Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

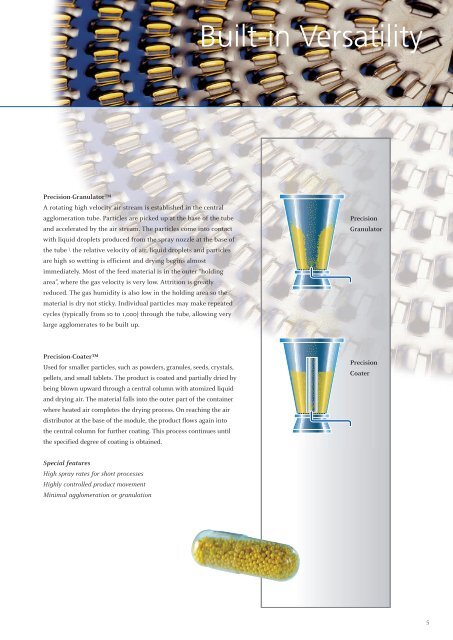

Built-in VersatilityPrecision-GranulatorA rotating high velocity air stream is established in the centralagglomeration tube. Particles are picked up at the base of the tubeand accelerated by the air stream. The particles come into contactwith liquid droplets produced from the spray nozzle at the base ofthe tube \ the relative velocity of air, liquid droplets and particlesare high so wetting is efficient and drying begins almostimmediately. Most of the feed material is in the outer “holdingarea”, where the gas velocity is very low. Attrition is greatlyreduced. The gas humidity is also low in the holding area so thematerial is dry not sticky. Individual particles may make repeatedcycles (typically from 10 to 1,000) through the tube, allowing verylarge agglomerates to be built up.PrecisionGranulatorPrecision-CoaterUsed for smaller particles, such as powders, granules, seeds, crystals,pellets, and small tablets. The product is coated and partially dried bybeing blown upward through a central column with atomized liquidand drying air. The material falls into the outer part of the containerwhere heated air completes the drying process. On reaching the airdistributor at the base of the module, the product flows again intothe central column for further coating. This process continues untilthe specified degree of coating is obtained.PrecisionCoaterSpecial featuresHigh spray rates for short processesHighly controlled product movementMinimal agglomeration or granulation5