Command THC

Command THC

Command THC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

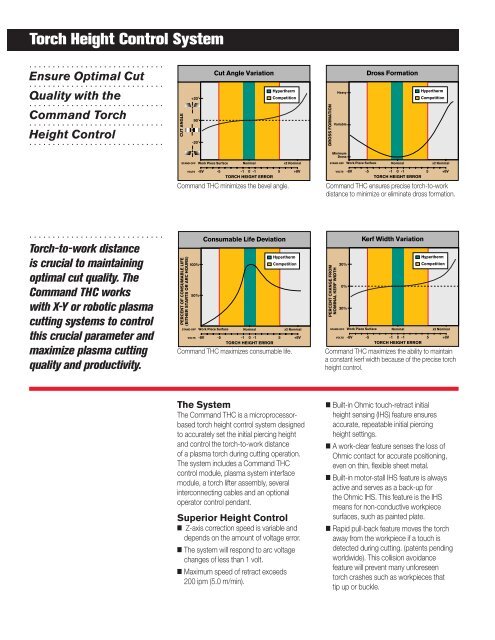

Torch Height Control System.............................Ensure Optimal Cut.............................Quality with the.............................<strong>Command</strong> Torch.............................Height Control.............................CUT ANGLE+20˚90˚-20˚Cut Angle VariationHyperthermCompetitionDROSS FORMATIONHeavyVariableDross FormationHyperthermCompetitionMinimumDrossSTAND-OFFWork Piece SurfaceNominalx2 NominalSTAND-OFFWork Piece SurfaceNominalx2 NominalVOLTS-8V -5 -1 0 -15 +8VTORCH HEIGHT ERROR<strong>Command</strong> <strong>THC</strong> minimizes the bevel angle.VOLTS-8V -5 -1 0 -15 +8VTORCH HEIGHT ERROR<strong>Command</strong> <strong>THC</strong> ensures precise torch-to-workdistance to minimize or eliminate dross formation..............................Torch-to-work distanceis crucial to maintainingoptimal cut quality. The<strong>Command</strong> <strong>THC</strong> workswith X-Y or robotic plasmacutting systems to controlthis crucial parameter andmaximize plasma cuttingquality and productivity.PERCENT OF CONSUMABLE LIFE(EITHER STARTS OR ARC HOURS)100%50%STAND-OFFVOLTSConsumable Life DeviationWork Piece SurfaceNominalHyperthermCompetitionx2 Nominal-8V -5 -1 0 -15 +8VTORCH HEIGHT ERROR<strong>Command</strong> <strong>THC</strong> maximizes consumable life.PERCENT CHANGE FROMNOMINAL KERF WIDTH30%30%STAND-OFFVOLTS0%Kerf Width VariationWork Piece SurfaceNominalHyperthermCompetitionx2 Nominal-8V -5 -1 0 -15 +8VTORCH HEIGHT ERROR<strong>Command</strong> <strong>THC</strong> maximizes the ability to maintaina constant kerf width because of the precise torchheight control.The SystemThe <strong>Command</strong> <strong>THC</strong> is a microprocessorbasedtorch height control system designedto accurately set the initial piercing heightand control the torch-to-work distanceof a plasma torch during cutting operation.The system includes a <strong>Command</strong> <strong>THC</strong>control module, plasma system interfacemodule, a torch lifter assembly, severalinterconnecting cables and an optionaloperator control pendant.Superior Height Control■ Z-axis correction speed is variable anddepends on the amount of voltage error.■ The system will respond to arc voltagechanges of less than 1 volt.■ Maximum speed of retract exceeds200 ipm (5.0 m/min).■ Built-in Ohmic touch-retract initialheight sensing (IHS) feature ensuresaccurate, repeatable initial piercingheight settings.■ A work-clear feature senses the loss ofOhmic contact for accurate positioning,even on thin, flexible sheet metal.■ Built-in motor-stall IHS feature is alwaysactive and serves as a back-up forthe Ohmic IHS. This feature is the IHSmeans for non-conductive workpiecesurfaces, such as painted plate.■ Rapid pull-back feature moves the torchaway from the workpiece if a touch isdetected during cutting. (patents pendingworldwide). This collision avoidancefeature will prevent many unforeseentorch crashes such as workpieces thattip up or buckle.