Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

Fluid Bed Processor - GEA Pharma Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

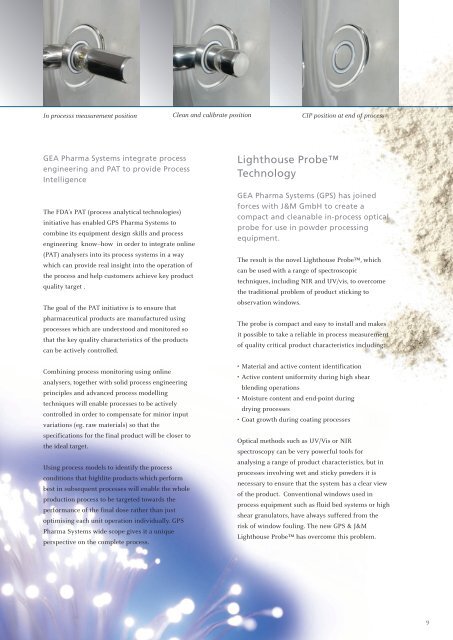

In processs measurement position Clean and calibrate position CIP position at end of process<strong>GEA</strong> <strong>Pharma</strong> <strong>Systems</strong> integrate processengineering and PAT to provide ProcessIntelligenceThe FDA’s PAT (process analytical technologies)initiative has enabled GPS <strong>Pharma</strong> <strong>Systems</strong> tocombine its equipment design skills and processengineering know–how in order to integrate online(PAT) analysers into its process systems in a waywhich can provide real insight into the operation ofthe process and help customers achieve key productquality target .The goal of the PAT initiative is to ensure thatpharmaceutical products are manufactured usingprocesses which are understood and monitored sothat the key quality characteristics of the productscan be actively controlled.Combining process monitoring using onlineanalysers, together with solid process engineeringprinciples and advanced process modellingtechniques will enable processes to be activelycontrolled in order to compensate for minor inputvariations (eg. raw materials) so that thespecifications for the final product will be closer tothe ideal target.Using process models to identify the processconditions that highlite products which performbest in subsequent processes will enable the wholeproduction process to be targeted towards theperformance of the final dose rather than justoptimising each unit operation individually. GPS<strong>Pharma</strong> <strong>Systems</strong> wide scope gives it a uniqueperspective on the complete process.Lighthouse ProbeTechnology<strong>GEA</strong> <strong>Pharma</strong> <strong>Systems</strong> (GPS) has joinedforces with J&M GmbH to create acompact and cleanable in-process opticalprobe for use in powder processingequipment.The result is the novel Lighthouse Probe, whichcan be used with a range of spectroscopictechniques, including NIR and UV/vis, to overcomethe traditional problem of product sticking toobservation windows.The probe is compact and easy to install and makesit possible to take a reliable in process measurementof quality critical product characteristics including:• Material and active content identification• Active content uniformity during high shearblending operations• Moisture content and end-point duringdrying processes• Coat growth during coating processesOptical methods such as UV/Vis or NIRspectroscopy can be very powerful tools foranalysing a range of product characteristics, but inprocesses involving wet and sticky powders it isnecessary to ensure that the system has a clear viewof the product. Conventional windows used inprocess equipment such as fluid bed systems or highshear granulators, have always suffered from therisk of window fouling. The new GPS & J&MLighthouse Probe has overcome this problem.9