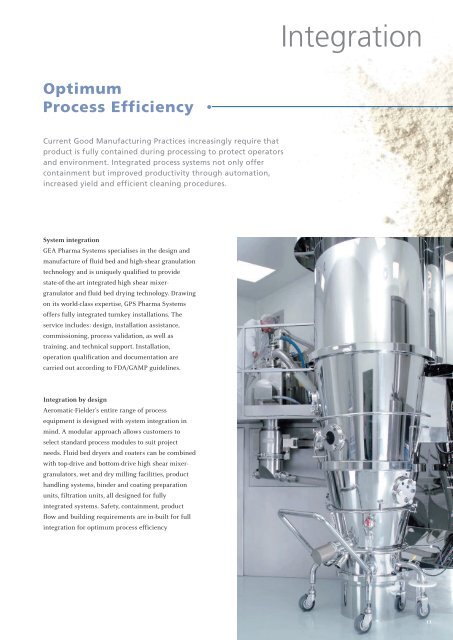

IntegrationOptimumProcess Efficiency•Current Good Manufacturing Practices increasingly require thatproduct is fully contained during processing to protect operatorsand environment. Integrated process systems not only offercontainment but improved productivity through automation,increased yield and efficient cleaning procedures.System integration<strong>GEA</strong> <strong>Pharma</strong> <strong>Systems</strong> specialises in the design andmanufacture of fluid bed and high-shear granulationtechnology and is uniquely qualified to providestate-of-the-art integrated high shear mixergranulatorand fluid bed drying technology. Drawingon its world-class expertise, GPS <strong>Pharma</strong> <strong>Systems</strong>offers fully integrated turnkey installations. Theservice includes: design, installation assistance,commissioning, process validation, as well astraining, and technical support. Installation,operation qualification and documentation arecarried out according to FDA/GAMP guidelines.Integration by designAeromatic-Fielder’s entire range of processequipment is designed with system integration inmind. A modular approach allows customers toselect standard process modules to suit projectneeds. <strong>Fluid</strong> bed dryers and coaters can be combinedwith top-drive and bottom-drive high shear mixergranulators,wet and dry milling facilities, producthandling systems, binder and coating preparationunits, filtration units, all designed for fullyintegrated systems. Safety, containment, productflow and building requirements are in-built for fullintegration for optimum process efficiency11