Modern Materials Handling - April 2011

Modern Materials Handling - April 2011

Modern Materials Handling - April 2011

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

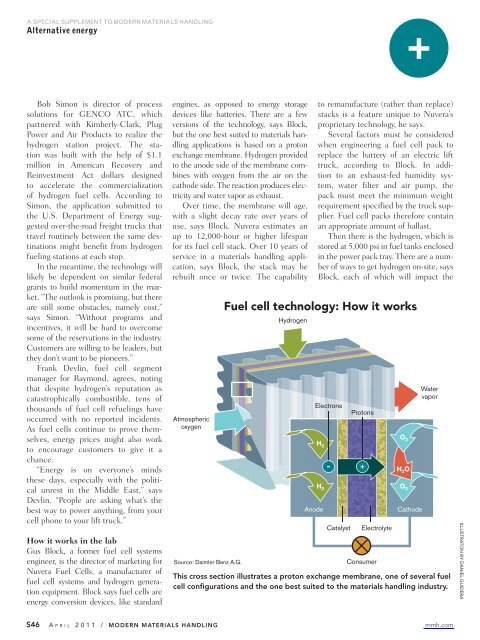

A special supplement to modern materials handlingAlternative energy+Bob Simon is director of processsolutions for GENCO ATC, whichpartnered with Kimberly-Clark, PlugPower and Air Products to realize thehydrogen station project. The stationwas built with the help of $1.1million in American Recovery andReinvestment Act dollars designedto accelerate the commercializationof hydrogen fuel cells. According toSimon, the application submitted tothe U.S. Department of Energy suggestedover-the-road freight trucks thattravel routinely between the same destinationsmight benefit from hydrogenfueling stations at each stop.In the meantime, the technology willlikely be dependent on similar federalgrants to build momentum in the market.“The outlook is promising, but thereare still some obstacles, namely cost,”says Simon. “Without programs andincentives, it will be hard to overcomesome of the reservations in the industry.Customers are willing to be leaders, butthey don’t want to be pioneers.”Frank Devlin, fuel cell segmentmanager for Raymond, agrees, notingthat despite hydrogen’s reputation ascatastrophically combustible, tens ofthousands of fuel cell refuelings haveoccurred with no reported incidents.As fuel cells continue to prove themselves,energy prices might also workto encourage customers to give it achance.“Energy is on everyone’s mindsthese days, especially with the politicalunrest in the Middle East,” saysDevlin. “People are asking what’s thebest way to power anything, from yourcell phone to your lift truck.”How it works in the labGus Block, a former fuel cell systemsengineer, is the director of marketing forNuvera Fuel Cells, a manufacturer offuel cell systems and hydrogen generationequipment. Block says fuel cells areenergy conversion devices, like standardengines, as opposed to energy storagedevices like batteries. There are a fewversions of the technology, says Block,but the one best suited to materials handlingapplications is based on a protonexchange membrane. Hydrogen providedto the anode side of the membrane combineswith oxygen from the air on thecathode side. The reaction produces electricityand water vapor as exhaust.Over time, the membrane will age,with a slight decay rate over years ofuse, says Block. Nuvera estimates anup to 12,000-hour or higher lifespanfor its fuel cell stack. Over 10 years ofservice in a materials handling application,says Block, the stack may berebuilt once or twice. The capabilityFuel cell technology: Fuel cell technology: How it works How it worksAtmosphericoxygenSource: Daimler Benz A.G.HydrogenAnodeto remanufacture (rather than replace)stacks is a feature unique to Nuvera’sproprietary technology, he says.Several factors must be consideredwhen engineering a fuel cell pack toreplace the battery of an electric lifttruck, according to Block. In additionto an exhaust-fed humidity system,water filter and air pump, thepack must meet the minimum weightrequirement specified by the truck supplier.Fuel cell packs therefore containan appropriate amount of ballast.Then there is the hydrogen, which isstored at 5,000 psi in fuel tanks enclosedin the power pack tray. There are a numberof ways to get hydrogen on-site, saysBlock, each of which will impact theElectronsProtonsH 2O 2– +H 2 O 2CatalystElectrolyteConsumerCathodeWatervaporThis cross section illustrates a proton exchange membrane, one of several fuelcell configurations and the one best suited to the materials handling industry.H 2 OIllustraton by Daniel GuideraS46 A p r i l 2 0 1 1 / <strong>Modern</strong> <strong>Materials</strong> <strong>Handling</strong> mmh.com